Hydraulic ABS device for motor vehicle

A technology of anti-lock braking and motor vehicles, applied in the direction of brakes, etc., can solve the problems of reducing the sensitivity of anti-lock braking devices, affecting the adaptability of anti-lock braking, prolonging the information transmission time, etc., and achieving volume reduction , large amplitude, and improved sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

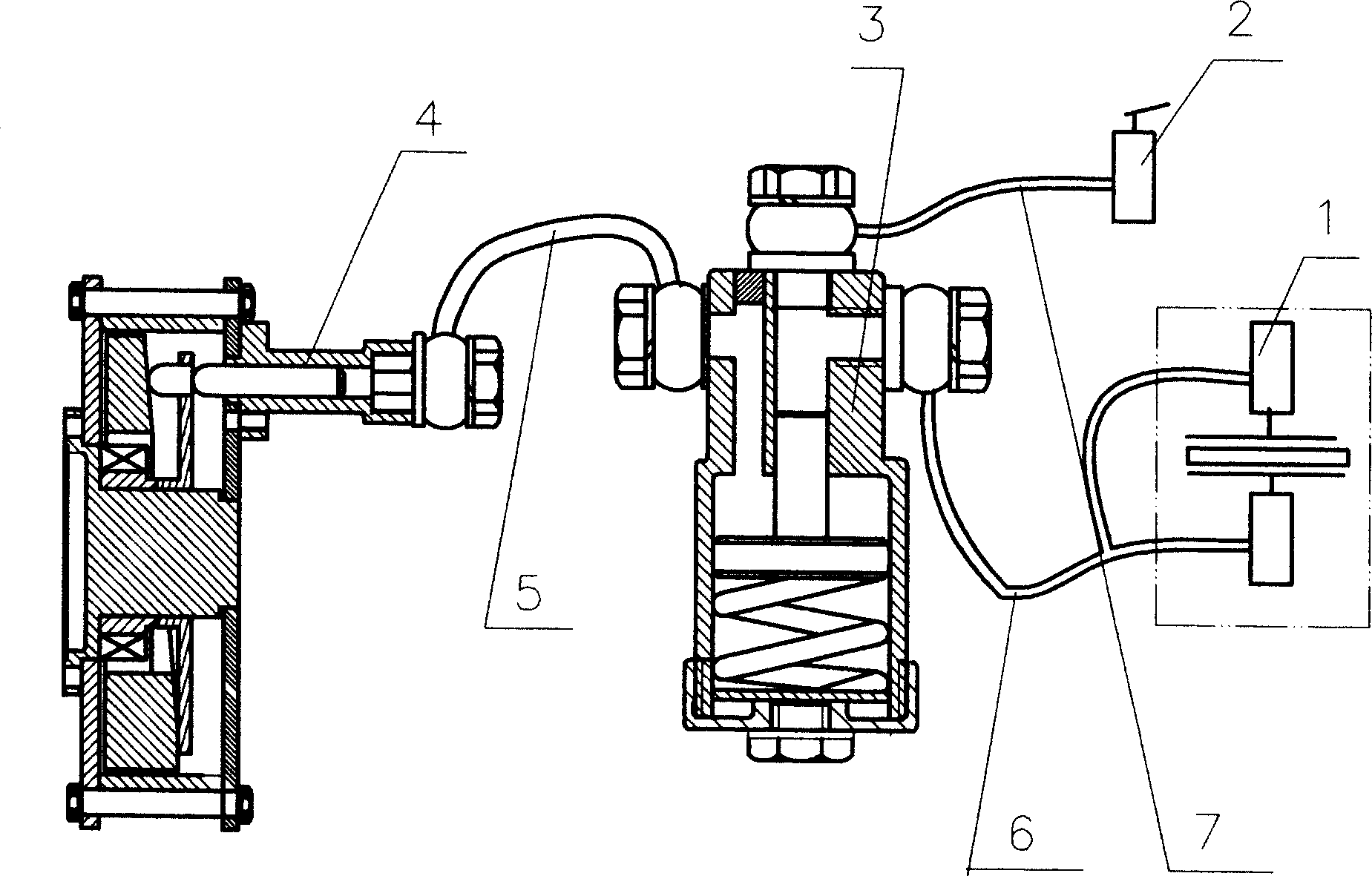

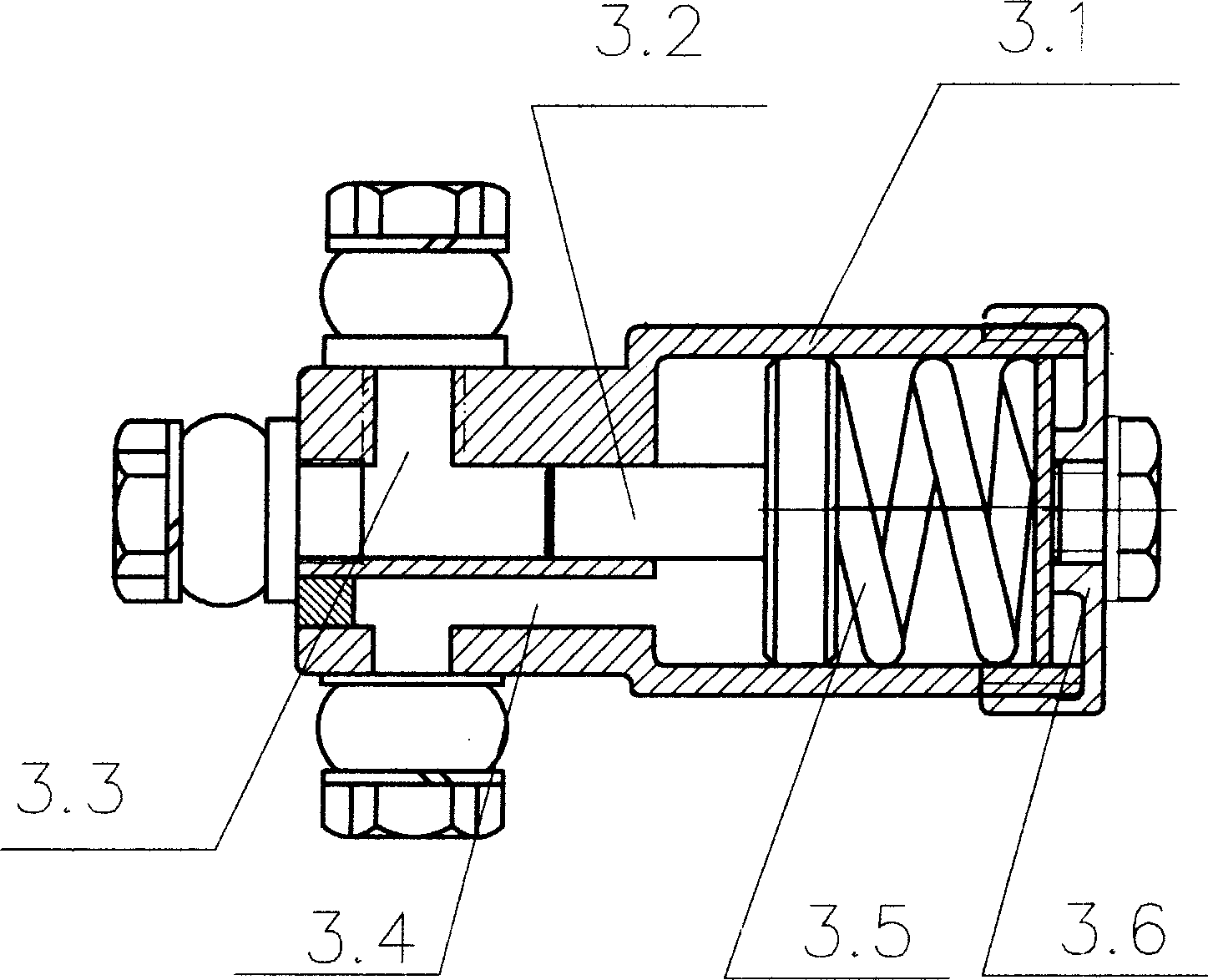

