Patents

Literature

67results about How to "Uniform optical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cellulose acylate laminate film, method for producing same, polarizer and liquid crystal display device

InactiveUS20100055356A1High degree of substitutionExcellent releasabilityLiquid crystal compositionsCellulosic plastic layered productsPolarizerLiquid-crystal display

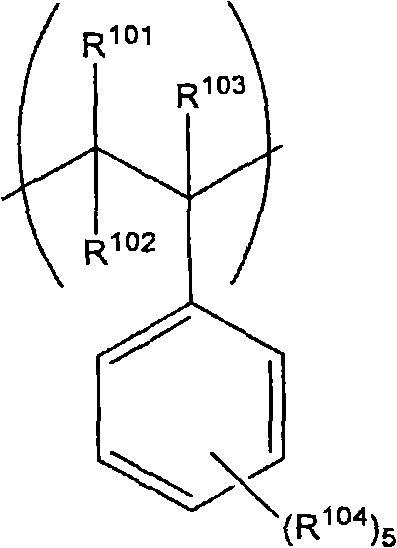

A stretched cellulose acylate laminate film having a skin layer containing a cellulose acylate with a total degree of acyl substitution of more than 2.7 and a core layer containing a cellulose acylate with a total degree of acyl substitution of 2.0-2.7 wherein the core layer is thicker than the skin B layer and at least one of these layers contains a retardation-controlling agent, is excellent in high expressibility, little optical unevenness and good releasability from a support.

Owner:FUJIFILM CORP

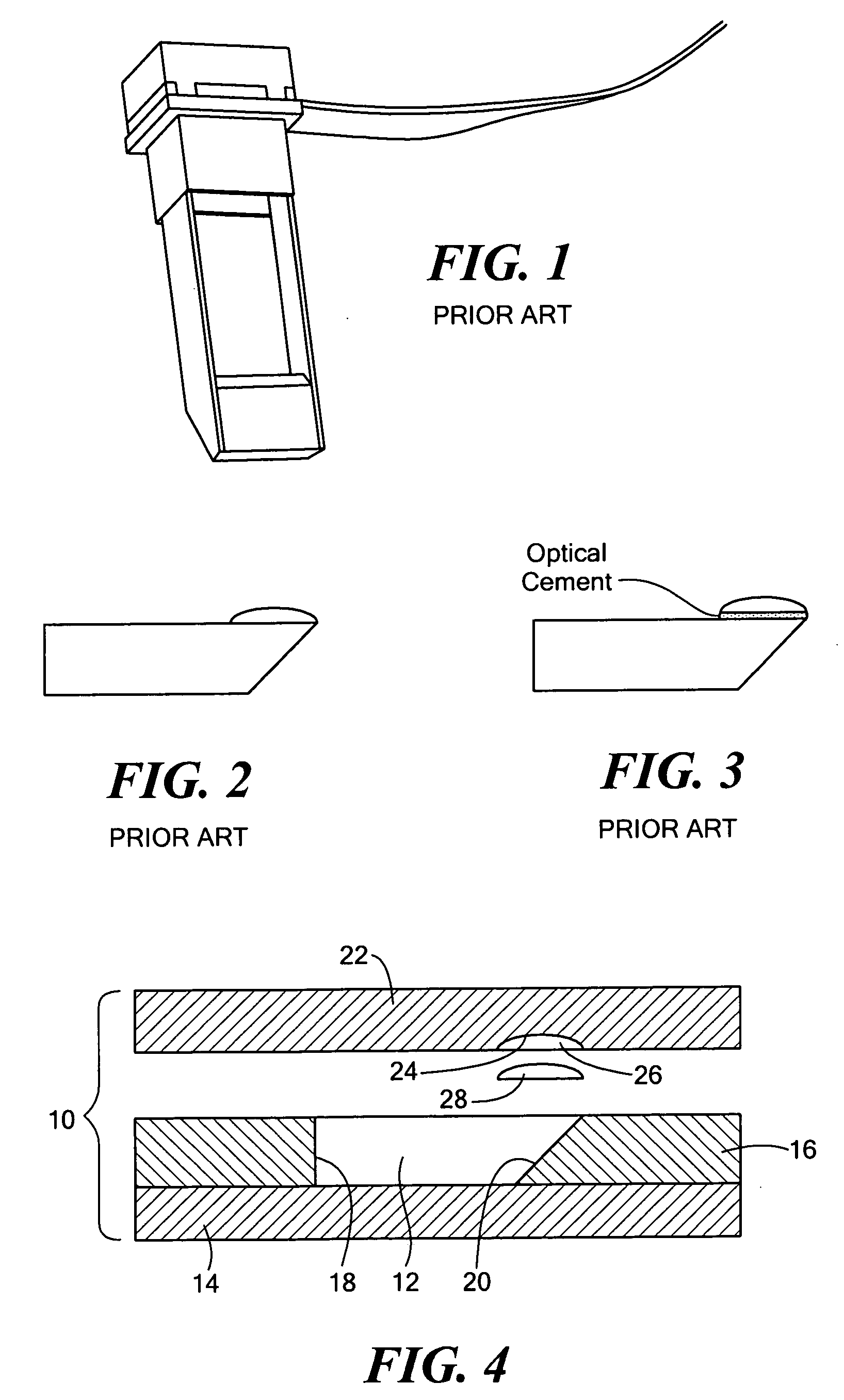

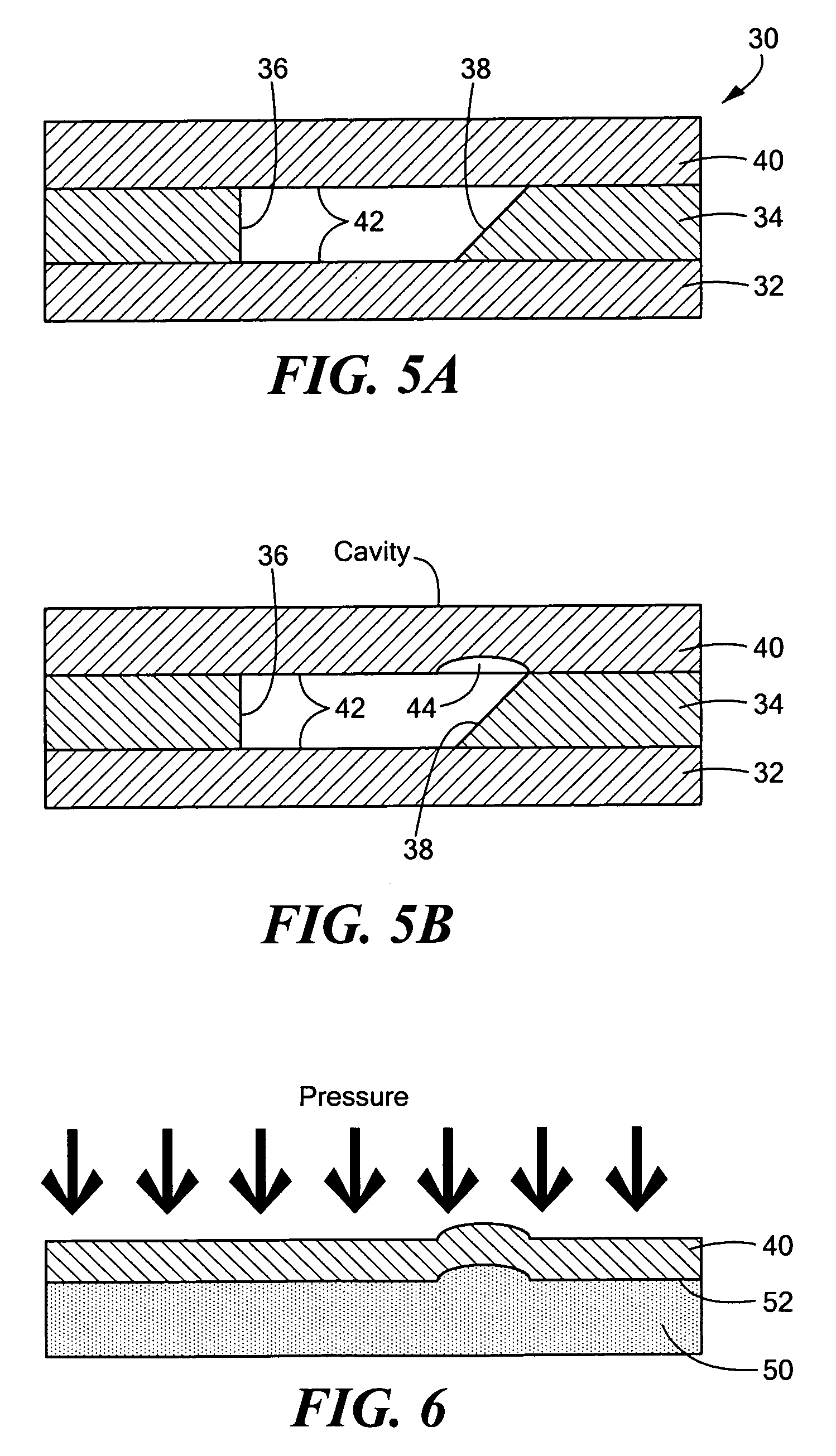

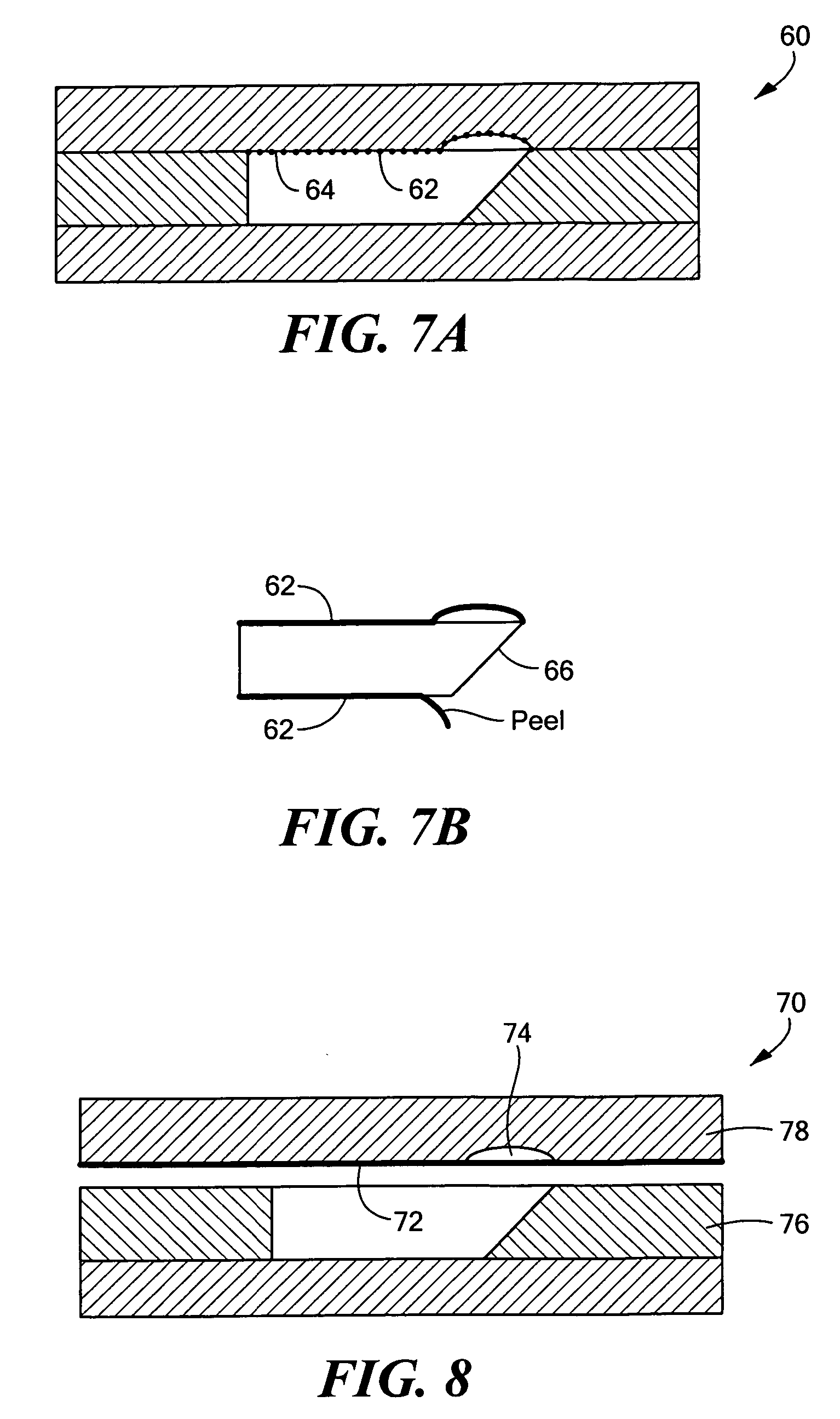

Method for producing high quality optical parts by casting

InactiveUS20060192307A1Quality improvementIncrease costOptical articlesPolymer sciencePolymer thin films

A casting method, rather than injection molding, to produce polymer optical components and systems is provided. The casting process controls shrinkage and stress, thus providing both high bulk uniformity and high quality, accurate surfaces, by incorporating polymer films into the mold. The films may remain incorporated into the part or may optionally be removed from the part after removal from the mold. In addition, the incorporation of separately produced components within the cast part is also provided, eliminating post-casting assembly manufacturing steps.

Owner:GOOGLE LLC

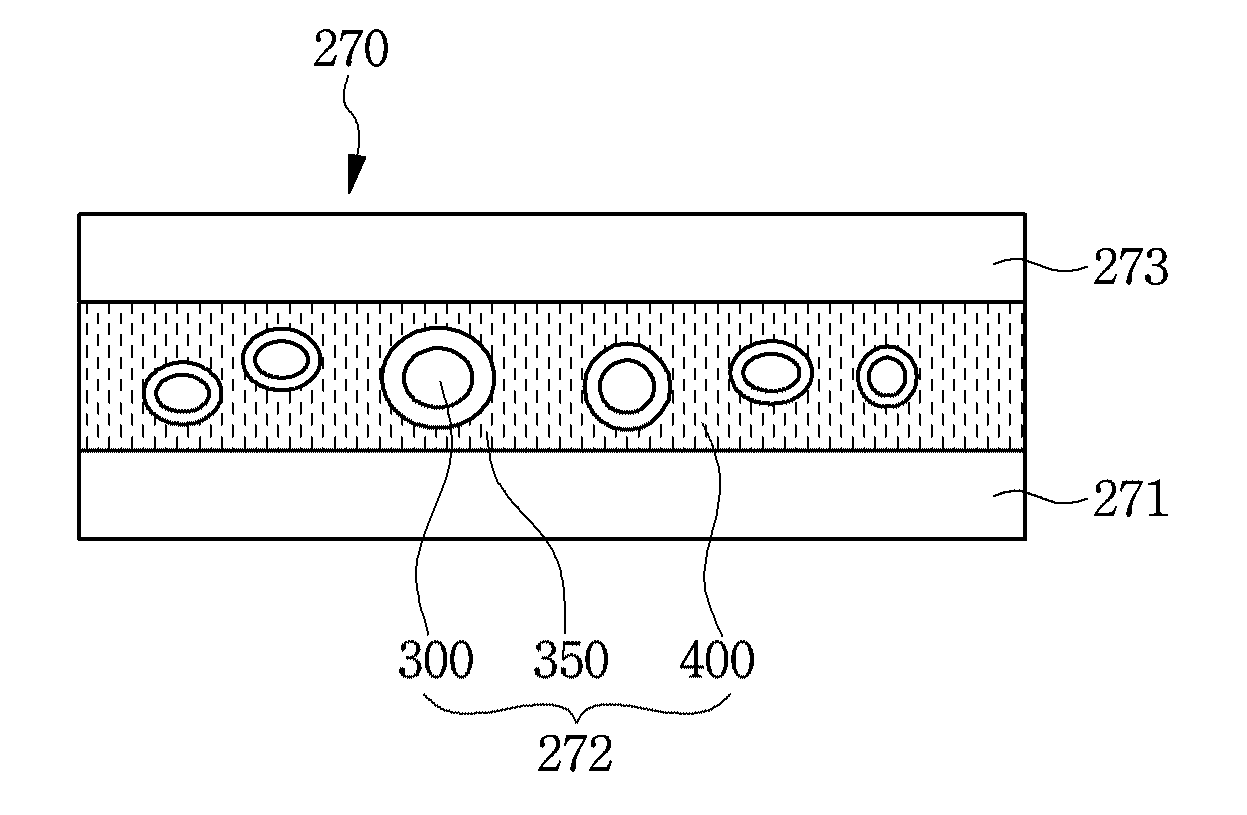

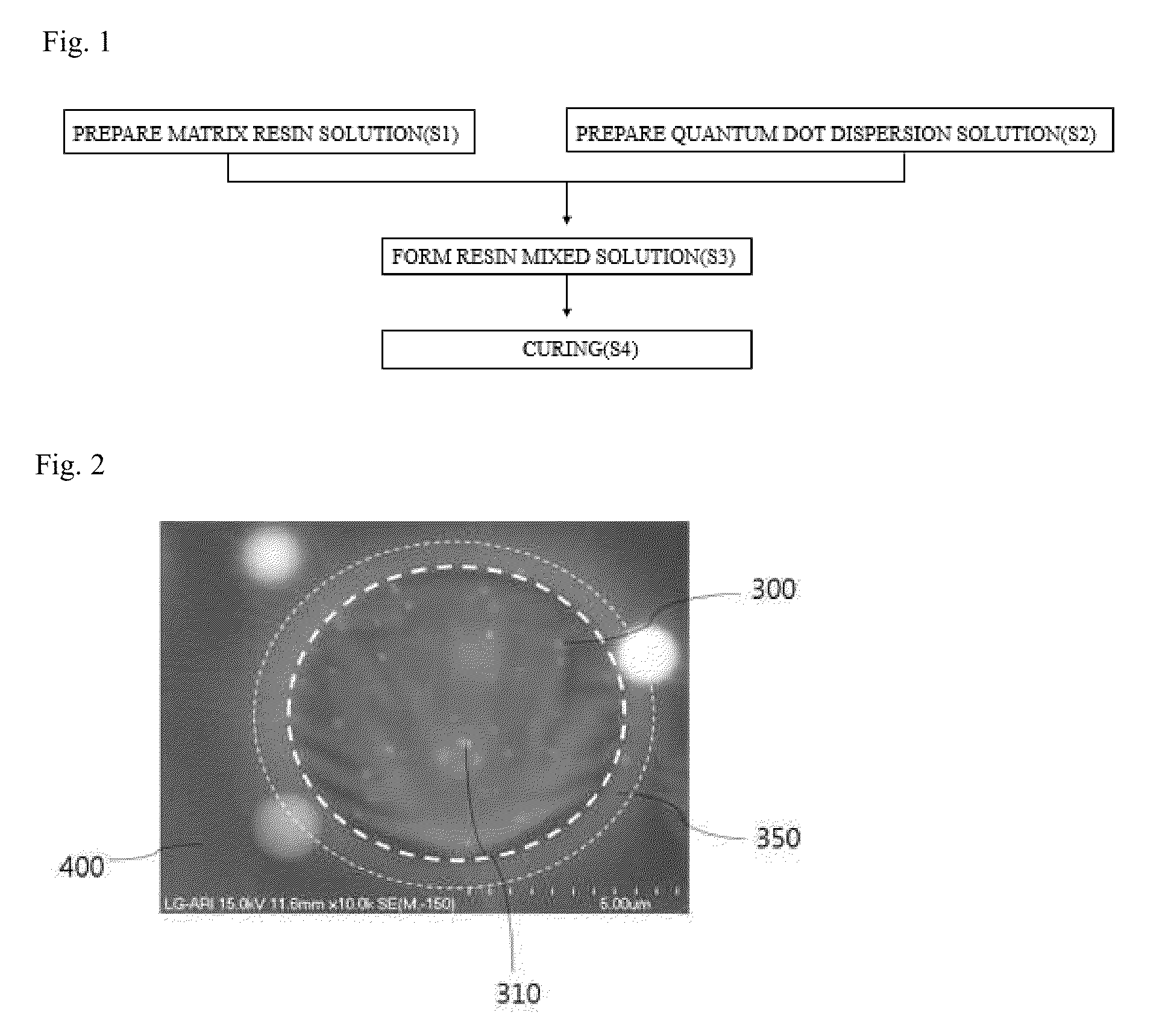

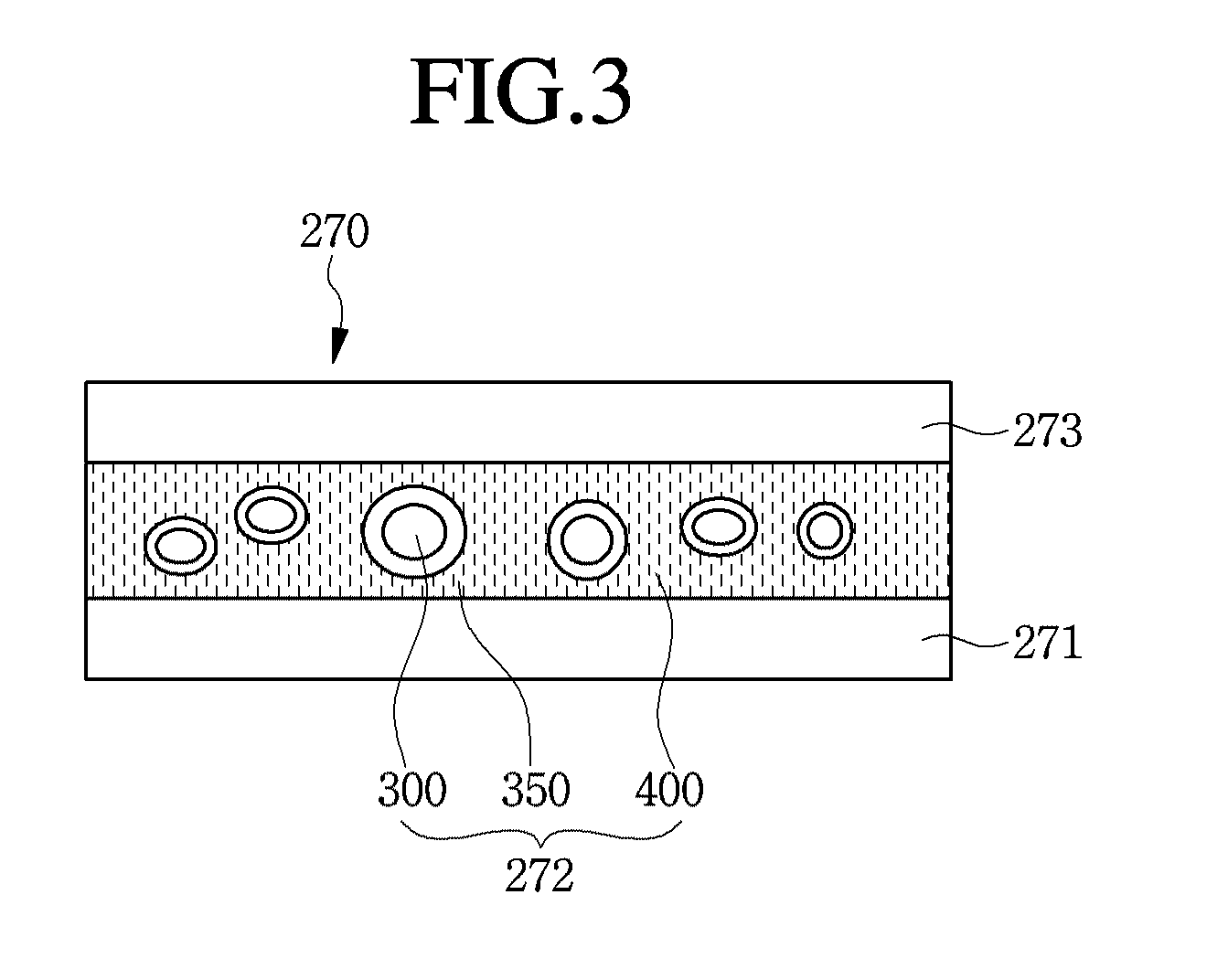

Method for preparing quantum dot-polymer complex, quantum dot-polymer complex, light conversion film, backlight unit and display device having the same

ActiveUS20160161066A1Uniform thicknessReduce degradationPoint-like light sourceSynthetic resin layered productsDisplay deviceQuantum dot

A quantum dot-polymer complex and a method for preparing the same. The quantum dot-polymer complex includes a first phase formed of a matrix resin, a globular second phase dispersed in the first phase, the second phase including a quantum dot therein, and a third phase disposed along a surface of the second phase between the first and second phases.

Owner:LG ELECTRONICS INC

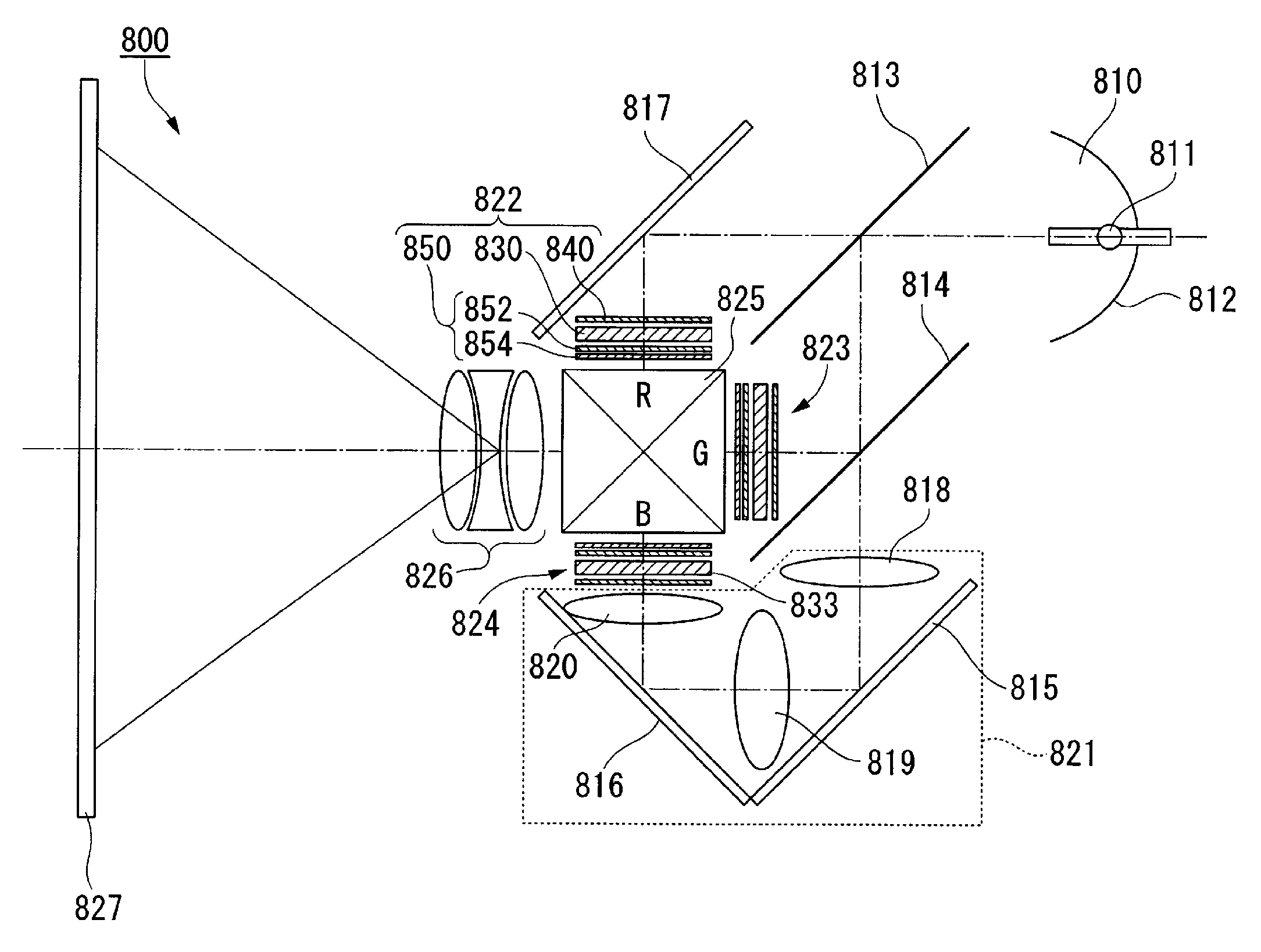

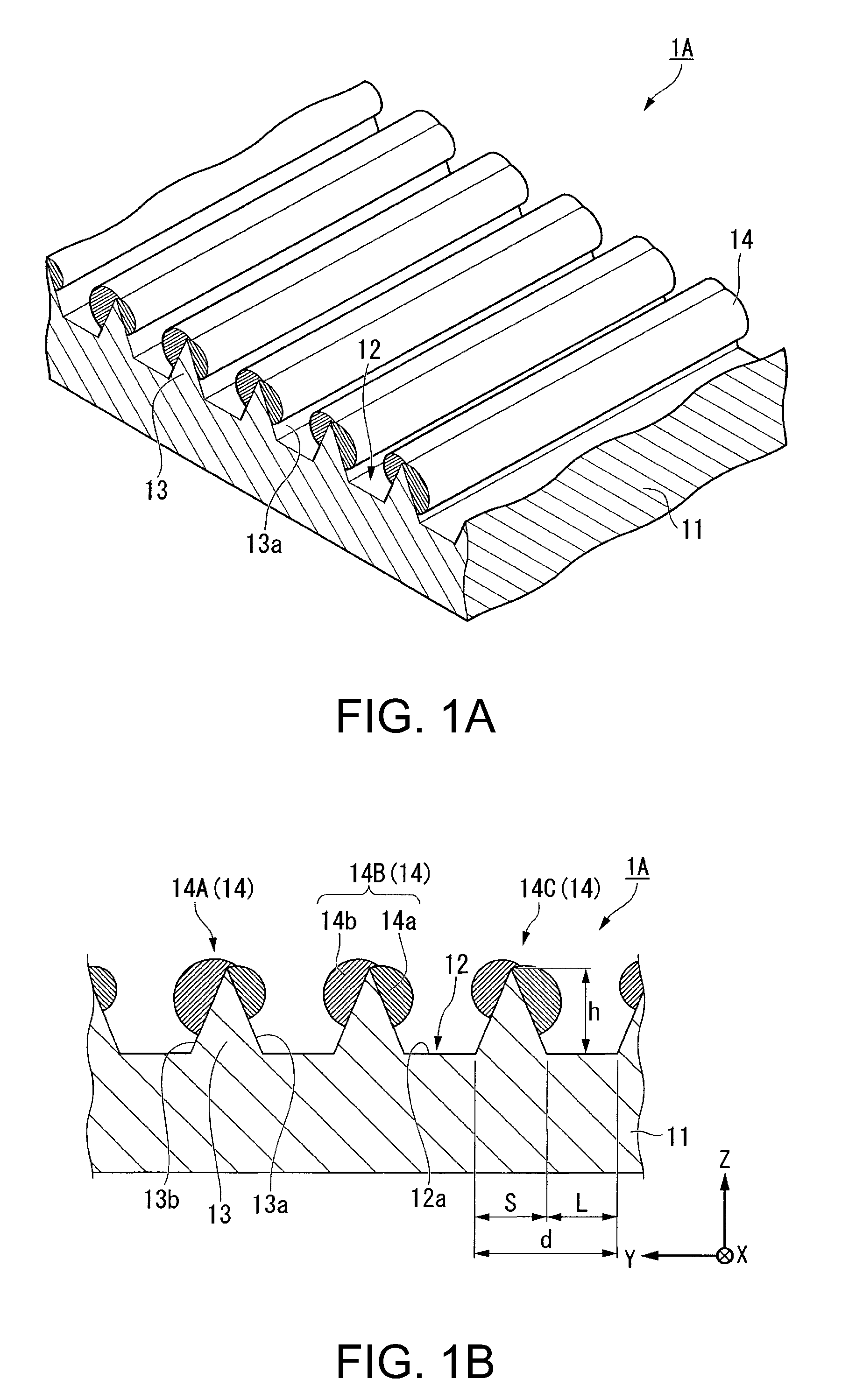

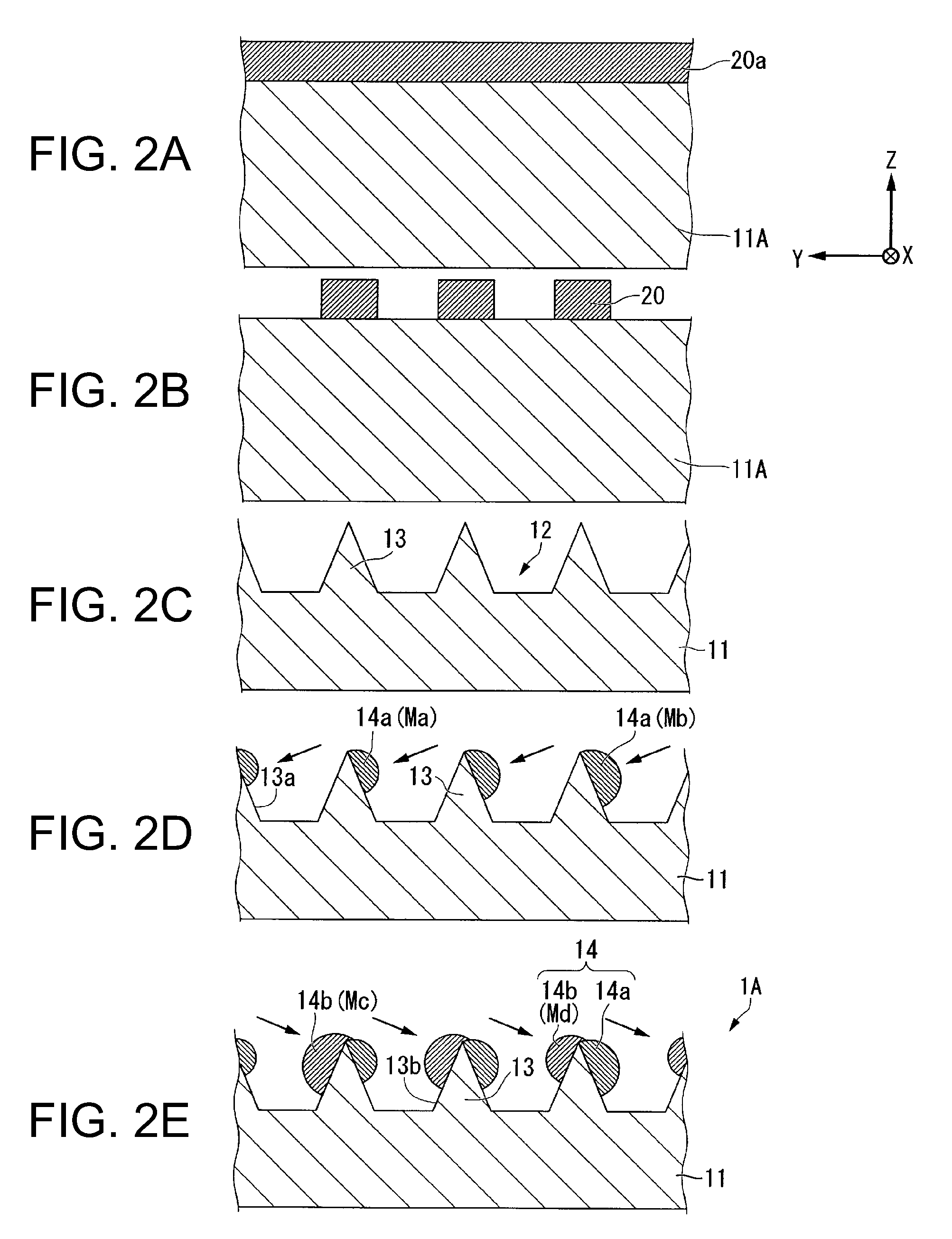

Polarizing element and method for manufacturing the same, projection type display, liquid crystal device, and electronic apparatus

ActiveUS20100225832A1Improve heat resistanceHigh output lightPolarising elementsSpecial surfacesDisplay deviceThin line

A polarizing element includes a substrate with protruded threads, and metal thin wires provided on the protruded threads. Each metal thin wire includes a first thin wire provided to a first side surface of the protruded thread and a second thin wire provided to a second side surface of the protruded thread. Each first thin wire has a first volume. Each second thin wire has a second volume. Each metal thin wire has a third volume which is the sum of the first and second volumes. As a distance from one end of the substrate increases, the volume of each first thin wire decreases and the volume of each second thin wire increases so that the third volume is maintained within a predetermined range.

