Mist generating device, and dishwasher and washing machine using same

A fog generating device and oscillator technology, which is applied in the field of tableware washing machines and washing machines, can solve problems such as failure of ultrasonic oscillators, inability to operate, and decrease in atomization volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

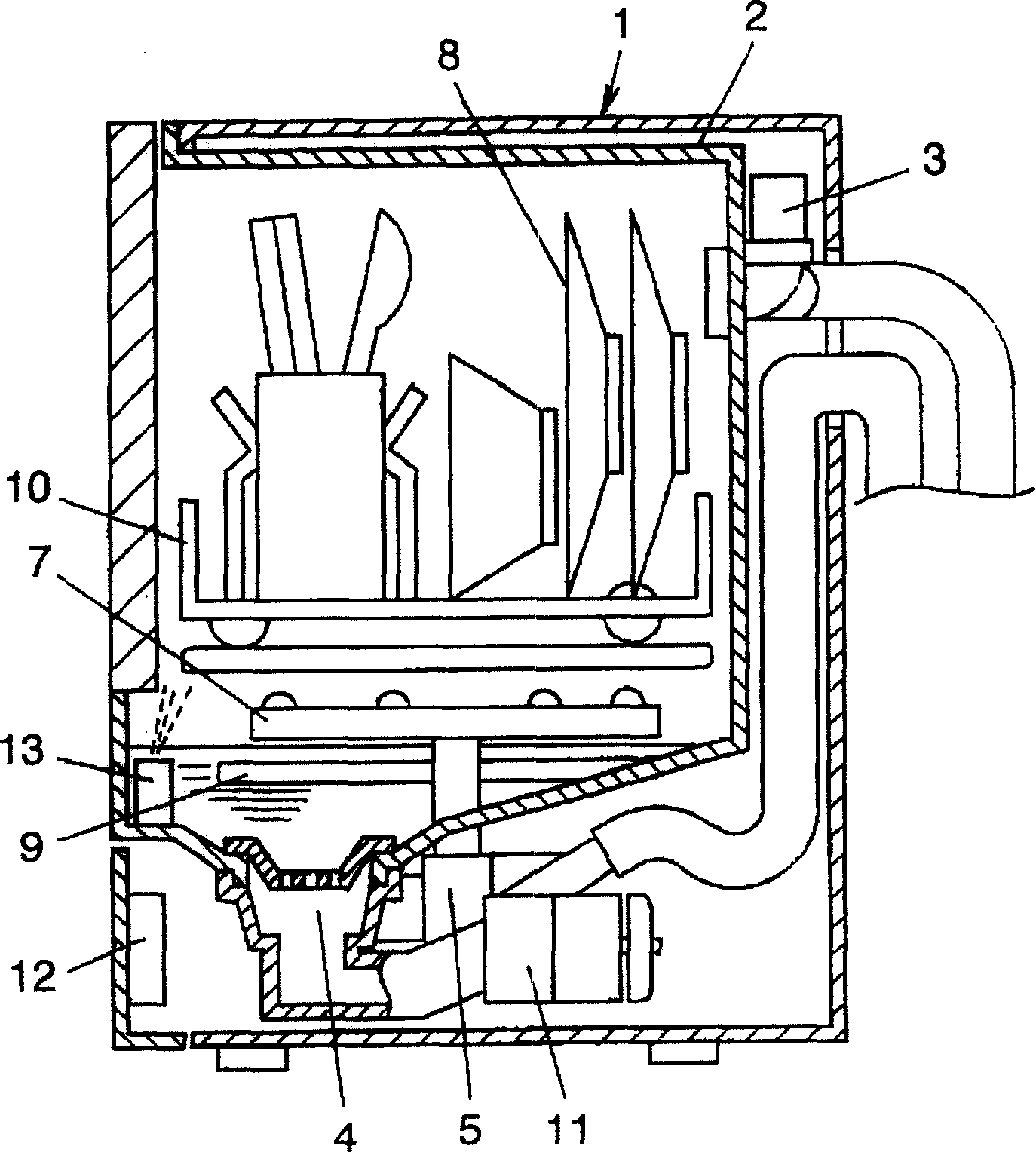

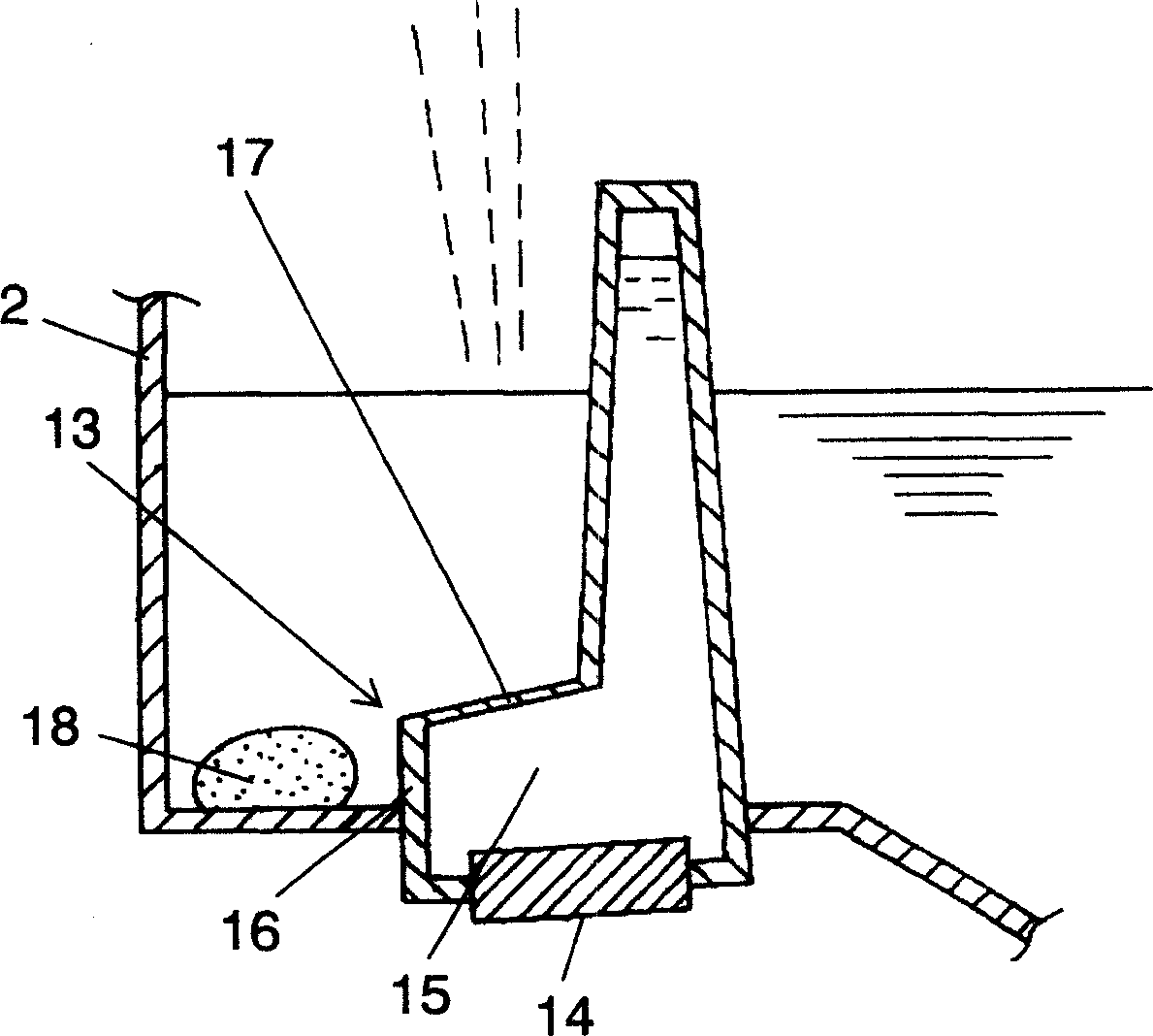

[0021] Refer below figure 1 , figure 2 A first embodiment in which the mist generating device of the present invention is applied to a dishwasher will be described.

[0022] In the dishwasher 1 of the first embodiment of the present invention, as figure 1 As shown, a mist generating device 13 is provided at the front and bottom of the cleaning tank 2 . The structure of this mist generating device 13 is as follows: figure 2 As shown in , the bottom surface is provided with a mist generating oscillator 14 composed of an ultrasonic oscillator, and the upper side of its vibrating surface is provided with a container 16 encapsulating the liquid 15, and the liquid 15 and the container 16 are integrated. state. Furthermore, the surface of the container 16 facing the ultrasonic oscillator 14 is formed by a film 17 . In this way, the ultrasonic vibration caused by the mist generating oscillator 14 vibrates the film 17 on the container 16 through the sealed liquid 15, and the l...