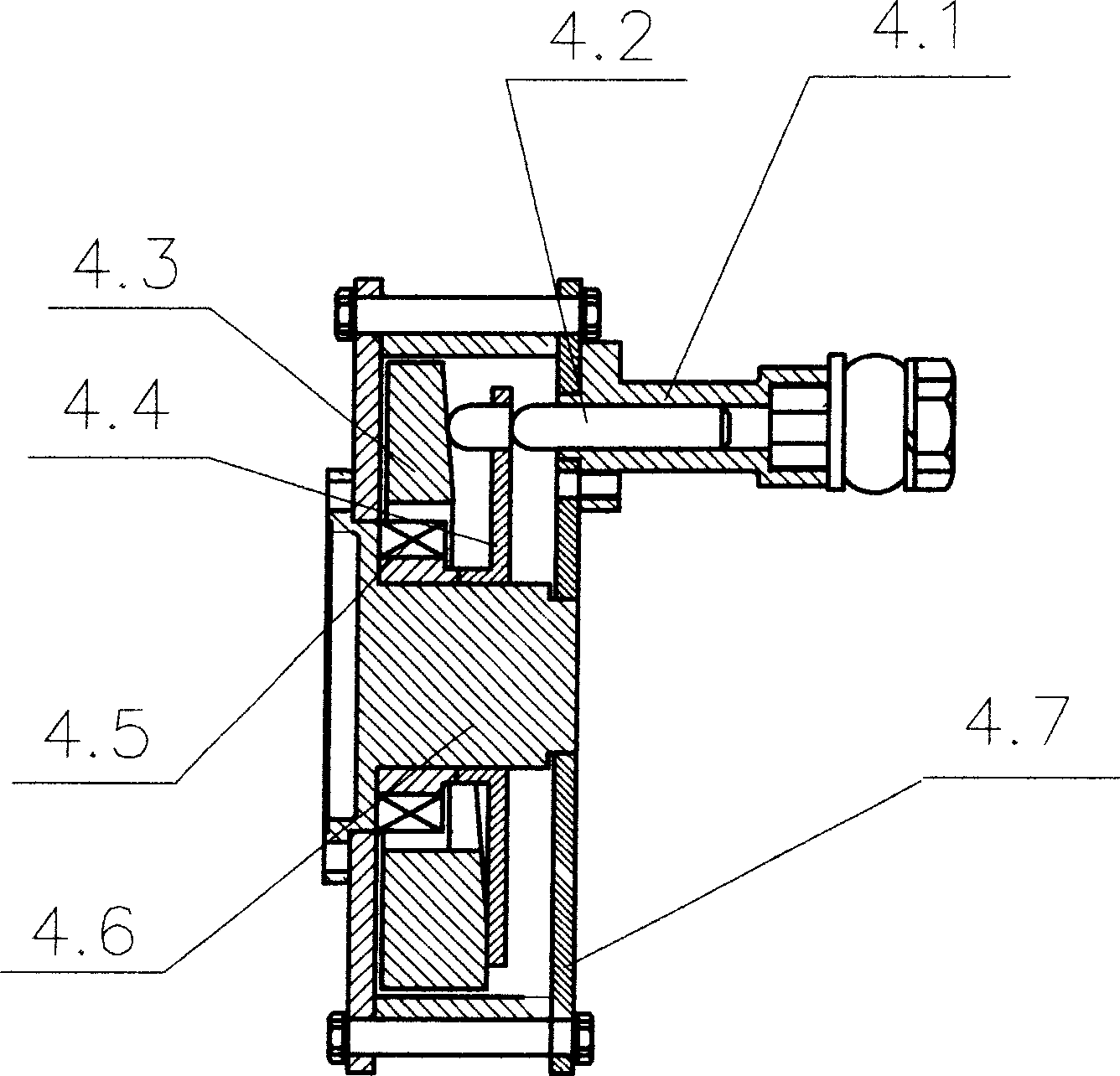

[0020] A motor vehicle hydraulic anti-lock braking device, comprising a brake pump 1, a brake 2, and a brake pressure adjusting device 3, characterized in that the brake pressure adjusting device 3 consists of a housing 3.1, a stepped plunger 3.2, a spring 3.5, composed of end cover 3.6, the stepped plunger 3.2 is installed in the working chamber of the housing 3.1, the spring 3.5 is pressed against the outside of the large end of the stepped plunger 3.2 through the end cover 3.6, and the stepped plunger 3.2 divides the working chamber into a brake chamber 3.3 and the control chamber 3.4, the brake chamber 3.3 communicates with the brake pump 1 and the brake 2 through the oil inlet and outlet pipes 7 and 6 respectively, the control chamber 3.4 communicates with the control pressure regulating device 4 through the oil pipe 5, and the control pressure regulating device 4 It is composed of cylinder 4.1, plunger 4.2, flywheel 4.3 with end cam, shaft push plate 4.4 with push rod and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com