Owner:SEIKO EPSON CORP

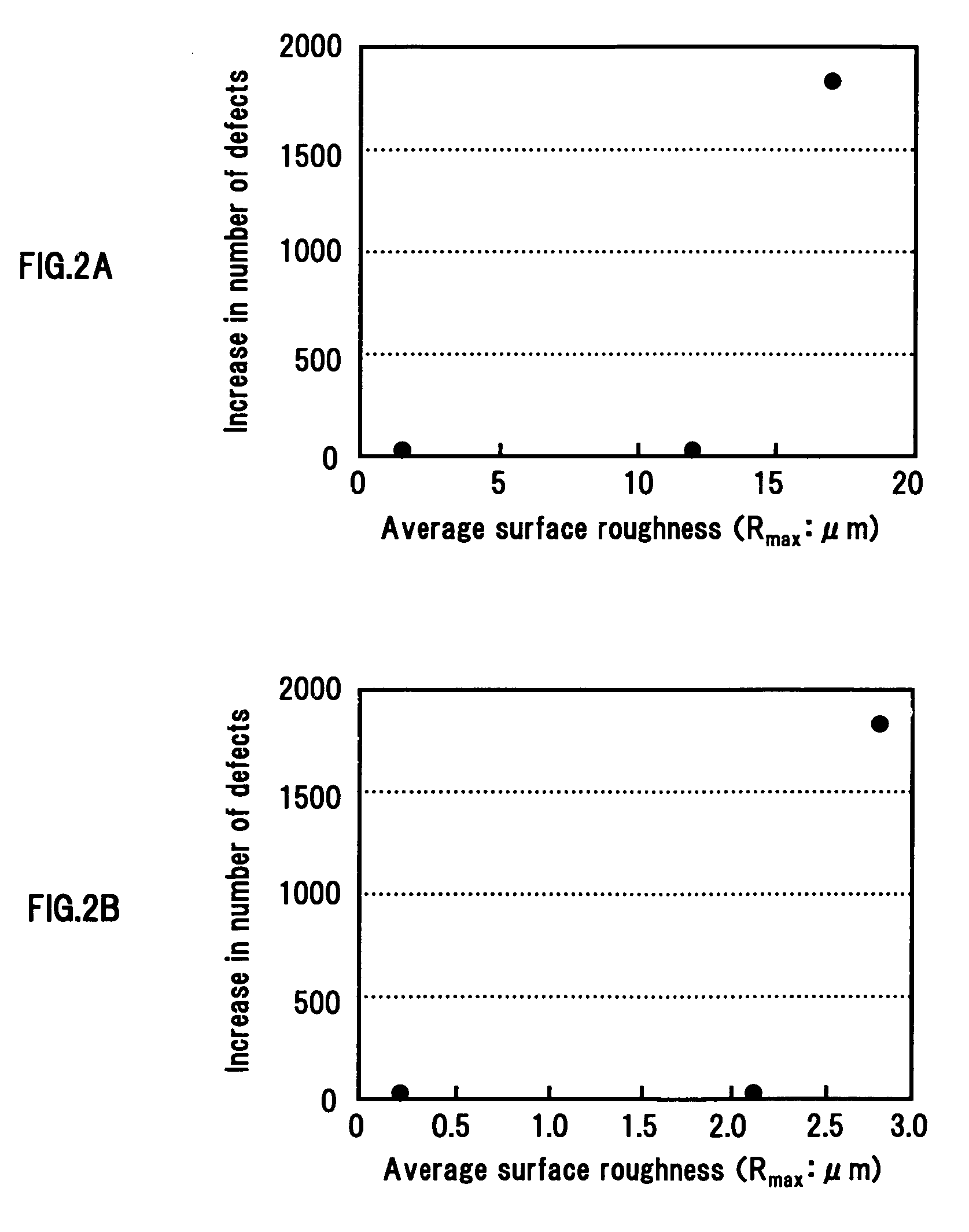

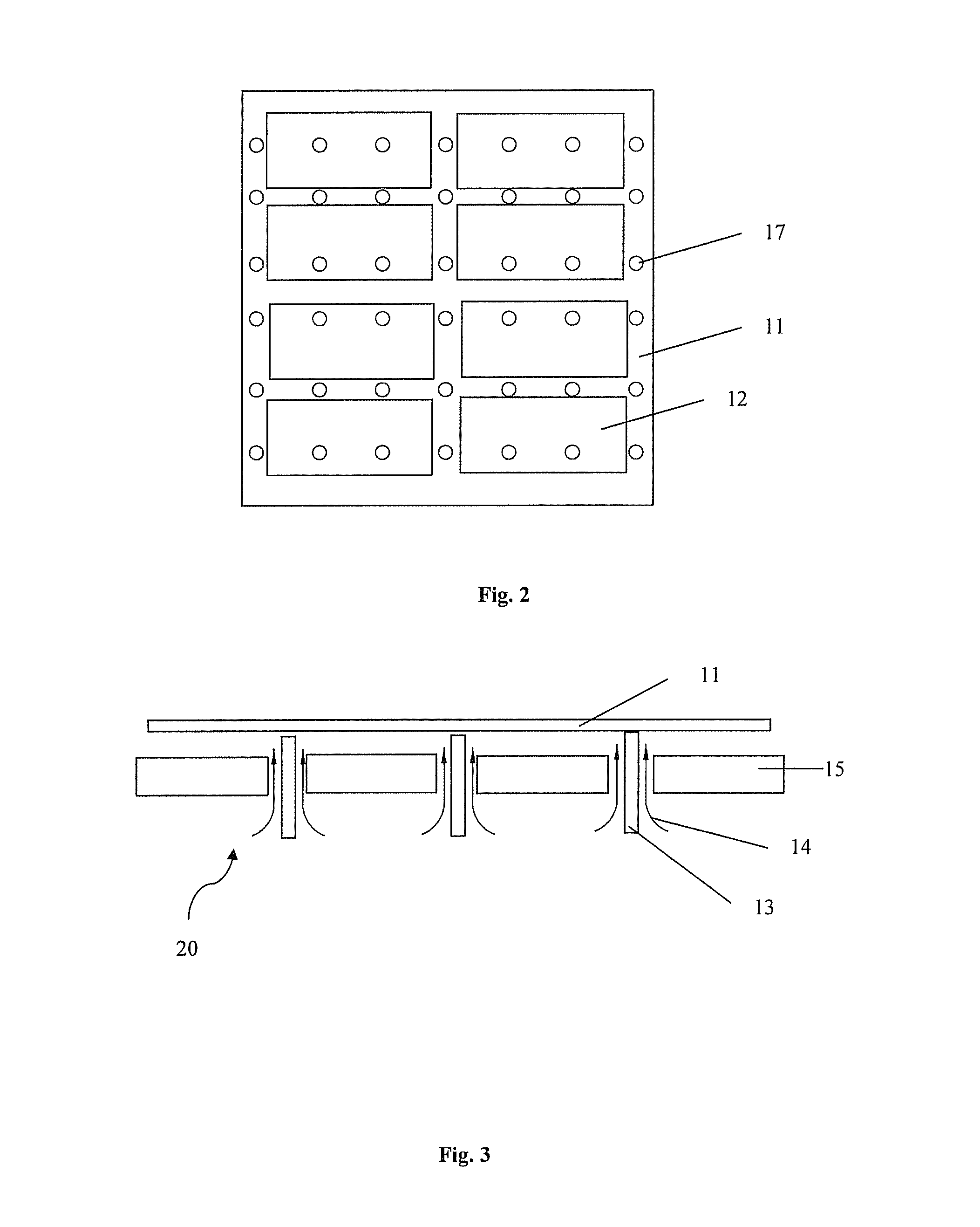

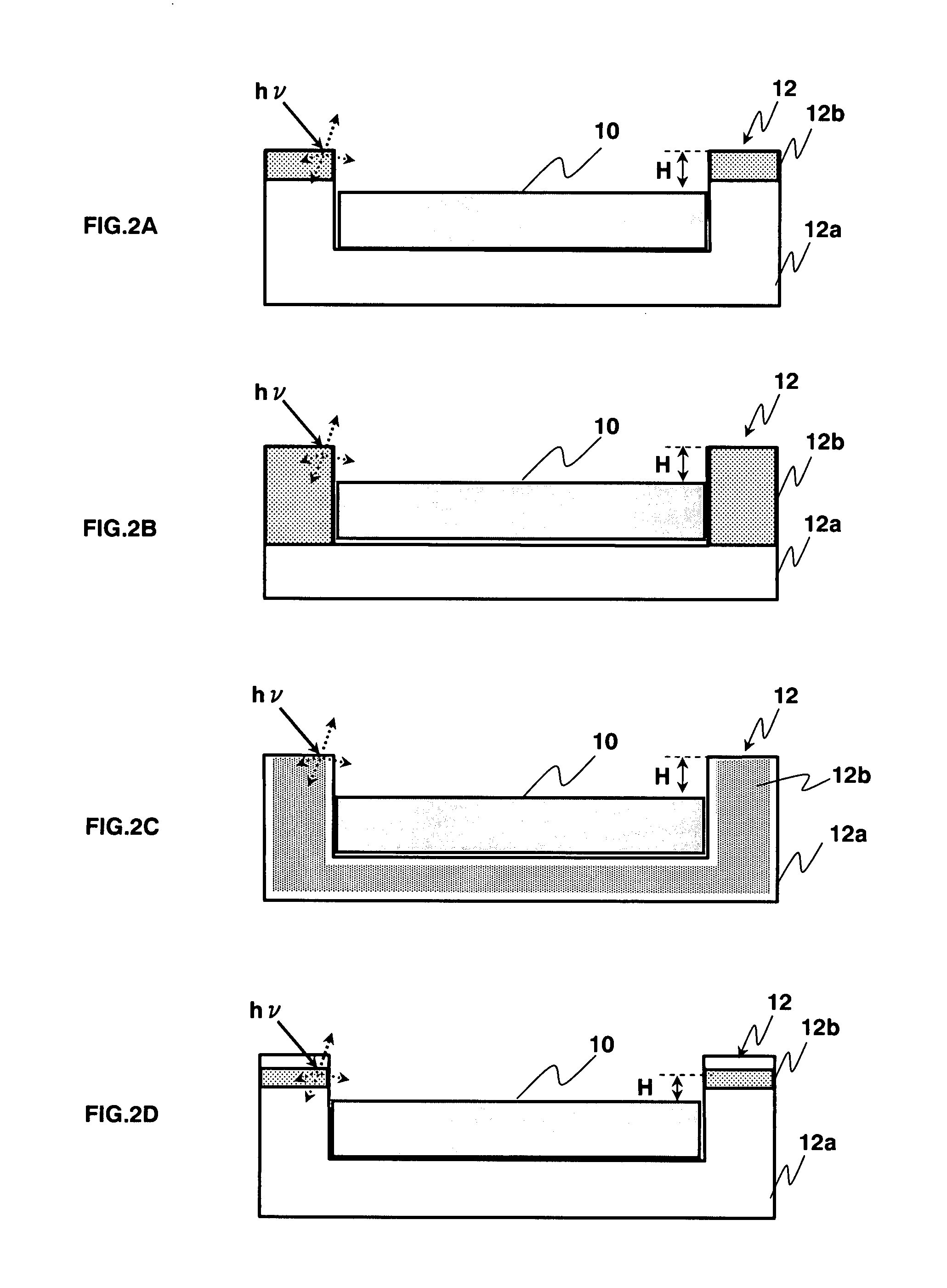

Fabrication method of photomask-blank

ActiveUS20070092807A1Excessive optical energyWeaken energyGlass/slag layered productsOriginals for photomechanical treatmentOptoelectronicsPhotomask

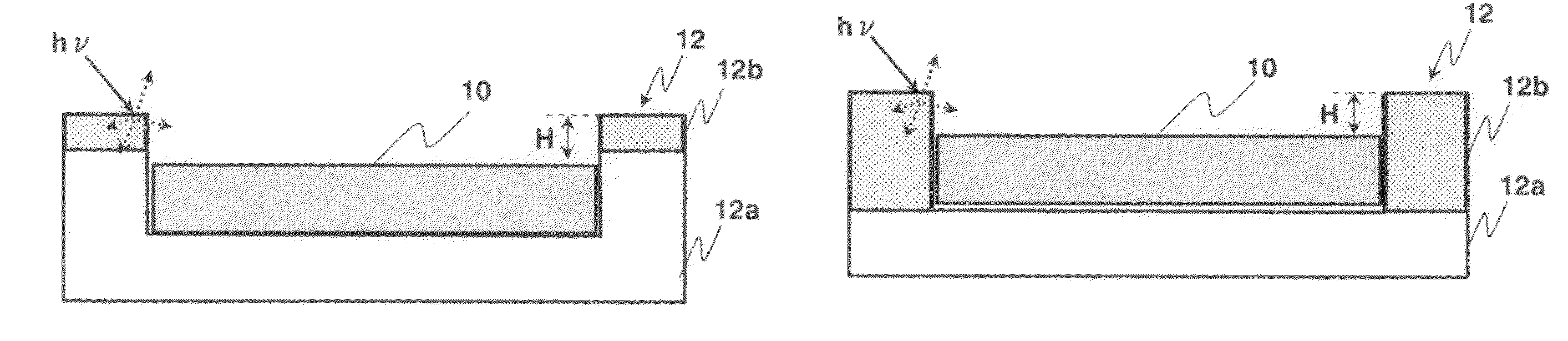

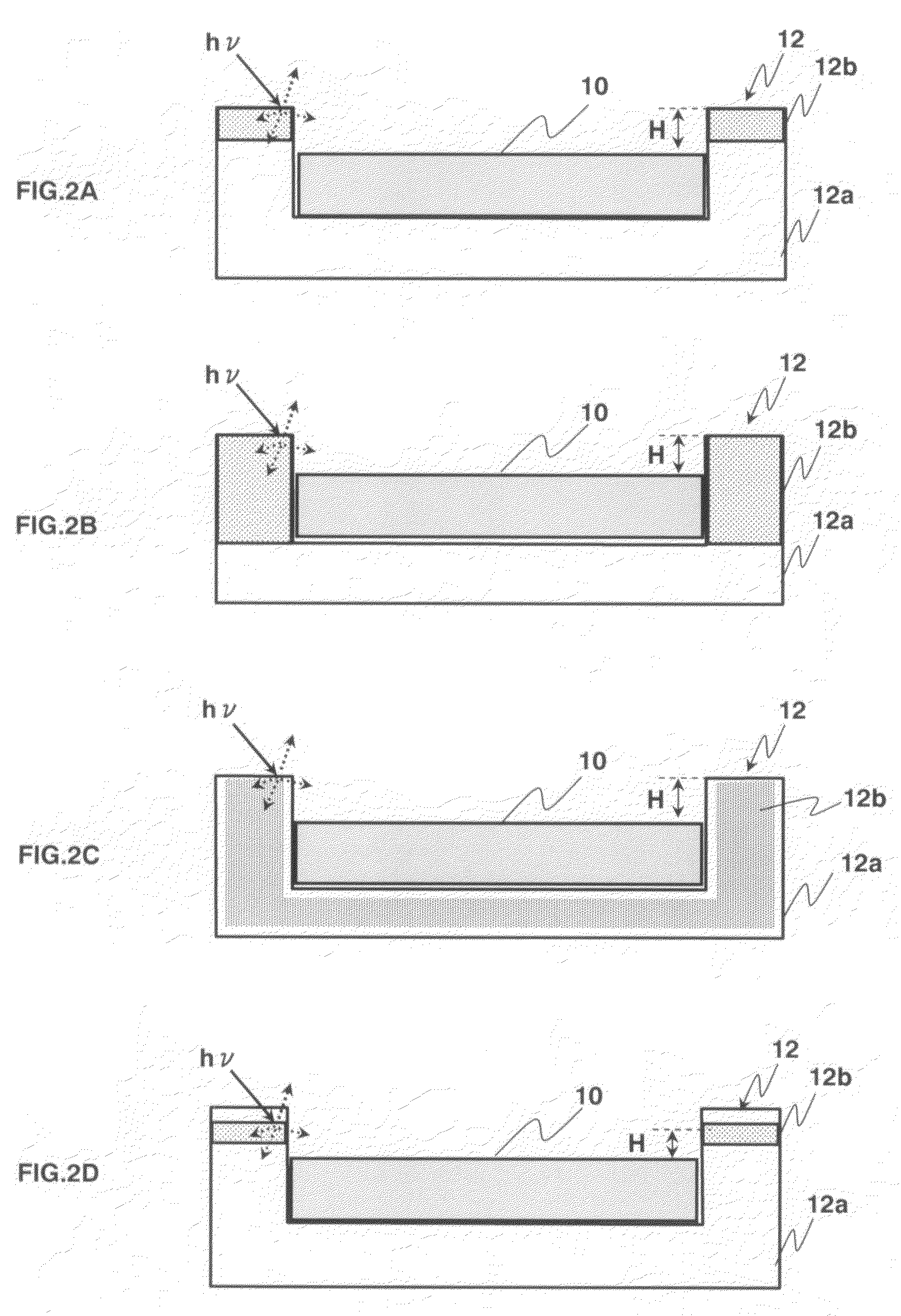

A susceptor having the most basic structure has a three-layer structure including a first and a second transparent quartz part and an opaque quartz part sandwiched therebetween. For example, the opaque quartz part is made of“foamed quartz”. In addition, the opacity of the opaque quartz part to flash light is determined to fall within an appropriate range based on the material or thickness of the opaque quartz part, taking into consideration the composition or thickness of a thin film formed on the substrate and various conditions concerning the energy of the irradiation light during flash light irradiation or the like. The stack structure may be composed of a stack of a plurality of opaque quartz layers having different opacities.

Owner:SHIN ETSU CHEM CO LTD

Lighting device for vehicles

InactiveUS20140160777A1Uniform optical characterEasily realizedOptical signallingVehicle lighting systemsBeam directionEngineering

A lighting device includes a first lamp unit mountable on a first body part and a second lamp unit mountable on a second body part and movable relative to the first body part, wherein a gap is formed between the first and second lamp units, the first and second lamp units each have a housing with light sources and covered by a transparent lens, wherein the lens has a base surface for transmitting a functional light beam in the main beam direction and a side section that borders the gap and runs parallel to a gap plane and through which a side light beam enters into the gap, wherein the side section of the lens and / or a light guiding part covered by the lens has scattering elements, so that the side light beam emitted by the light source can be emitted along the gap plane in the main beam direction.

Owner:HELLA KGAA HUECK & CO

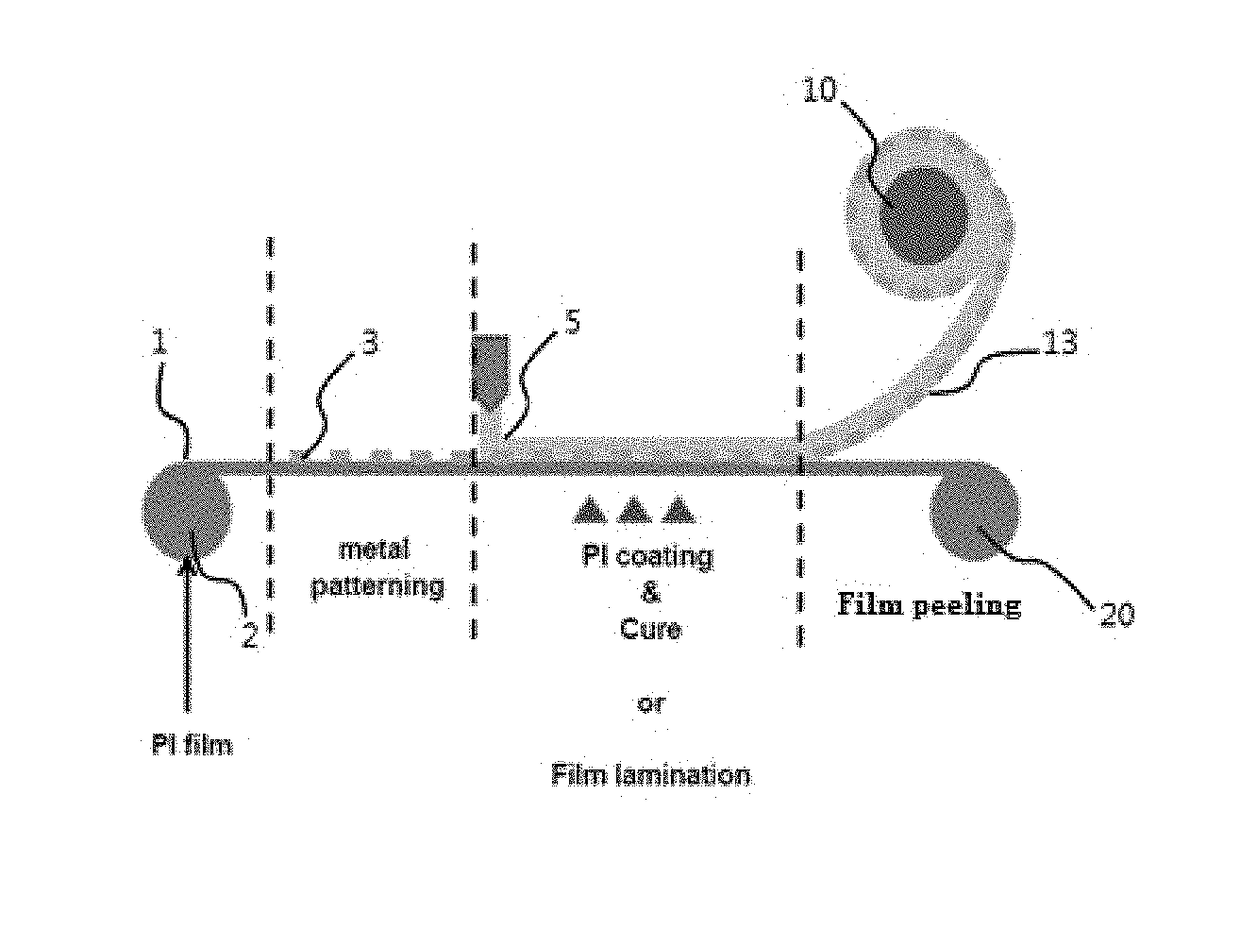

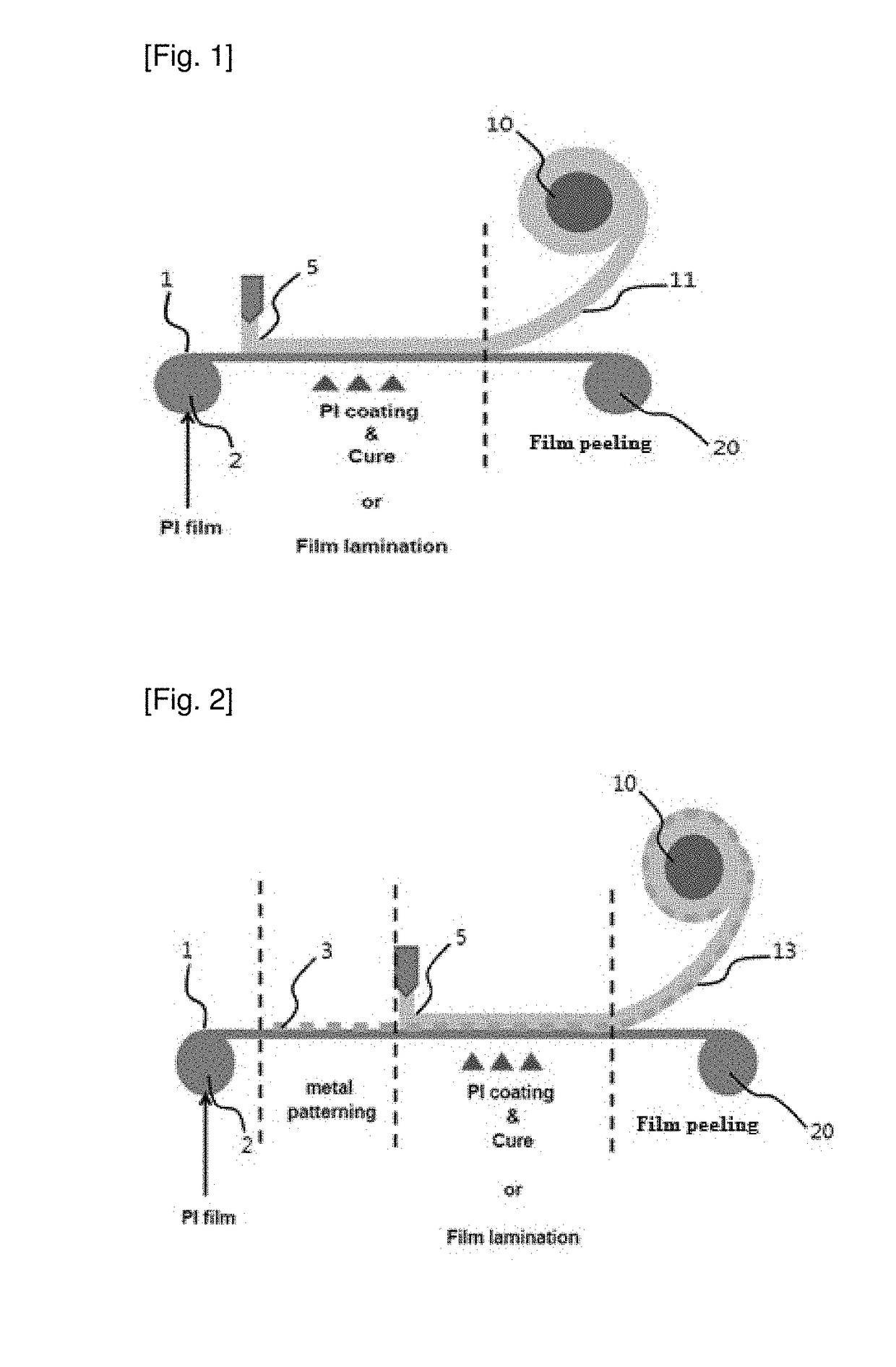

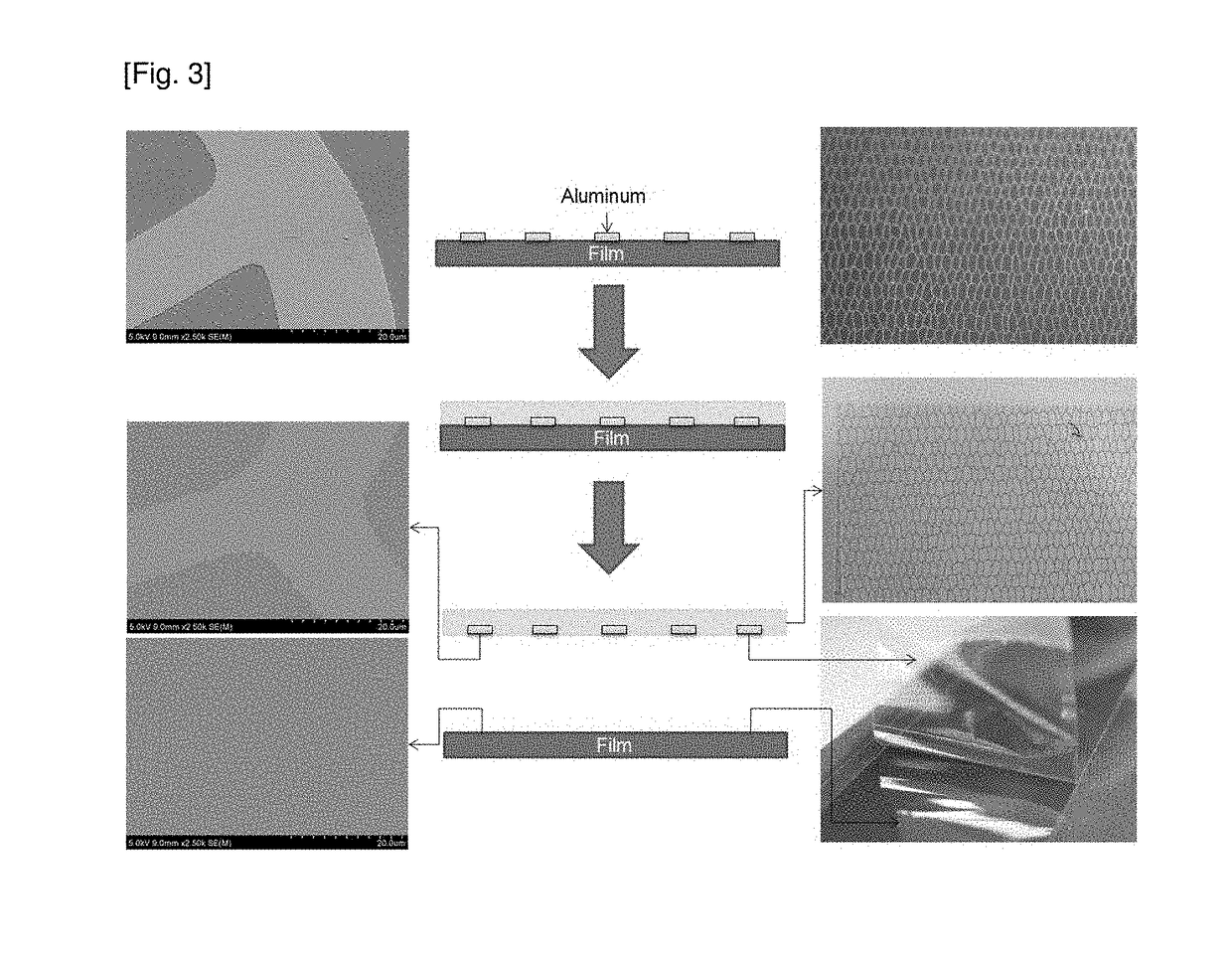

Method for fabricating flexible substrate

ActiveUS20170374737A1Easy to separateSimple processConductive layers on insulating-supportsApparatus for manufacturing conducting/semi-conducting layersLight irradiationEngineering

The present invention relates to a method for producing a flexible substrate. According to the method of the present invention, a flexible substrate layer can be easily separated from a carrier substrate even without the need for laser or light irradiation so that a device can be prevented from deterioration of reliability and occurrence of defects caused by laser or light irradiation. In addition, according to the method of the present invention, a flexible substrate can be continuously produced in an easier manner based on a roll-to-roll process.

Owner:LG CHEM LTD

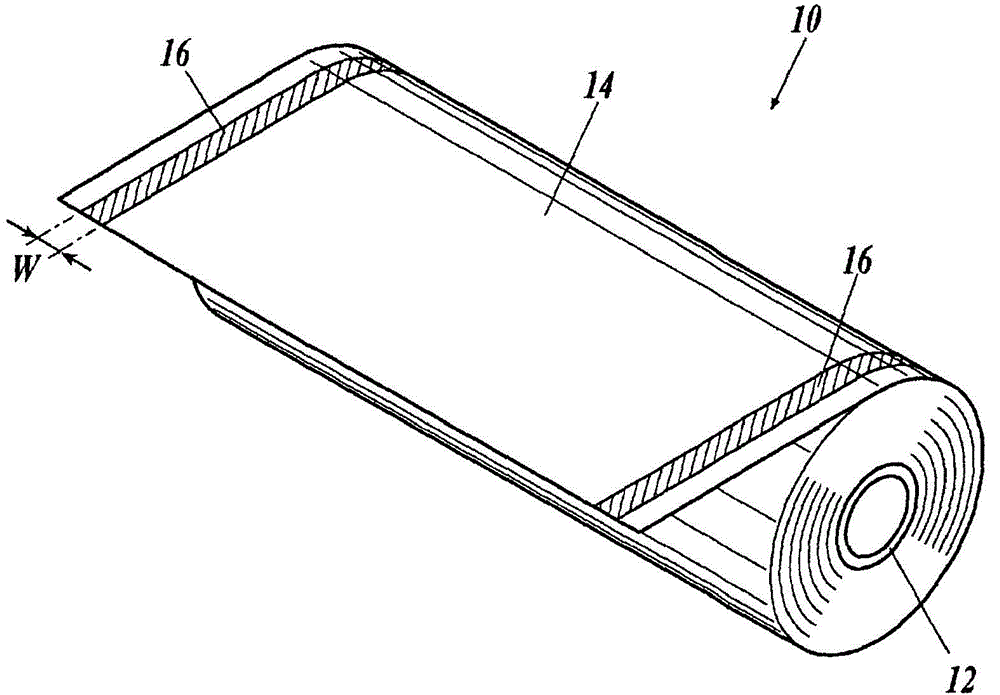

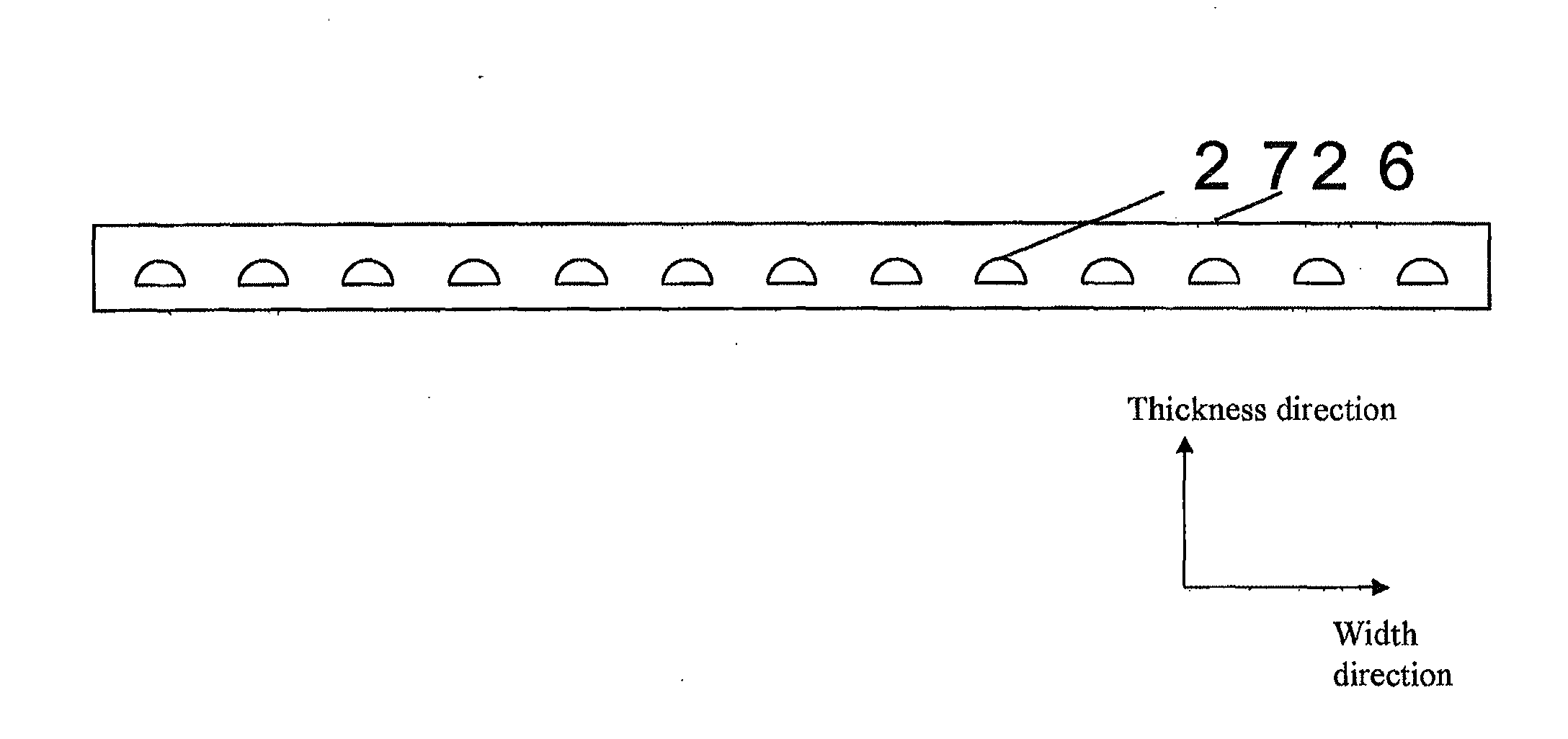

Optical film roll, method for producing same, polarizing plate, and display device

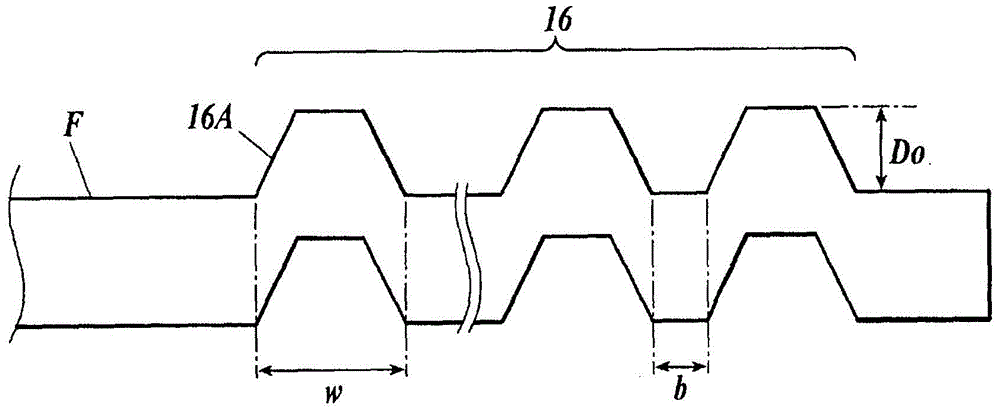

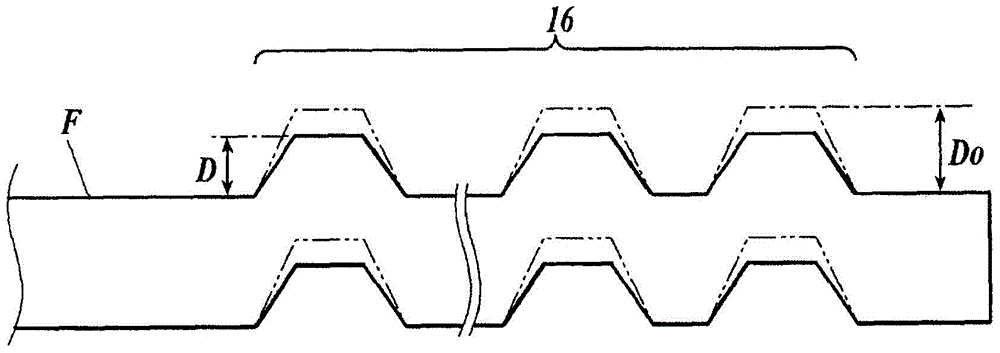

ActiveCN104870352APrevent deterioration of winding shapeStable and uniform optical propertiesPolarising elementsDisplay deviceEngineering

The present invention addresses the problem of providing an optical film roll which exhibits an elastic modulus within the plane of the film in an angled direction in relation to the lengthwise direction thereof, is unlikely to produce a shift in the rolling of the roll even due to moisture during storage or transport thereof, and has a uniform optical value even during storage or after transport thereof. This optical film roll is a lengthwise-oriented optical film roll in which the direction (A) having the maximum elastic modulus in the plane of the film is angled in relation to the lengthwise direction thereof, and the ratio of the values of the elastic modulus (EA) in the direction (A) having the maximum value to the elastic modulus (EB) in a direction (B) perpendicular to the direction (A) is 1.4≤EA / EB. The optical film roll is characterized by having an embossed section on both ends thereof having a height within the range of 1-20μm, and in that the crushing resistance (%) stipulated by formula (1) of the embossed sections is at least 50% for the embossed sections on both ends. (Formula 1) Crushing resistance (%) = D / Do×100% (Do and D are the heights of the projections before and after applying weight to the embossed sections.)

