Gear box redirection mechanism with floating intermediate wheel

A technology of direction changing mechanism and gear box, which is applied in the direction of gear transmission, belt/chain/gear, transmission device, etc. It can solve the problems of reduced contact accuracy of gear pairs, affecting project progress, and scrapped gearboxes, etc., to improve contact accuracy , extended service life, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

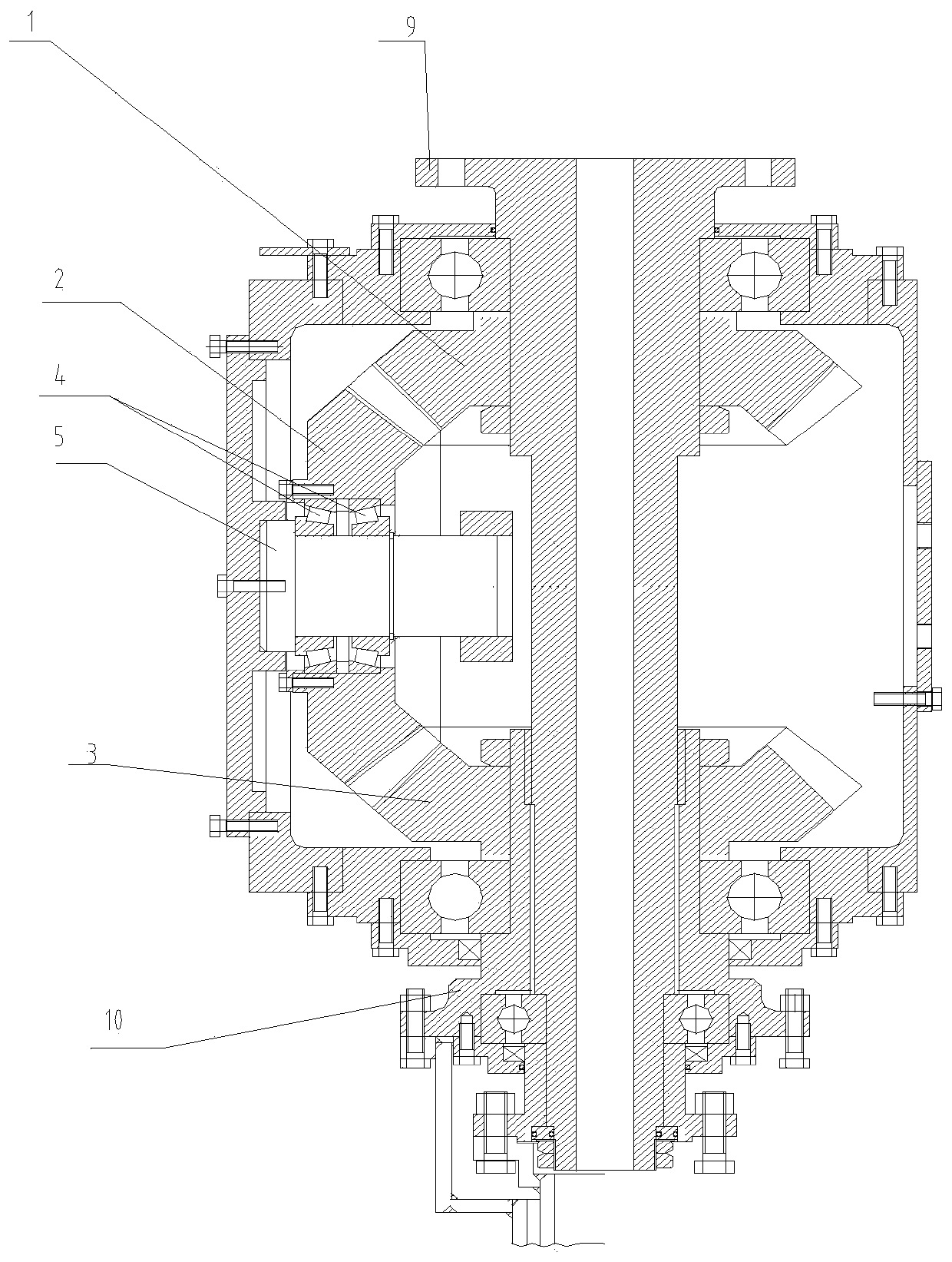

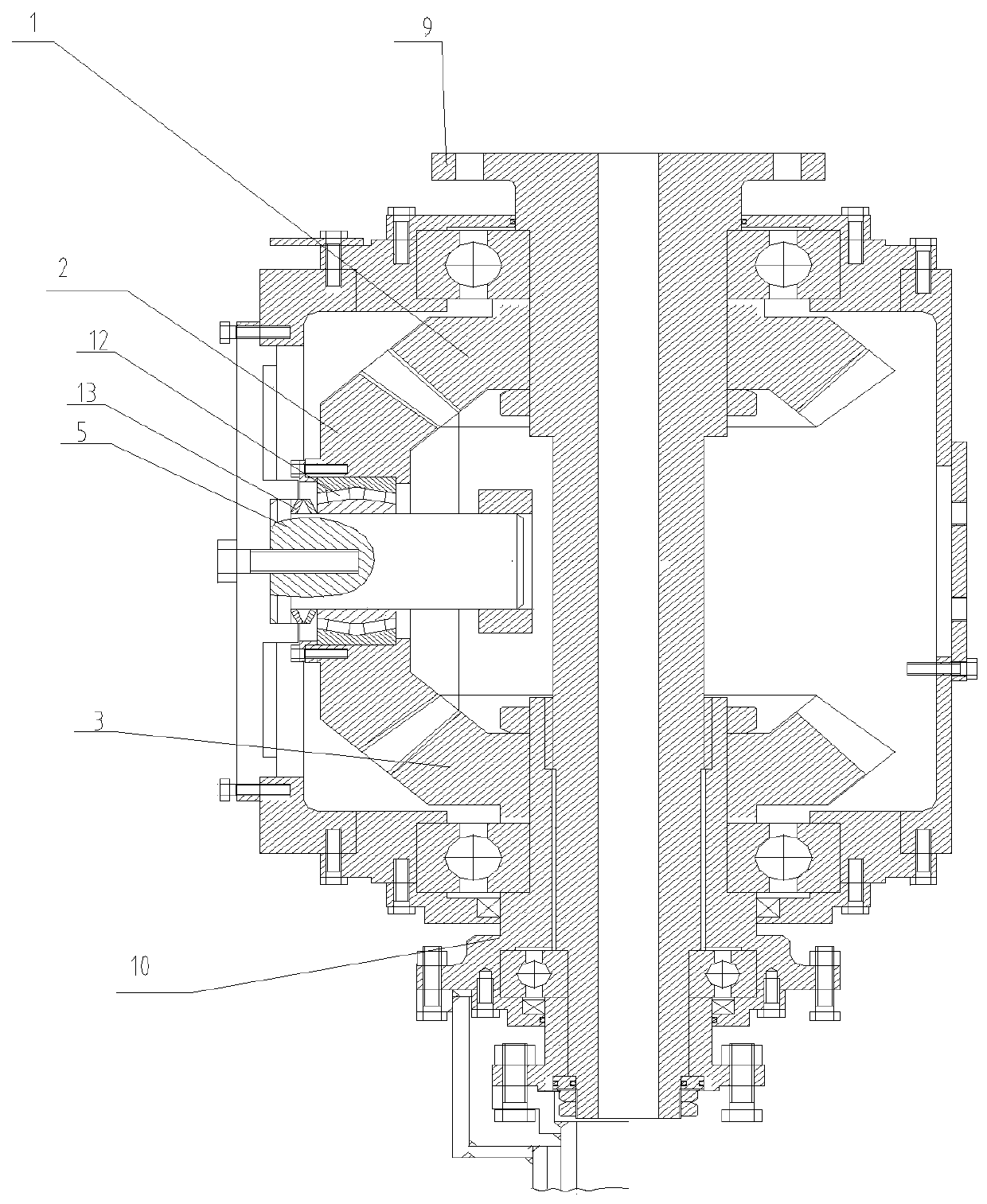

[0015] This embodiment proposes a gear box direction changing mechanism with a floating intermediate wheel, its structure is as follows figure 2 shown. The gear box direction change mechanism uses a set of self-aligning roller bearings 12 to replace the two sets of tapered roller bearings 4 in the prior art. In the center hole of the intermediate wheel 2. Two or more leaf springs 13 are installed on the left end of the intermediate shaft 5 to push the inner ring of the self-aligning roller bearing 12, and the inner ring of the self-aligning roller bearing 12 pushes the rolling body of the self-aligning roller bearing 12, and the rolling body pushes The outer ring of the spherical roller bearing 12 drives the intermed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com