Cellulose acylate laminate film, method for producing same, polarizer and liquid crystal display device

A technology of cellulose acylate and manufacturing method, applied in the direction of cellulose plastic material layered products, chemical instruments and methods, polarizing elements, etc., capable of solving insufficient performance of optical compensation film, deviation of optical manifestation, and appearance of optical characteristics To solve the problem of low performance and achieve the effect of improving poor film production and peelability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0389] (preparation of mucilage)

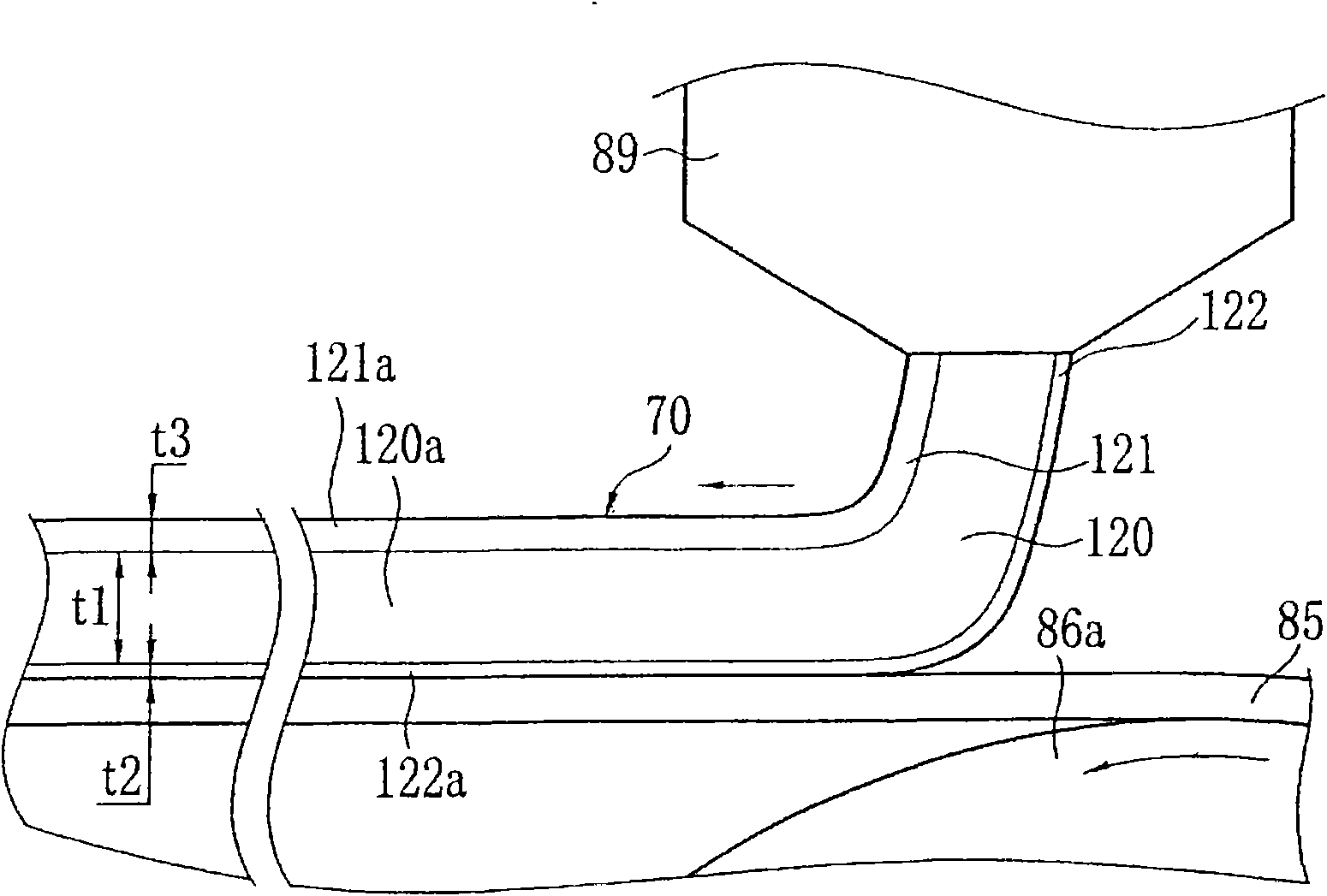

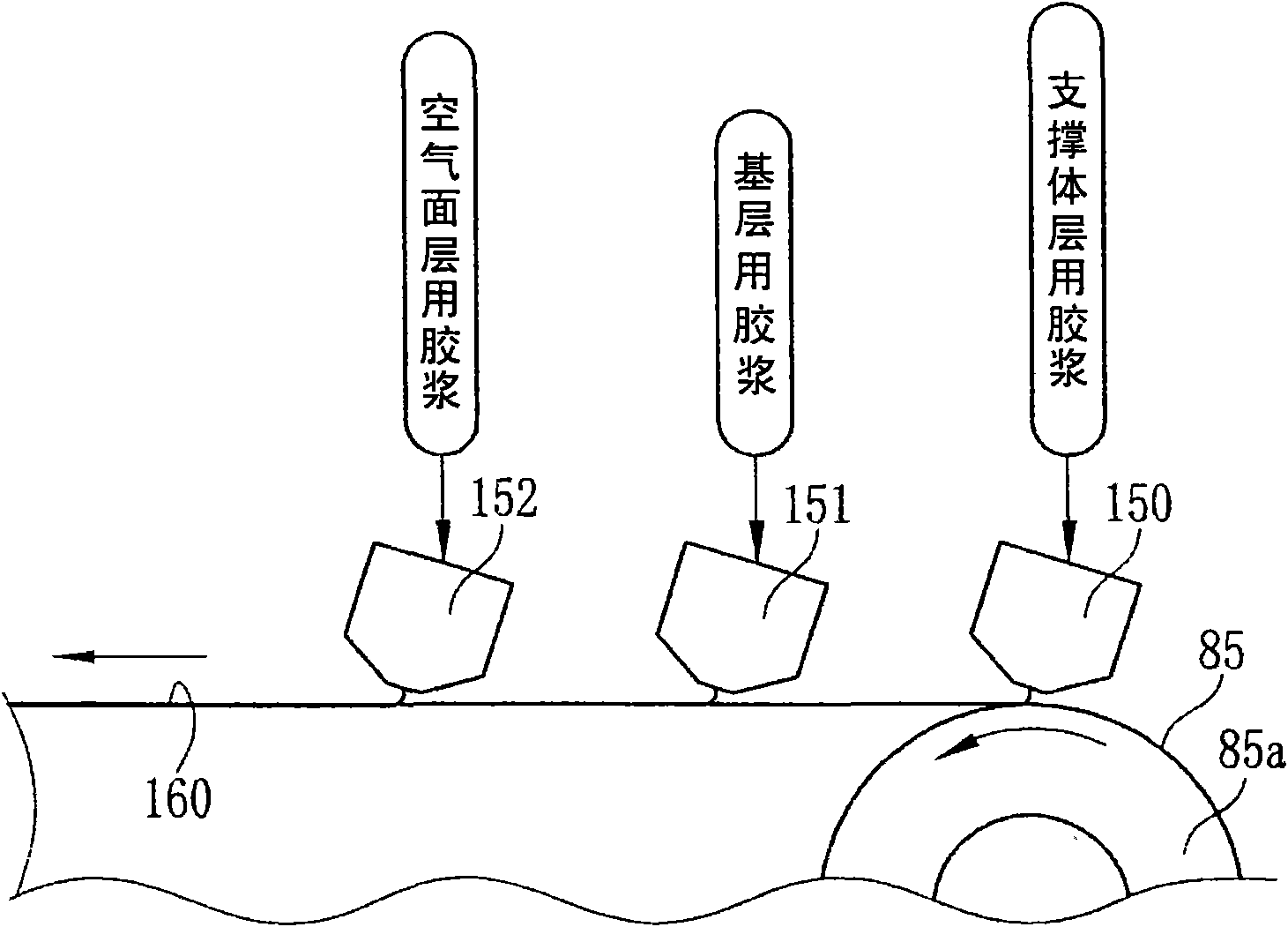

[0390] Specifically, the production method of the present invention produces the film of the present invention by a solvent casting method using a solution (dope) obtained by dissolving cellulose acylate in an organic solvent.

[0391] The above-mentioned organic solvent preferably contains a solvent selected from ethers with 3 to 12 carbon atoms, ketones with 3 to 12 carbon atoms, esters with 3 to 12 carbon atoms, and halogenated hydrocarbons with 1 to 6 carbon atoms. . Ethers, ketones and esters can have a cyclic structure. A compound having two or more functional groups of ether, ketone and ester (ie -O-, -CO- and -COO-) can also be used as