Owner:KONICA MINOLTA INC

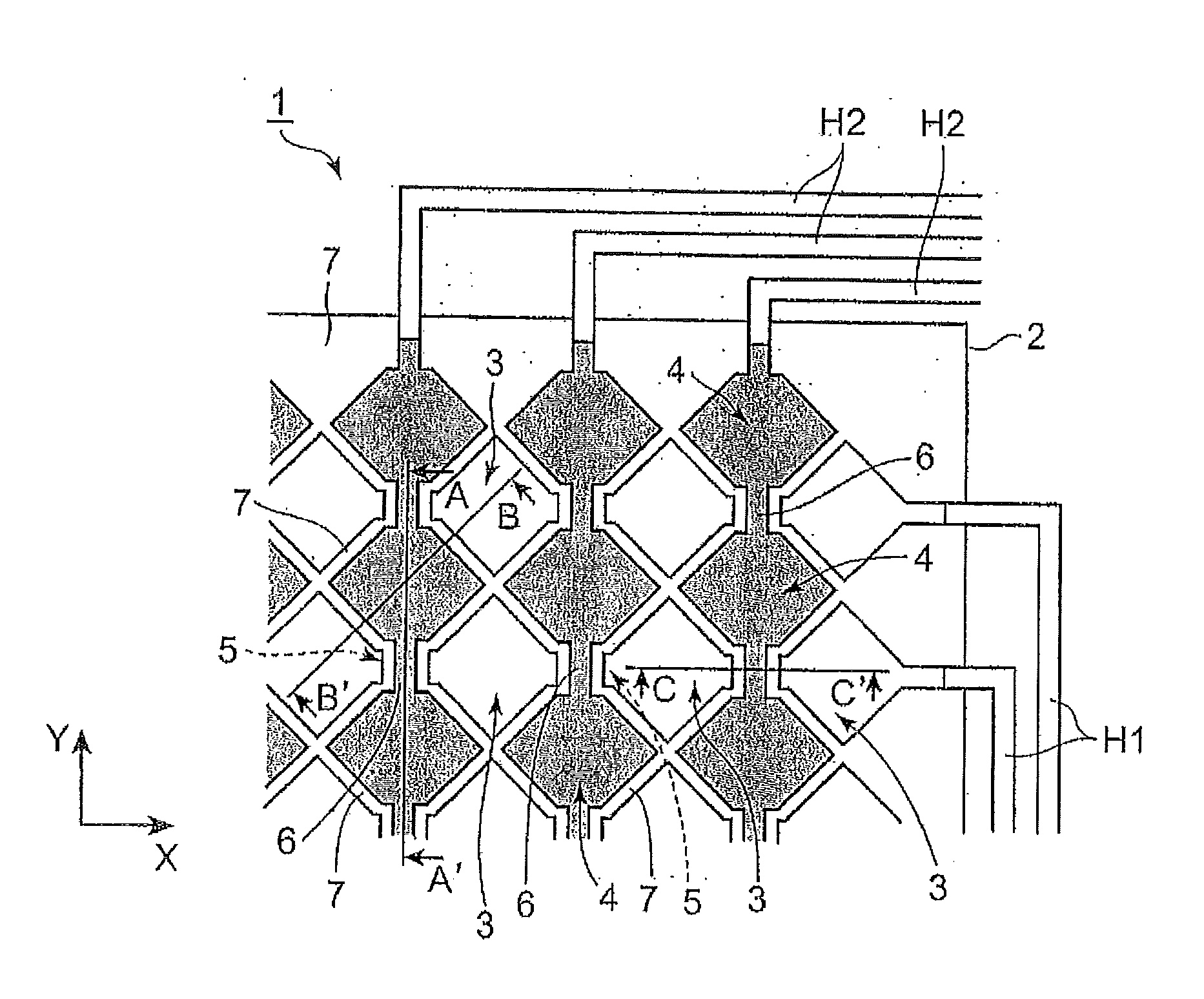

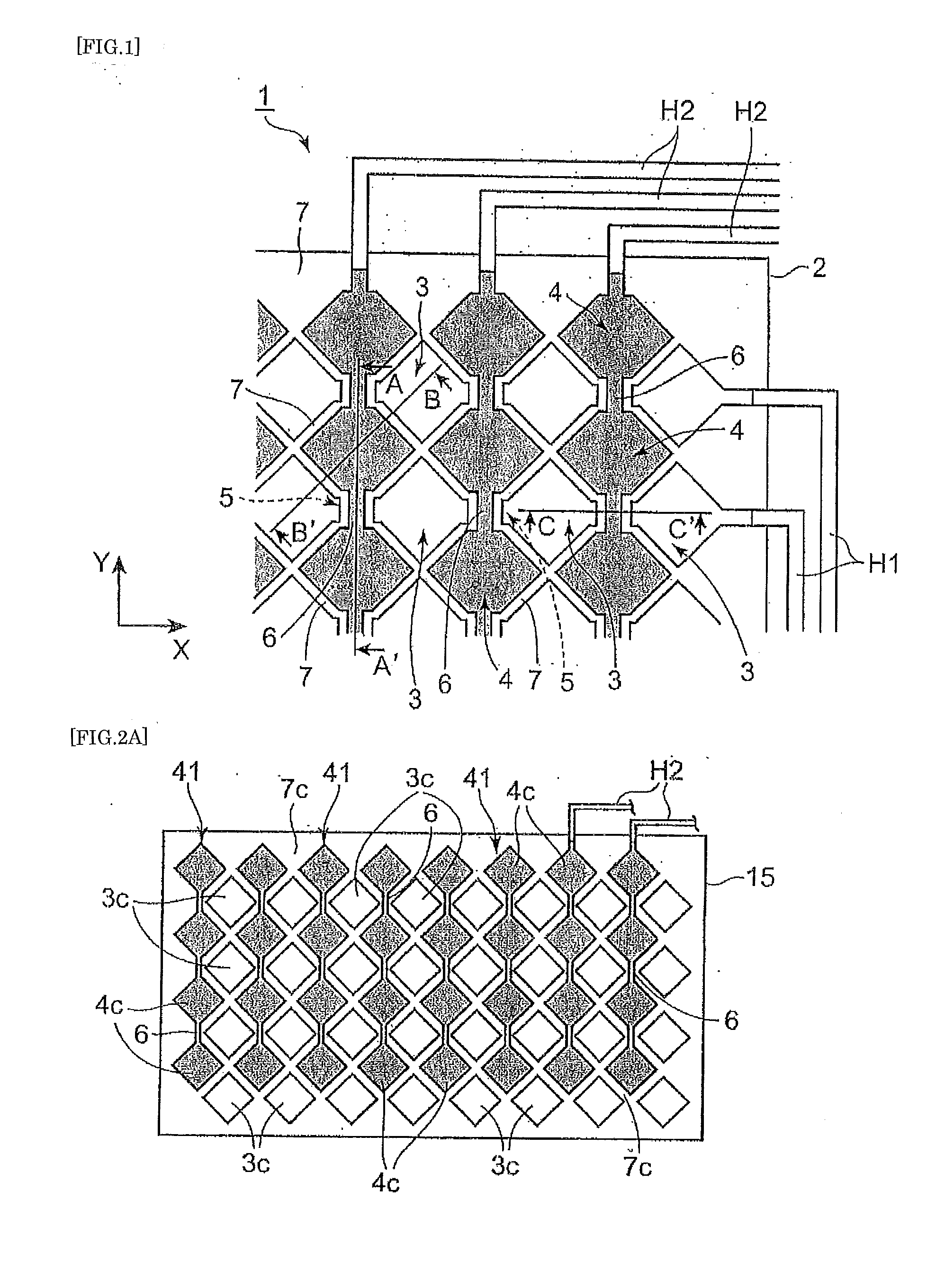

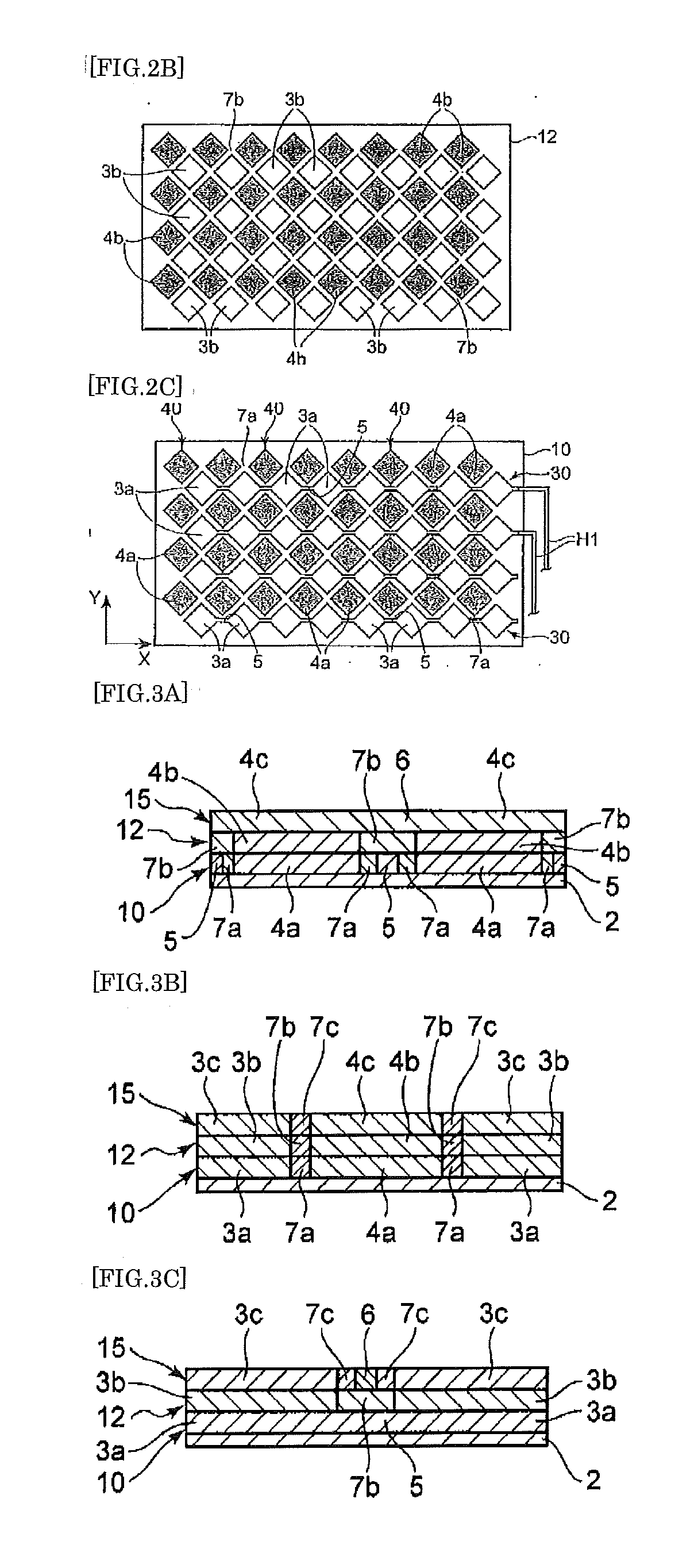

Capacitive touch sensor, manufacturing method therefor, and display device

ActiveUS20150277623A1Pattern visibility caused by step formation can be suppressedPattern visibility can be suppressed and preventedLayered product treatmentLaminationDisplay deviceElectrode

Provided herein are a capacitive touch sensor capable of reducing pattern visibility, a manufacturing method therefor, and a display device with the touch sensor. In a capacitive touch sensor (1), a first layer (10) has first first-layer electrodes (3a); first-layer conductive portions (5) connecting the adjacent first first-layer electrodes (3a); second first-layer electrodes (4a); and first-layer insulating portions (7a) formed between the second first-layer electrodes (4a) and the first-layer conductive portions (5). An intermediate layer (12) has first intermediate-layer electrodes (3b) formed on the first first-layer electrodes (3a); second intermediate-layer electrodes (4b) formed on the second first-layer electrodes (4a); and intermediate-layer insulating portions (7b) formed between the first-layer conductive portions (5) and second-layer conductive portions (6). A second layer (15) has first second-layer electrodes (3c); second second-layer electrodes (4c); second-layer conductive portions (6) connecting the adjacent second second-layer electrodes (4c) in the Y-axis direction so as to intersect with the first-layer conductive portions (5); and second-layer insulating portions (7c) formed between the first second-layer electrodes (3c) and the second-layer conductive portions (6).

Owner:NISSHA PRINTING COMPANY

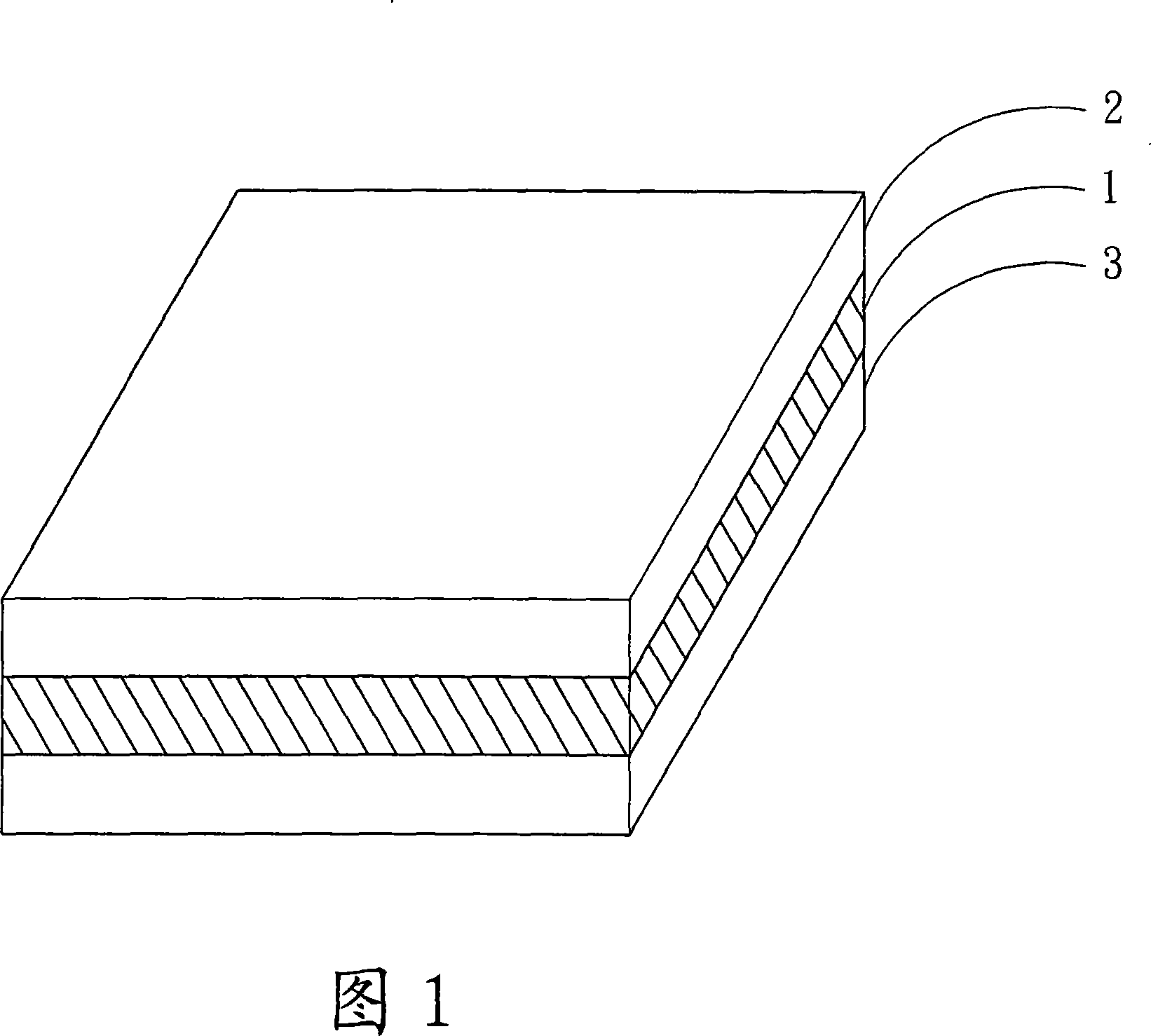

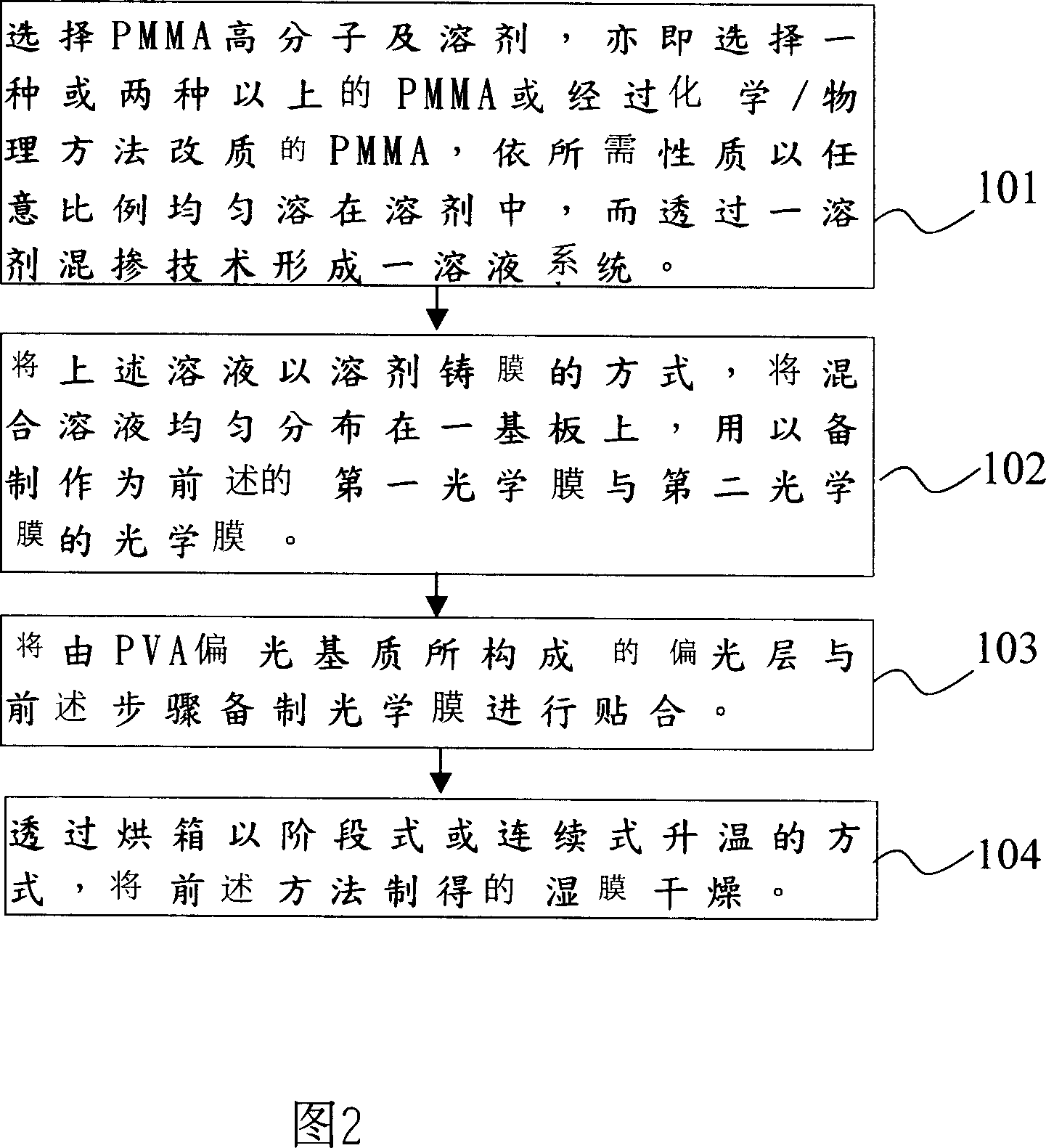

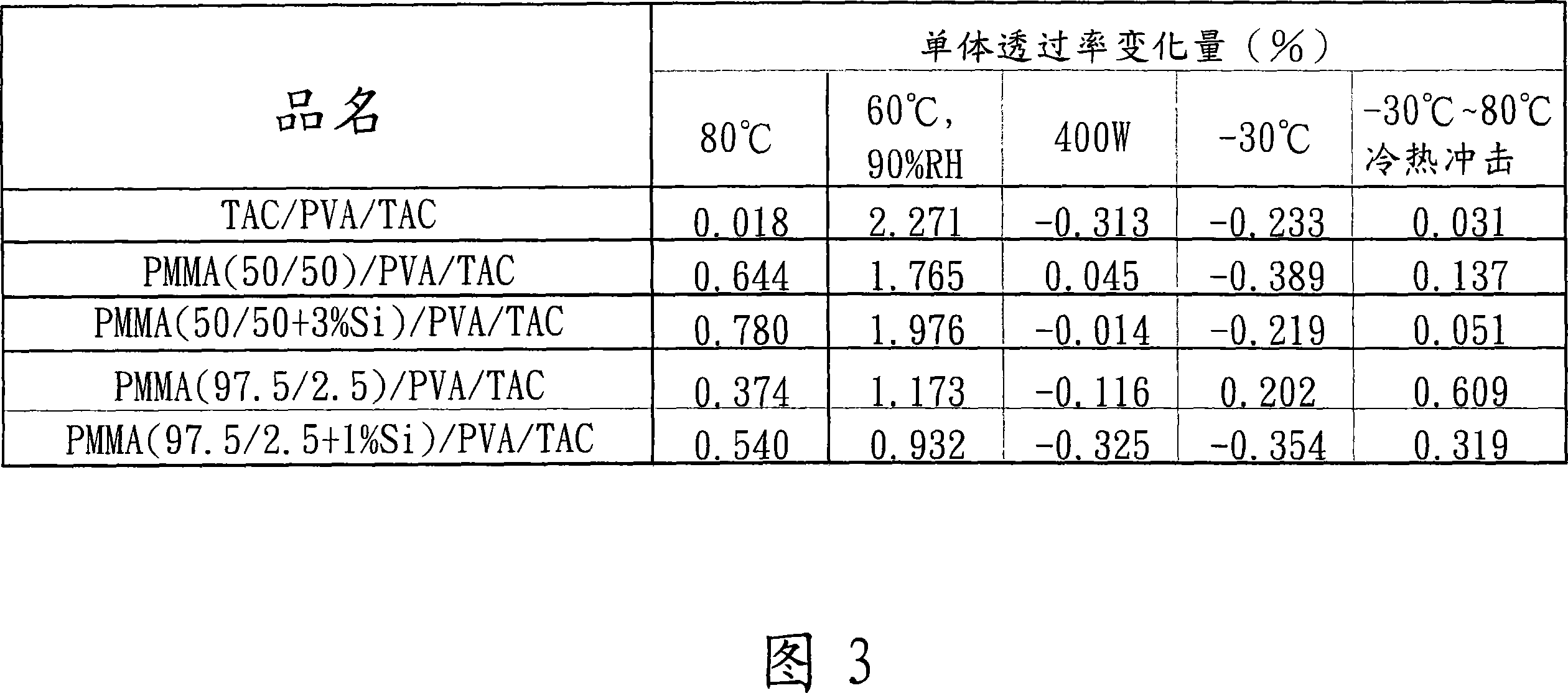

Polarized plate structure

InactiveCN101097269AGood heat resistanceModerate mechanical propertiesPolarising elementsBoard structureOptical film

The present invention relates to a polarized light board structure which is provided with a polarized light layer, a first optical film and a second optical film, the first optical film is formed above the polarized light layer and the second optical film is formed below the polarized light layer, wherein, at least one optical film selected from the first optical film and the second optical film is polymethyl methacrylate optical film. Into the bargain, the optical film is formed by pasting the mixed solution to the polarized light board and doing heat treatment when penetrating the mixed solution and distributing on the substrate to prepare for making have finished, or the optical film is formed by penetrating the mixed solution and distributing on the substrate and doing thermal treatment.

