Quick clamping head for electric jig saw

A curve saw, fast technology, applied in the direction of sawing machine, metal sawing equipment, metal processing equipment, etc., can solve the problems of complicated processing and manufacturing, easy movement of knife and saw blades, low work efficiency, etc., and achieve simple structure, not easy to move dynamic and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

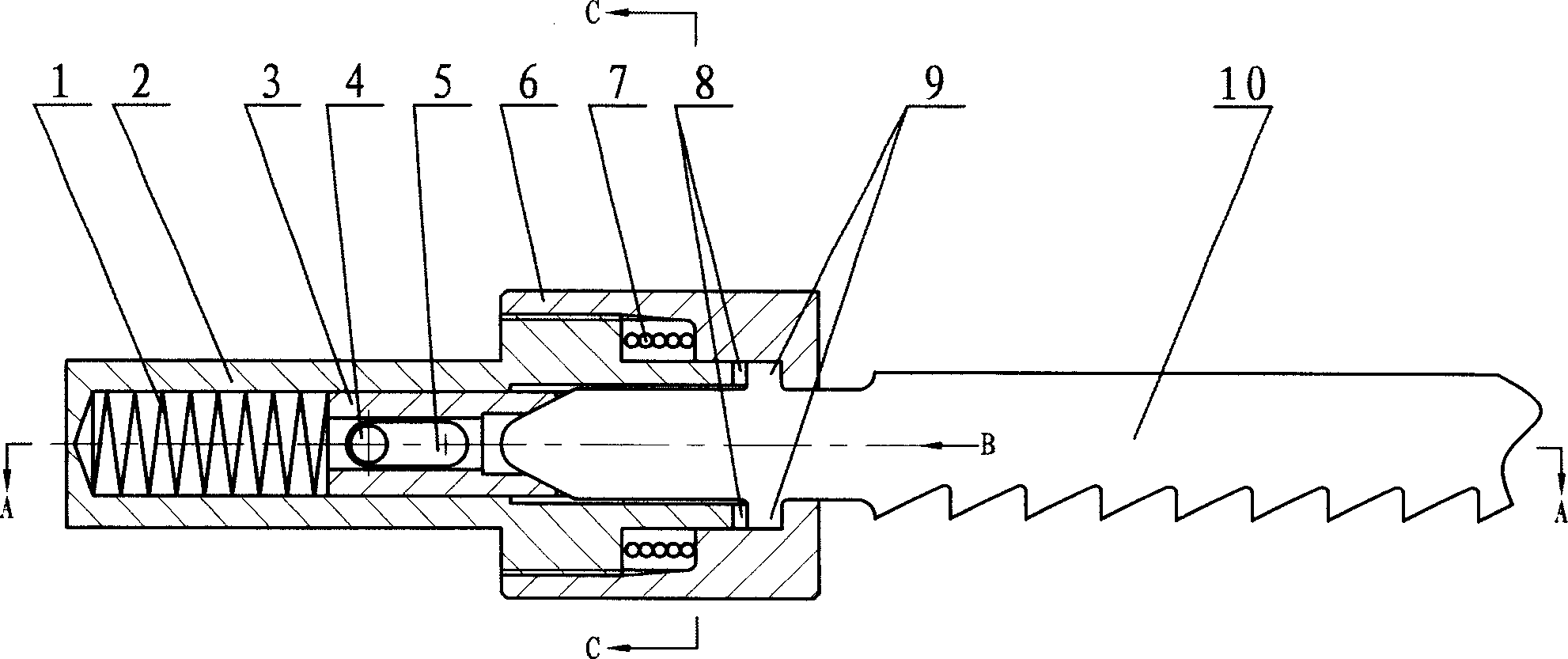

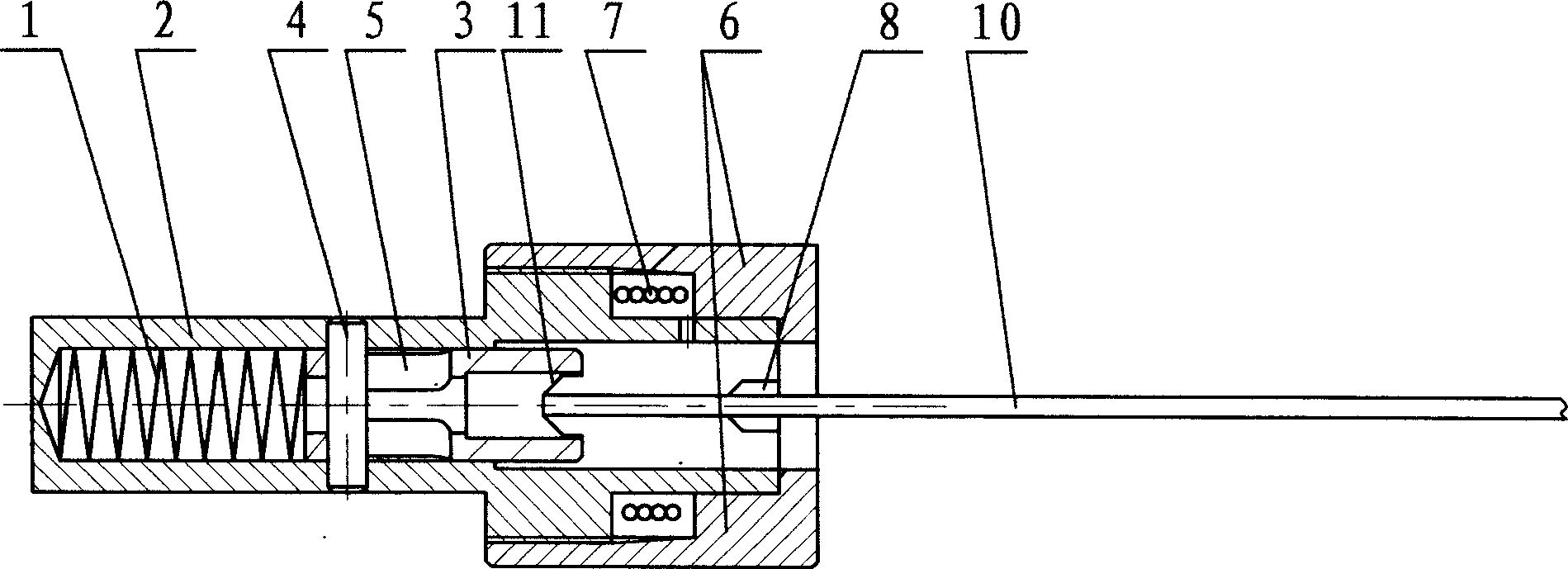

[0012] Describe in detail below in conjunction with accompanying drawing and embodiment:

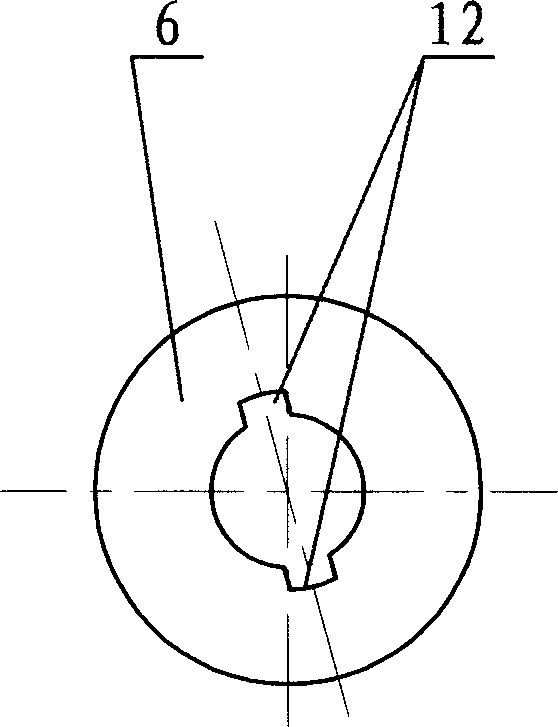

[0013] figure 1 The utility model relates to a quick chuck of an electric curve saw of the present invention. Including clip 2, lock sleeve 6, lock sleeve reset torsion spring 7, the main points are: the lock sleeve 6 and clip 2 are provided with matching right-handed reset tightening threads, and the inner cavity of clip 2 is provided with a pressure Spring 1 is provided with the positioning pressing piece 3 that slides and is positioned in the clip part 2 inner cavity before the stage clip 1, and the positioning pressing piece 3 front end is provided with knife saw end positioning groove 11. When installing the knife saw blade 10, as long as the lock sleeve 6 is left-handed until the slot 12 provided on the lock sleeve 6 is parallel to the saw end positioning groove 11 provided on the front end of the positioning pressure piece 3, the knife saw blade 10 is inserted. Push the knife an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com