Detection standardization experimental apparatus platform for high-temperature high-pressure chemical sensor

A technology for chemical sensors and experimental devices, applied in measurement devices, scientific instruments, instruments, etc., can solve problems such as easy failure, damage to electrodes, short circuit of measurement circuits, etc., and achieve good sealing effect and high sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

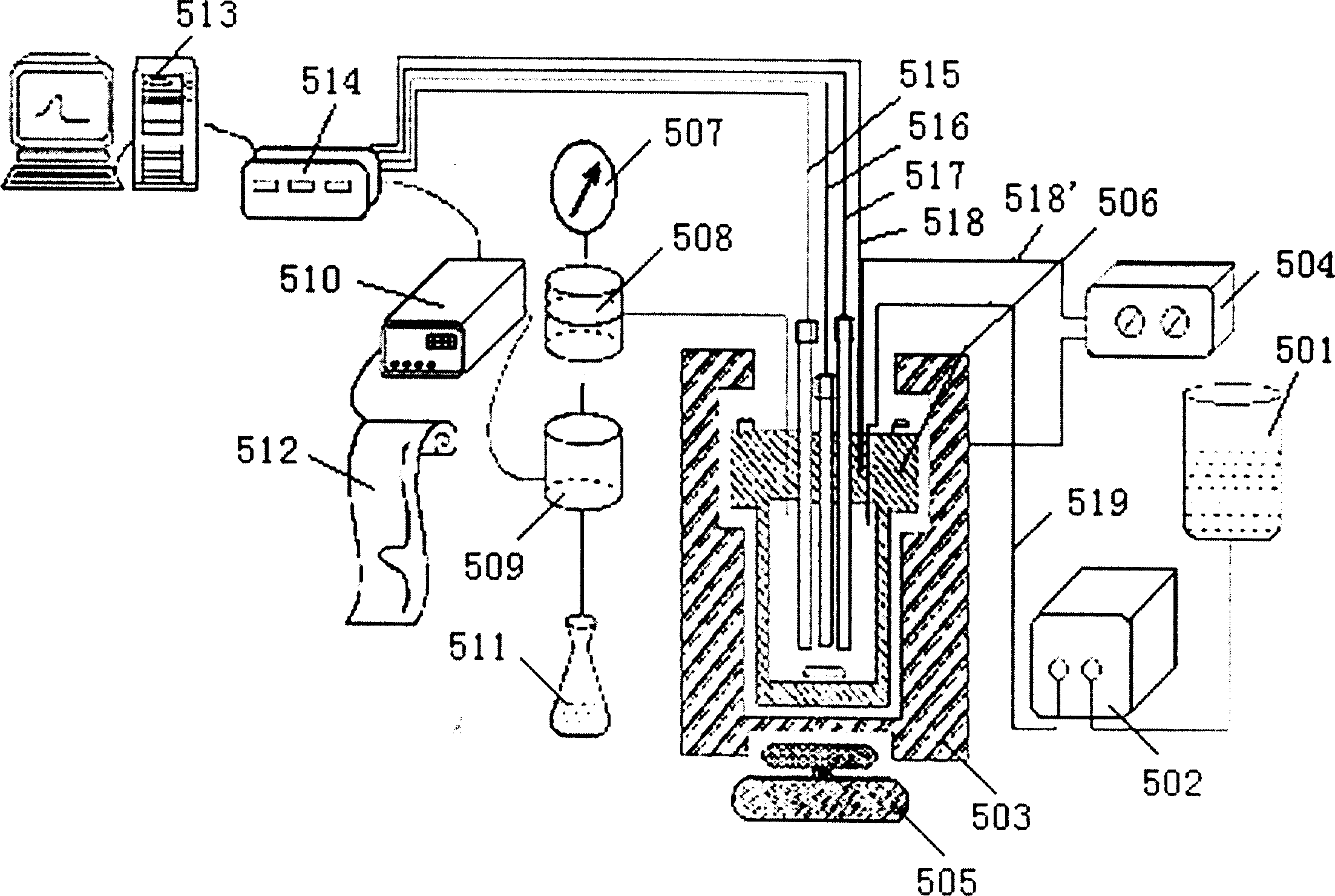

[0071] Such as figure 1 As shown, a high-temperature and high-pressure solution pH chemical sensor detection and calibration experimental device platform includes an autoclave 506 capable of installing multiple chemical probes of pH chemical sensors, and also includes a high-temperature and high-pressure flow system connected to the autoclave 506, which includes a medium Input system and media output system.

[0072]The medium input system includes a high-pressure liquid pump 502, the input end of which is connected to a liquid container 501 through a pipeline, and the output end is connected to the fluid inlet on the autoclave 506 through a high-pressure pipeline; the medium output system includes a high-pressure meter 507, a back The pressure controller 508, the output solution pipeline, the liquid collection container 511, and the liquid output port of the autoclave are sequentially connected to the high pressure meter, the back pressure controller and the output solution cont...

Embodiment 2

[0098] Such as Figure 6 As shown, it is a kind of H 2 High temperature and high pressure of autoclave for chemical sensor H 2 Chemical sensor detection and calibration experimental device platform.

[0099] The H 2 Chemical sensor detection and calibration experimental device platform, including the ability to install H 2 The tubular autoclave 602 of the multiple chemical probes 603 of the chemical sensor is made of titanium (or Hastelloy), which is installed with high pressure and high temperature H 2 Tubular autoclave for chemical sensors. There are 4 electrode jacks. The electrode jacks are arranged on the evenly distributed circumferential side wall in the middle of the autoclave and are located on the same horizontal plane. Two of the holes are M20 and two are M8. Four chemical sensor electrodes are inserted on the side wall of the autoclave. In this embodiment, three electrodes can be inserted: Au (or Pt) electrode, YSZ / HgO / Hg electrode and Zr / ZrO 2 electrode. The above-men...

Embodiment 3

[0127] Such as Picture 9 As shown, the experimental device platform is equipped with two sets of autoclaves, which share a liquid input system. The liquid outlet of each autoclave is connected to its own liquid output system. The two autoclaves are each equipped with several chemical sensor electrodes. It can either be connected to their respective electrochemical parameter measurement system, or can be connected to an electrochemical parameter measurement system for data collection and display. Specifically, the input port of the high-pressure liquid pump 904 is connected to the solution bottle 910 through a pipeline, and the output port of the high-pressure liquid pump is connected to a three-way, leading out two branch pipes, each of which is provided with a stop valve 911. The branch pipes are each connected to the liquid inlet of an autoclave 902. The two autoclaves 902 are provided with a number of chemical sensor electrodes 901, which are all connected to the data collecto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com