Owner:OPTIMAX TECHNOLOGY CORPORATION

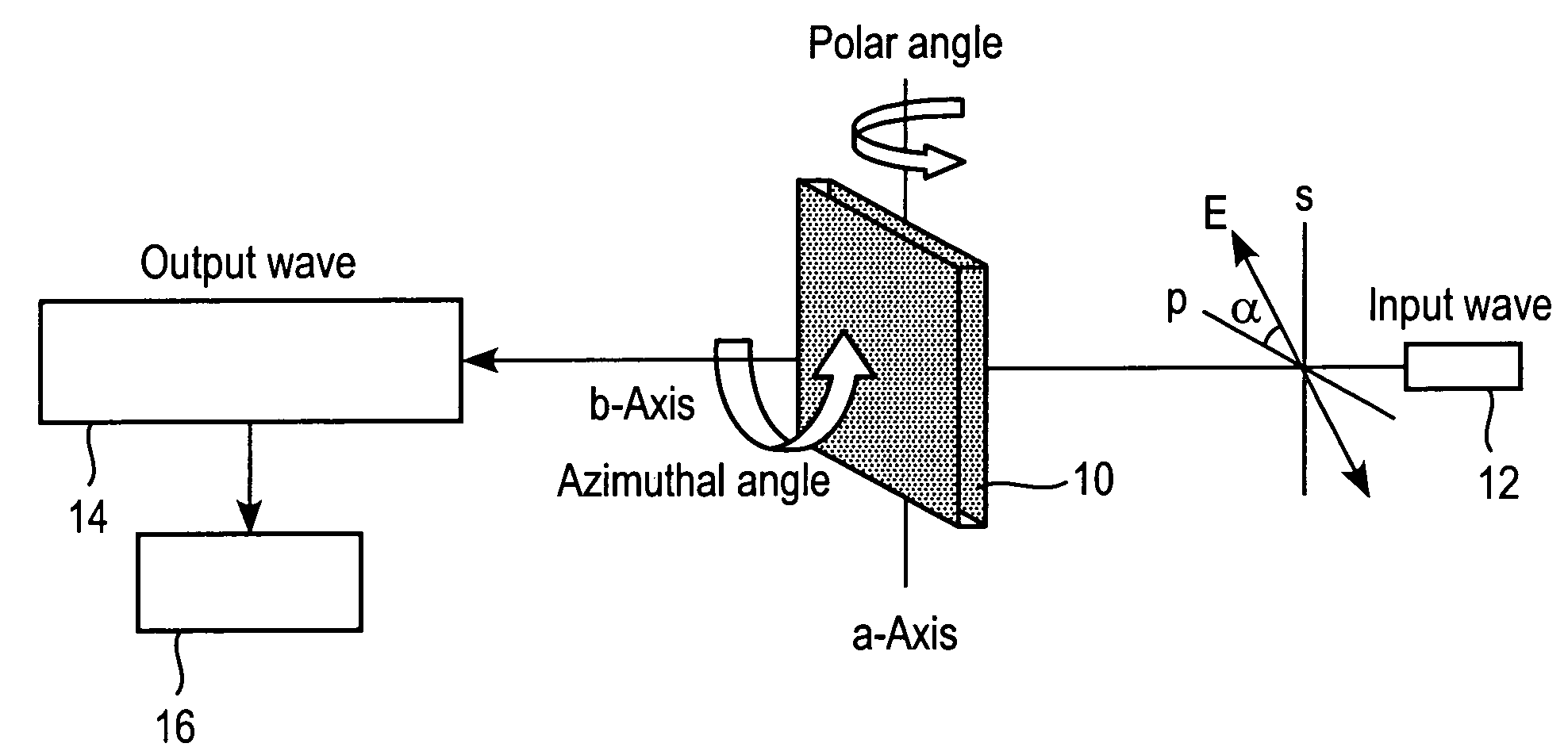

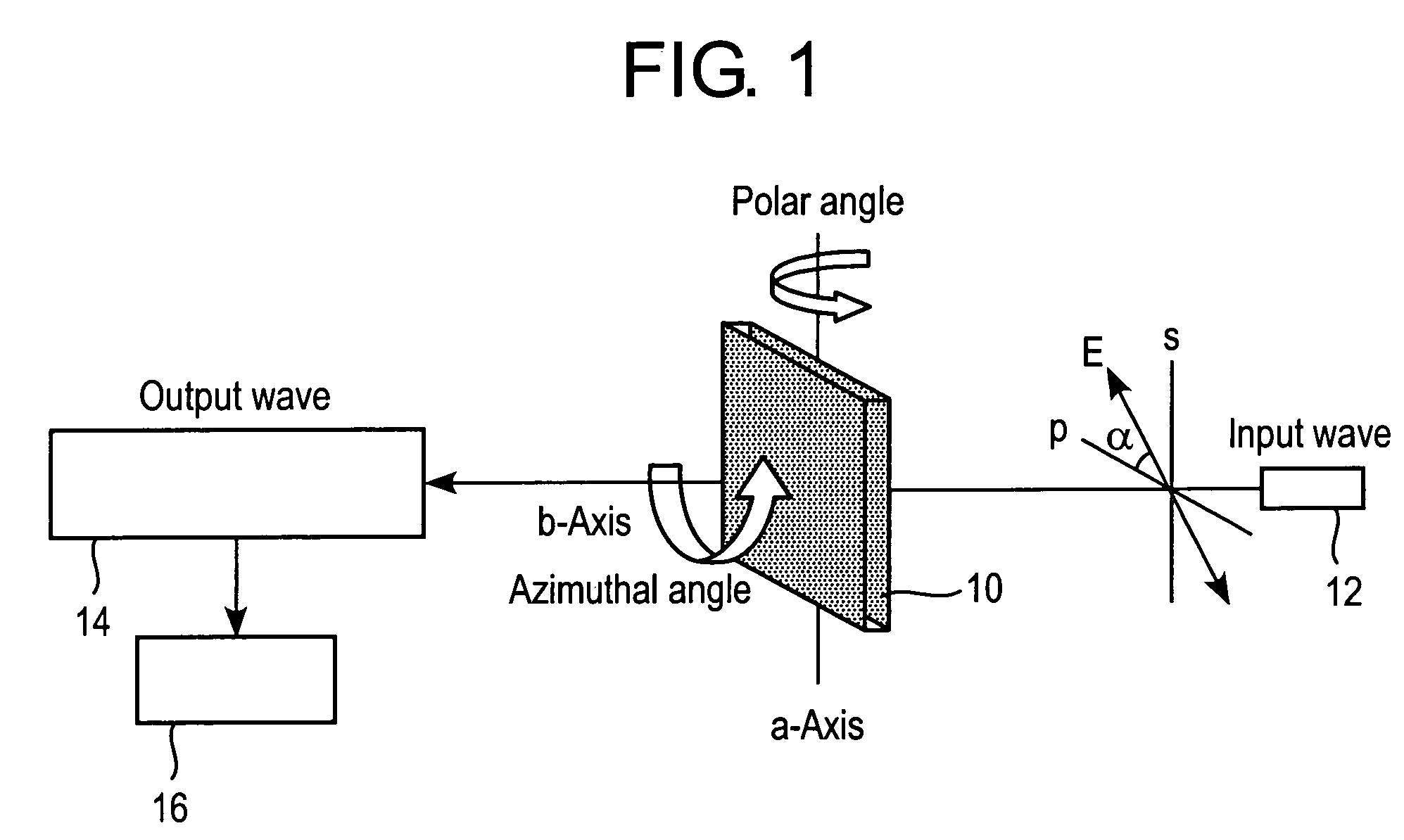

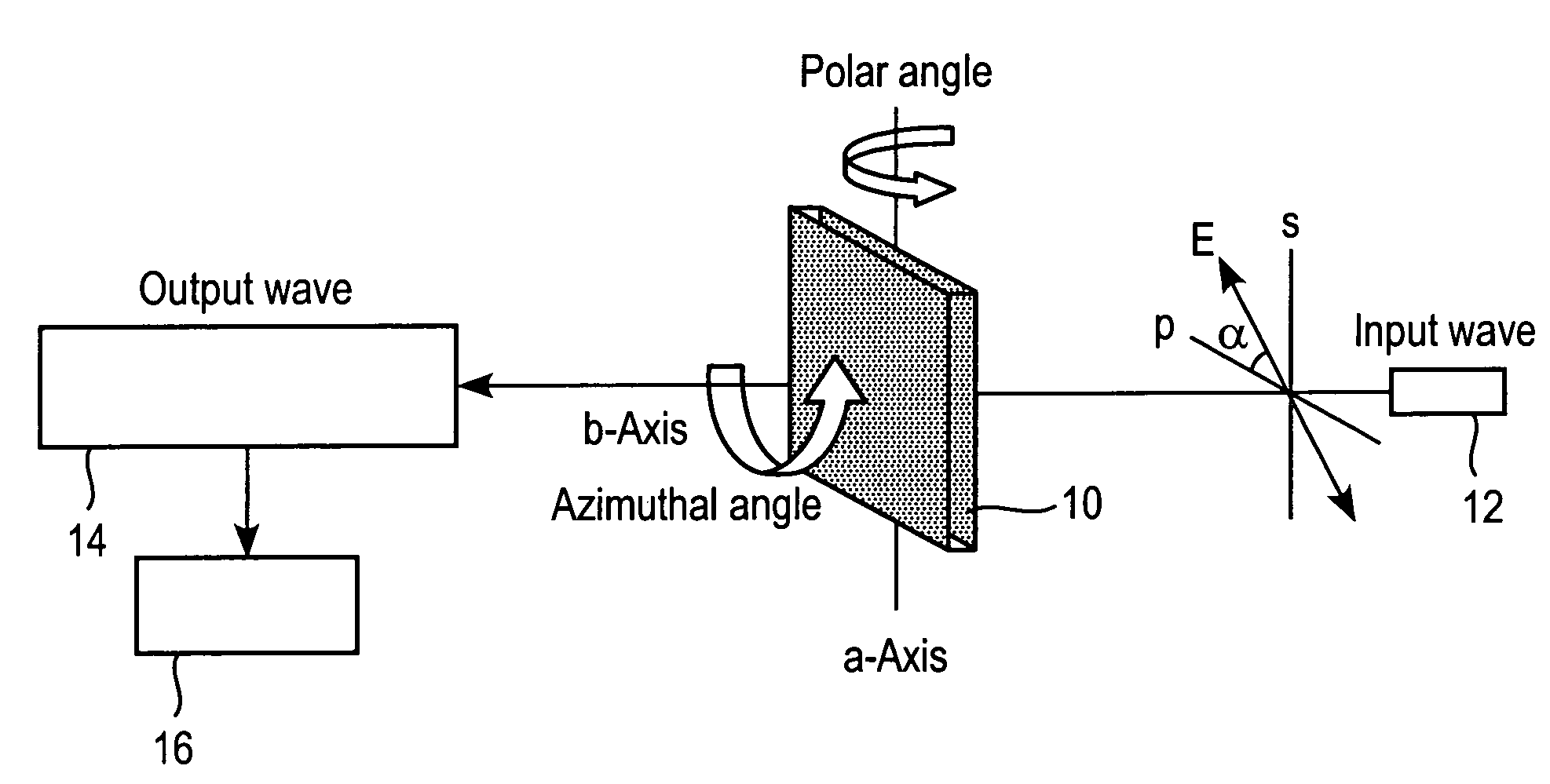

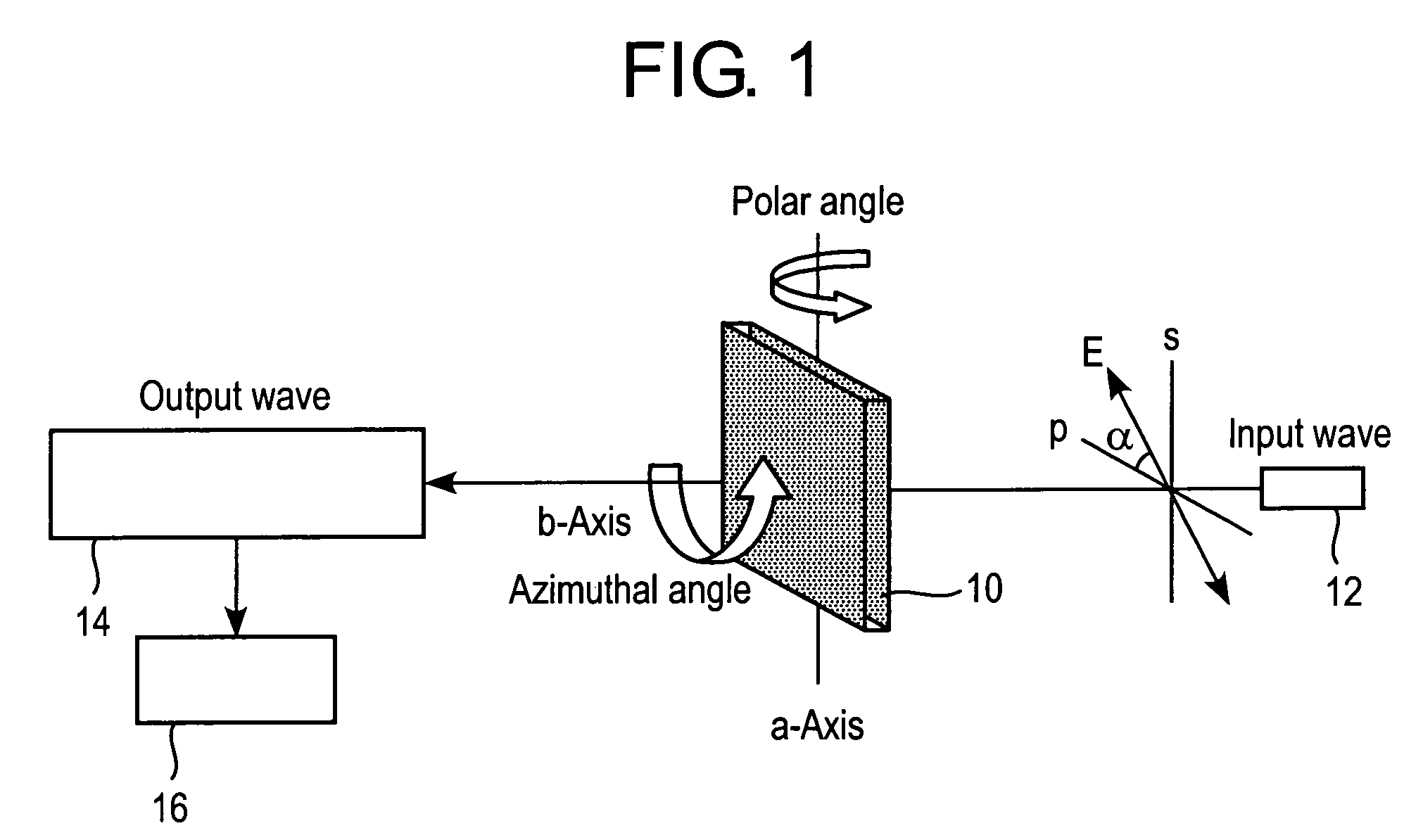

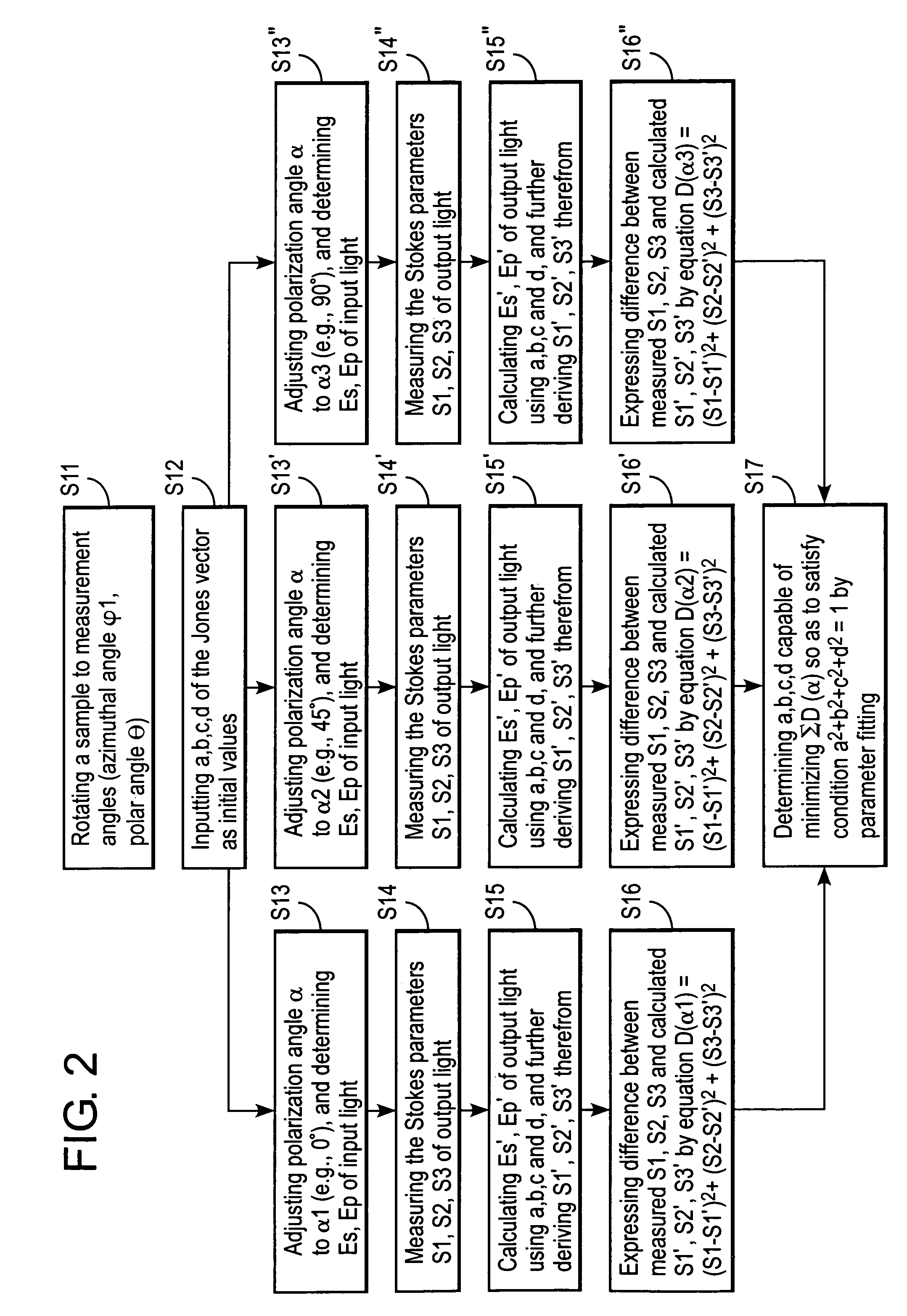

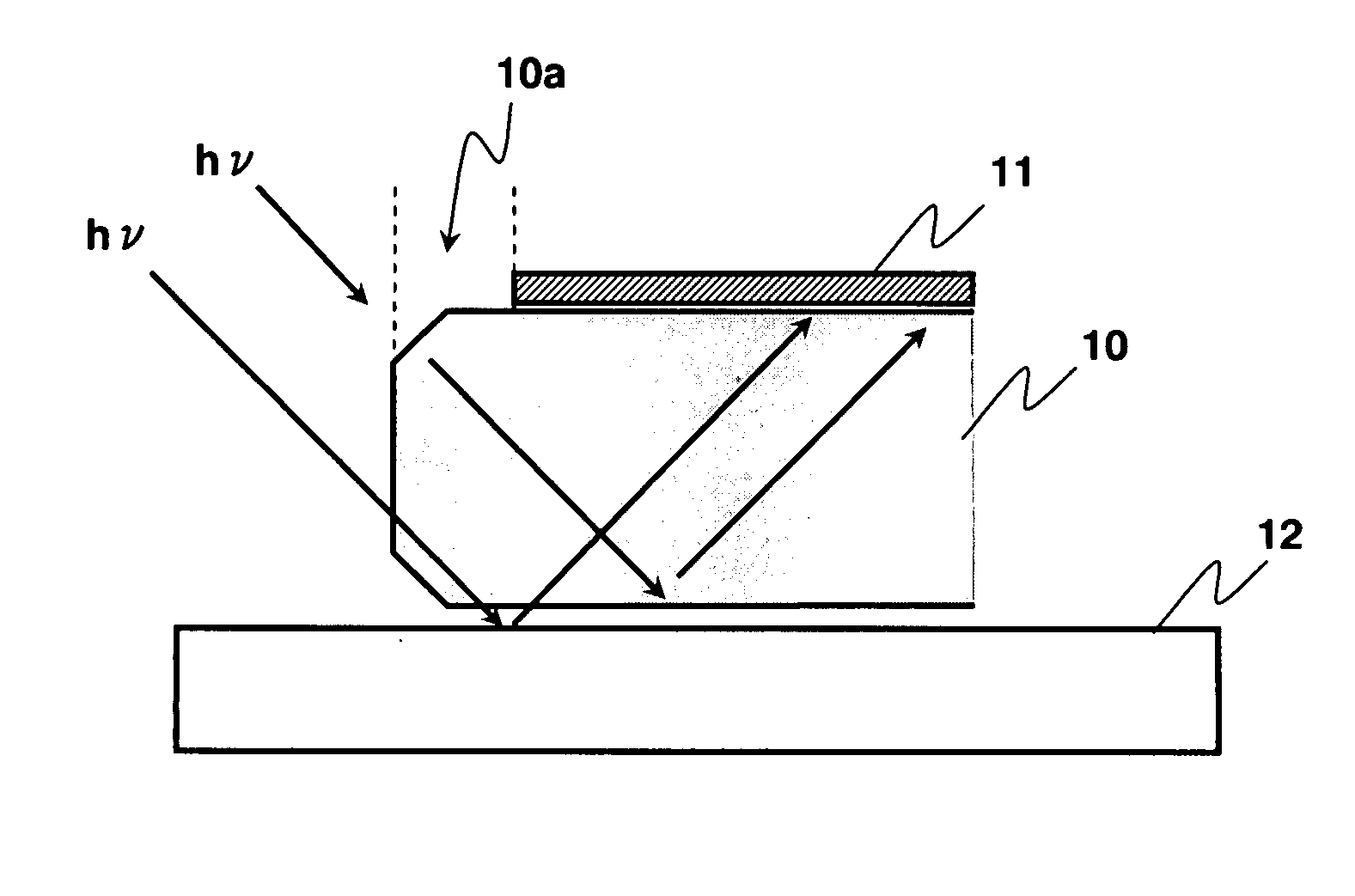

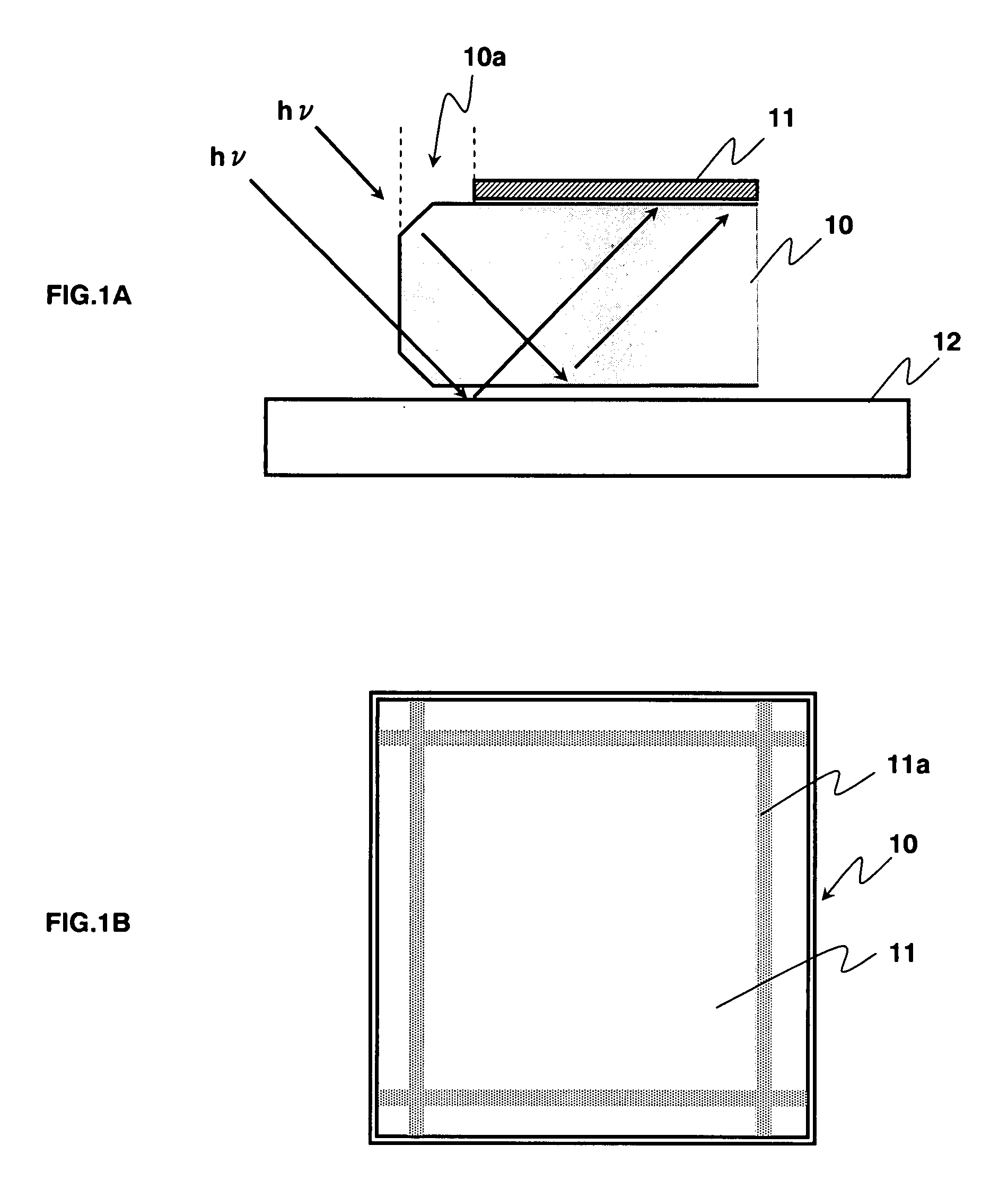

Method and apparatus for analyzing optical characteristics of optical medium and method for production monitoring

ActiveUS20060215158A1Stably producing optical mediumsUniform optical propertiesPolarisation-affecting propertiesLight polarisation measurementComing outOptical property

A novel method for analyzing optical characteristics of an optical medium is disclosed. The method comprises illuminating an optical medium, having an input surface and an output surface of light, with at least three input light beams differed from each other in a polarization state, respectively from a direction inclined by a polar angle θ (0°<θ<90°) with regard to the input surface; obtaining polarization states of output light beams coming out from the output surface, corresponded to the input light beams; and determining the Jones matrix M which can satisfy the equation (1) below with polarization vectors of the input light beams and polarization vectors of the output light beams: (Es′Ep′)=Q′×M×Q×(EsEp)(1)where, Es and Ep are polarization vectors of s-polarization and p-polarization of an input light beam, respectively; Es′ and Ep′ are polarization vectors of s-polarization and p-polarization of a correspondent output light beam, respectively; Q is a dynamics matrix expressing change in a polarization state of an input light beam going into the optical medium from the air; and Q′ is a dynamics matrix expressing change in a polarization state of an output light beam going out the optical medium into the air.

Owner:FUJIFILM CORP

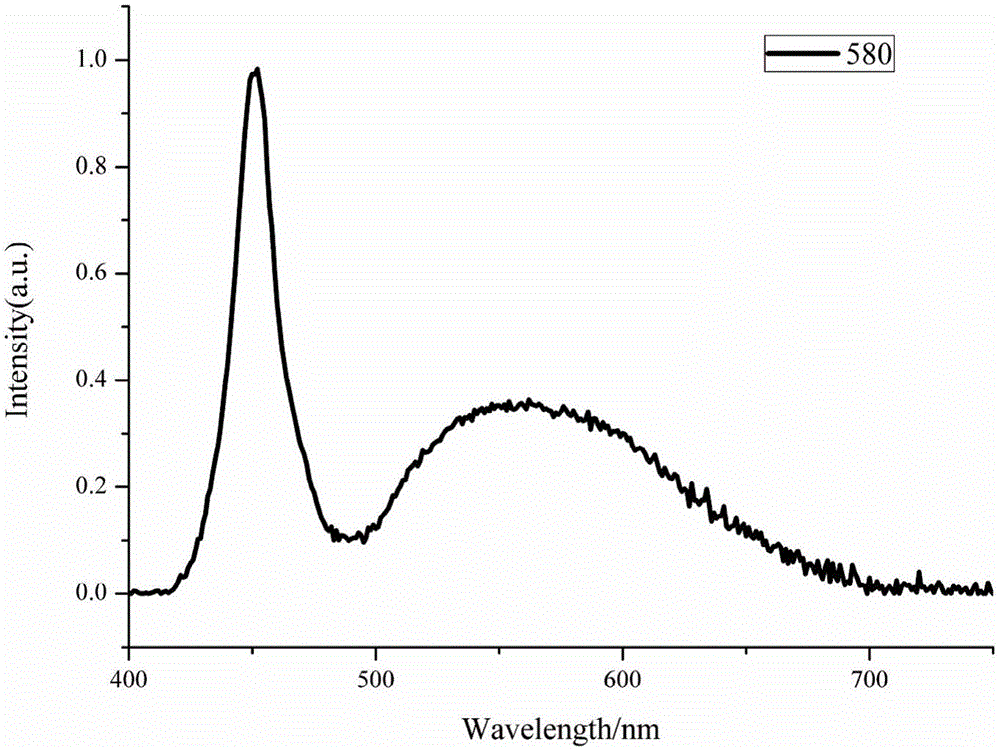

Borosilicate fluorescent glass with high heat conductivity coefficient and preparation method thereof

The invention discloses borosilicate fluorescent glass with high heat conductivity coefficient which is prepared from matrix glass powder and Ce: YAG fluorescent powder. The matrix glass powder is prepared from the following components: 0-15mol% of SiO2, 20-55mol% of B2O3, 10-50mol% of ZnO, 0-15mol% of TiO2, 5-20mol% of Na2O and 0-5mol% of Li2O; and the doping amount of the Ce: YAG fluorescent powder is 1-10wt% of the total weight of the matrix glass powder. The invention also provides a preparation method of the fluorescent glass. A fluorescent glass sheet, serving as a fluorescence conversion material of a white-light LED, has the advantages of high thermal conductivity and good thermal stability. Compared with the traditional encapsulation modes of silica gel and epoxy resin, the borosilicate fluorescent glass with the high heat conductivity coefficient is good in environment stability, does not have the problem of ageing, yellowing, color decaying, light efficiency lowering and the like and is particularly suitable for certain high-power LED illumination devices.

Owner:SHANGHAI INST OF TECH

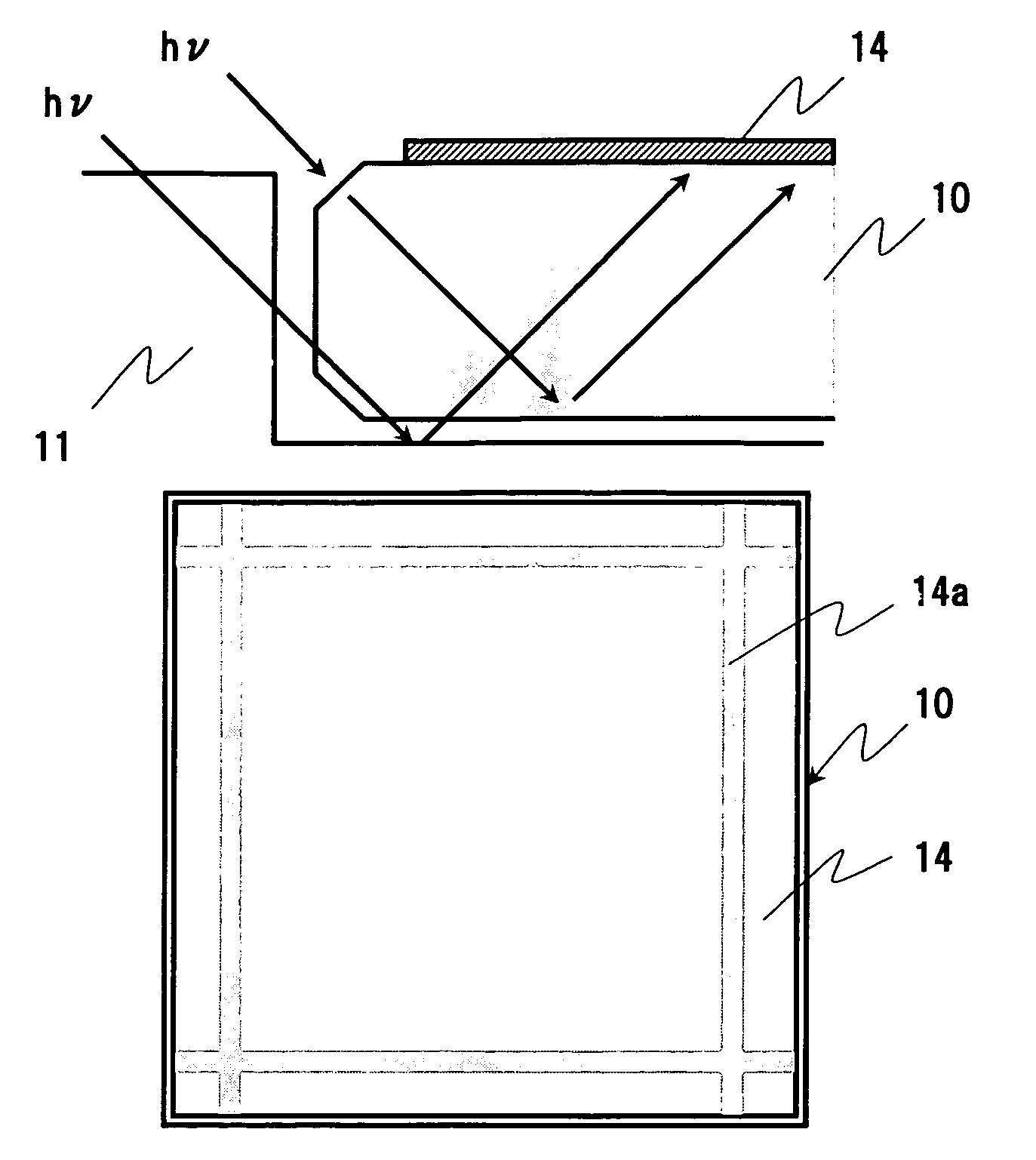

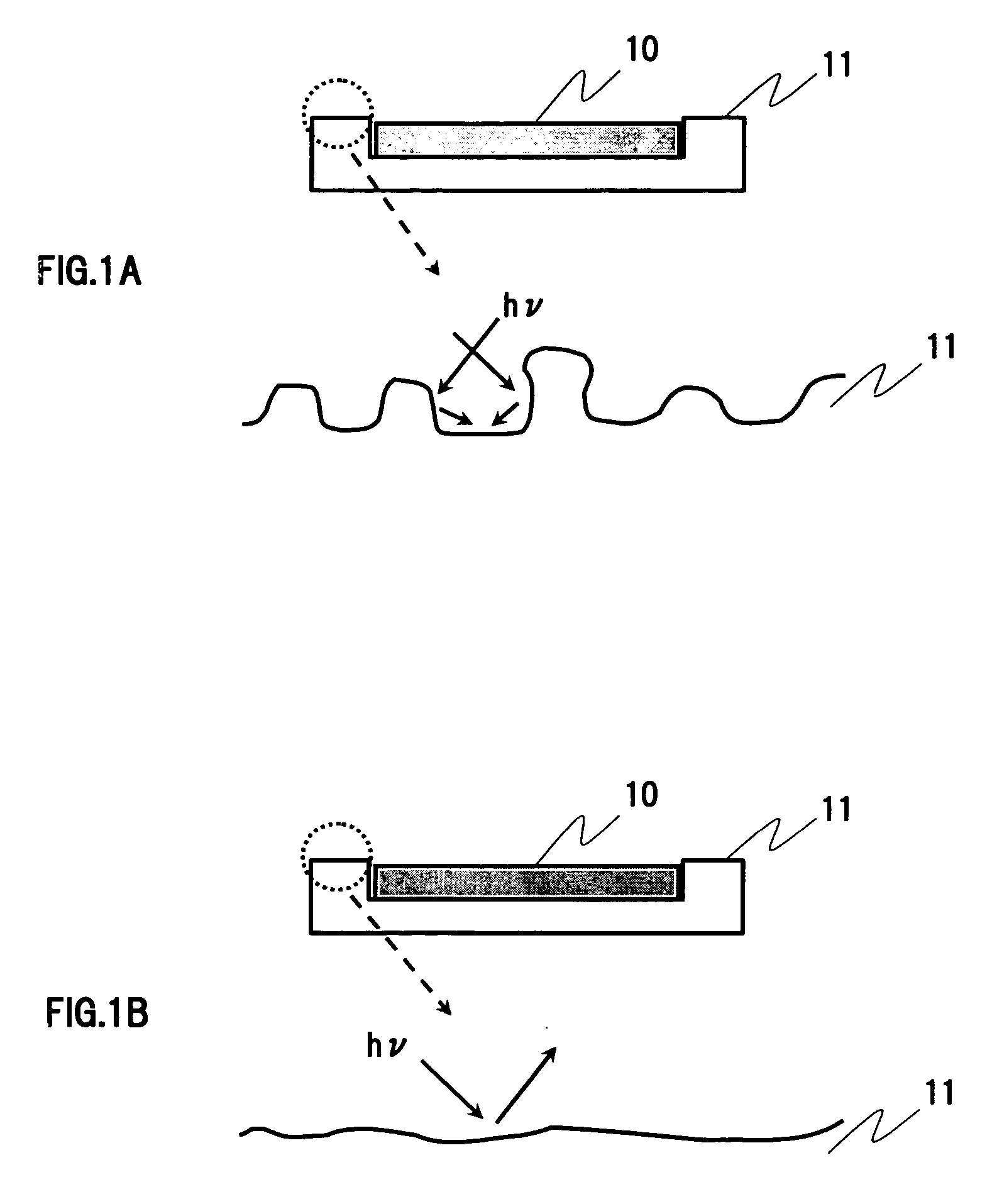

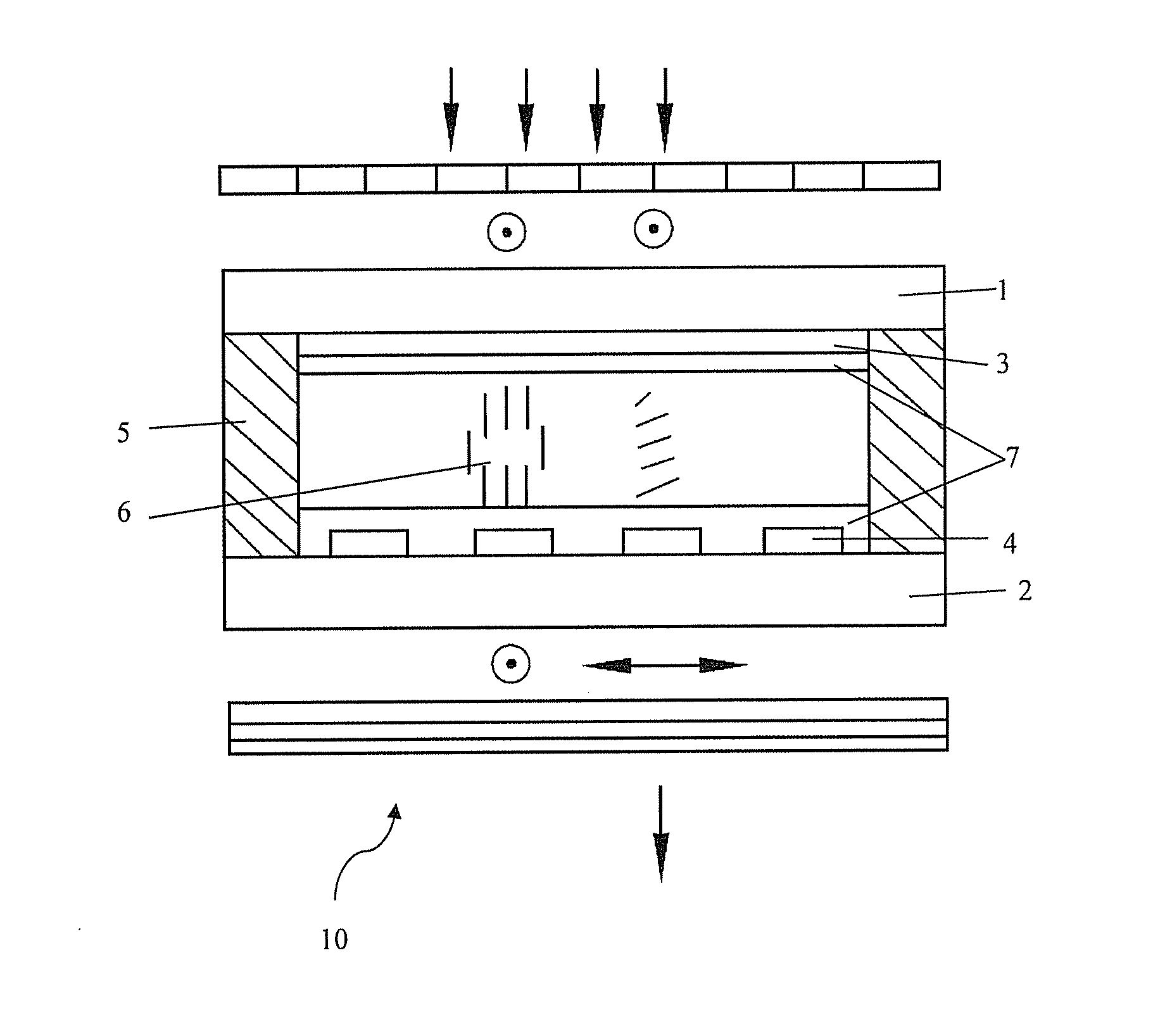

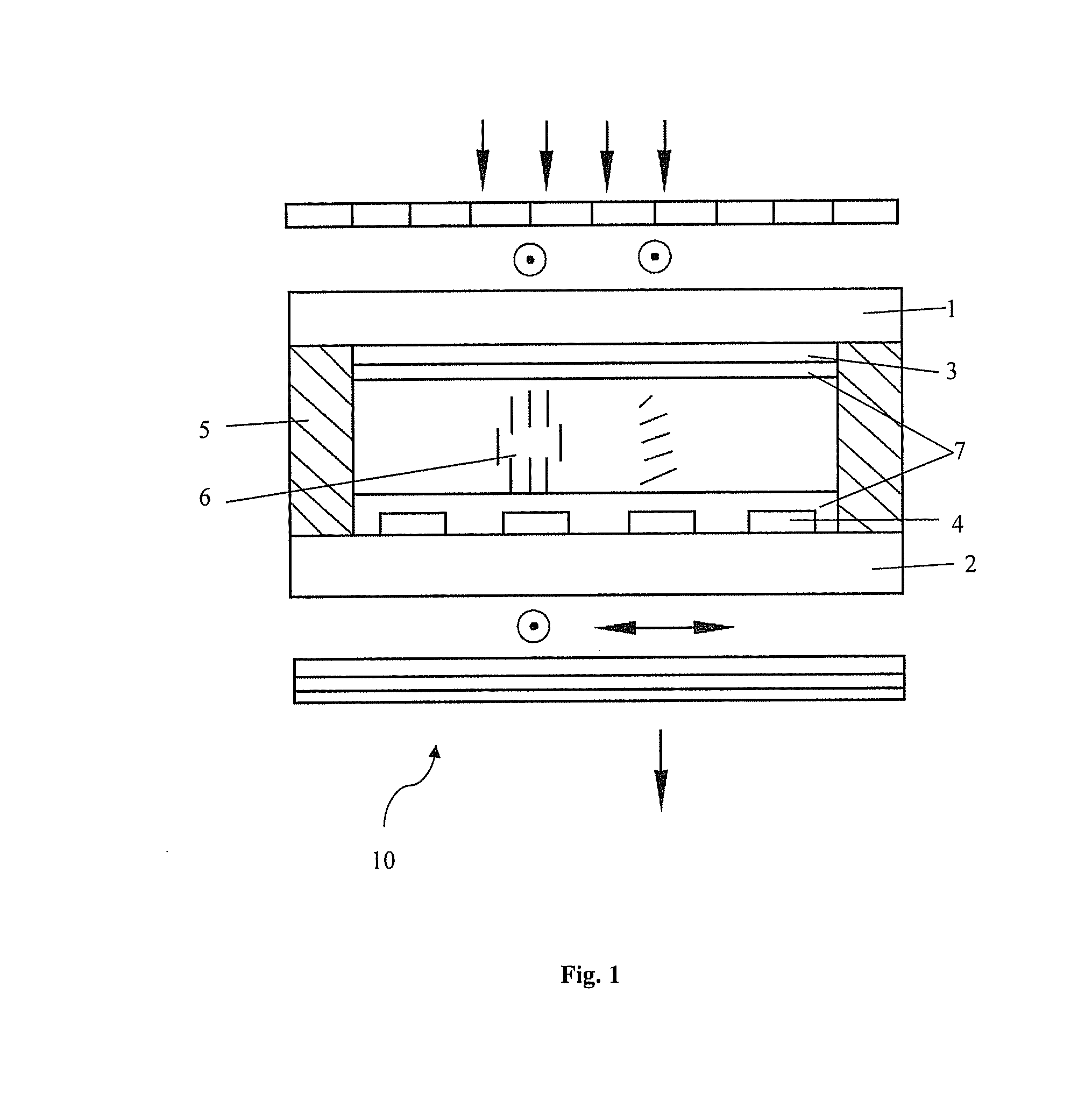

Polarized light irradiation apparatus polarized light irradiation method, photo alignment film, and retardation film

