Technology for improving mesh accuracy between screwdown nut and screwdown screw of strip steel rough mill and plate mill

A technology for pressing down nuts and a process method is applied in the technical field of improving the meshing accuracy of pressing nuts and pressing screw rods in strip steel roughing mills and medium and heavy plate rolling mills, and can solve the problems of reducing contact stress, pressing down nuts and pressing down wires. The problem of low contact accuracy of the rod can reduce the contact stress, ensure the reliability and improve the contact accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

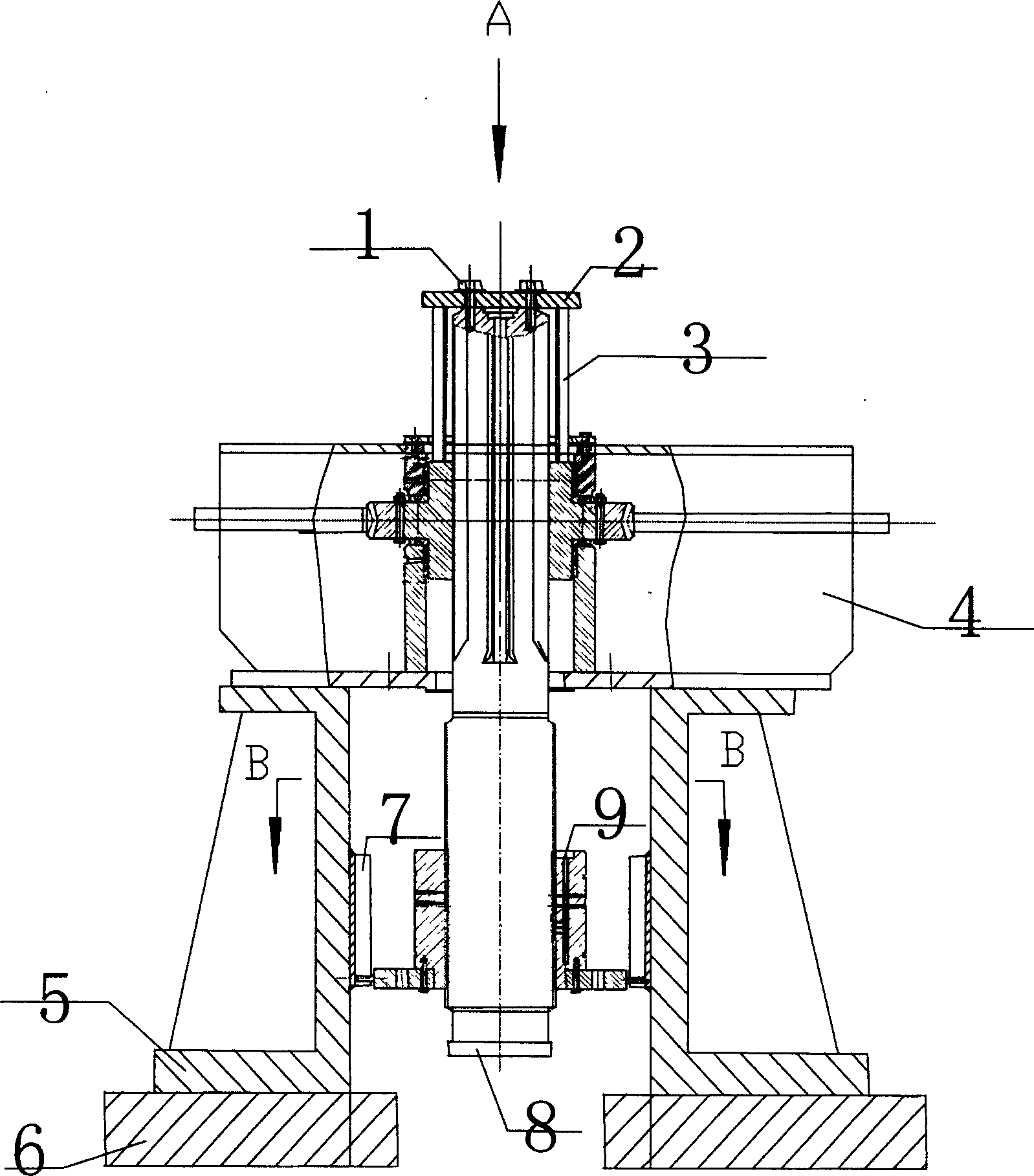

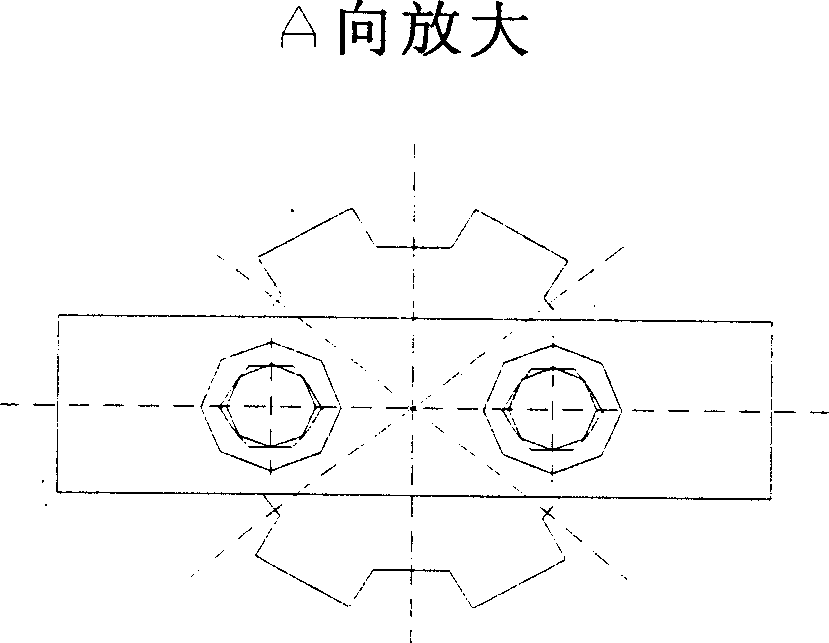

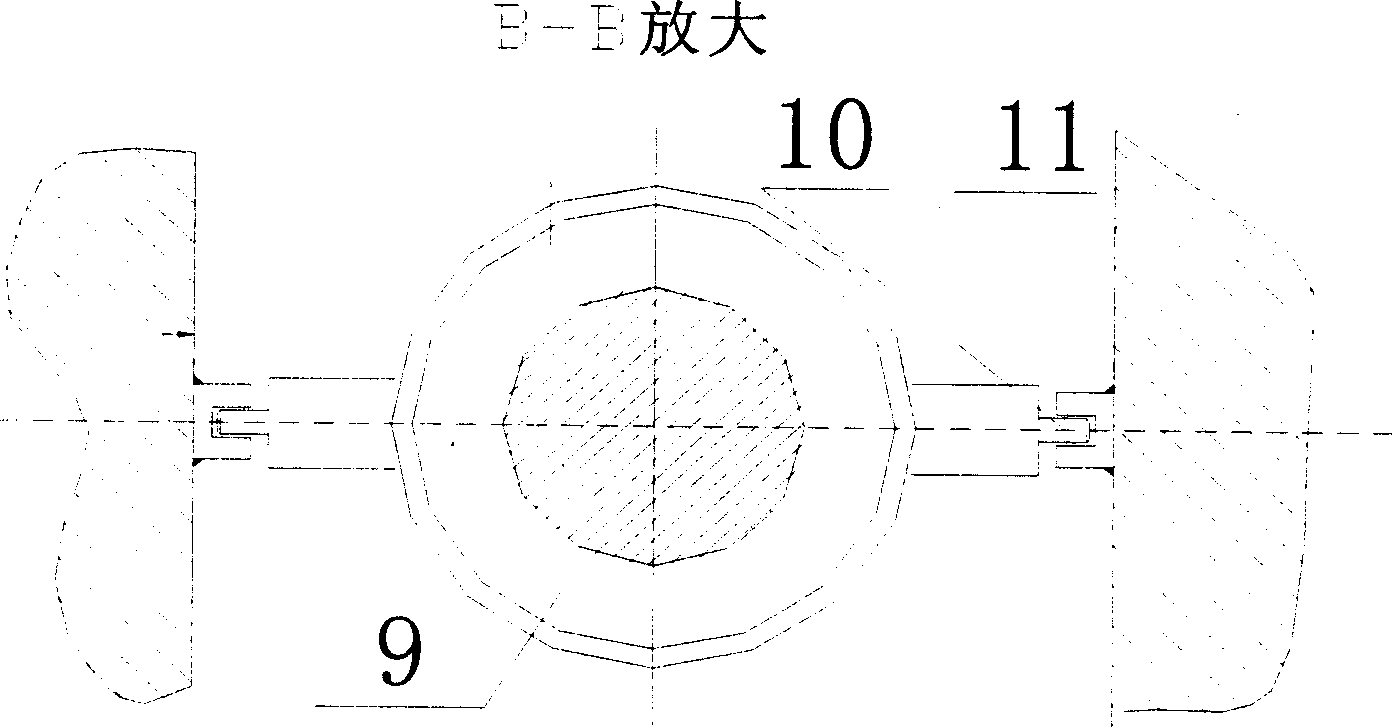

[0016] as the picture shows. A method for improving the meshing accuracy of a pressing nut and a pressing screw rod of a medium and thick plate rolling mill, which is characterized in that it includes a process of installing the pressing nut and the pressing screw rod on special technological equipment for running and grinding. When formulating the research and cooperation process, it is determined that the screw rod is only rotated without displacement, while the nut is moved up and down in a straight line, which is completely opposite to the on-site use situation. The reverse simulates the working state, and the up and down displacement distance is controlled by a delay switch. The total stroke is 500-800mm. The grinding material is added during the grinding process, and the grinding effect is very good. The quality of the produced pressing screws and pressing nuts has reached the international advanced level.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com