Crushing tooth for crusher

A technology of pulverizers and crushing teeth, which is applied to mechanically driven excavators/dredgers, grain processing, etc., can solve the problems of narrow and difficult replacement operations, and achieve the effect of simple replacement operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

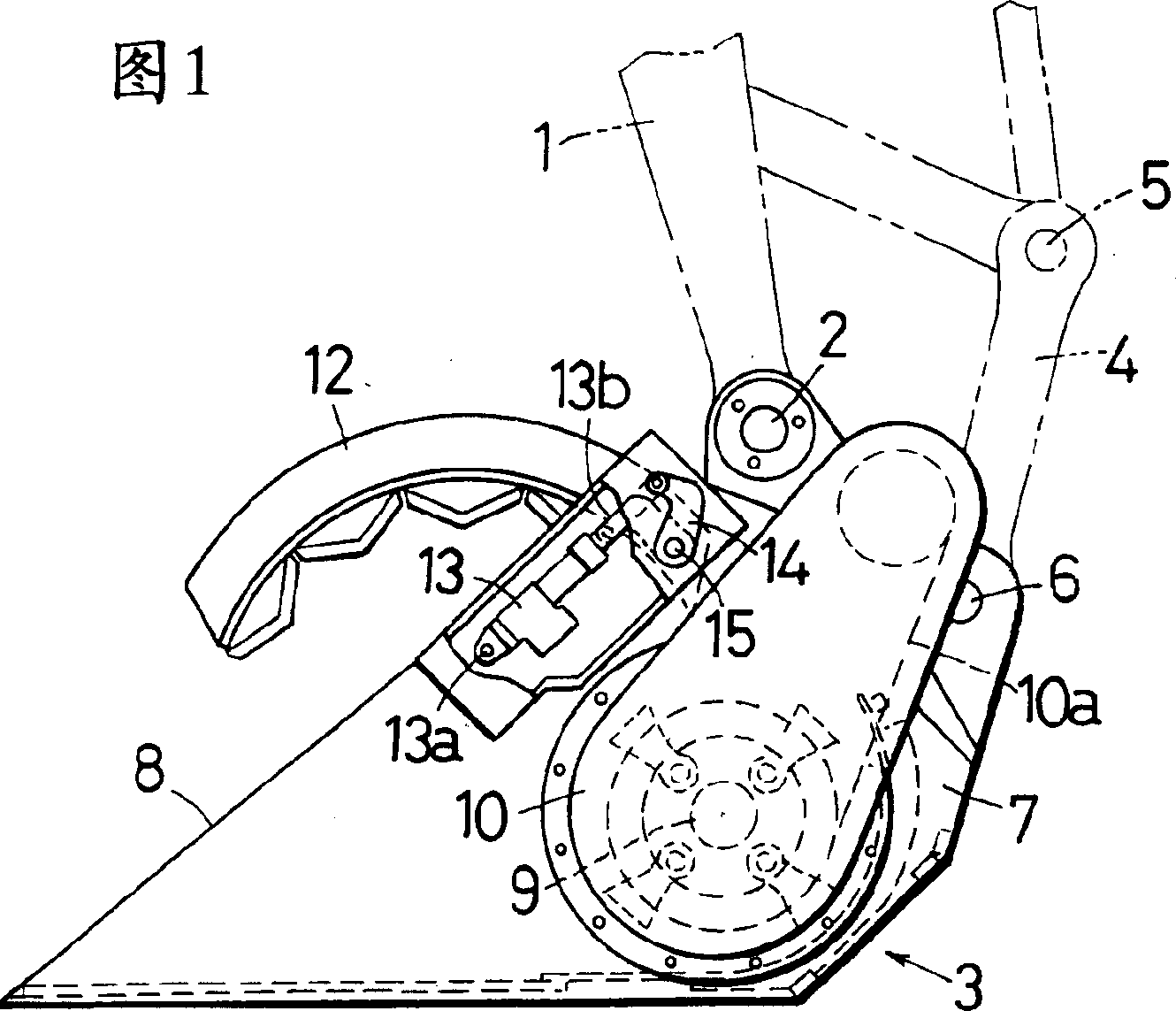

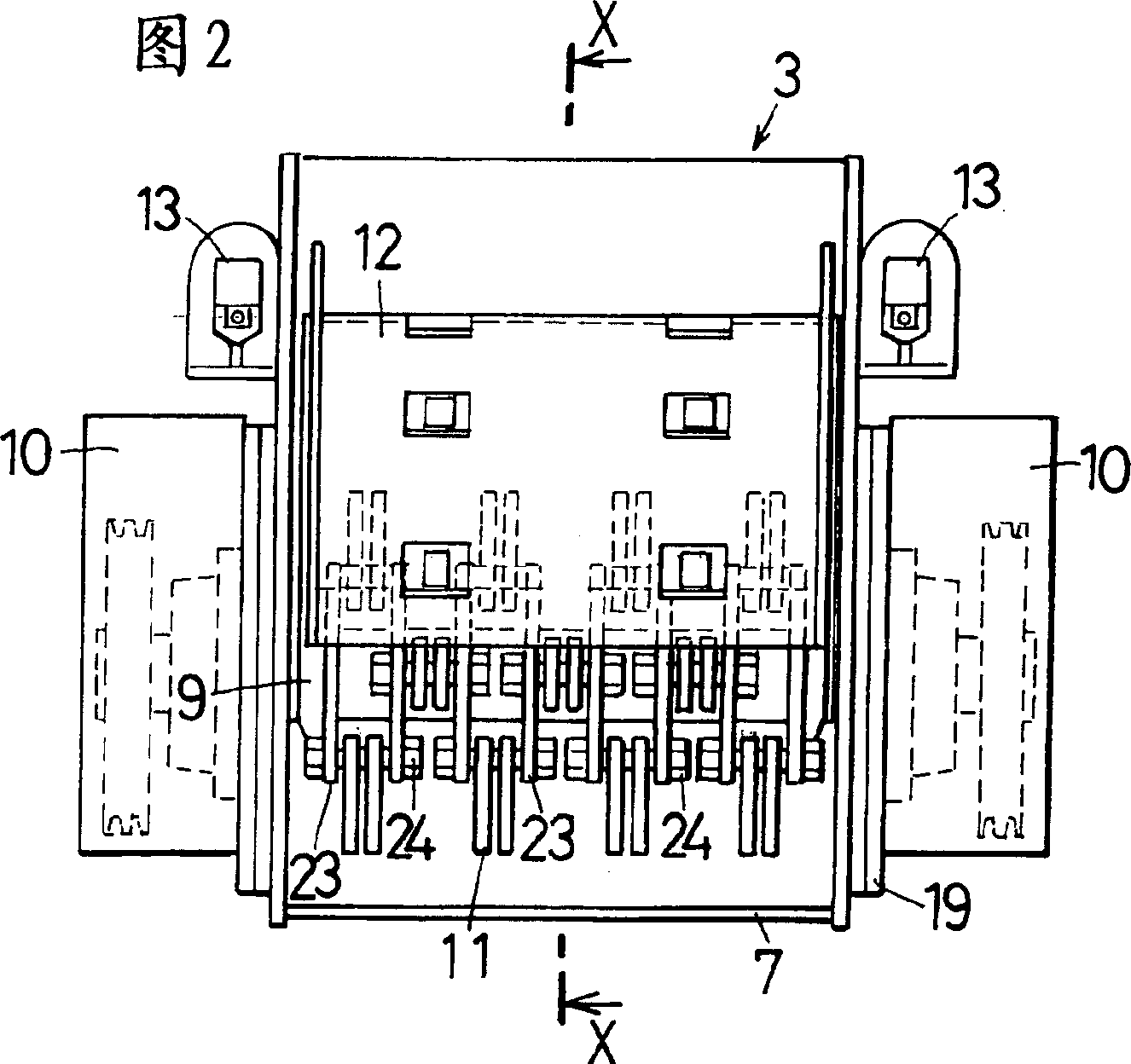

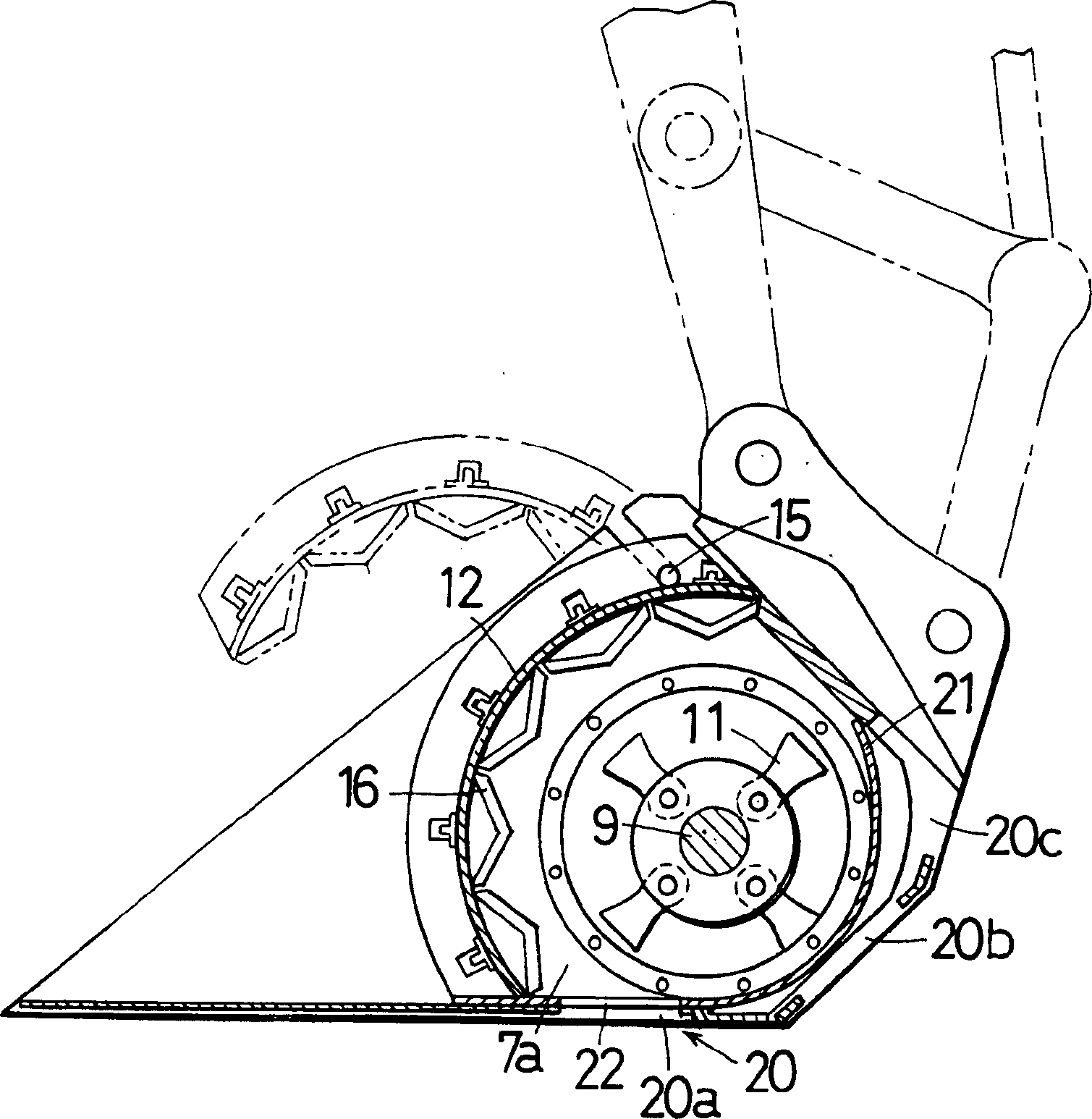

[0041] Embodiments of the present invention will be described in detail below based on a bucket with a crushing cover equipped with crushing teeth for a crushing machine. Fig. 1 is a side view of a bucket with a crushing cover equipped with grinding teeth for a pulverizer according to the present invention, and Fig. 2 is a front view of the bucket with a crushing cover. image 3 It is a cross-sectional view taken along line X-X in FIG. 2 and shows a cross-sectional view corresponding to the side of FIG. 1 . Figure 4 It is a side view of the crushing cover, showing the state where the backwash plate liner is installed on the inner wall and the first splash prevention member is installed on the side wall.

[0042] Figure 5 It is a side view of the crushing cover, showing the state where the backwash liner is attached to the inner wall and the second splash prevention member is attached to the top end. Fig. 6 is an explanatory diagram showing a structure in which the crushing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com