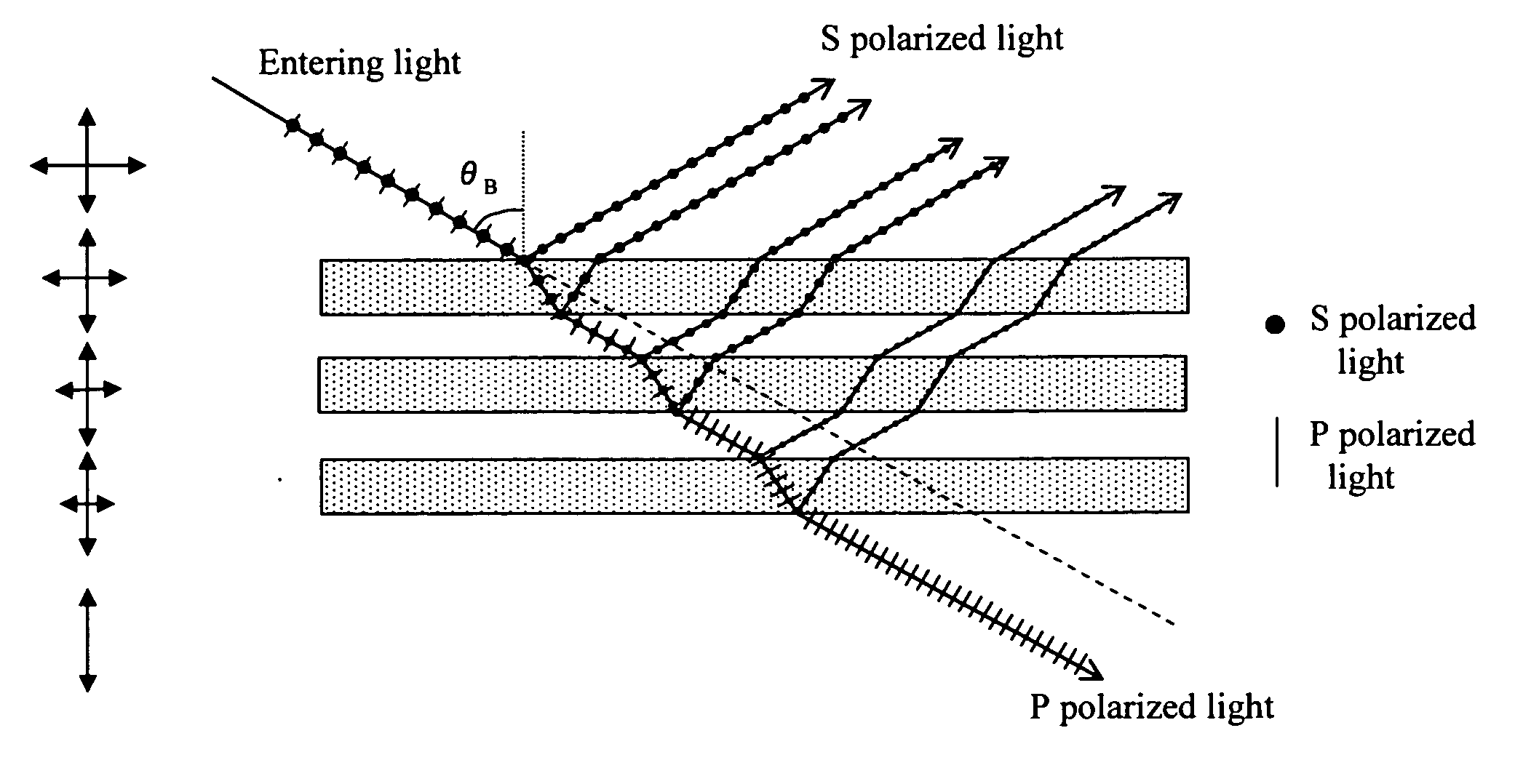

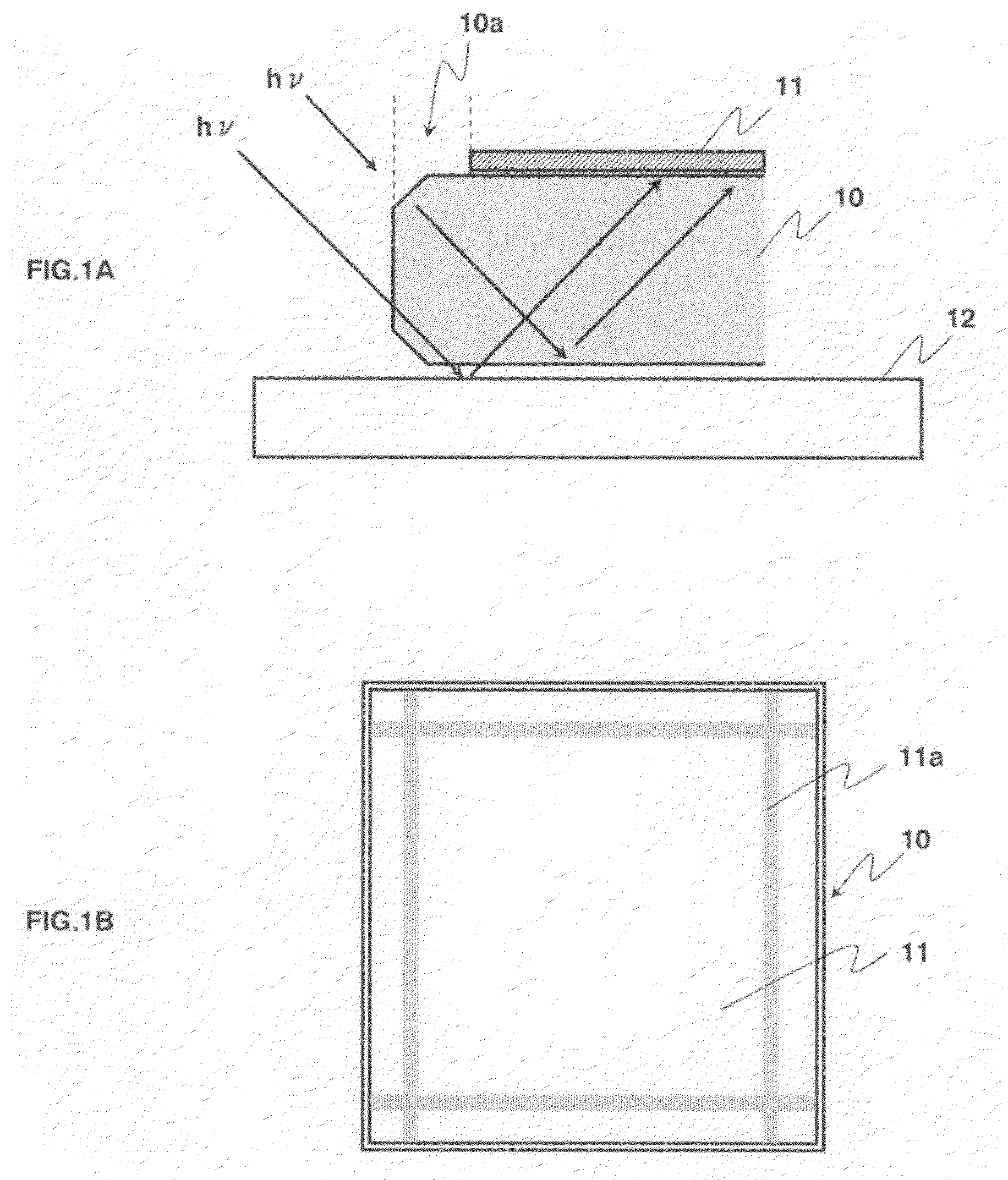

InactiveUS20060187547A1Uniform alignment abilityUniform optical propertiesPoint-like light sourcePolarising elementsLight irradiationProjection image

The main object of the invention is to provide a polarized light irradiation apparatus capable of providing a uniform alignment ability for an alignment film without using a highly parallelized light, and capable of conducting a photo-alignment in a larger area efficiently, and having an excellent durability. To this end, there is proposed a polarized light irradiation apparatus comprising: a light source; a projection device for projecting a light from the light source as a projection light including a non-parallel light; a polarizer for passing the projection light therethrough and comprising one glass plate disposed at a tilt by Brewster angle relative to an incident direction of a center part of the projection light, or comprising a plurality of glass plates disposed in parallel with each other at a predetermined interval and at a tilt by Brewster angle relative to the incident direction of the center part of the projection light; and a substrate transportation device for transporting an irradiation target substrate in a direction perpendicular to a straight line including a projection image which is obtained by projecting an incident plane of a light entering at the Brewster angle among the projection light onto the substrate.

Owner:DAI NIPPON PRINTING CO LTD

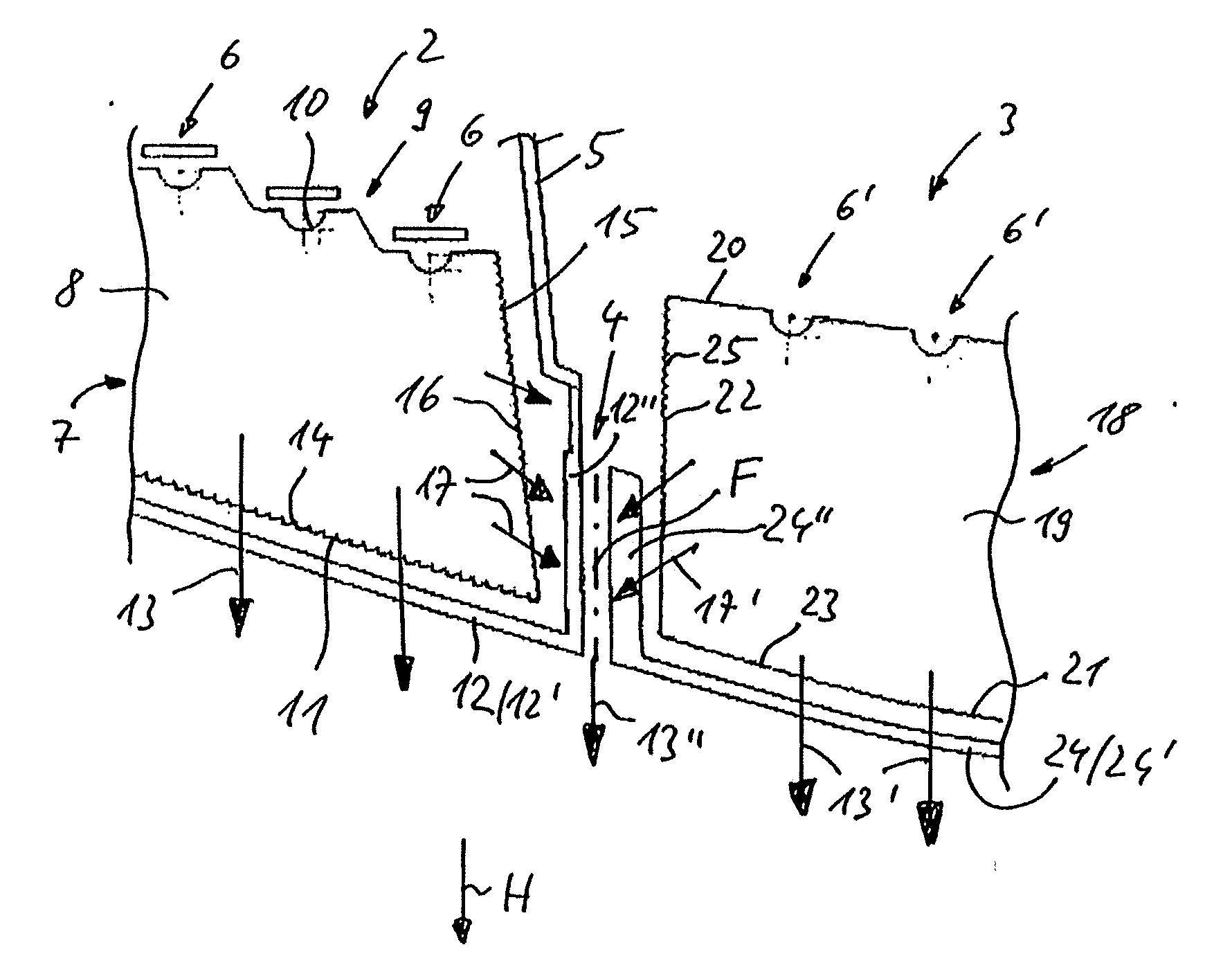

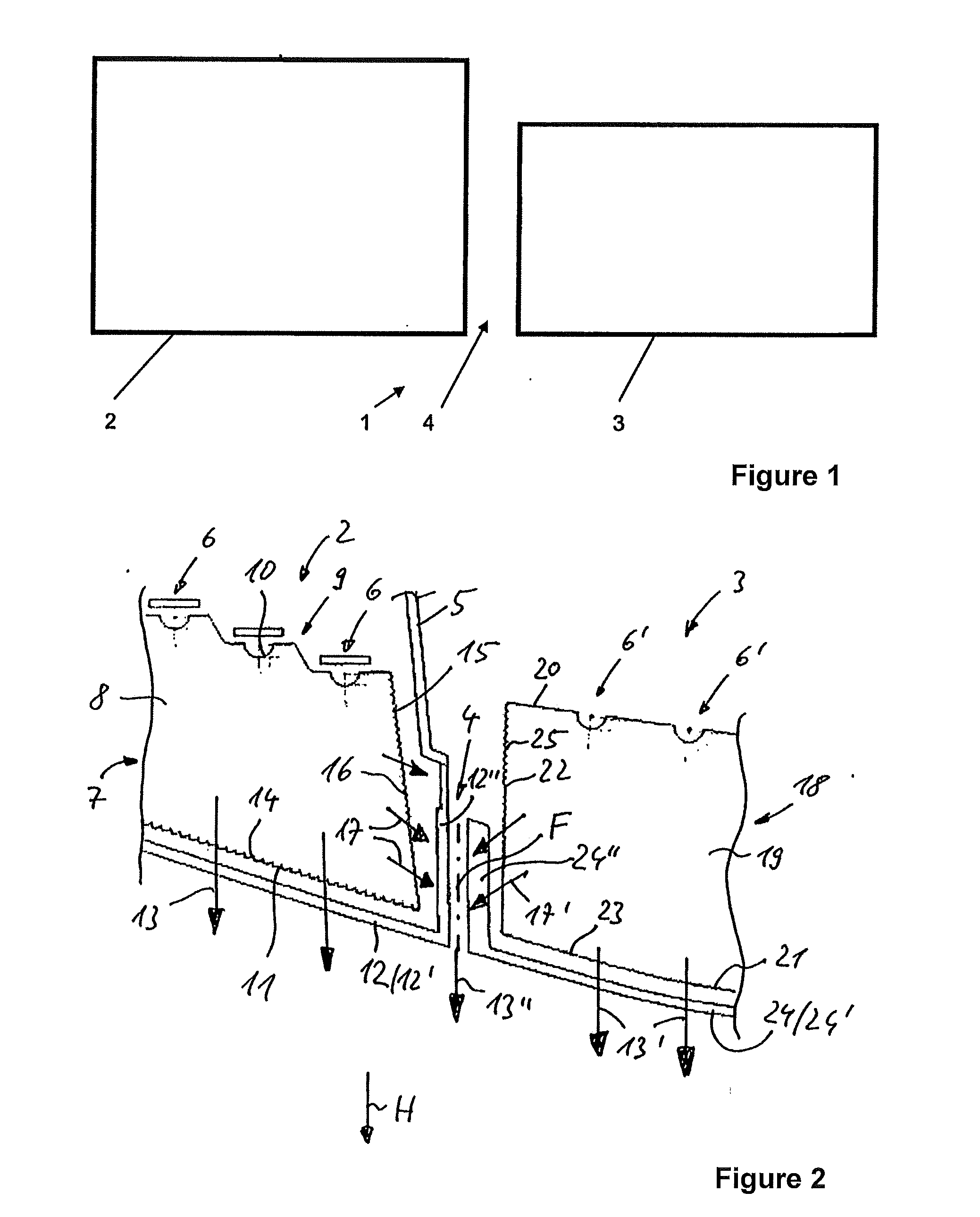

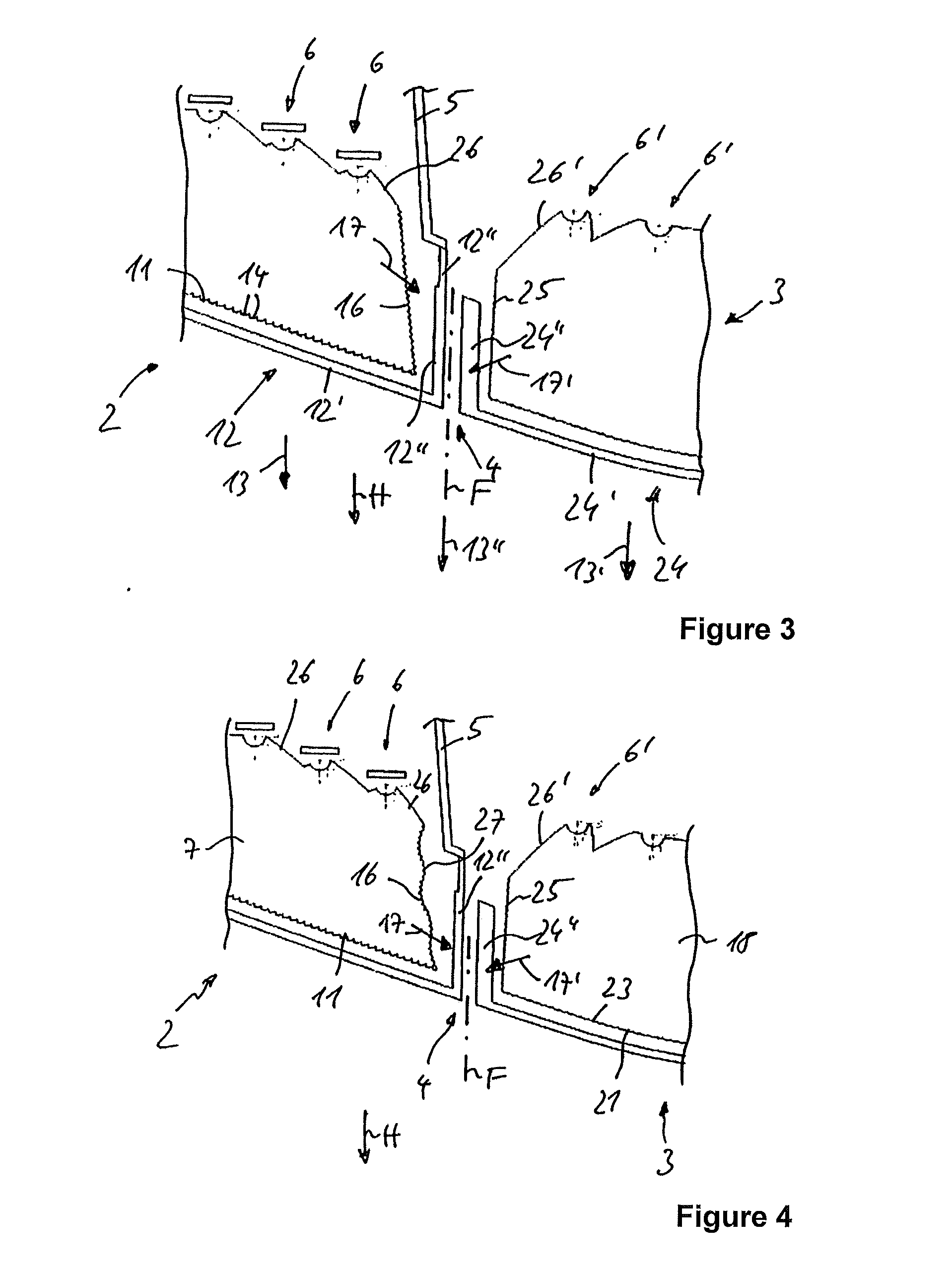

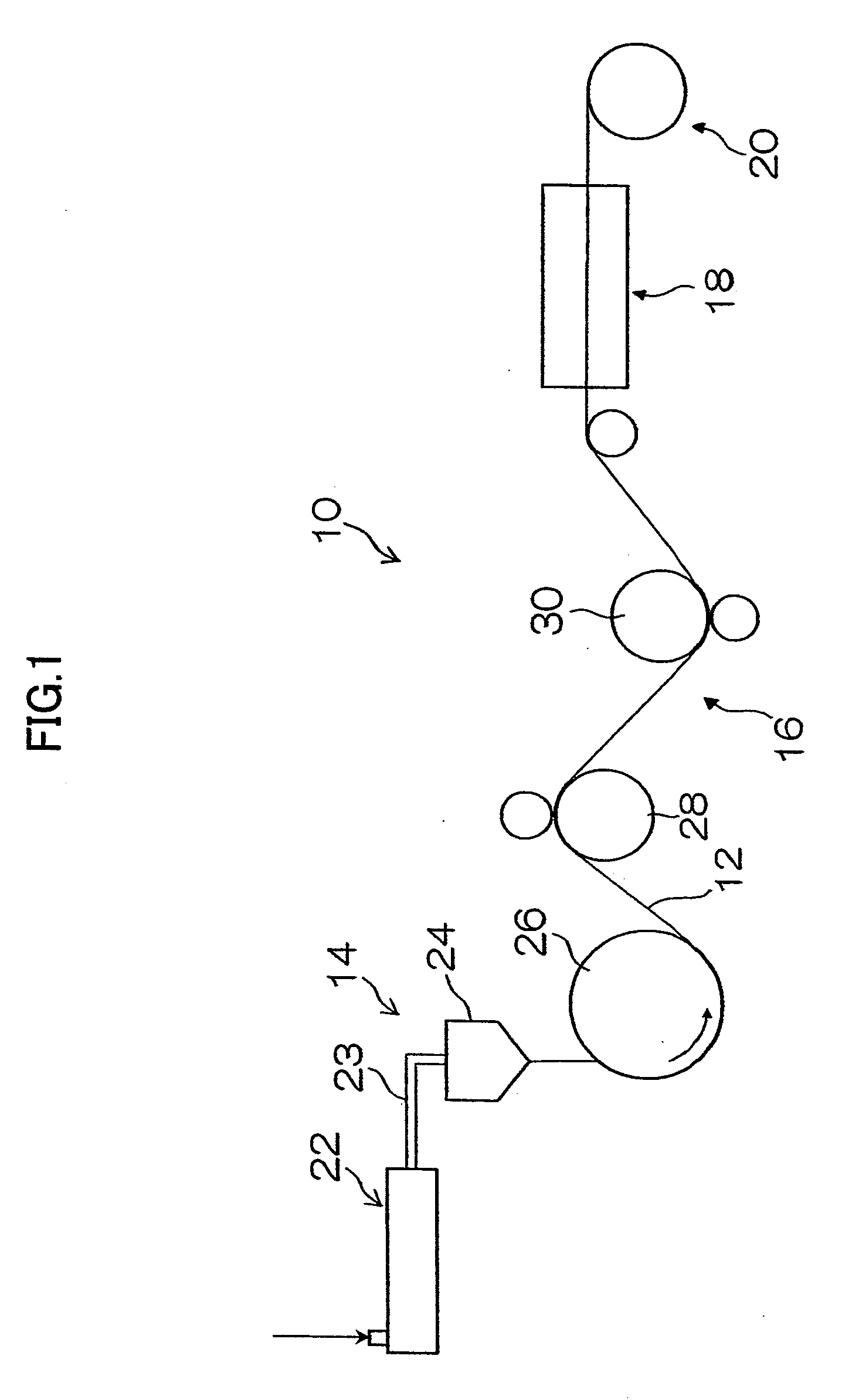

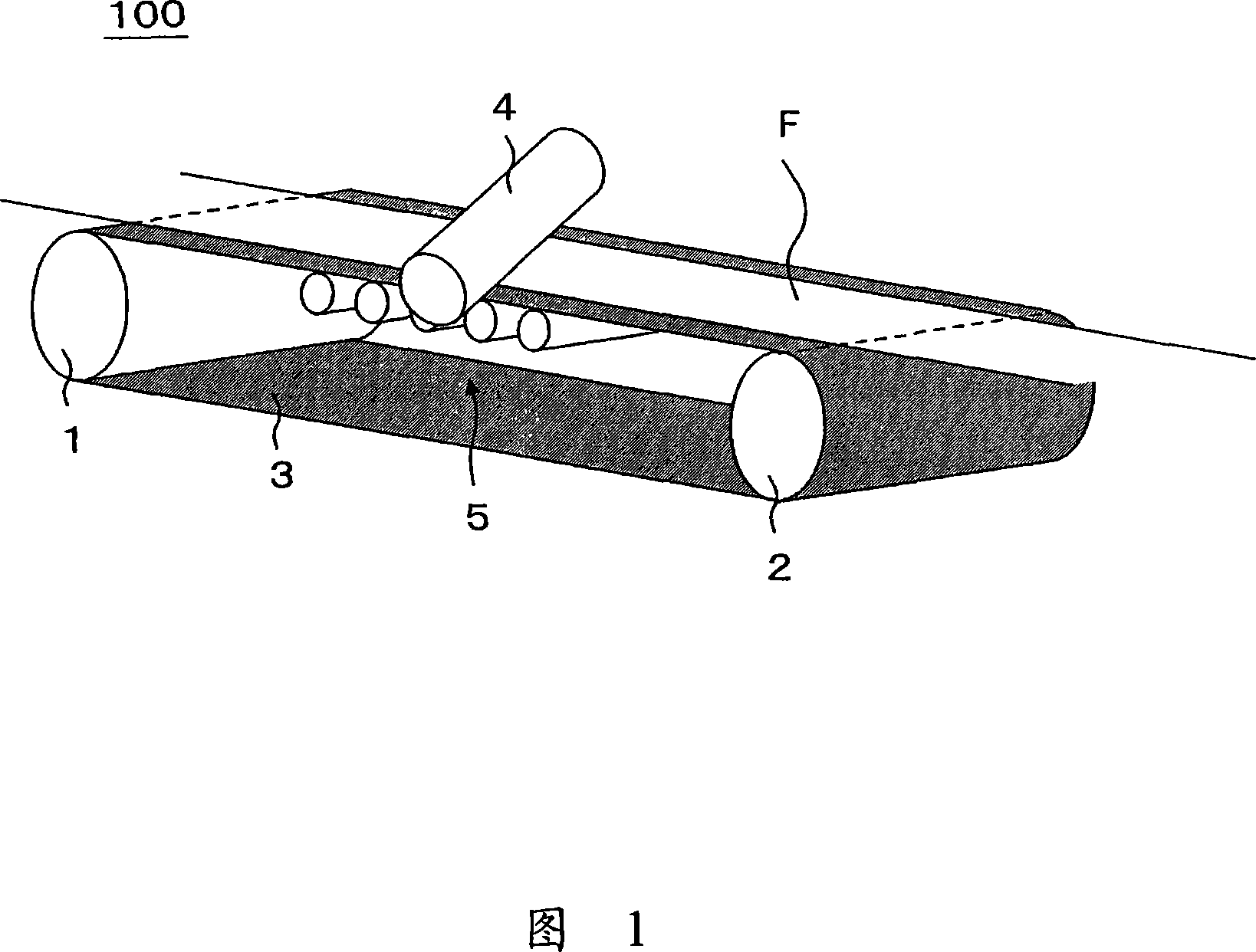

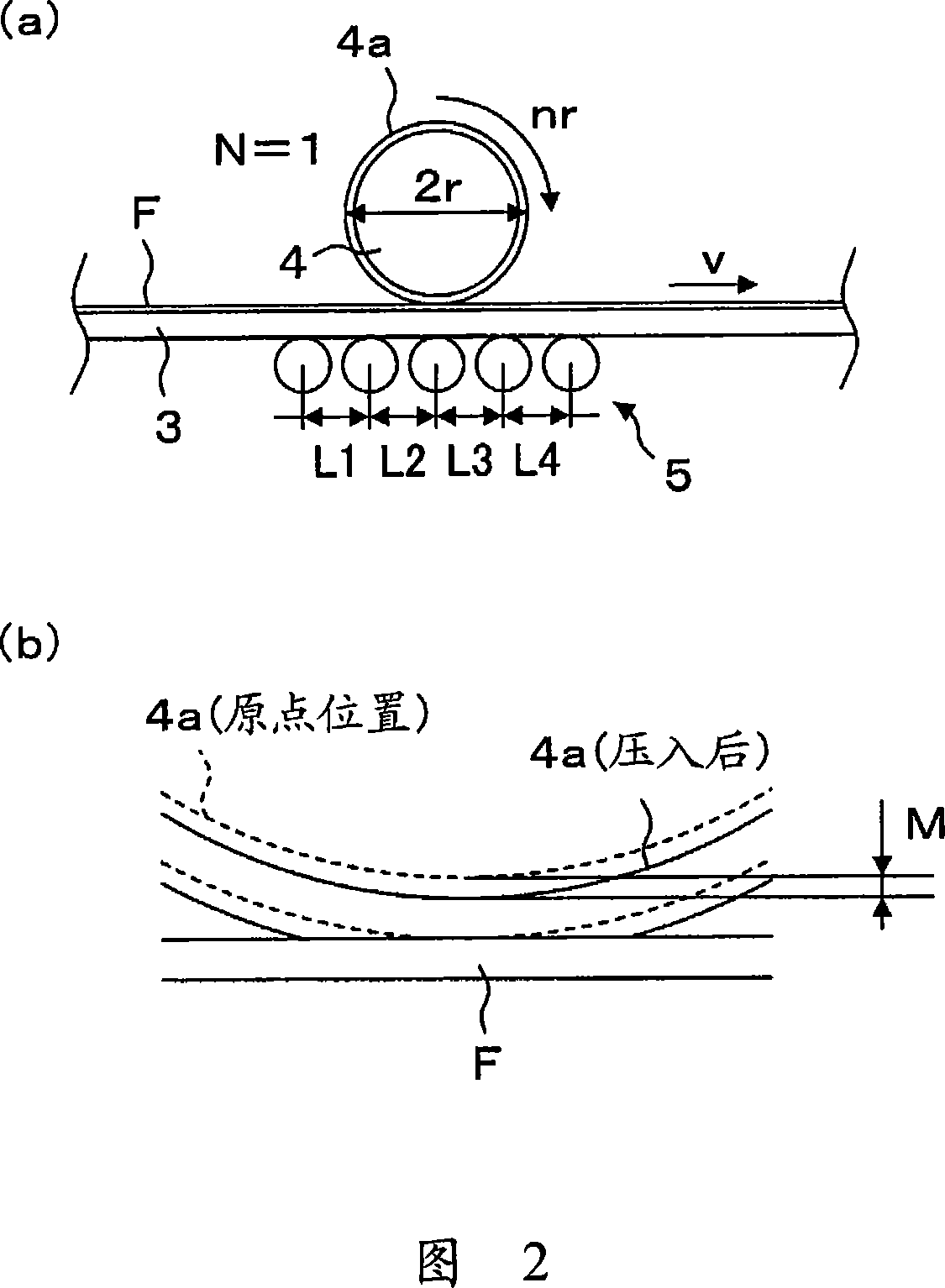

Method for producing optical film

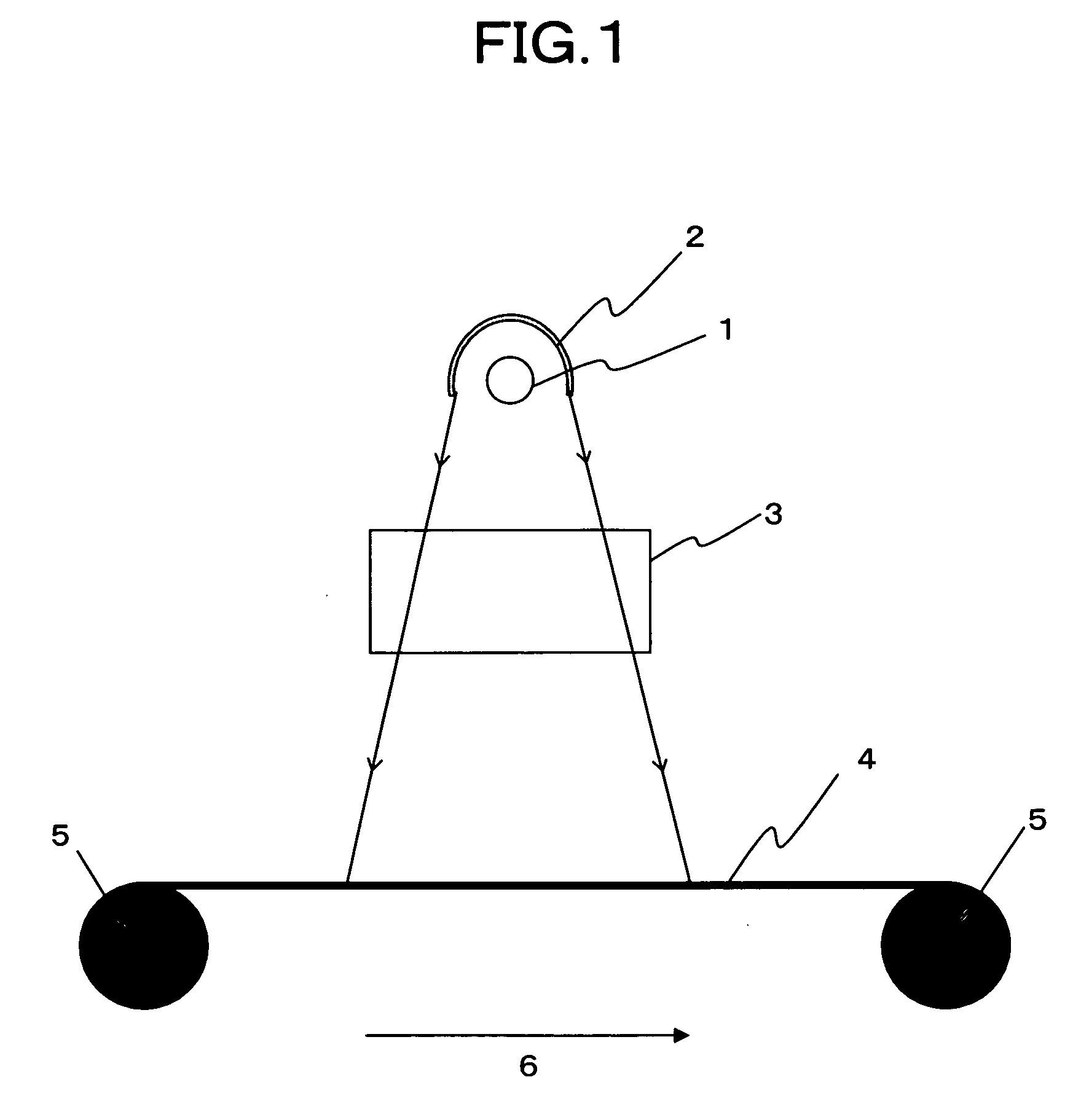

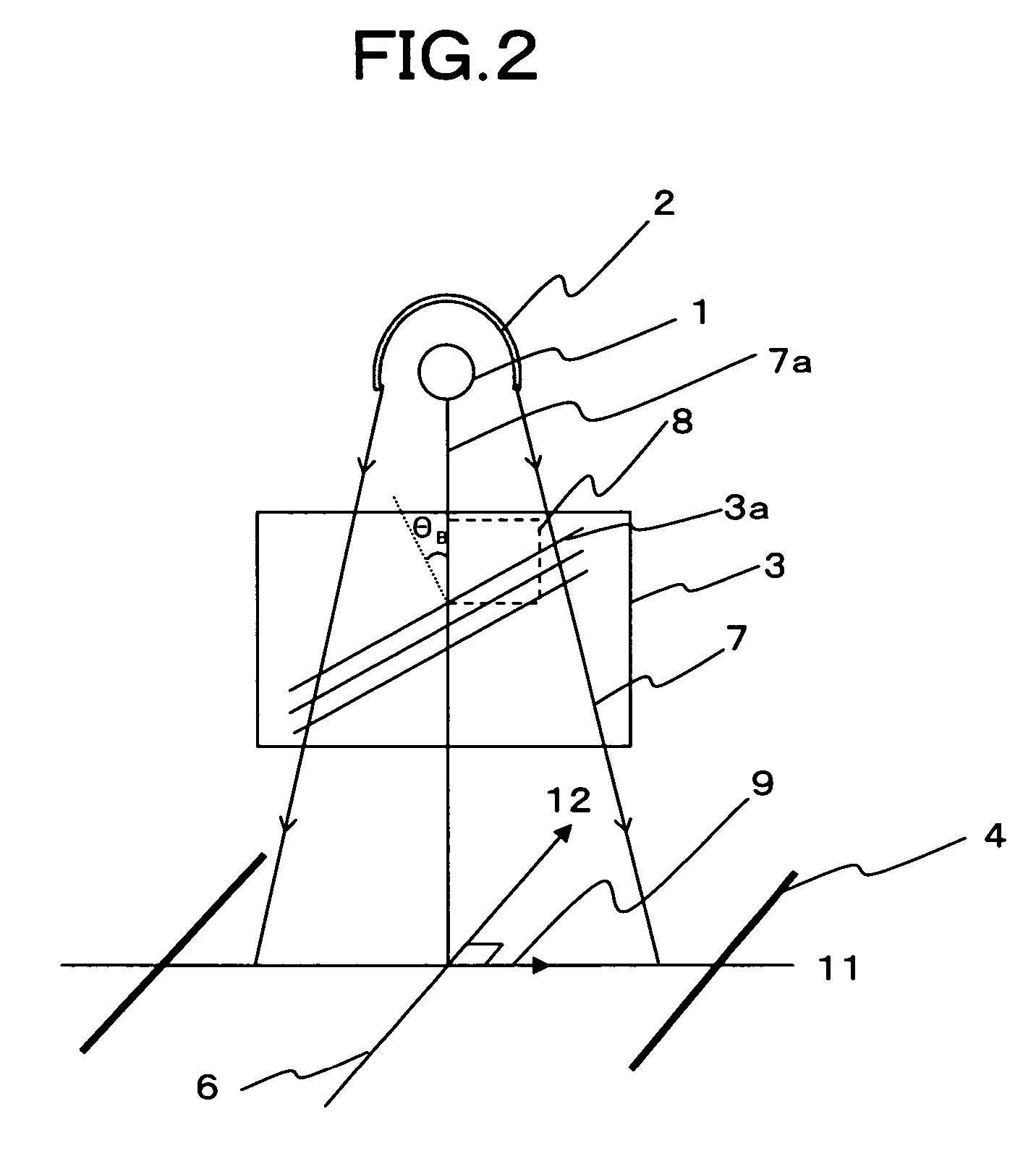

InactiveUS20090017203A1Give flexibilityUniform optical propertiesLiquid crystal compositionsPretreated surfacesLiquid crystallineEngineering

