Supersonic cleaning fixture

A technology of ultrasonic cleaning and fixtures, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of metal surface peeling off, easy to be blocked, inconvenient disassembly and assembly, and achieve the effect of reducing adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The ultrasonic cleaning fixture of the present invention will be further described below in conjunction with the examples, but the scope of protection of the present invention should not be limited by this.

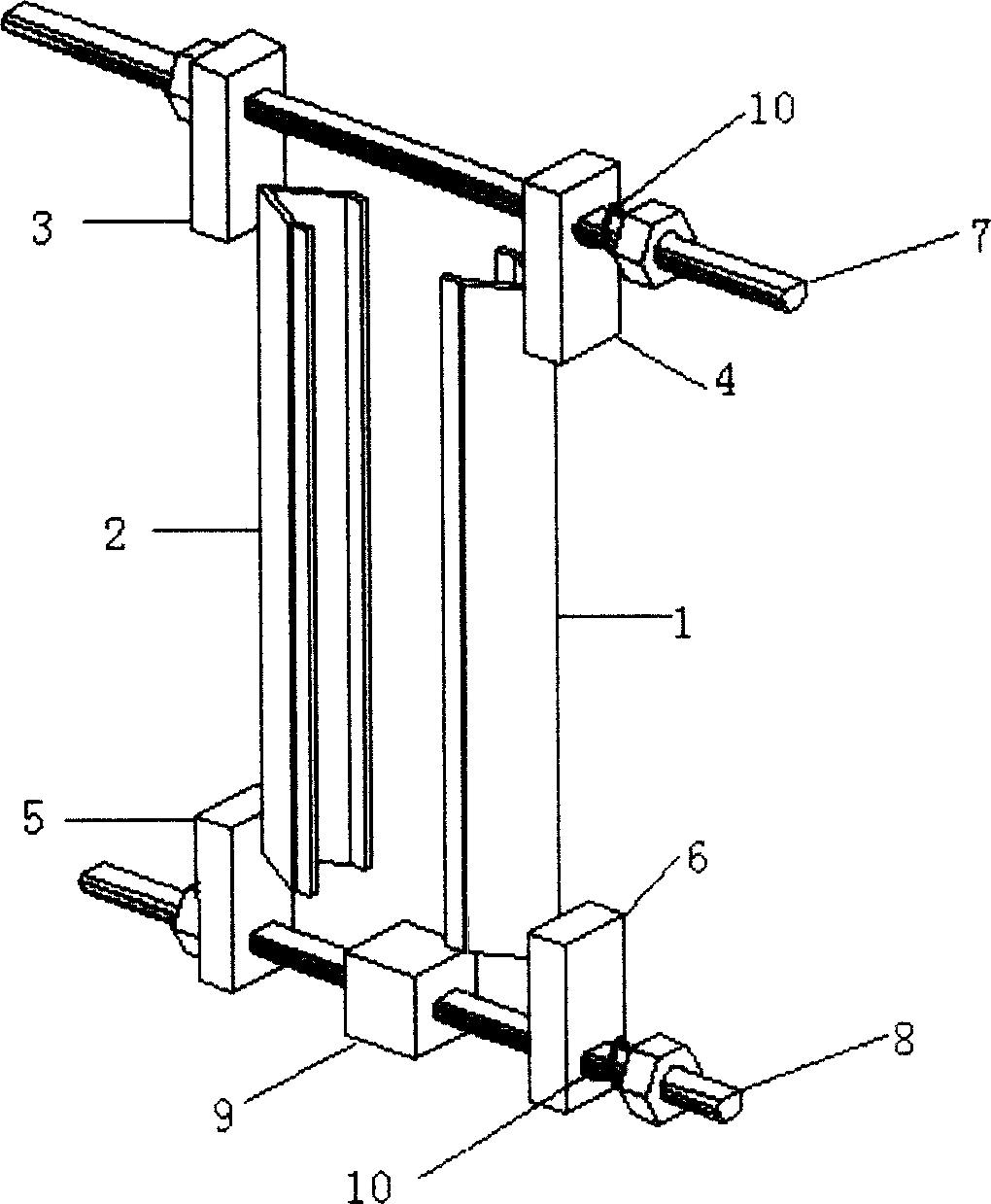

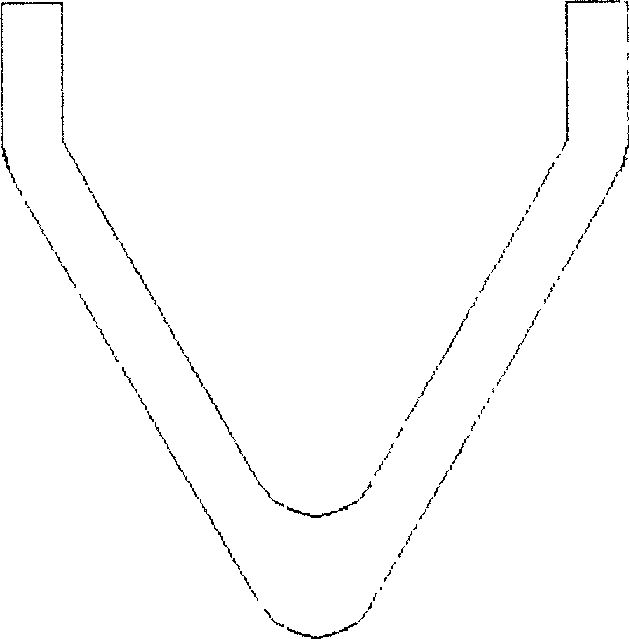

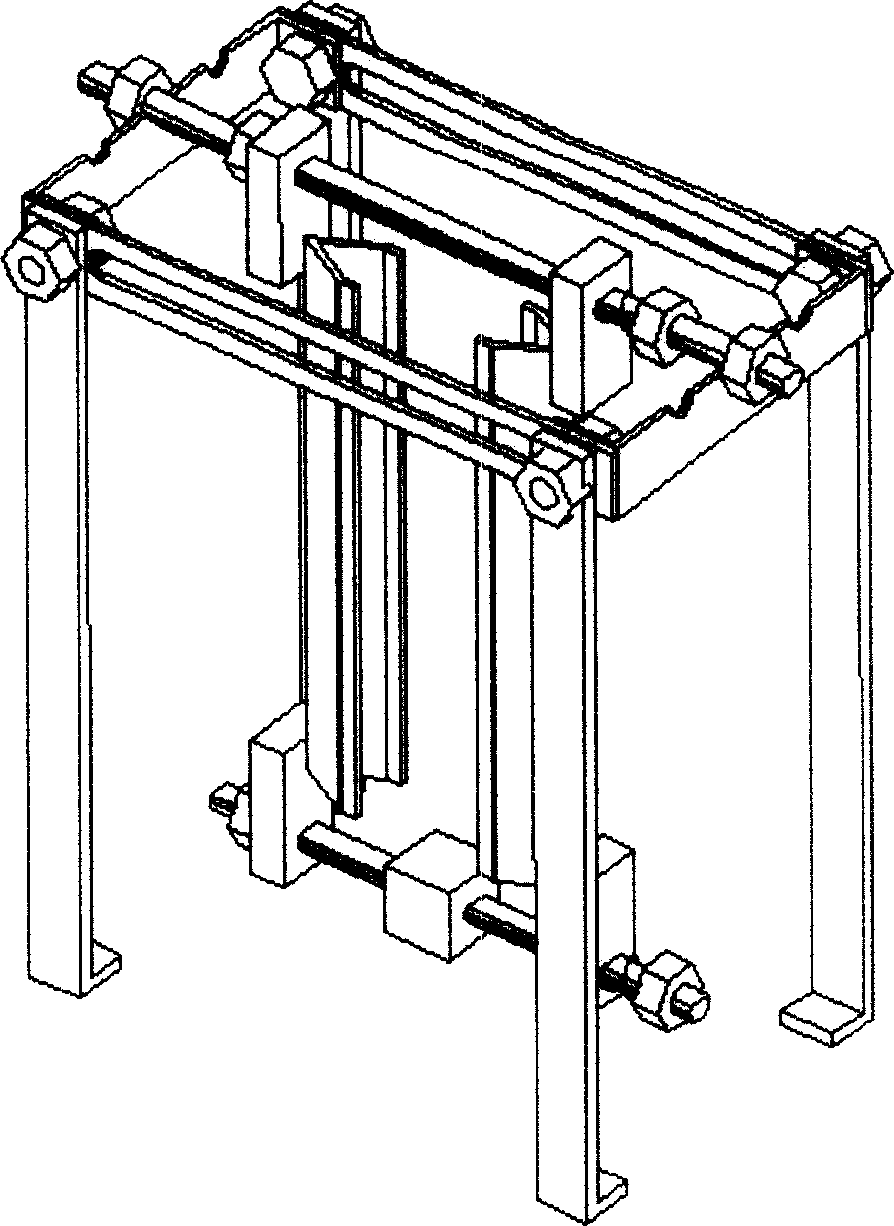

[0019] see first figure 1 and figure 2 , figure 1 It is a structural schematic diagram of an embodiment of the ultrasonic cleaning jig of the present invention. It can be seen from the figure that an ultrasonic cleaning fixture of the present invention is composed of: the first triangular clamp arm 1 and its upper block 4 and lower block 6 are fixed together; the second triangular clamp arm 2 and its upper block 3 and lower block 5 fixed together; the upper block and the lower block shown are provided with corresponding through holes; a long upper positioning screw 7 and a short lower positioning screw 8, and the lower positioning screw 8 passes through the fastening nut in turn screw hole, buffer spring 10, the through hole of block 6 under the first triangula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com