no. 2 Embodiment

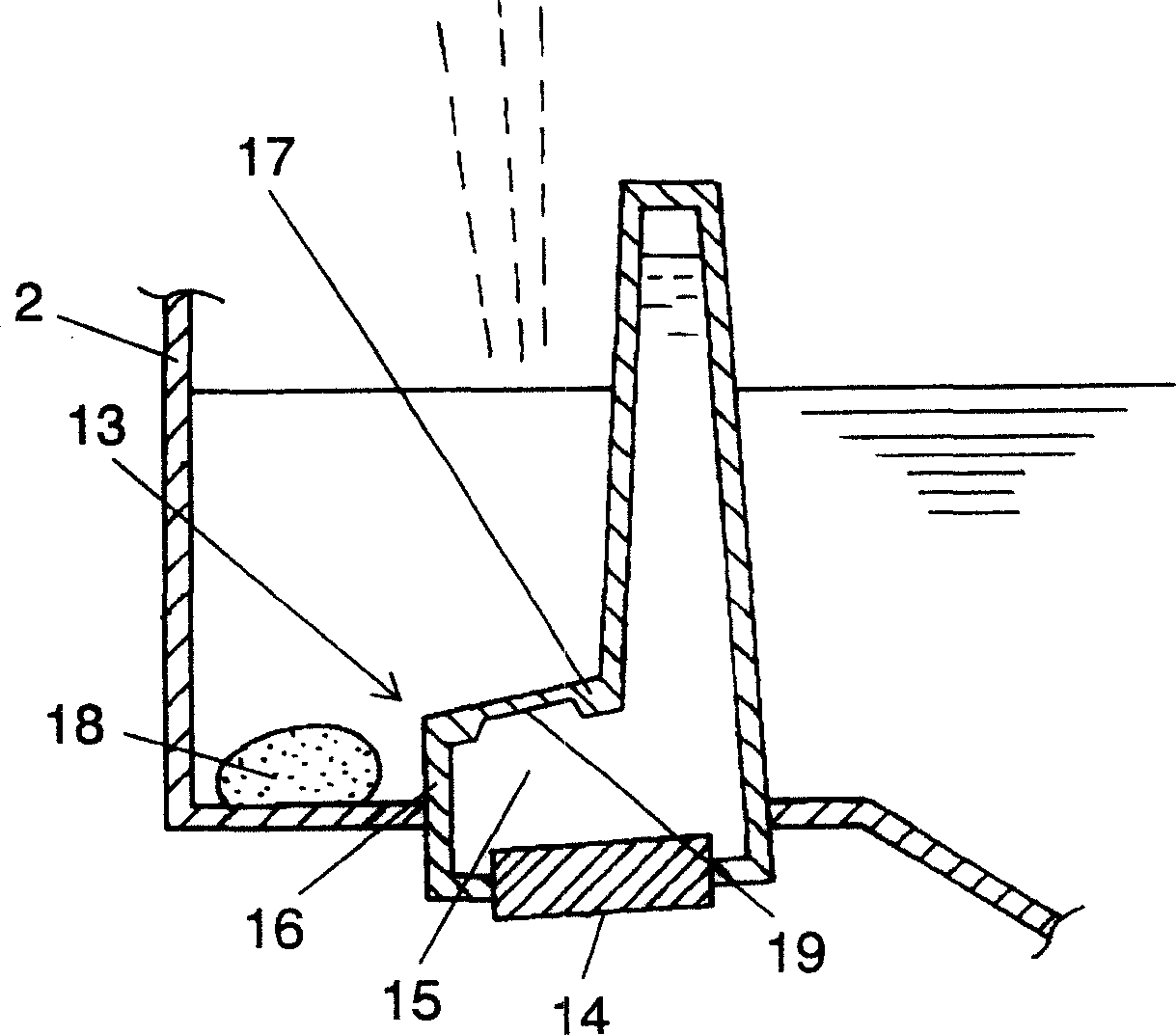

[0039] Next, refer to image 3 A second embodiment of the present invention will be described. In addition, when new embodiments are described below, the same components as those of the previously described embodiments are assigned the same reference numerals, and repeated description thereof will be omitted, and only differences will be described.

[0040] In the second embodiment of the present invention, such as image 3 As shown in , the film 17 is structured such that a concave portion 19 is formed on the surface facing the mist generating oscillator 14 in the container 16 of the mist generating device 13 . In addition, the concave portion 19 is provided on the surface side in which the liquid 15 is sealed. In addition, this concave portion 19 is formed by compressing a part of the surface facing the mist generating oscillator 14 in the thickness direction after resin injection when extruding the container 16 .

[0041] After adopting this structure, since the film 17 ...

no. 3 Embodiment

[0044] Next, refer to Figure 4 A third embodiment of the present invention will be described in detail.

[0045] In the third embodiment of the present invention, as Figure 4 As shown in , in the container 16 of the mist generating device 13, an opening 16a is formed on the surface facing the mist generating oscillator 14, and the opening 16a is airtightly covered by a sheet-like resin 20. The resin 20 constitutes the film 17 described above.

[0046] After adopting this structure, since an opening 16a is provided on the face facing the mist generating oscillator 14 of the container 16, and this opening 16a is airtightly covered by the sheet-like resin 20 to form the film 17, Therefore, even if the container 16 is formed of a resin with poor fluidity, the thin film 17 through which ultrasonic waves can easily pass can be formed on the surface of the container 16 facing the mist generating oscillator 14 . In addition, by constituting the thin film 17 with a sheet-like resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com