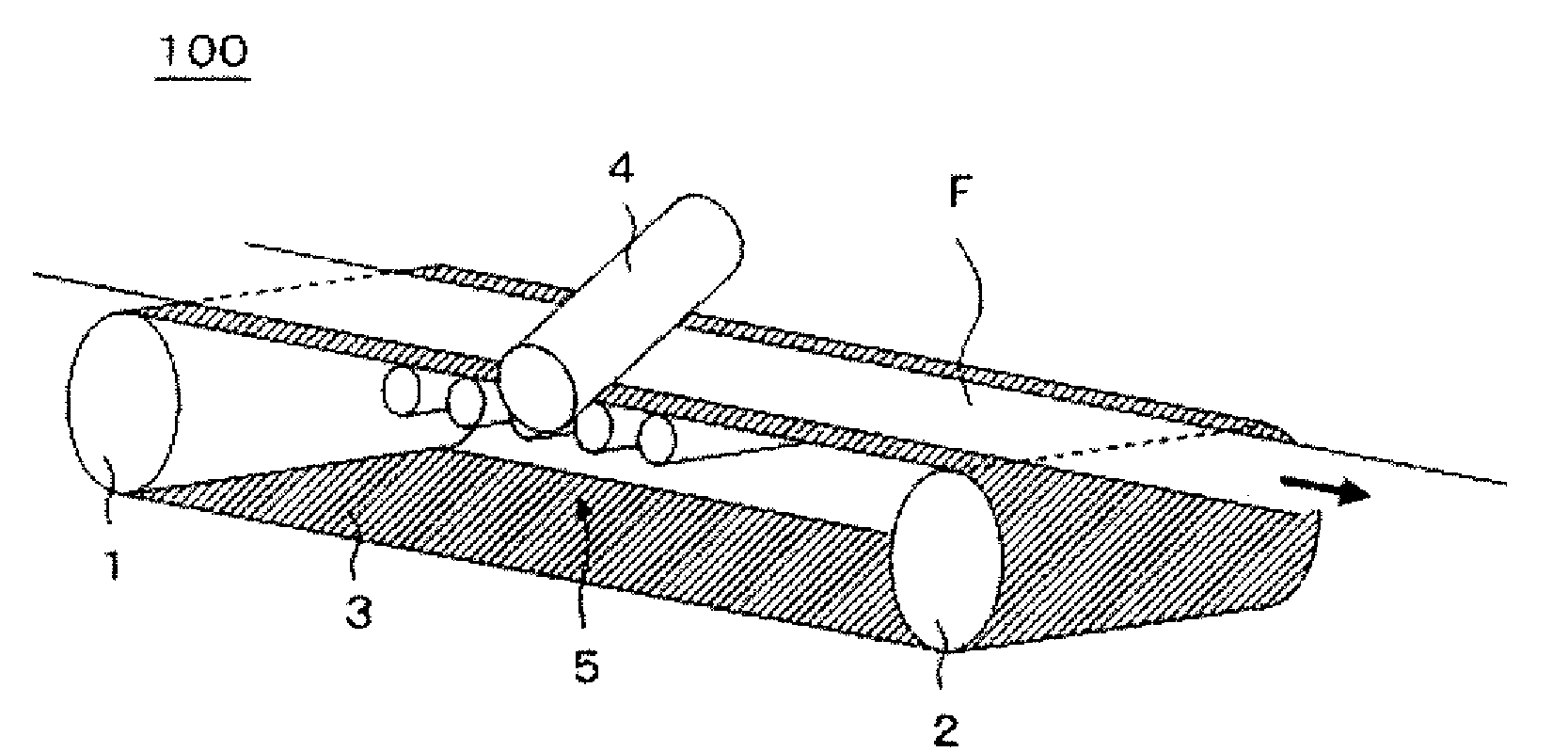

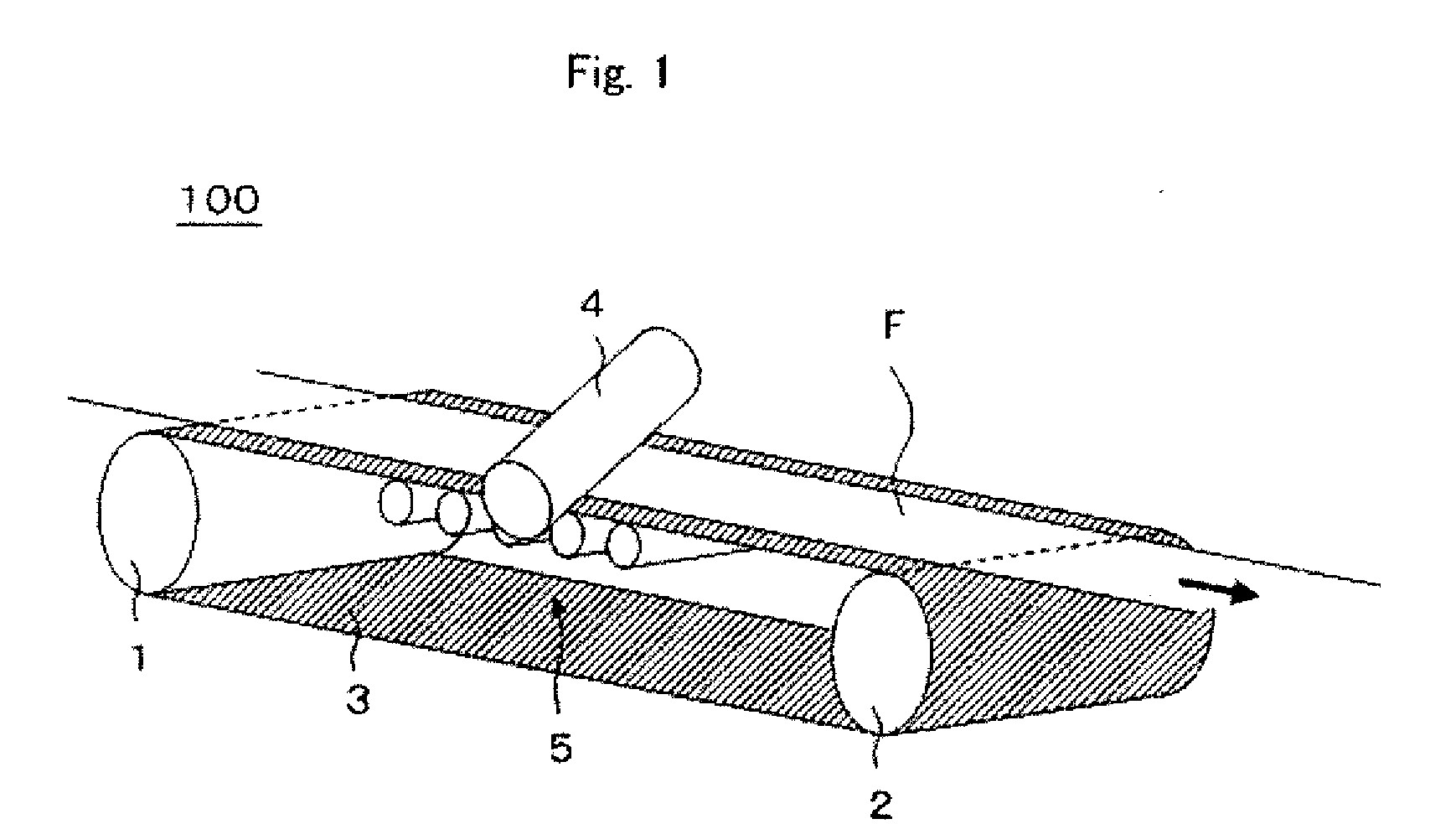

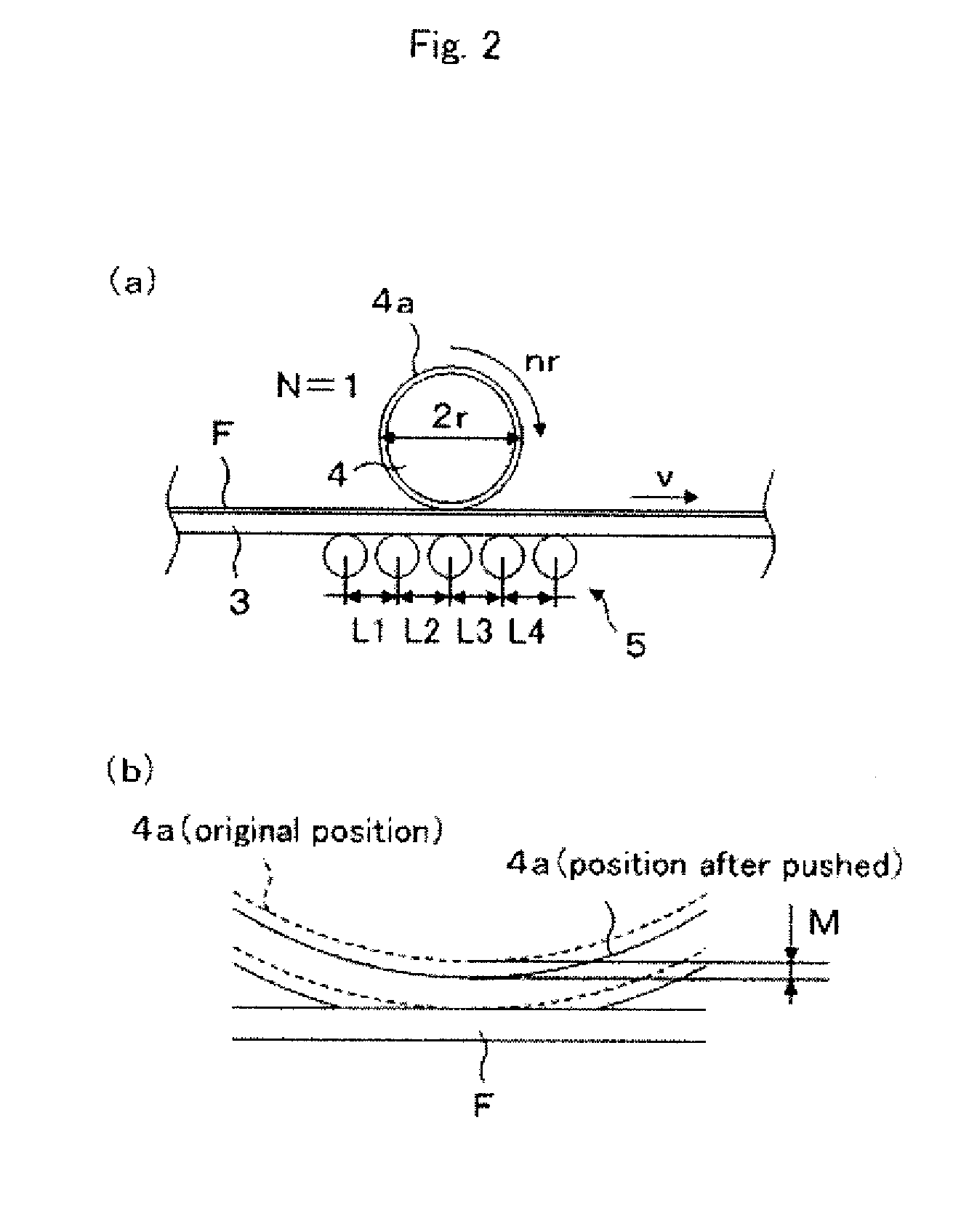

This invention provides a method for producing an optical film, the method comprising a rubbing treatment step of rubbing the surface of a lengthy plastic film F with a rubbing roll 4 obtained by winding a raised fabric 4a, an application step of applying a liquid crystalline molecule to the surface of the plastic film processed through said rubbing treatment step and a fixing step of fixing said applied liquid crystalline molecule. In the rubbing treatment step, the lengthy plastic film is supported and conveyed by a conveyer belt 3 having a metal surface, and plural backup rolls 5 which support the underside of the conveyer belt supporting the plastic film are disposed opposite to said rubbing roll, to set a rubbing strength RS defined by the following equation (1) to 2600 mm or more (more preferably 3400 mm or more).

Owner:NITTO DENKO CORP

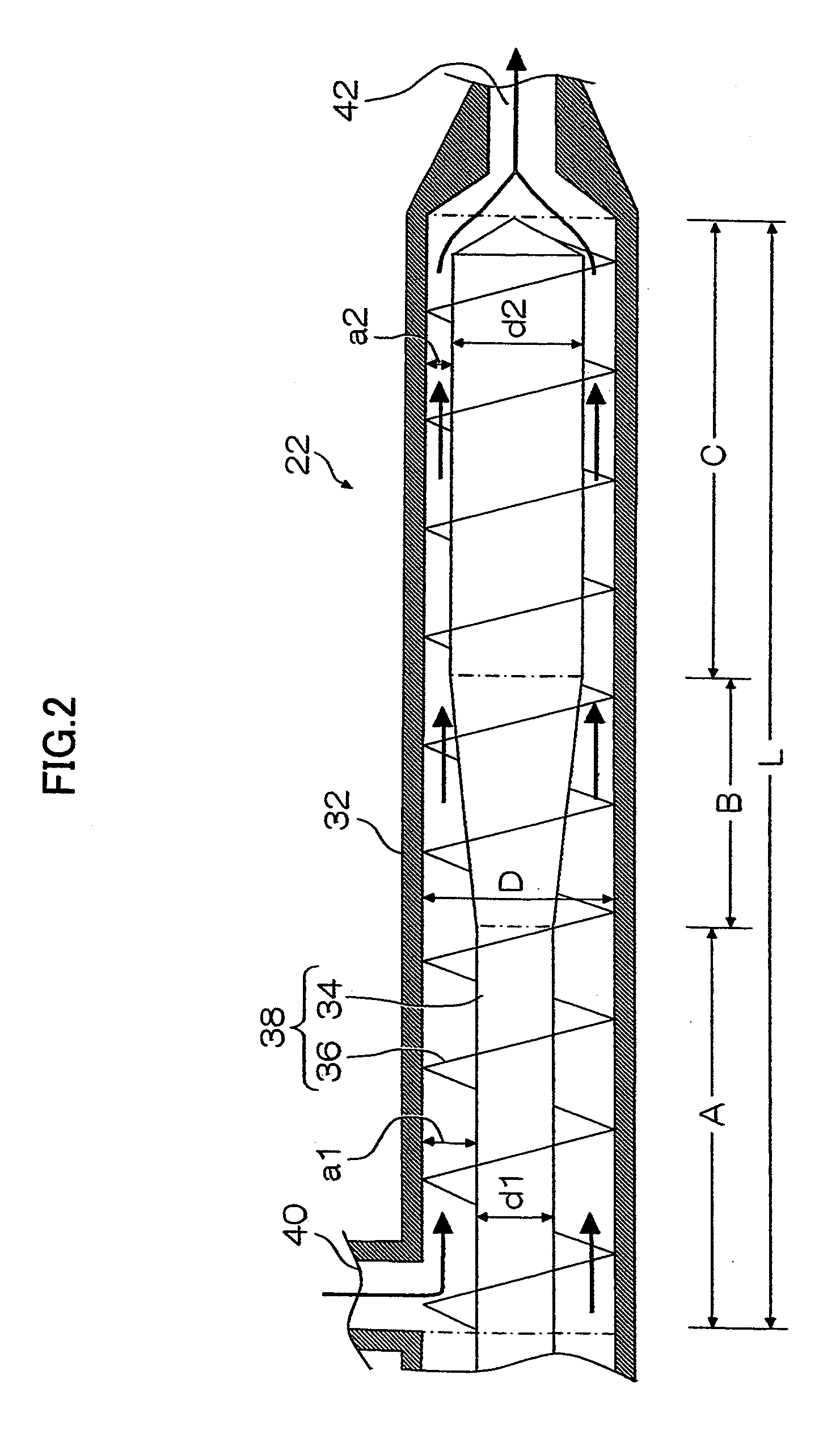

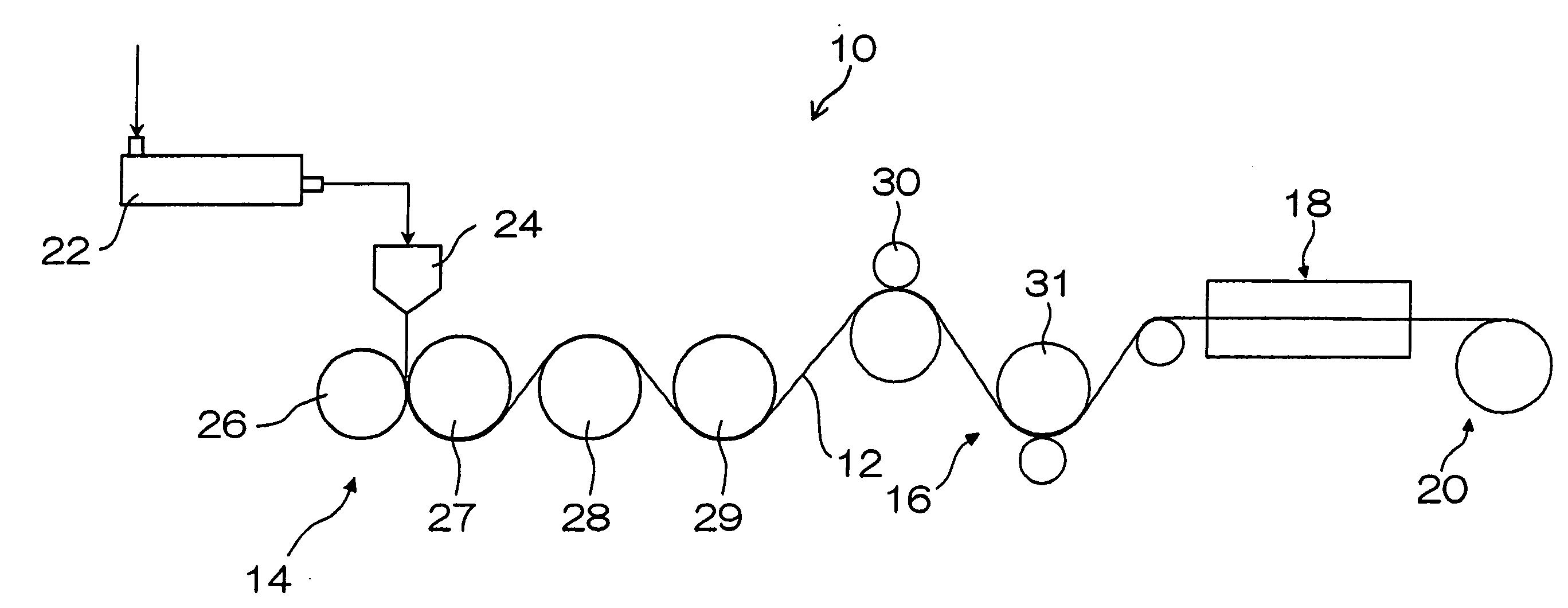

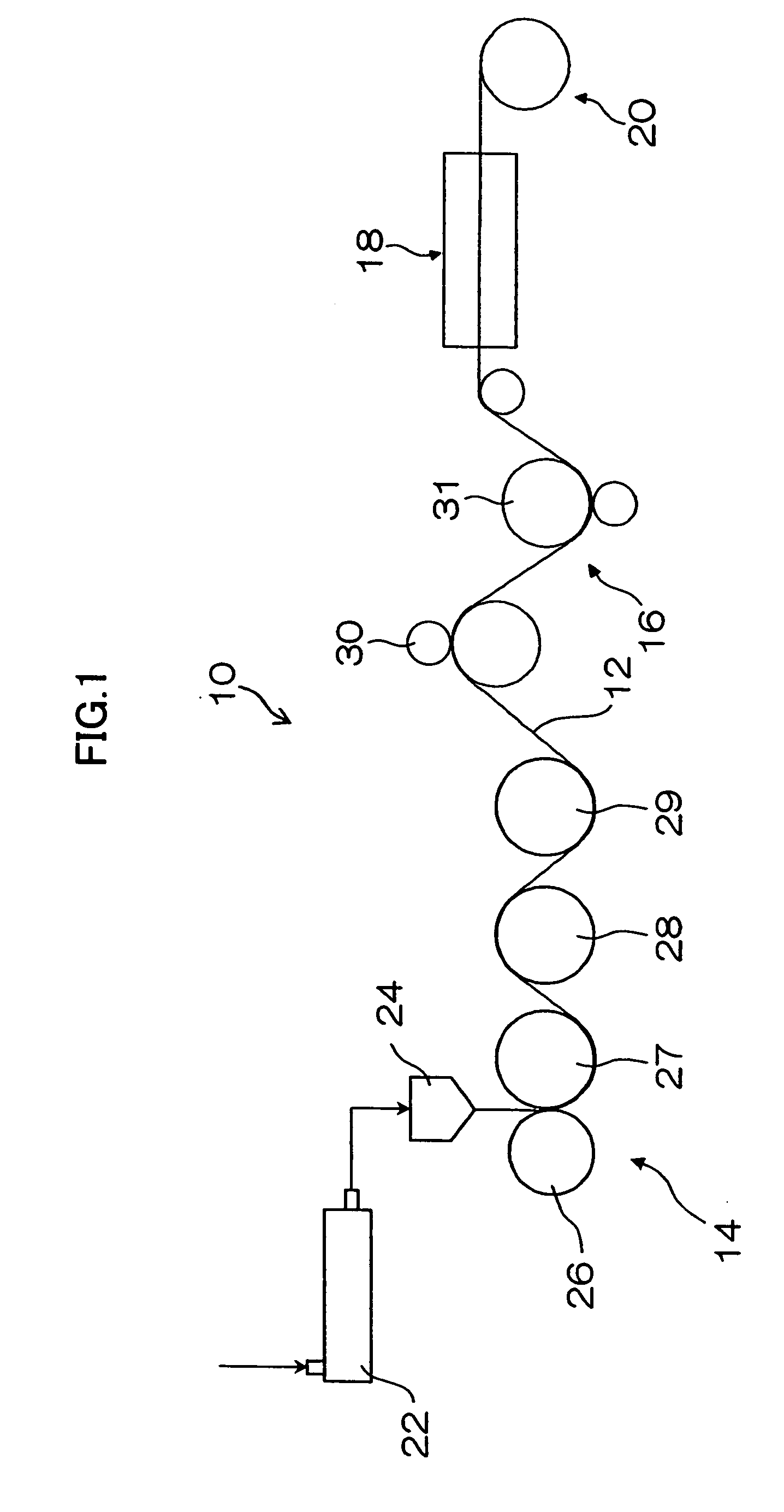

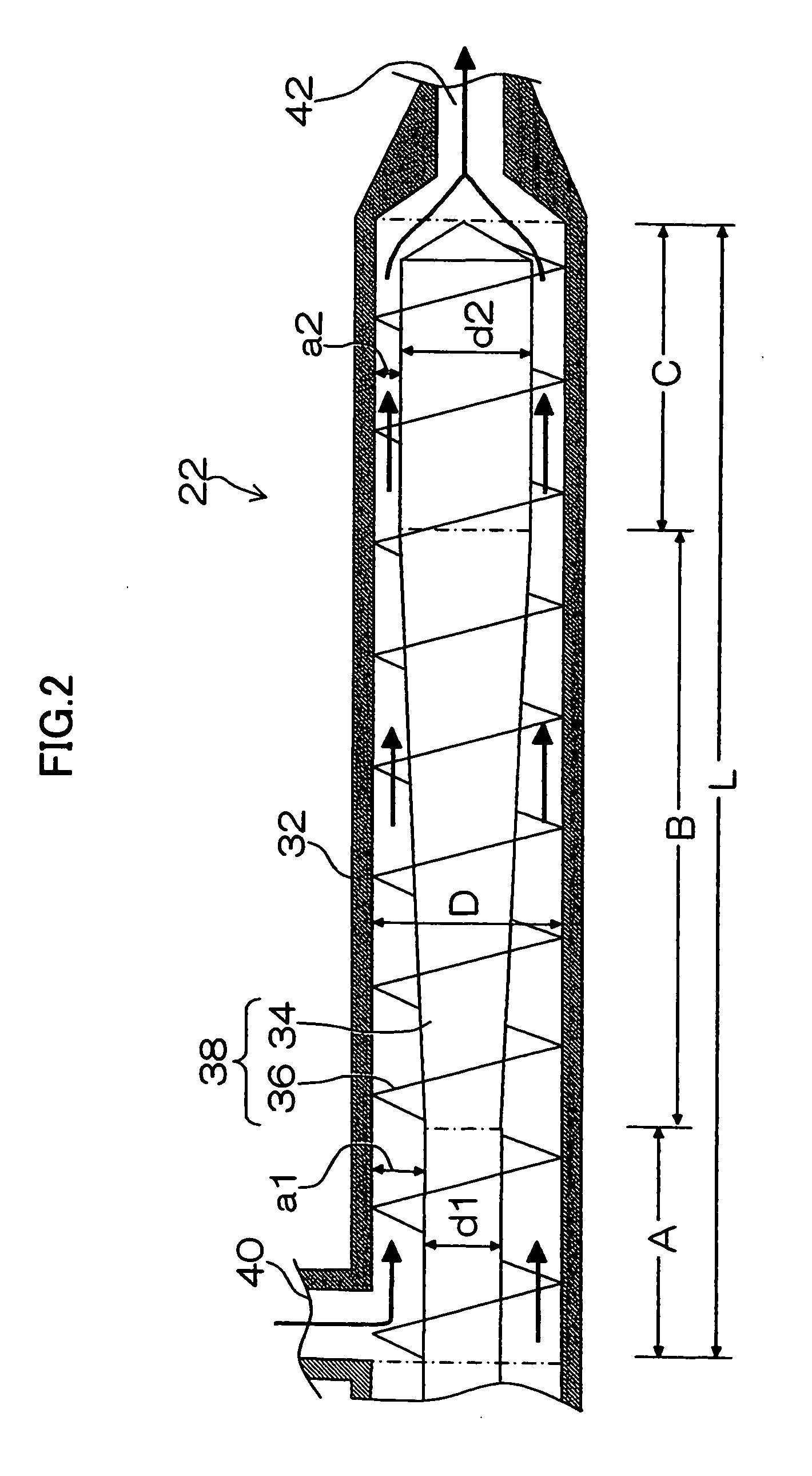

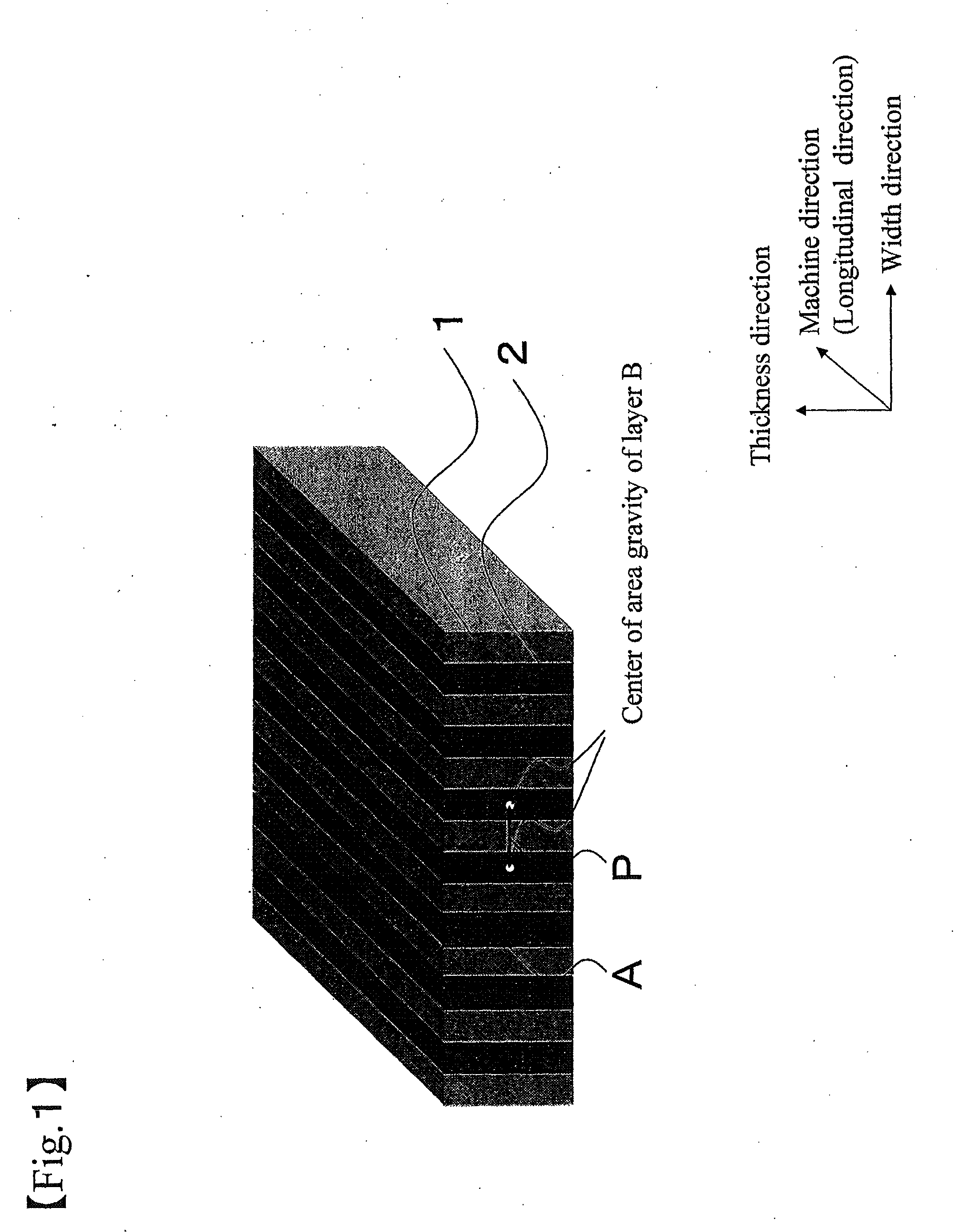

Thermoplastic resin film and method for producing the same

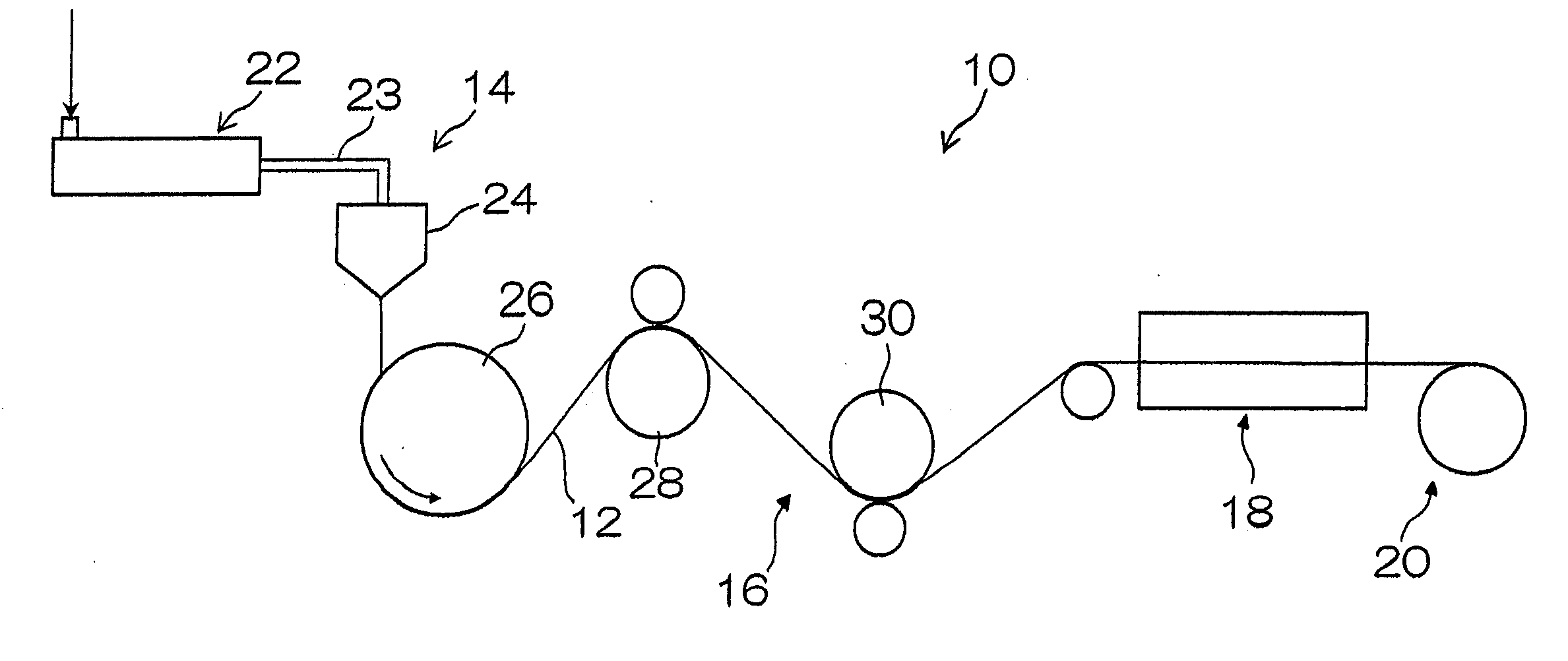

The present invention provides a thermoplastic resin film which has uniform optical properties and can be used for a high quality functional film and a method for producing the same to suppress uneven thickness in the machine direction of a film and streaks in the film. The method for producing a cellulose acylate film (12), includes the steps of melting a thermoplastic resin in a single screw extruder (22), discharging and feeding the molten resin to a die (24) through the extruder (22), extruding the molten resin from the die (24) in the form of a sheet, and solidifying the molten resin by cooling, wherein the extruder has a feed section (A), a compression section (B) and a metering section (C) and transport efficiency ηF of the thermoplastic resin in the feed section (A) is 0.2 to 0.7.

Owner:FUJIFILM CORP

Laminated phase resistant film and liquid crystal display device using said film

InactiveCN1458538AImprove flatnessUniform optical propertiesSynthetic resin layered productsPolarising elementsIn planeOptical property

The objective of the present invention is to provide a laminated phase retarder film that is superior in evenness, exhibits a biaxial optical property as a whole, and makes it possible to set the biaxial optical property over a wide range and a LCD used same. This object is achieved by a laminated phase retarder film comprising a transparent resin film as a substrate and at least one coat layer having a refractive-index anisotropy laminated on at least one surface of the substrate, wherein a in-plane retardation value (R0) is not less than 20 nm, a retardation value (R') in the film-thickness direction, which is calculated from a retardation value (R40) measured by inclining by 40 degrees around the slow axis of the film and the in-plane retardation value (R0), is greater than 40 nm.

