High strength organic / inorganic nano composite transparent film layer materials and method for preparing same

An inorganic nano and transparent film technology, applied in coatings, optics, instruments, etc., can solve the problems of low refractive index, can not well meet the design requirements of anti-reflection coatings on the surface of high refractive index optical materials, etc. High rate, continuously adjustable refractive index, good film-forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

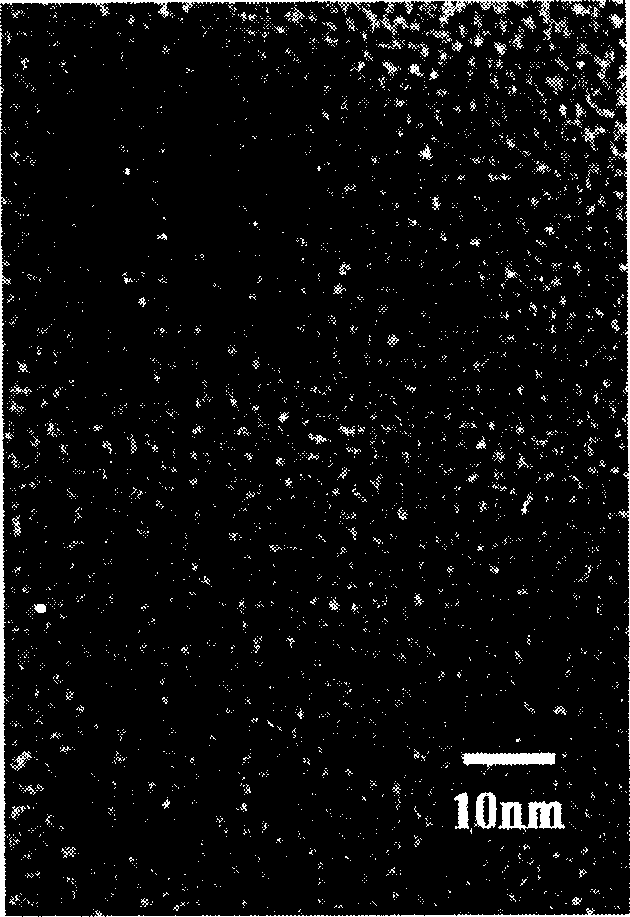

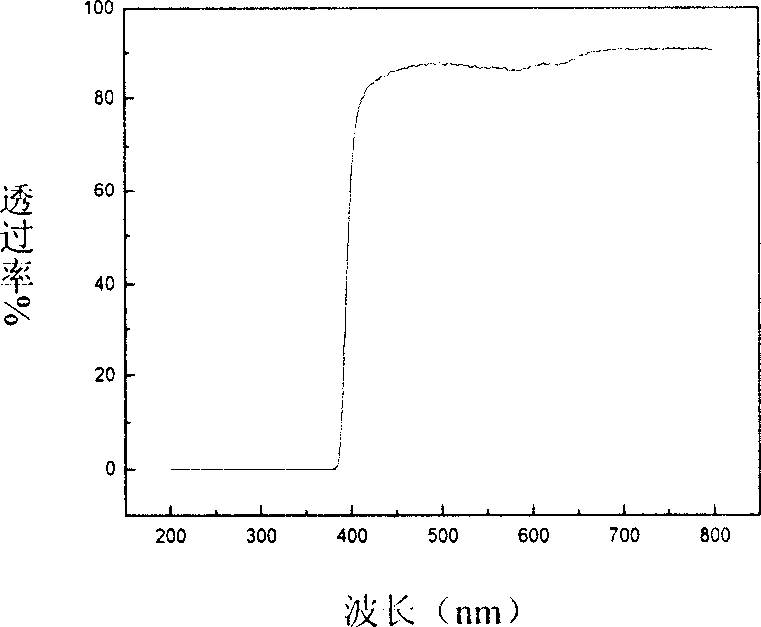

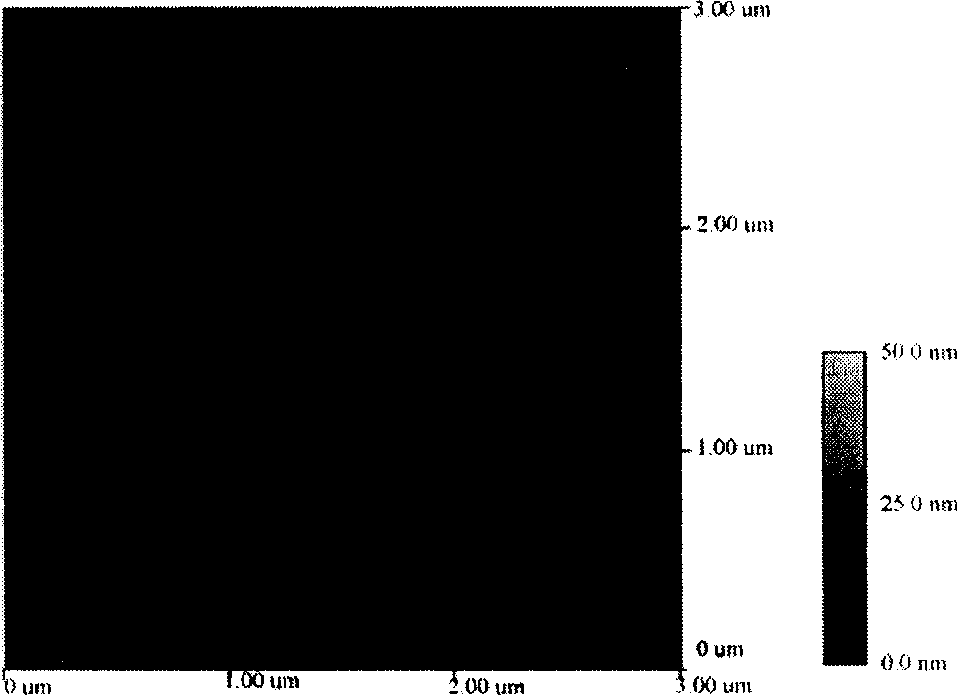

Image

Examples

Embodiment 1

[0034] For the preparation of titanium sol, dissolve 24g of n-tetrabutyl titanate in 6.28g of isopropanol, stir well, and record it as solution A; dissolve 1.28g of water and 0.15g of hydrochloric acid in 15.71g of isopropanol, mix well, Record it as solution B; under the condition of stirring, pour solution B into A and react for 12 hours. In this way, a titanium sol with a molar ratio of titanium to water of 1:1 is obtained, and can be stored for a long time.

Embodiment 2

[0036] The experimental method is the same as in Example 1, except that 16 g of ethyl titanate is used instead of 24 g of n-tetrabutyl titanate to obtain a titanium sol with a molar ratio of titanate to water of 1:1, which can be stored for a long time.

Embodiment 3

[0037] Embodiment 3: the preparation method one of titanium, silicon blended sol

[0038] Dissolve 223.70g of n-tetrabutyl titanate in 87.85g of isopropanol and stir evenly; add 175.69g of isopropanol solution dissolved in 11.75g of water and 1.12g of hydrochloric acid into the above solution and react for 10 hours; Add 119.58g gamma-(2,3-glycidyloxy) propyltrimethoxysilane, stir and make it mix evenly, add the 363.75g isopropanol solution that is dissolved with 13.73g water and 1.67g hydrochloric acid at last, continue reaction 10 Hour, add 4g sodium acetate and 2g polydimethylsiloxane therein, obtain homogeneous, stable transparent solution, wherein the mass percent composition of each component is: n-tetrabutyl titanate 22.26%; γ-(2, 3-glycidoxy)propyltrimethoxysilane 11.90%; water 2.54%; hydrochloric acid 0.28%; sodium acetate 0.4%; polydimethylsiloxane 0.2%; isopropanol 62.43%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com