an organic solvent. The organic solvent may have other functional groups such as alcoholic hydroxyl groups. In the case of an organic solvent having two or more functional groups, the number of carbon atoms may be within the prescribed range for compounds having any one of the functional groups.

[...

Embodiment 1~19

[0450] Cellulose acylate dopes shown below were prepared to make dopes for core layers.

[0451] (Preparation of cellulose acylate glue for core layer)

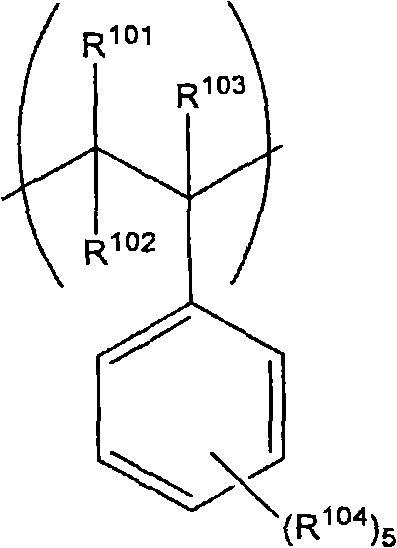

[0452] Cellulose acylate resin: 100 parts by mass of resins listed in Table 1

[0453] Retardation adjuster: the amount described in Table 2 of the adjuster listed in Table 2 (unit: parts by mass)

[0454] Dichloromethane 406 parts by mass

[0455] Methanol 61 parts by mass

[0456] (Preparation of cellulose acylate glue for surface layer B)

[0457] Cellulose acylate resin: 100 parts by mass of resins listed in Table 1

[0458] Retardation adjuster: the amount described in Table 2 of the adjuster listed in Table 2 (unit: parts by mass)

[0459] Matting agent: 0.05 parts by mass of the following compound G

[0460] Peeling accelerator: 0.03 parts by mass of the following compound H

[0461] Dichloromethane 406 parts by mass

[0462] Methanol 61 parts by mass

[0463] (Preparation of cellulose acylate glue for surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com