Owner:SUMITOMO CHEM CO LTD

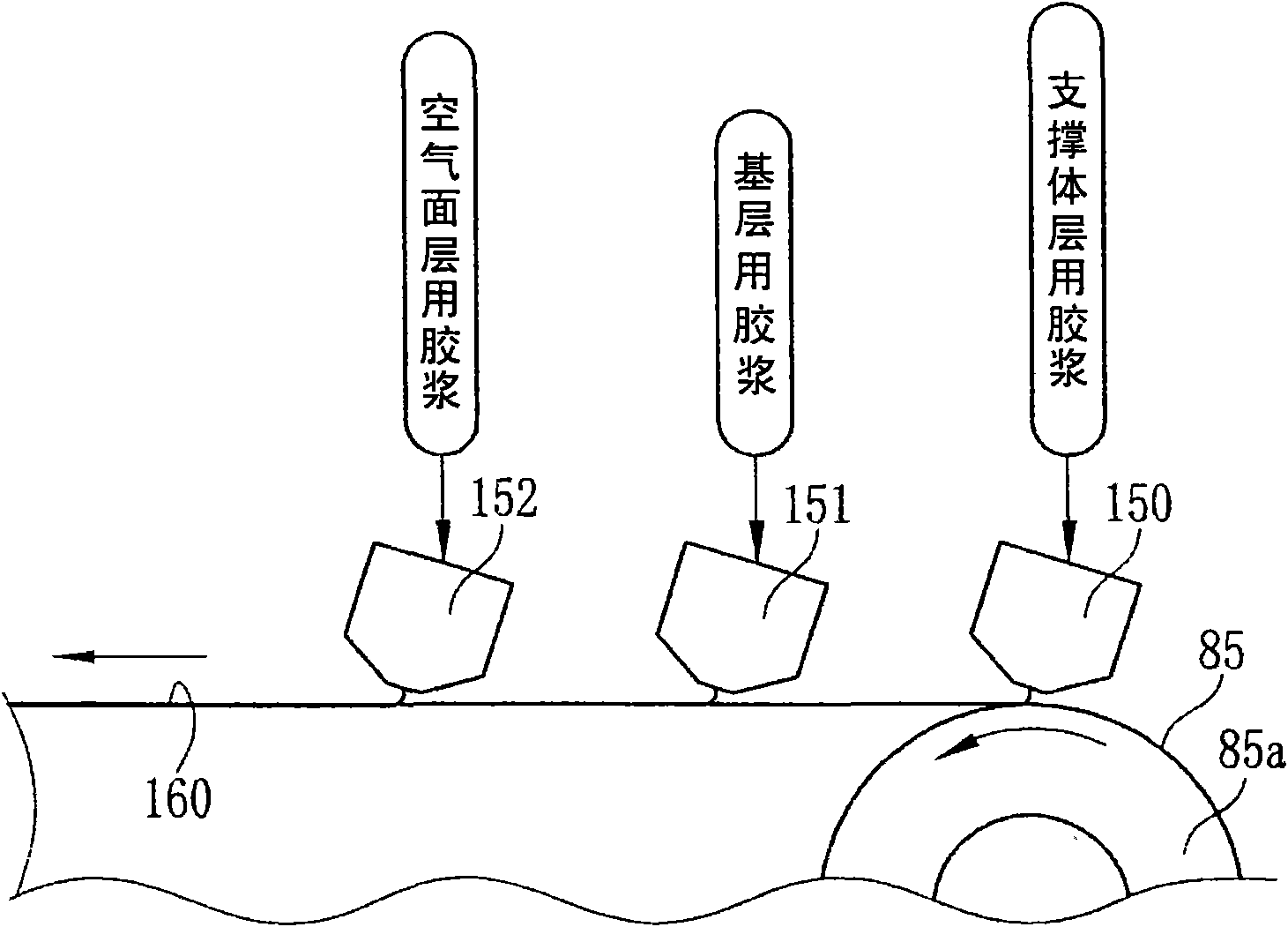

Manufacturing method of optical film

InactiveCN101107548ALow costUniform optical propertiesLiquid crystal compositionsLayered productsLiquid crystallineEngineering

This invention provides a process for producing an optical film, comprising a rubbing treatment step of rubbing a surface of a continuous plastic film (F) by a rubbing roll (4) around which a brushed cloth (4a) has been wound, a coating step of coating liquid crystalline molecules on the surface of the film, and a fixation step of fixing the liquid crystalline molecules. The process is characterized in that, in the rubbing treatment step, the film is supported on and transported by a transfer belt (3) having a metal surface, a plurality of backup rolls (5) are provided so as to support the lower surface of the transfer belt for supporting the film and to face the rubbing roll, and the rubbing strength RS defined by the following equation (1) is set to not less than 2600 mm (more preferably not less than 3400 mm). RS = NM (1 + 2prr / v) (1).

Owner:NITTO DENKO CORP

Thermoplastic resin film and method of manufacturing the same

InactiveUS20070264448A1Growth retardationAvoid damageLiquid crystal compositionsPolarising elementsPolymer scienceGlass transition

The present invention provides a method of manufacturing a thermoplastic resin film comprising the steps of: extruding a molten thermoplastic resin from a die in a form of sheet; cooling and solidifying the thermoplastic resin sheet by sandwiching the sheet between a pressurizing / cooling roller and a press roller; and further cooling and solidifying the thermoplastic resin sheet while transferring the thermoplastic resin sheet by a plurality of cooling rollers, wherein the temperature of each of the cooling rollers is set at within a range of ±3° C. relative to sheet temperature of the thermoplastic resin sheet in contact with the cooling roller; at the same time, the sheet temperature of the thermoplastic resin sheet when removed from the cooling roller arranged most downstream of the cooling rollers is set to be equal to or less than a glass transition temperature Tg(° C.) of the thermoplastic resin −15° C.

Owner:FUJIFILM CORP

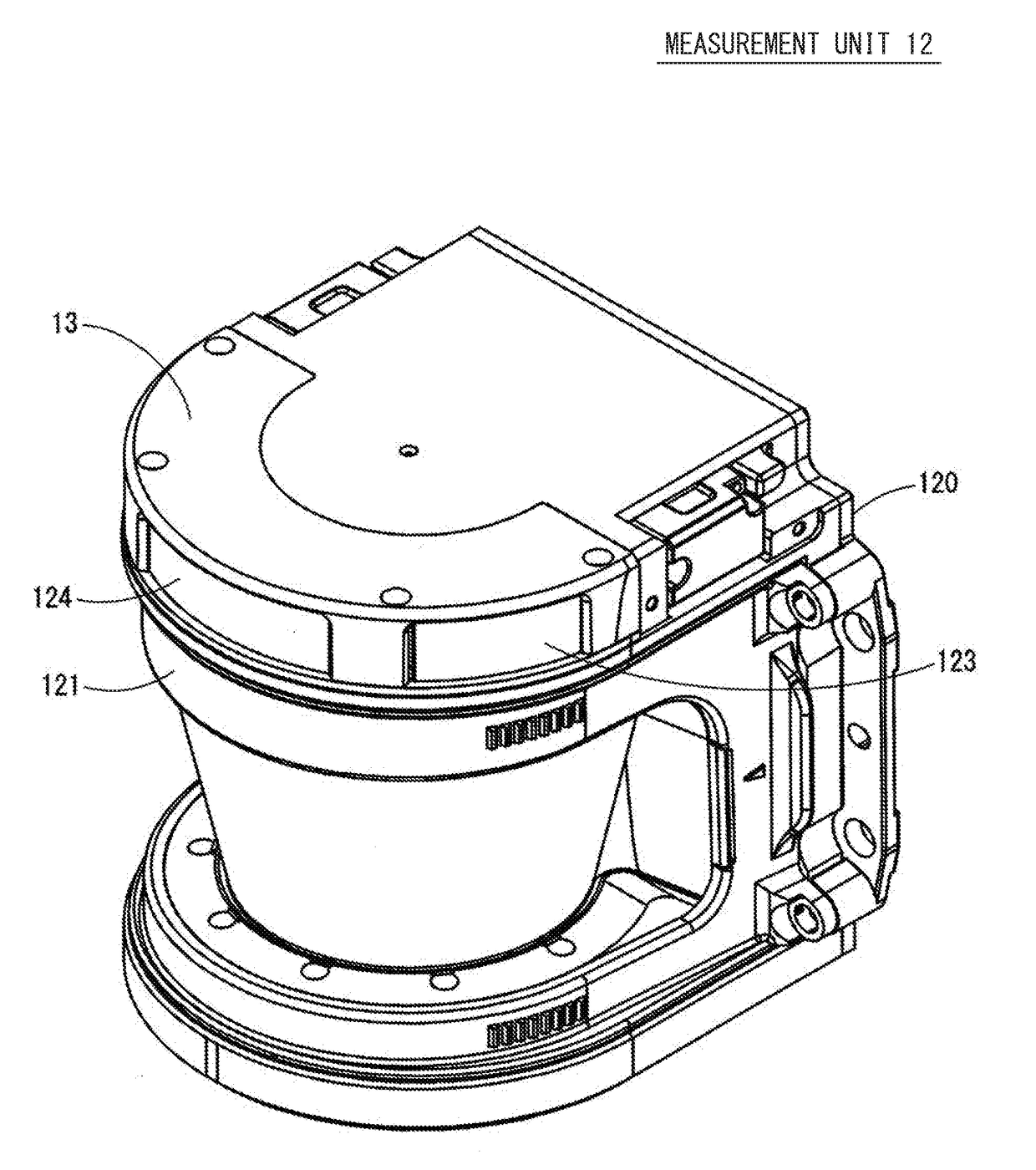

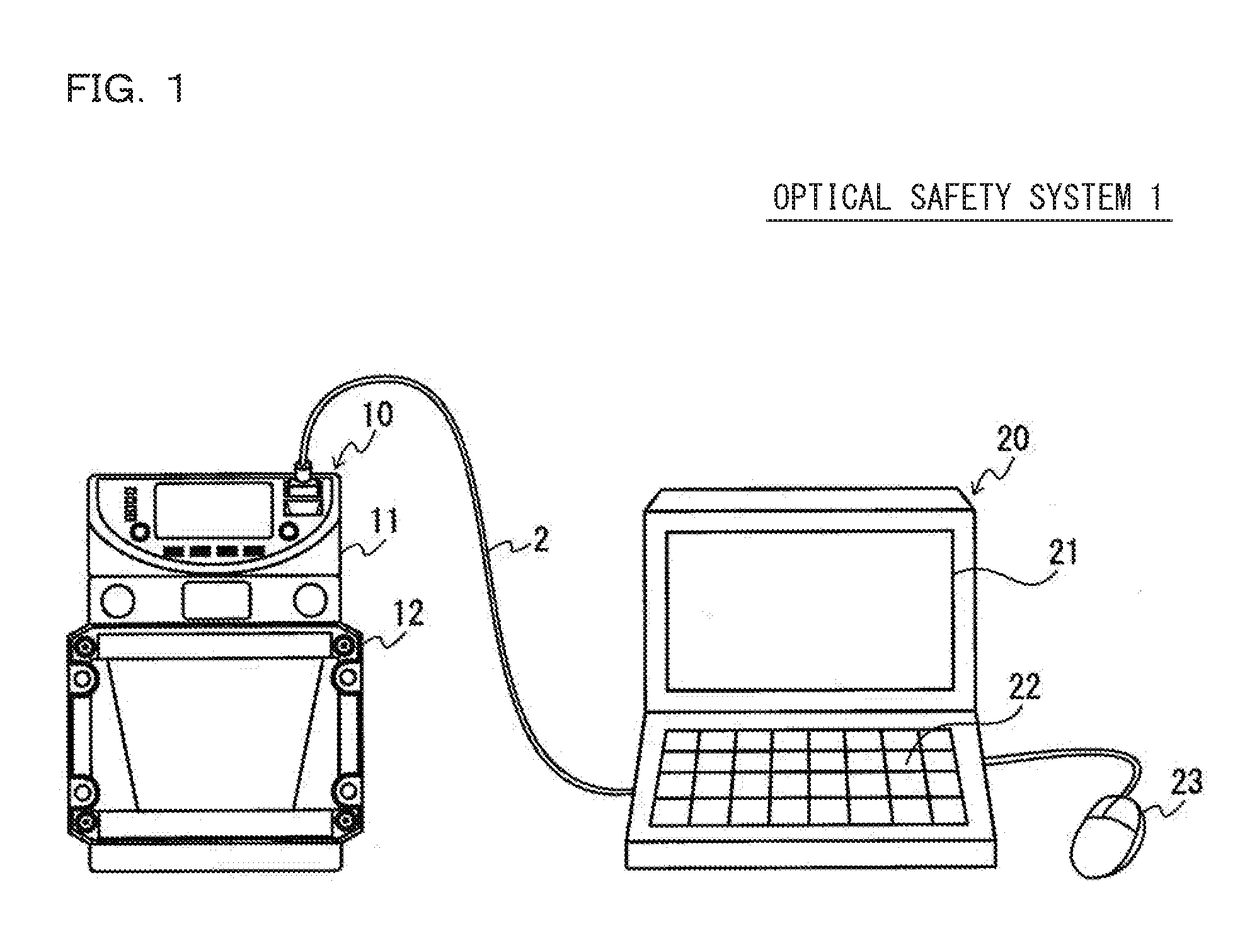

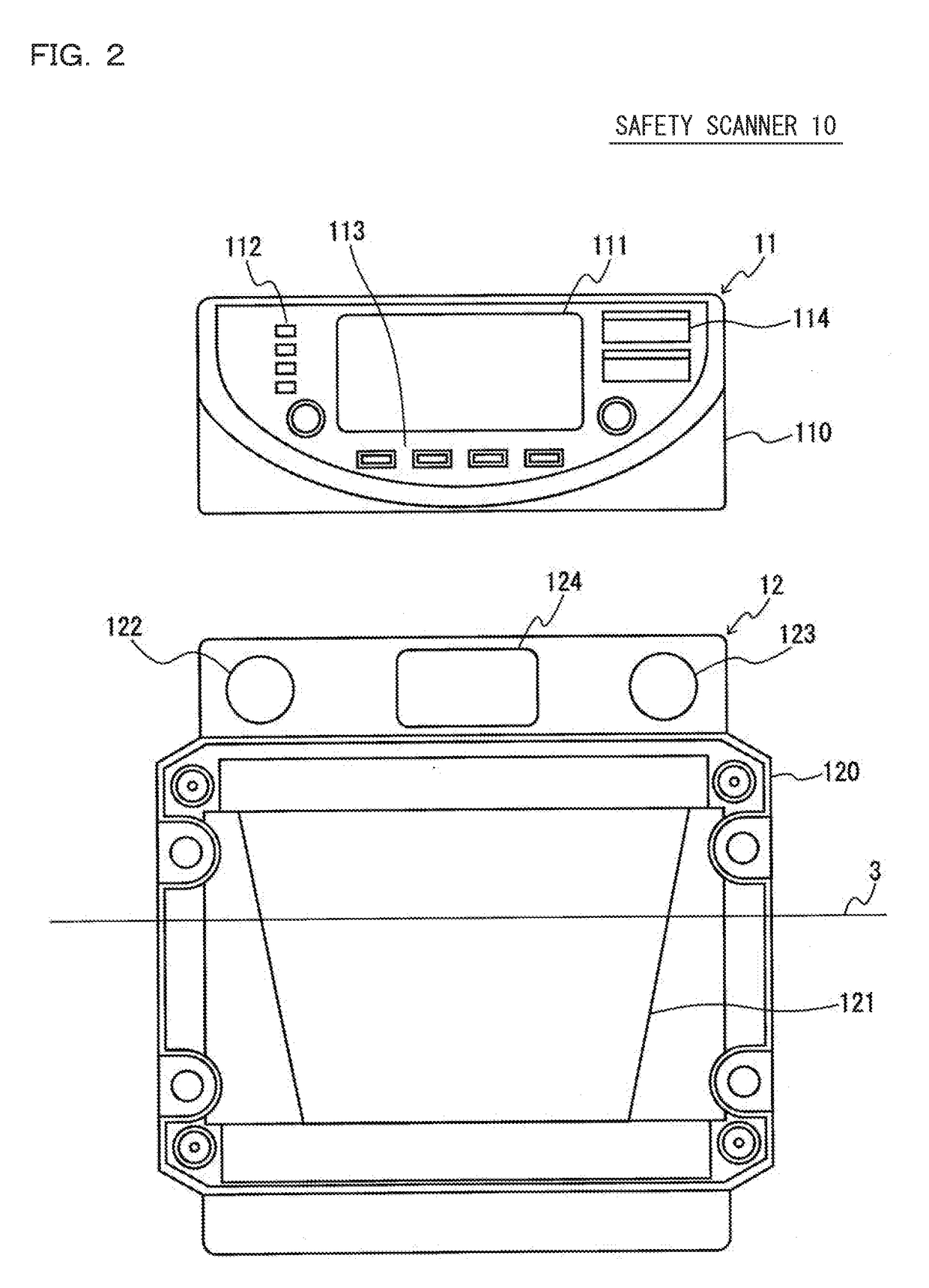

Safety Scanner

InactiveUS20170242101A1Uniform optical propertiesWithout increasing size of casingElectromagnetic wave reradiationBurglar alarm electric actuationLight sourceView angle

Provided is a safety scanner capable of obtaining uniform optical performance for a view angle of 180° or more. The safety scanner includes an optical rotator that emits detection light from a light source to a detection area and causes the detection light to perform scanning in a circumferential direction, a light receiving element that receives reflected light from an object within the detection area through the optical rotator, a casing that houses the light receiving element. The casing includes a canopy part, a bottom part facing the canopy part, and a coupling part that couples a rear end of the canopy part to a rear end of the bottom part. The protective cover includes a window formed in a circular arc shape, corresponding to an optical path of the detection light and the reflected light, having a central angle larger than 180° with respect to the rotation axis.

Owner:KEYENCE

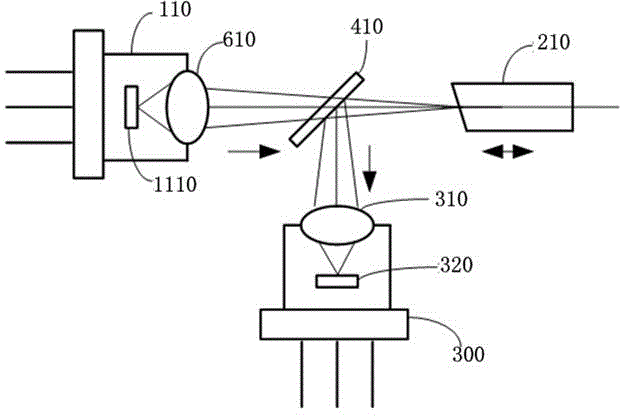

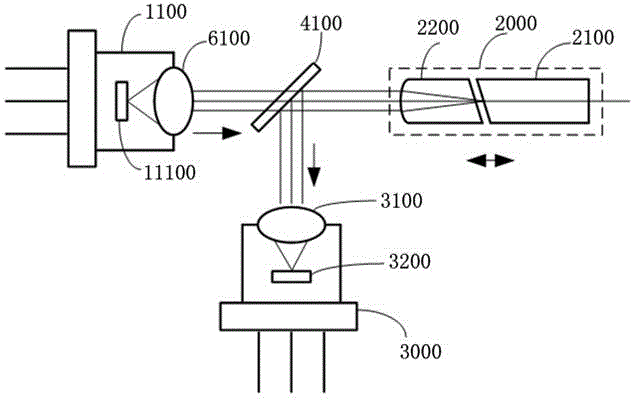

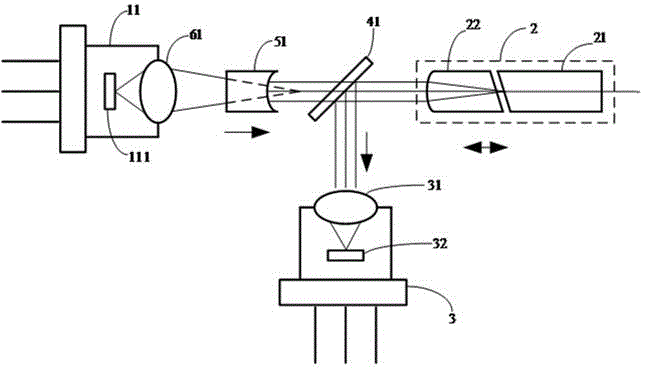

Multi-wavelength component for fiber optic communication

InactiveCN104808299AEasy to debugIncrease brightnessCoupling light guidesFiber-optic communicationLength wave

The invention discloses a multi-wavelength component for the fiber optic communication. The component is used for multi-wavelength laser coupling for single optical fiber transceiving communication and comprises an emitting portion, a receiving portion, an optical coupling portion and an optical fiber terminal. The optical fiber terminal is provided with a straightening portion used for straightening the laser; the emitting portion comprises more than one emitting terminal comprising laser chips generating laser and straightening lens groups; the wavelengths of laser generated by the laser chips of the emitting terminals are different; the straightening lens groups are located in the light emitting ports of the emitting terminals, and the laser generated by the laser chips is concentrated through the straightening lens groups before emitting to the optical coupling portion through the light emitting ports. An optical path component is optimized, the brightness and parallelism of laser emitted through the emitting portion can be guaranteed well, the optical path component is easy to package and adjust, and the multi-wavelength laser coupling capability of an optical coupling component can be improved.

Owner:RISING ELECTRO OPTICS LTD

Cellulose acylate laminate film, method for producing same, polarizer and liquid crystal display device

ActiveCN101666887ANature of controlUniform optical propertiesCellulosic plastic layered productsPolarising elementsCelluloseLiquid-crystal display

The present invention provides a cellulose acylate laminate film having high expressibility, little optical unevenness and good releasability from a support. The cellulose acylate laminate film is characterized in that the cellulose acylate laminate film is obtained by preparing a skin layer B containing the cellulose acylate satisfying the formula (2) and a core layer containing a cellulose acylate satisfying the formula (1) into film on the support according to the order, wherein at least one of the core layer or the skin layer B contains a retardation-controlling agent, and the cellulose acylate laminate film is formed by stretching. Formula (1), Z1 is more than 2.0 but less than 2.7, wherein Z1 represents a total degree of acyl substitution of cellulose acylate; formula (2) Z2 is morethan 2.7, wherein Z2 represents a total degree of acyl substitution of cellulose acylate.

Owner:FUJIFILM CORP

Method of fabricating photomask blank

ActiveUS7767368B2Relieve pressureUniform optical propertiesOriginals for photomechanical treatmentSusceptorOptoelectronics

Owner:SHIN ETSU CHEM IND CO LTD

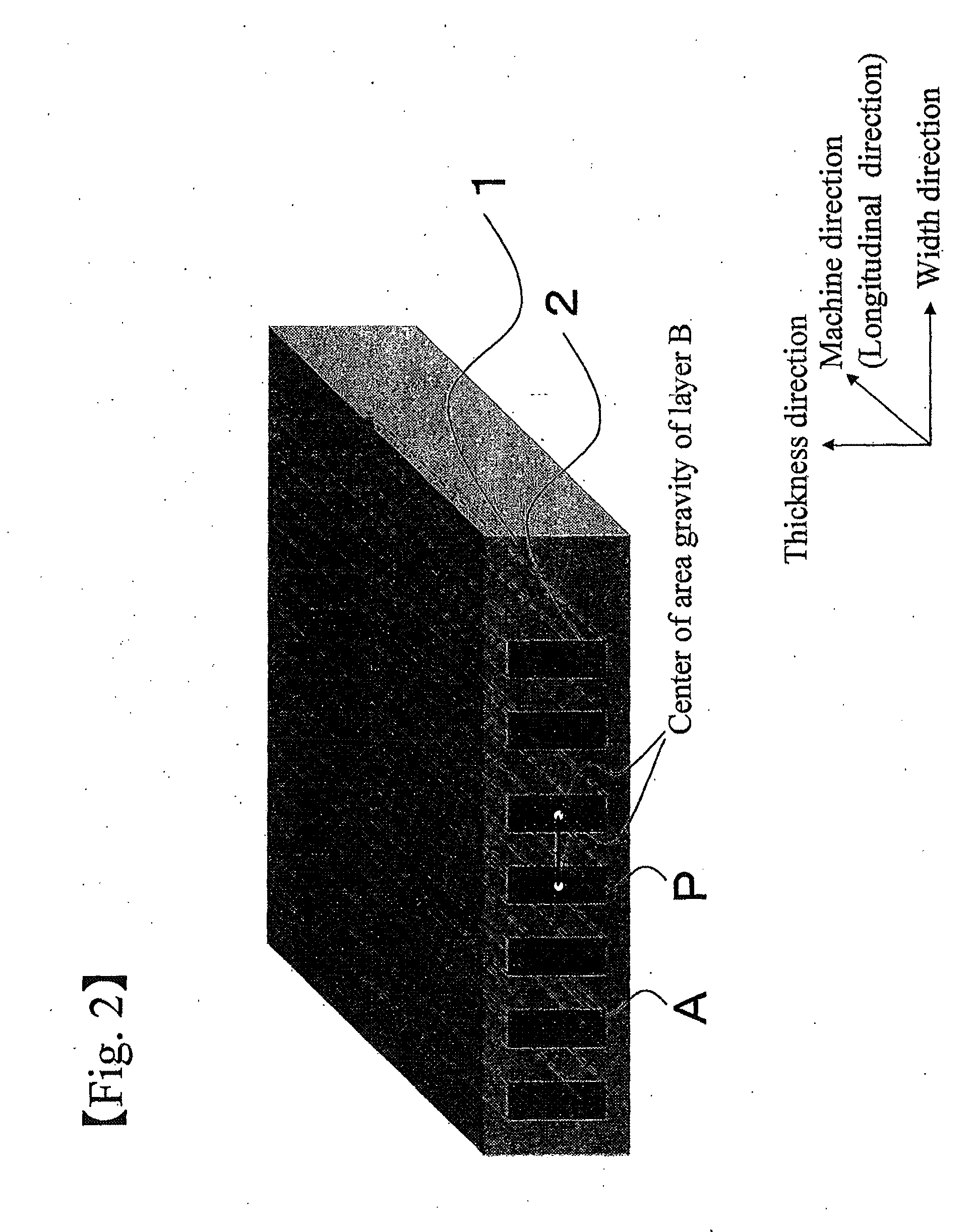

Laminated film

ActiveUS20150086671A1Uniform optical propertiesIncrease the areaConfectioneryCeramic shaping apparatusOptical propertyLight guide

A width-direction multilayer laminated film having a large area and uniform optical properties is provided. A light guide, a light diffusion film, a light collecting film, a viewing angle control film, and an optical waveguide film, which are low cost and have excellent optical properties, as well as an illuminating device, a communication device, and a display using these films. The laminated film may include at least a structure in which a layer made of resin A (layer A) and a layer made of resin B (layer B) are alternately laminated in the width direction, wherein the width of the film is 400 nm or more and the number of layer Bs, each having a cross-sectional width from 0.1 μm to 10,000 μm, is 10 or larger.

Owner:TORAY IND INC

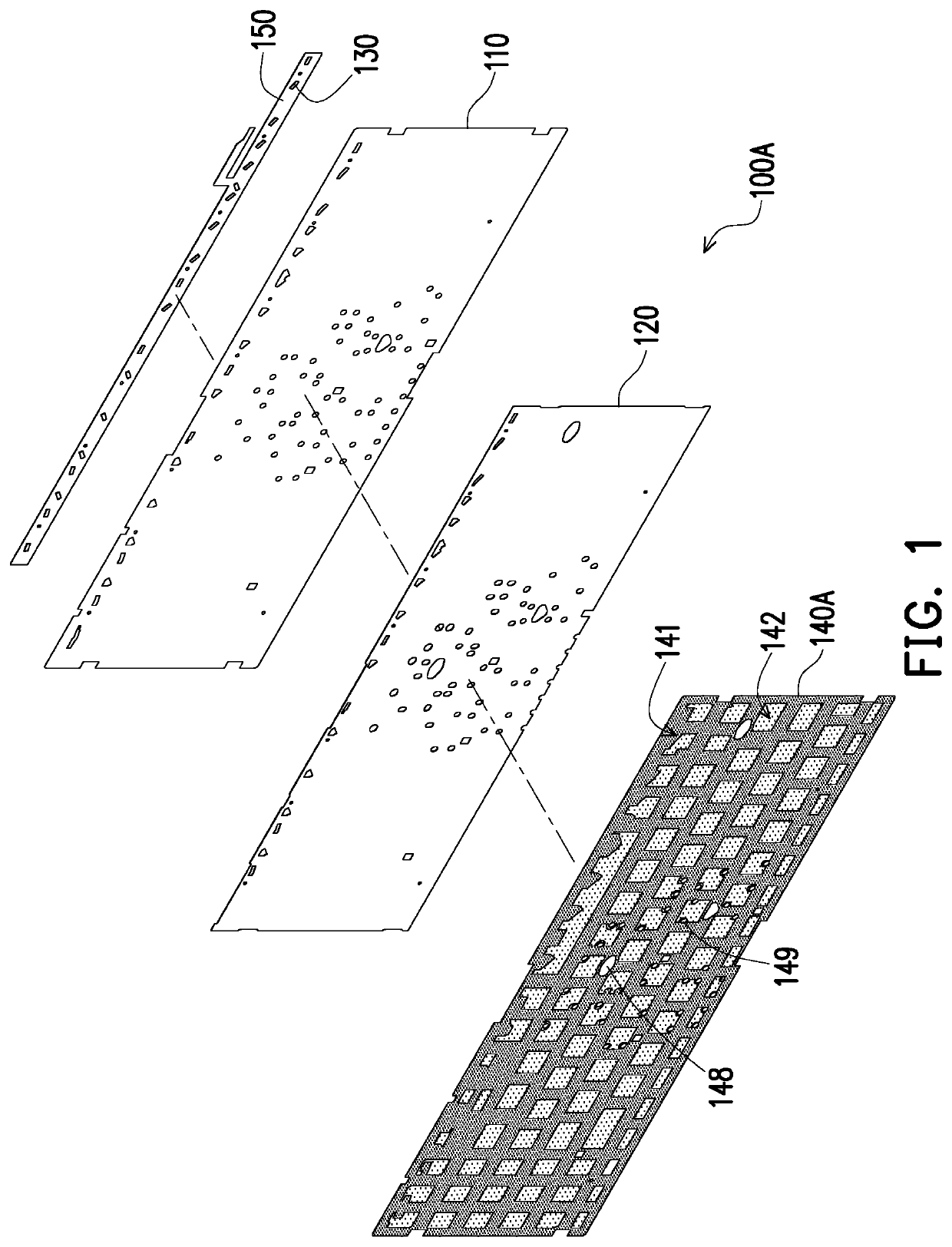

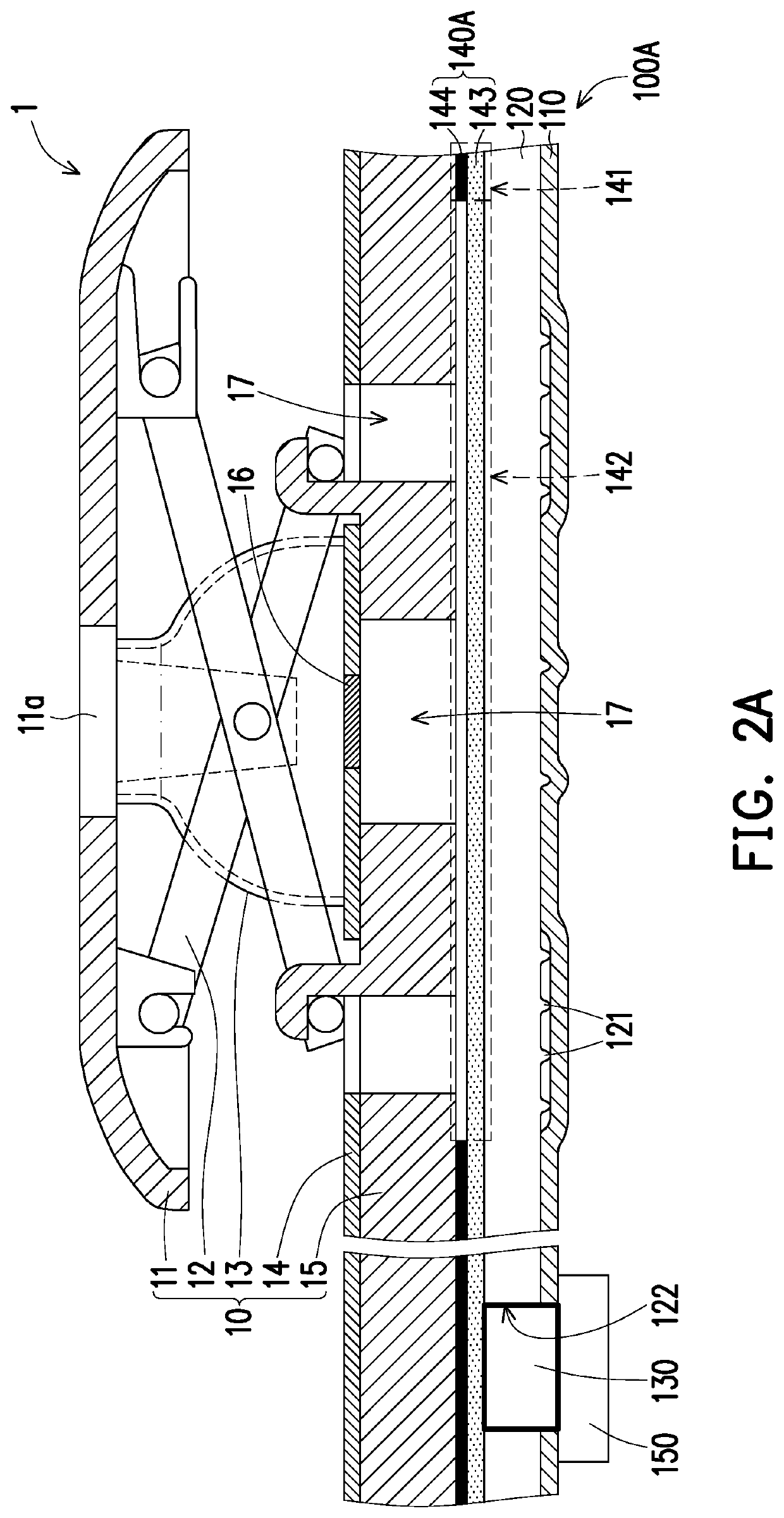

Backlight module and input device

ActiveUS20200042101A1Uniform optical propertiesSoften lightInput/output for user-computer interactionMechanical apparatusLight guideTransmittance

The disclosure provides a backlight module and an input device, wherein the backlight module is adapted to be arranged under a bracket of the input device. The backlight module includes a reflector, a light guide plate, a light source, and a shading plate. The light guide plate is disposed on the reflector and includes a plurality of diffusing elements. The light source is located on a light incident side of the light guide plate. The shading plate is disposed on the light guide plate. The shading plate has a shading area and a translucent area. The diffusing elements are arranged corresponding to the translucent area, wherein a transmittance of the translucent area is greater than a transmittance of the shading area. The scattering or diffusing particles are arranged in the translucent area.

Owner:LITE ON ELECTRONICS (GUANGZHOU) LTD +1

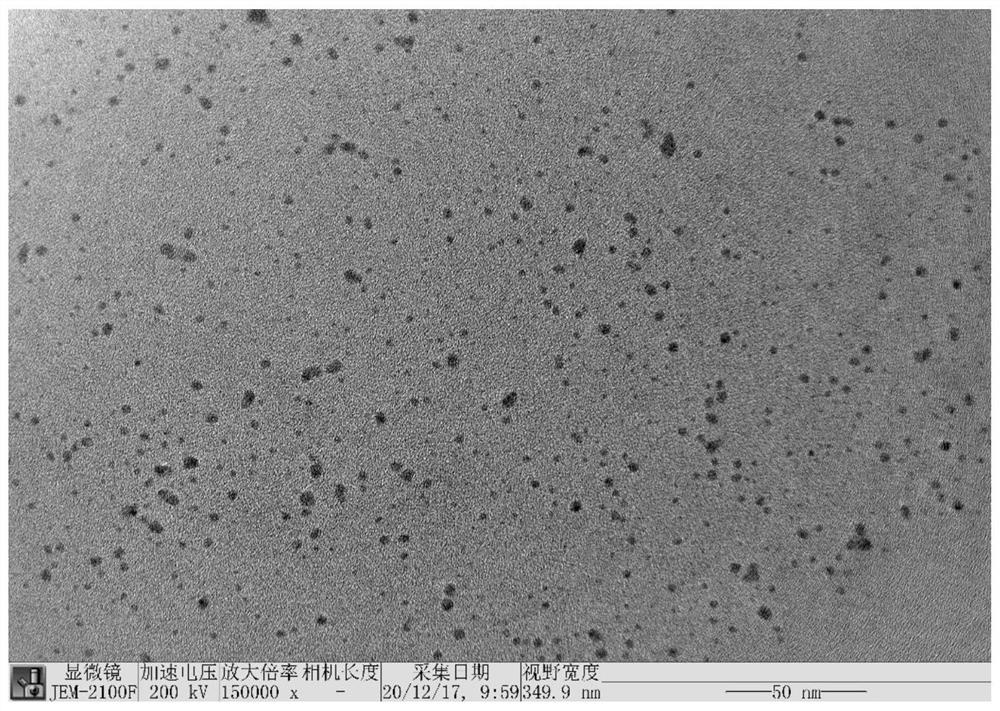

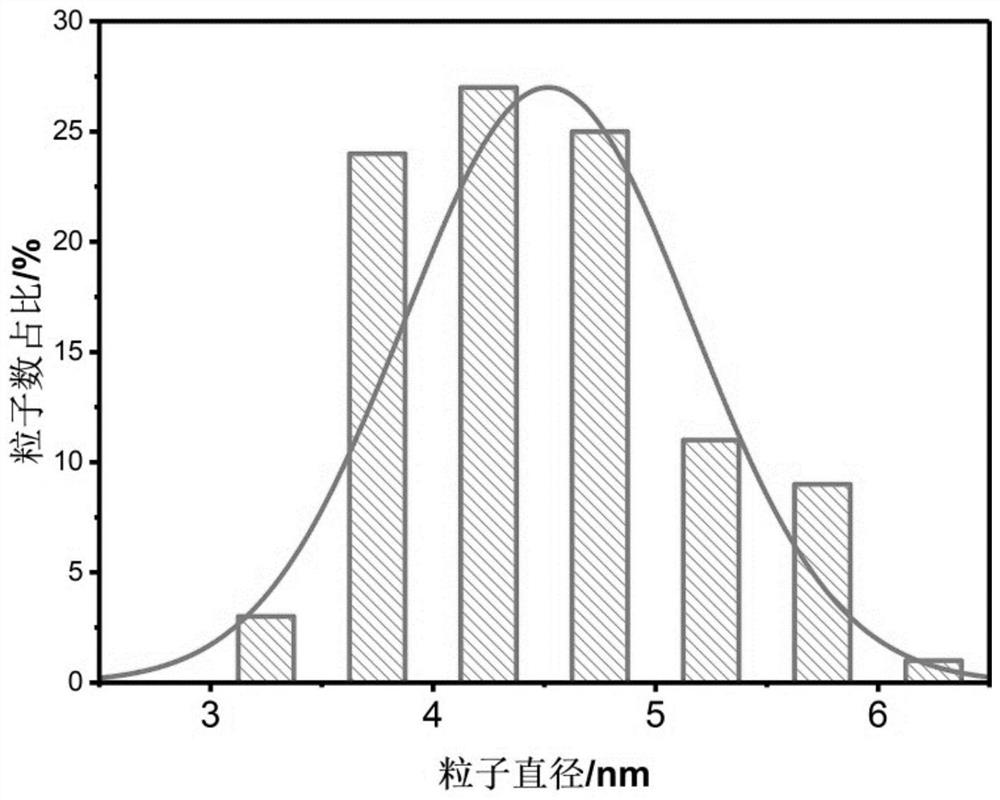

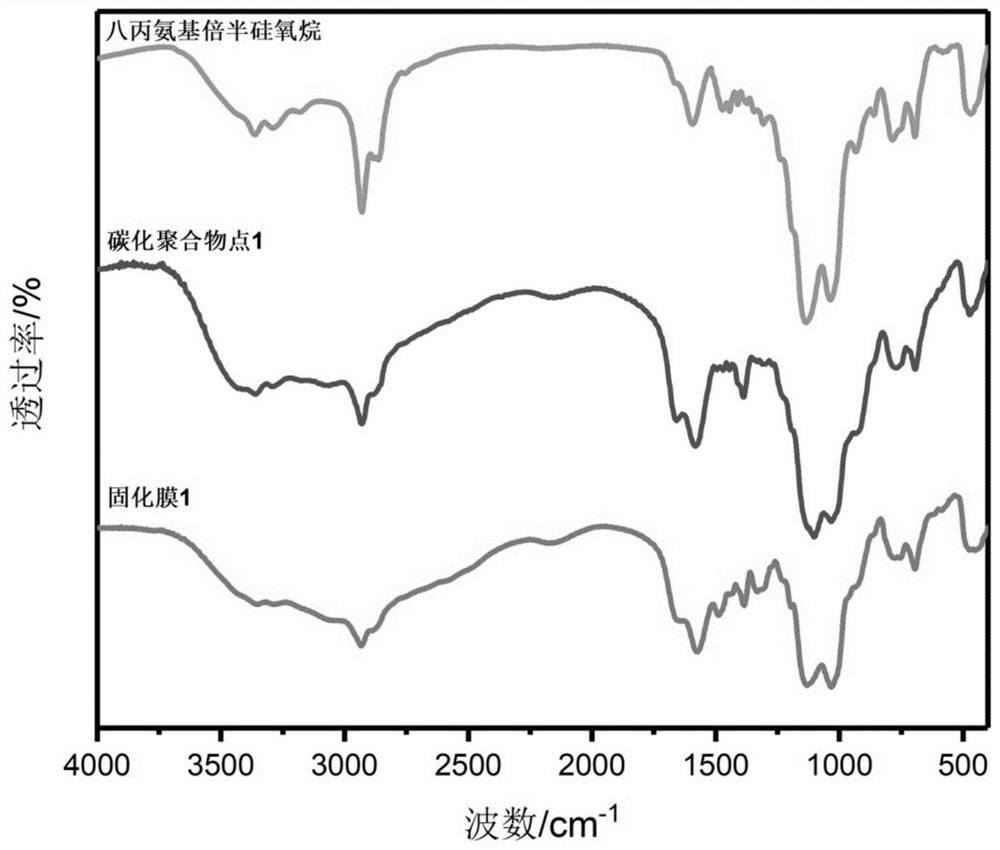

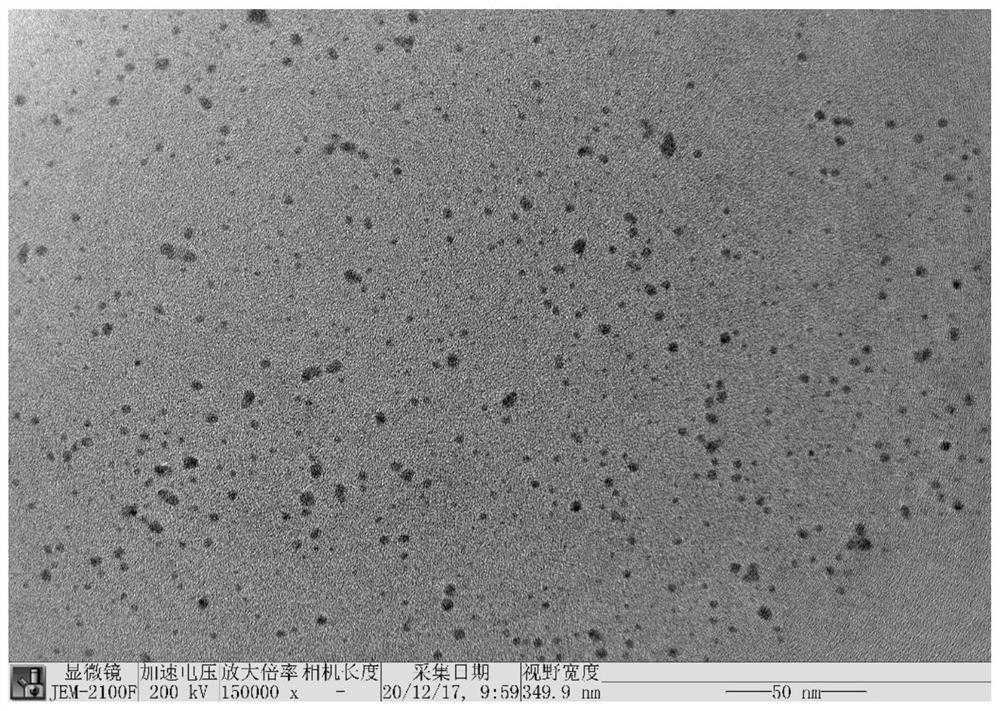

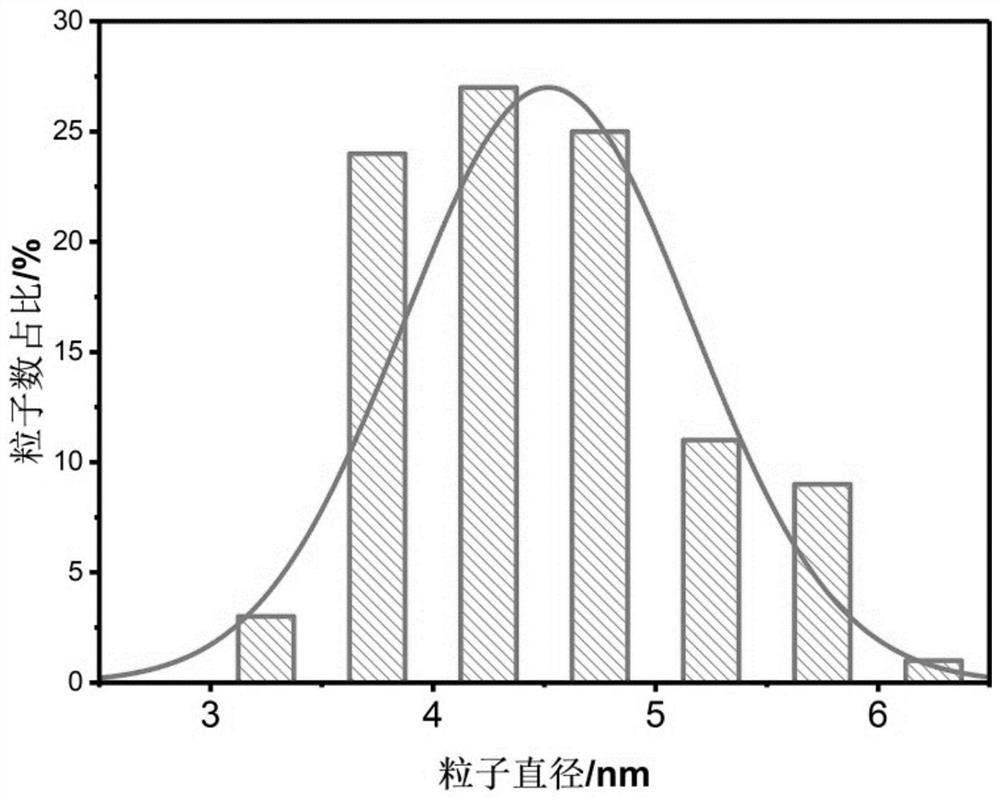

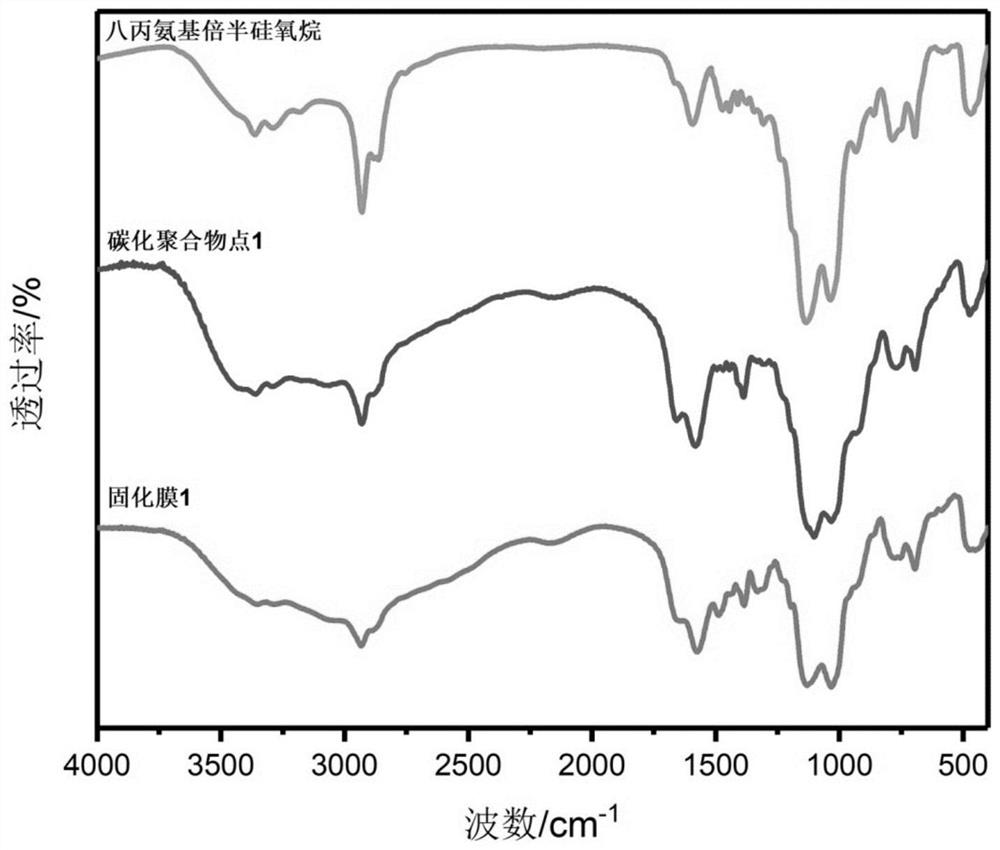

Ultra-hard wear-resistant transparent film material with silicon-doped carbonized polymer dots as building blocks and preparation method thereof

ActiveCN113105766BGood film formingUniform optical propertiesNano-carbonCoatingsDisplay deviceSolar cell

The invention relates to an ultra-hard wear-resistant transparent film layer material compounded on the nanometer scale with silicon-doped carbonized polymer dots as building blocks and a preparation method thereof, belonging to the technical field of preparation of super-hard wear-resistant scratch-resistant transparent film materials. It is to weigh propylaminosilsesquioxane and citric acid with a molar ratio of 1:0.1~4 and dissolve them in deionized water, then hydrothermally react at 160~200°C for 3~8 hours; then cool naturally to room temperature to obtain light The yellow and transparent Si-CPDs aqueous solution is filtered with a 0.22 μm polyethersulfone filter membrane to obtain a Si-CPDs solidified solution containing silicon hydroxyl groups on the surface; the solidified solution is spin-coated, dip-coated or spray-coated on Plasma for 3-5 minutes The surface of the glass slide is cured at 60-200° C. for 0.5-3 hours, so as to obtain the superhard wear-resistant transparent film layer of the present invention. The film layer material can be used to prepare the surface hard wear-resistant protective layer of displays, transparent optical devices and solar cells.

Owner:JILIN UNIV

Method and apparatus for analyzing optical characteristics of optical medium and method for production monitoring

ActiveUS7477387B2Stably producing optical mediumsUniform optical propertiesPolarisation-affecting propertiesLight polarisation measurementComing outOptical property

A novel method for analyzing optical characteristics of an optical medium including illuminating an optical medium, having an input surface and an output surface of light, with at least three input light beams differed from each other in a polarization state, respectively from a direction inclined by a polar angle θ (0°<θ<90°) with regard to the input surface; obtaining polarization states of output light beams coming out from the output surface, corresponded to the input light beams; and determining the Jones matrix M which can satisfy the equation (1) below with polarization vectors of the input light beams and polarization vectors of the output light beams:(Es′Ep′)=Q′×M×Q×(EsEp)(1)

Owner:FUJIFILM CORP

Super-hard wear-resistant transparent film layer material taking silicon-doped carbonized polymer point as construction element and preparation method thereof

ActiveCN113105766AGood film formingUniform optical propertiesNano-carbonCoatingsPolymer scienceDisplay device

The invention relates to a super-hard wear-resistant transparent film layer material which is compounded on a nano scale and takes the silicon-doped carbonized polymer point as a construction element and a preparation method of the super-hard wear-resistant transparent film layer material, and belongs to the technical field of preparation of super-hard wear-resistant scratch-resistant transparent film materials. The preparation method comprises the following steps: weighing propylamino silsesquioxane and citric acid in a molar ratio of 1: (0.1-4), dissolving the propylamino silsesquioxane and the citric acid in deionized water, and then carrying out hydrothermal reaction at 160-200 DEG C for 3-8 hours; then naturally cooling to room temperature to obtain a faint yellow transparent Si-CPDs aqueous solution, and filtering by using a 0.22 mu m polyether sulfone filter membrane to obtain Si-CPDs curing liquid with silicon hydroxyl on the surface; and spin coating, dip coating or spray coating the curing liquid onto the surface of a glass slide subjected to Plasma treatment for 3-5 minutes, and curing for 0.5-3 hours at the temperature of 60-200 DEG C to obtain the super-hard wear-resistant transparent film layer. The film material can be used for preparing surface hard wear-resistant protective layers of displays, transparent optical devices and solar cells.

Owner:JILIN UNIV

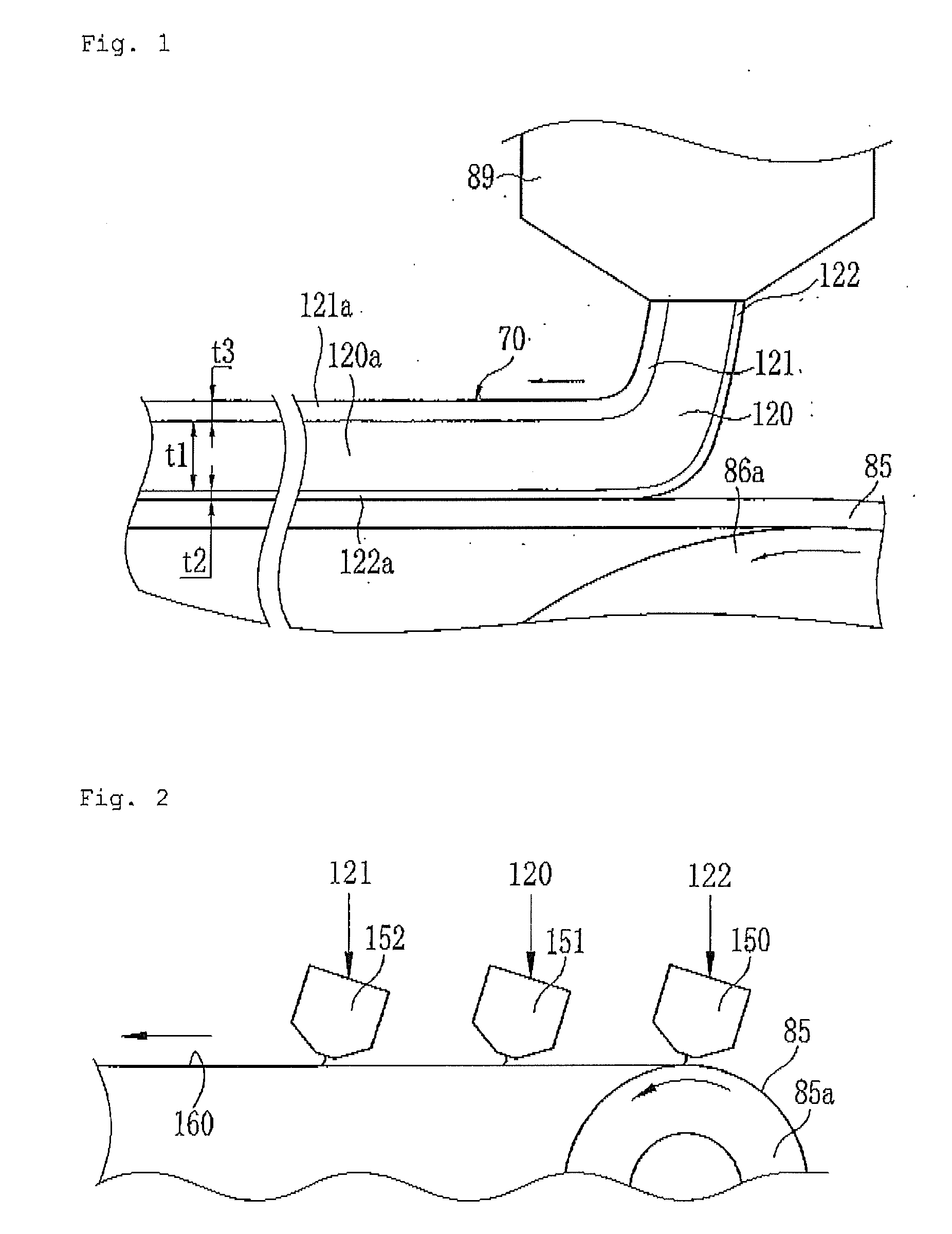

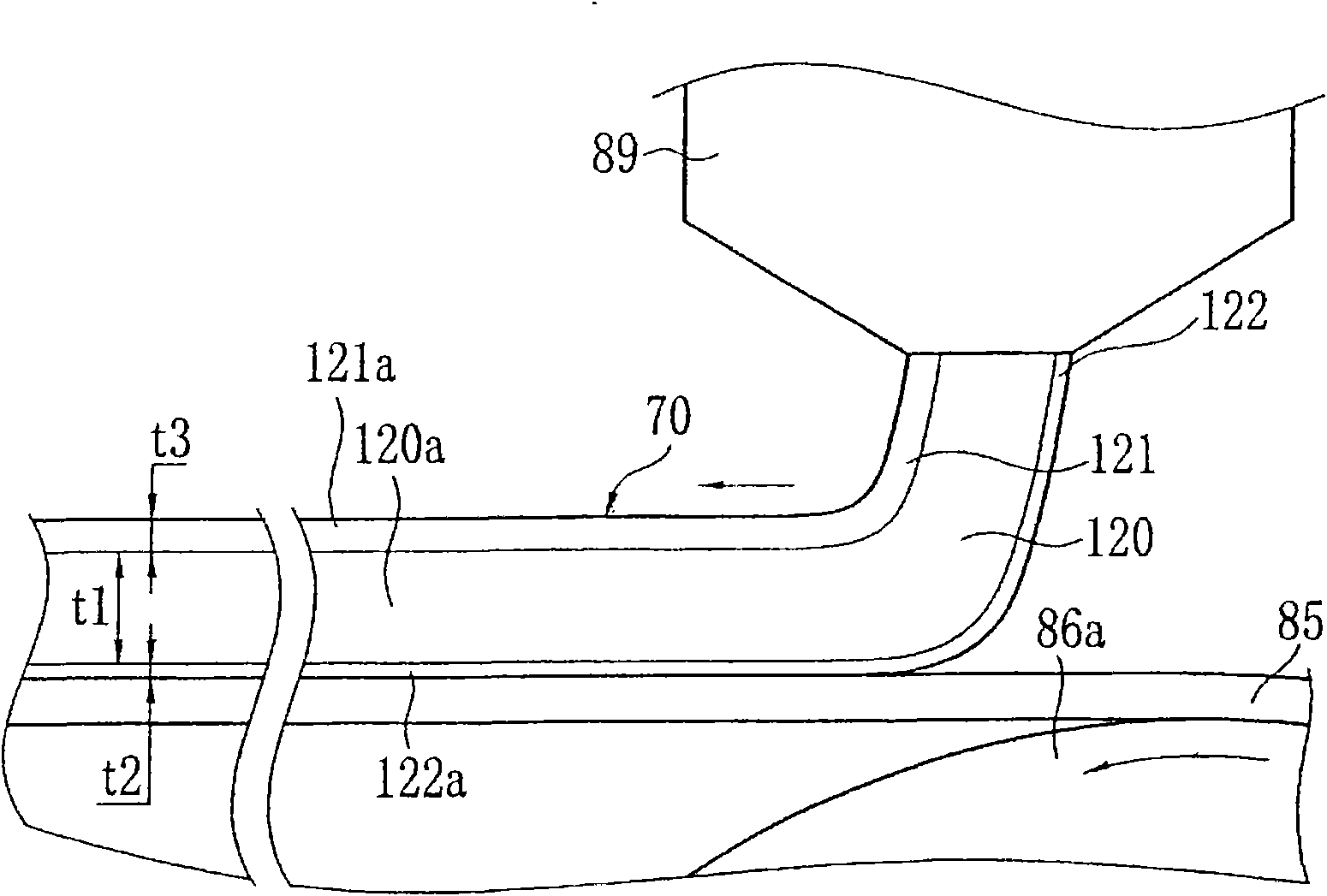

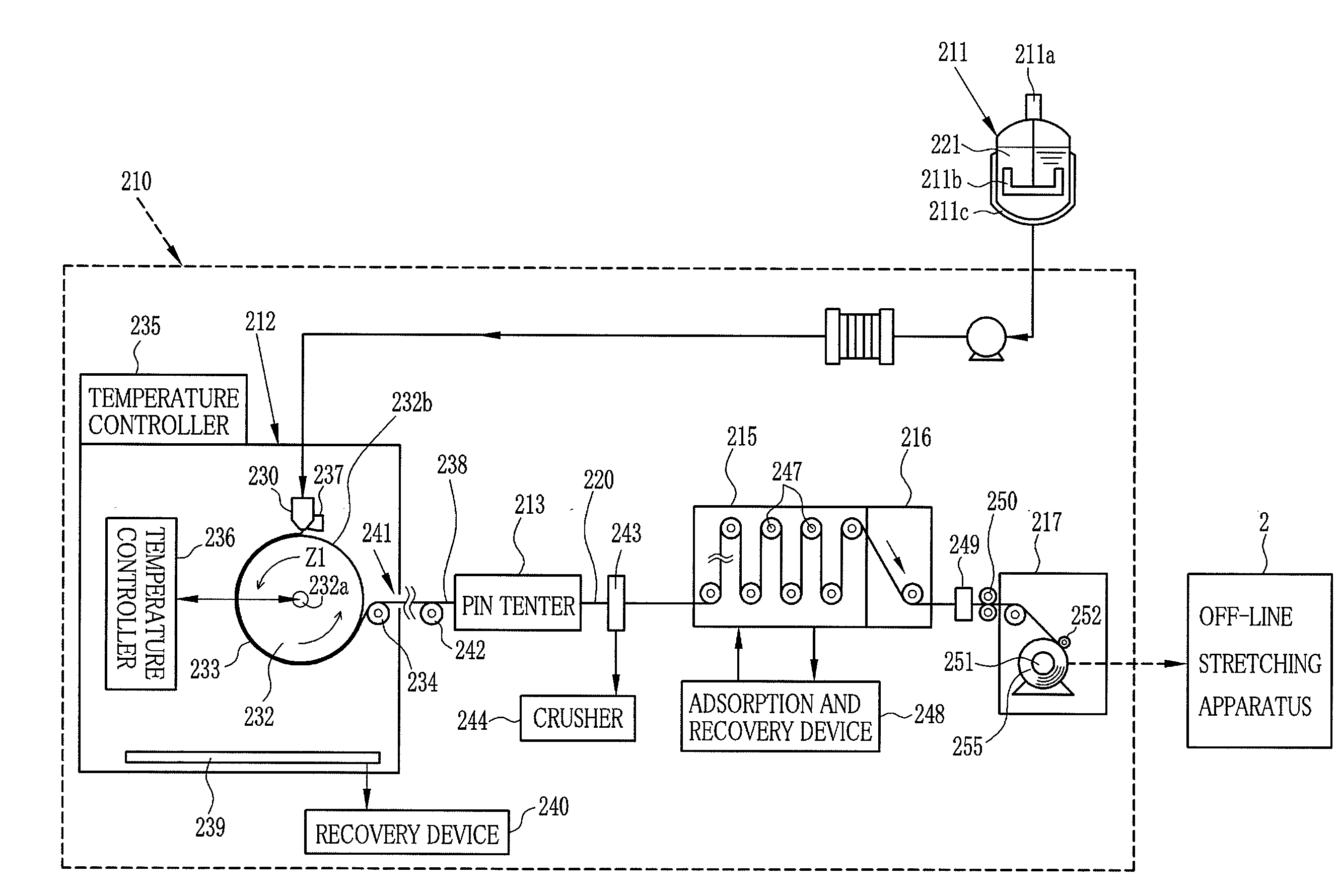

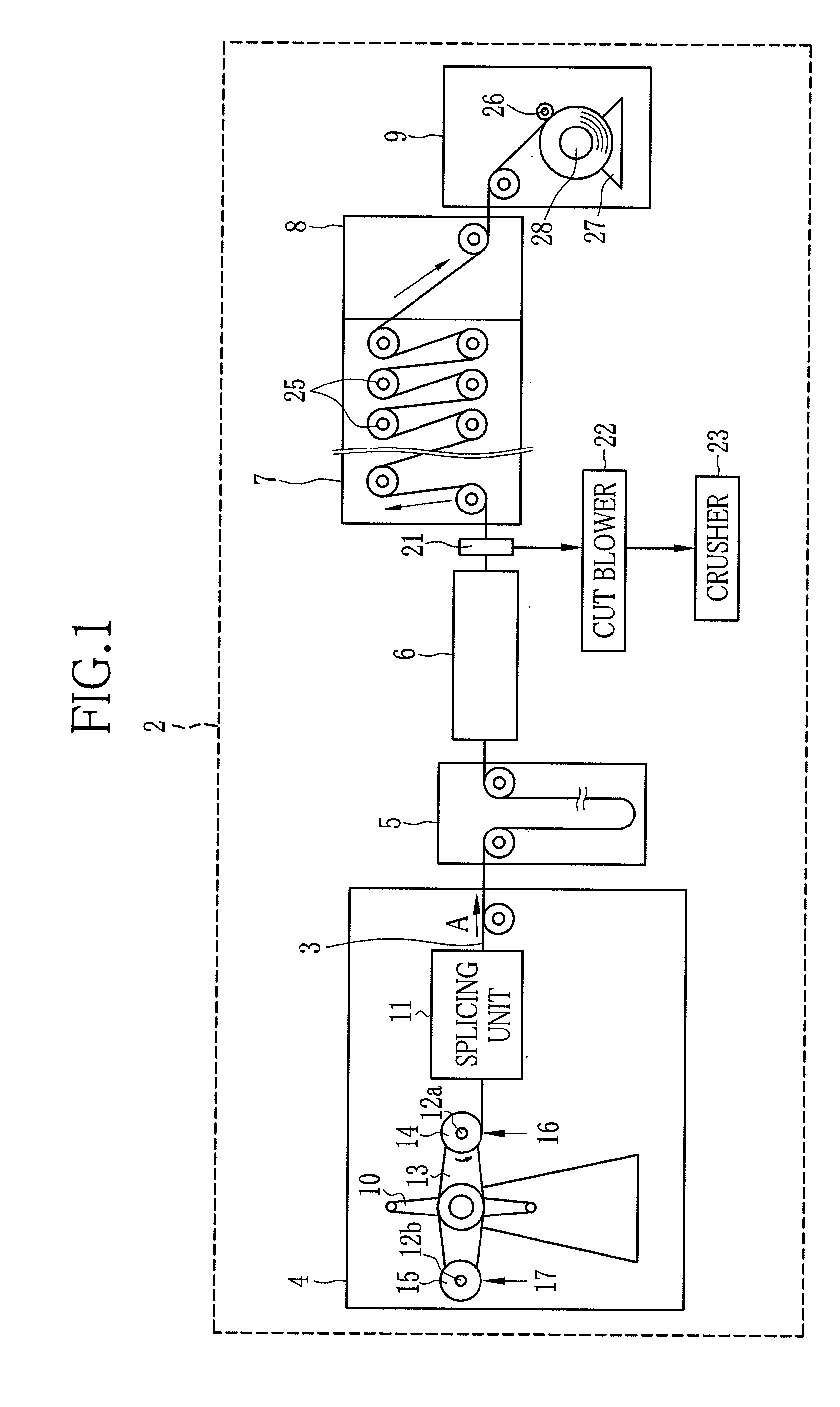

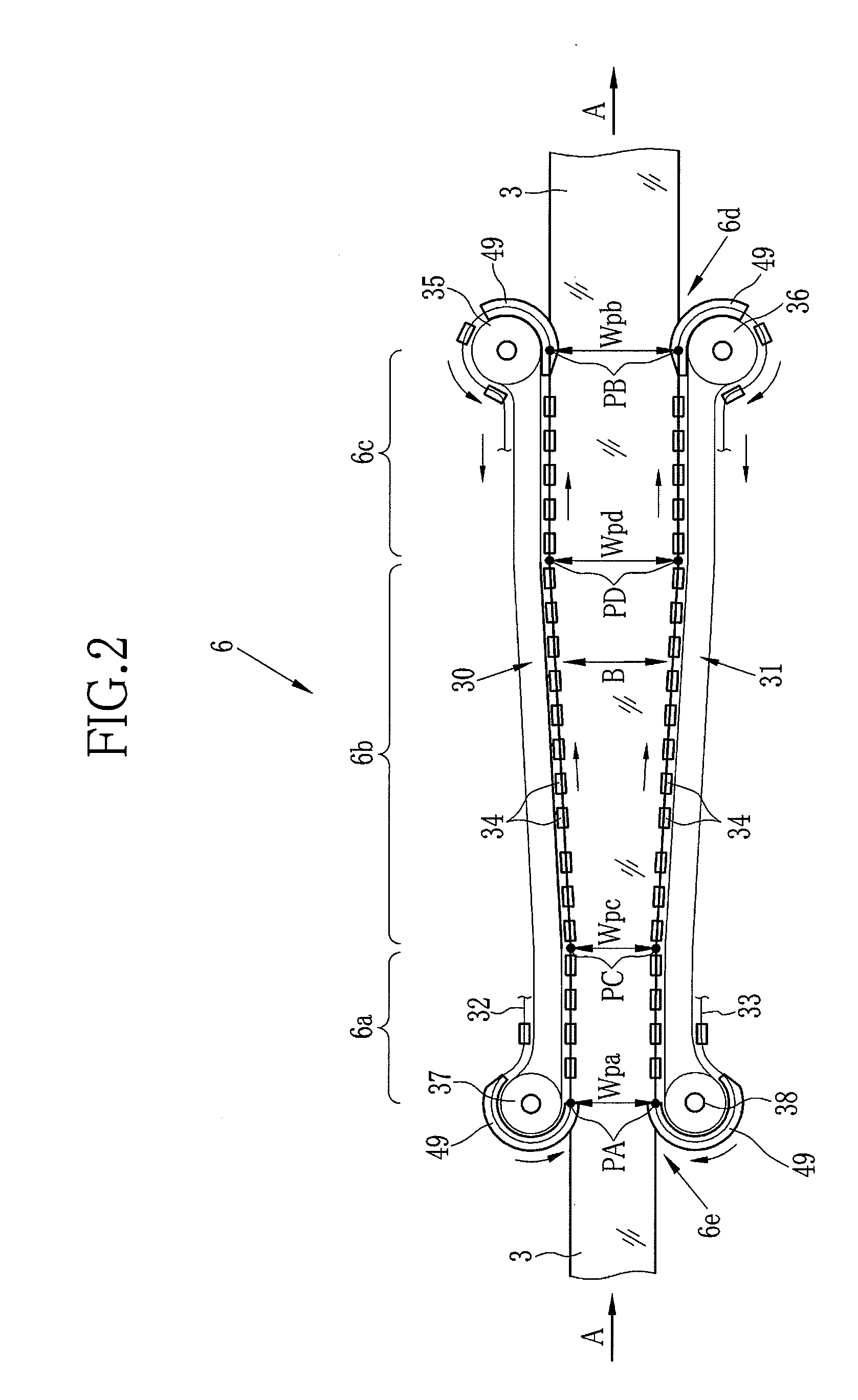

Method and apparatus for continuously stretching polymer films

InactiveUS20090151862A1Efficiently produceExcellent surface conditionMechanical working/deformationFilament handlingEngineeringMechanical engineering

A rear end of a preceding film and a front end of a trailing film are overlapped with an overlap length Lo. Each of a pair of welding heads has a contact surface and a film heating surface. The contact surface has a length Lp in a conveying direction. The film heating surface has a length Lh in the conveying direction. The lengths Lh, Lo, and Lp satisfy Lh<Lo<Lp. Center portions of an overlapped portion, the contact surface, and the heat surface are approximately aligned with each other in the conveying direction. The overlapped portion is sandwiched by the welding heads in an overlapping direction C. The overlapped portion is welded through the film heating surfaces such that temperatures of the films at both ends of each contact surface in the conveying direction are heated to a temperature at which the films are welded.

Owner:FUJIFILM CORP

Baking device for liquid crystal alignment films

ActiveUS20150153105A1Uniform optical propertiesReduce materialCharge supportsCooking & bakingStream flow

The present disclosure provides a baking device for liquid crystal alignment films, wherein the baking device includes a heating table with openings and lift pins extending and penetrating through the openings, and the lift pins can move between a retracting position and a stretching position to support a glass substrate coated with alignment films, wherein a blocking member is arranged on the lift pin in a surrounding manner to be tightly engaged thereon, so as to block the air stream flowing toward the glass substrate through the openings when the lift pins are situated in the retracting position. With the provision of the blocking members, the air streams flowing toward the glass substrate coated with alignment films can be resisted in the baking process, which prevents the air streams from affecting heat distribution and temperature distribution.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Method of fabricating photomask blank

ActiveUS20080076040A1Relieve pressureUniform optical propertiesOriginals for photomechanical treatmentSusceptorOptoelectronics

An opaque area is formed in a sidewall portion of a susceptor by stacking a material that is transparent to flash light and a material that is opaque to the flash light to form the sidewall portion or coating a surface of the opaque material with the transparent material. A top surface of the opaque area in the sidewall portion of the susceptor is designed to have a predetermined positional relationship with a top surface of a substrate; the top surface of the opaque area is set at the same position as that of the top surface of the substrate or higher than the top surface of the substrate by a predetermined height. Thus, obliquely incident flash light is absorbed or irregularly reflected by the opaque quartz portion, surrounding an excavated portion of the susceptor.

Owner:SHIN ETSU CHEM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com