Electronic gearshift apparatus of sub gearshift for 4 wheel drive vehicle

一种变速装置、四轮驱动的技术,应用在传动装置控制、控制装置、车辆部件等方向,能够解决厌烦、疲劳、很难多样化变速等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

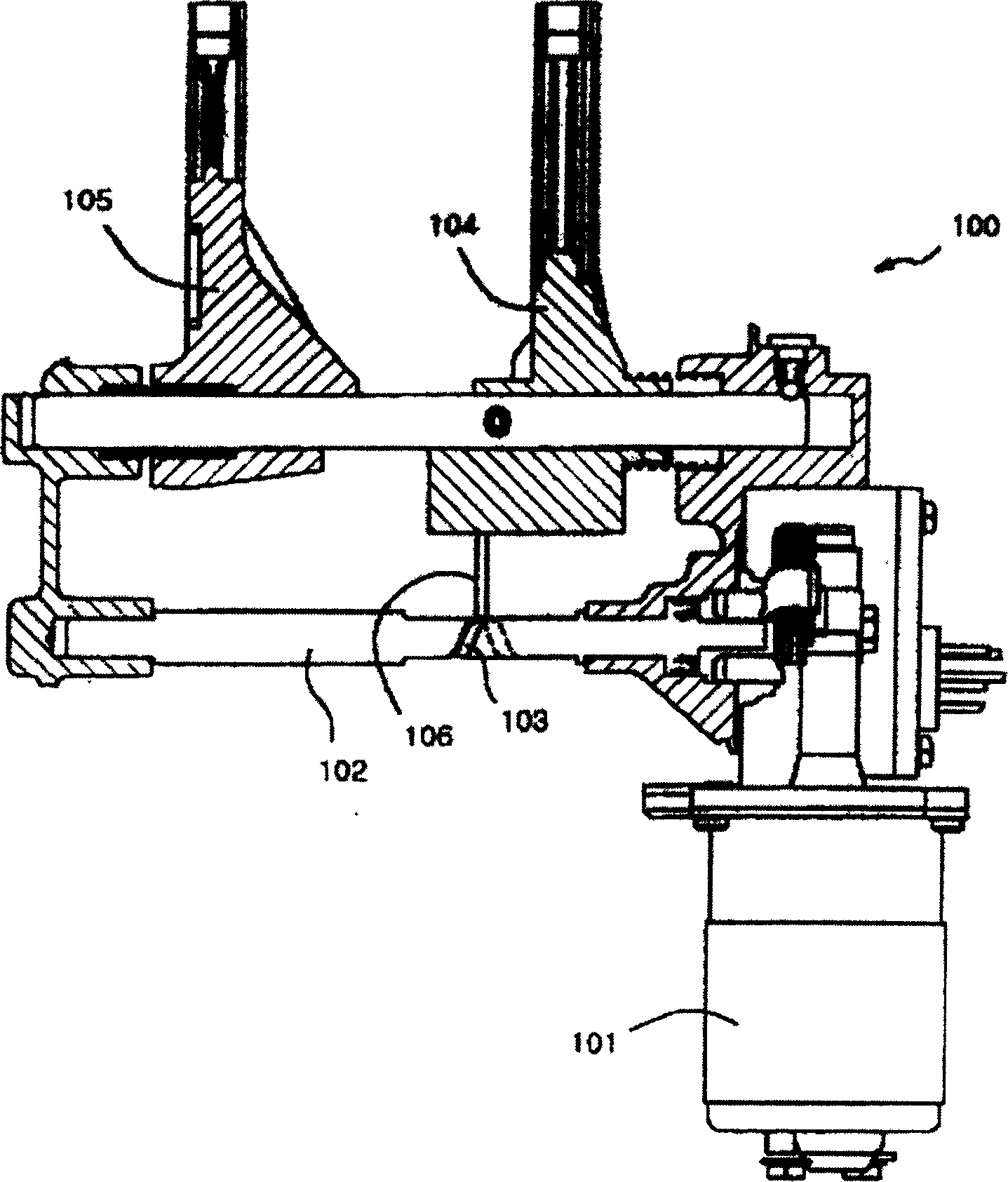

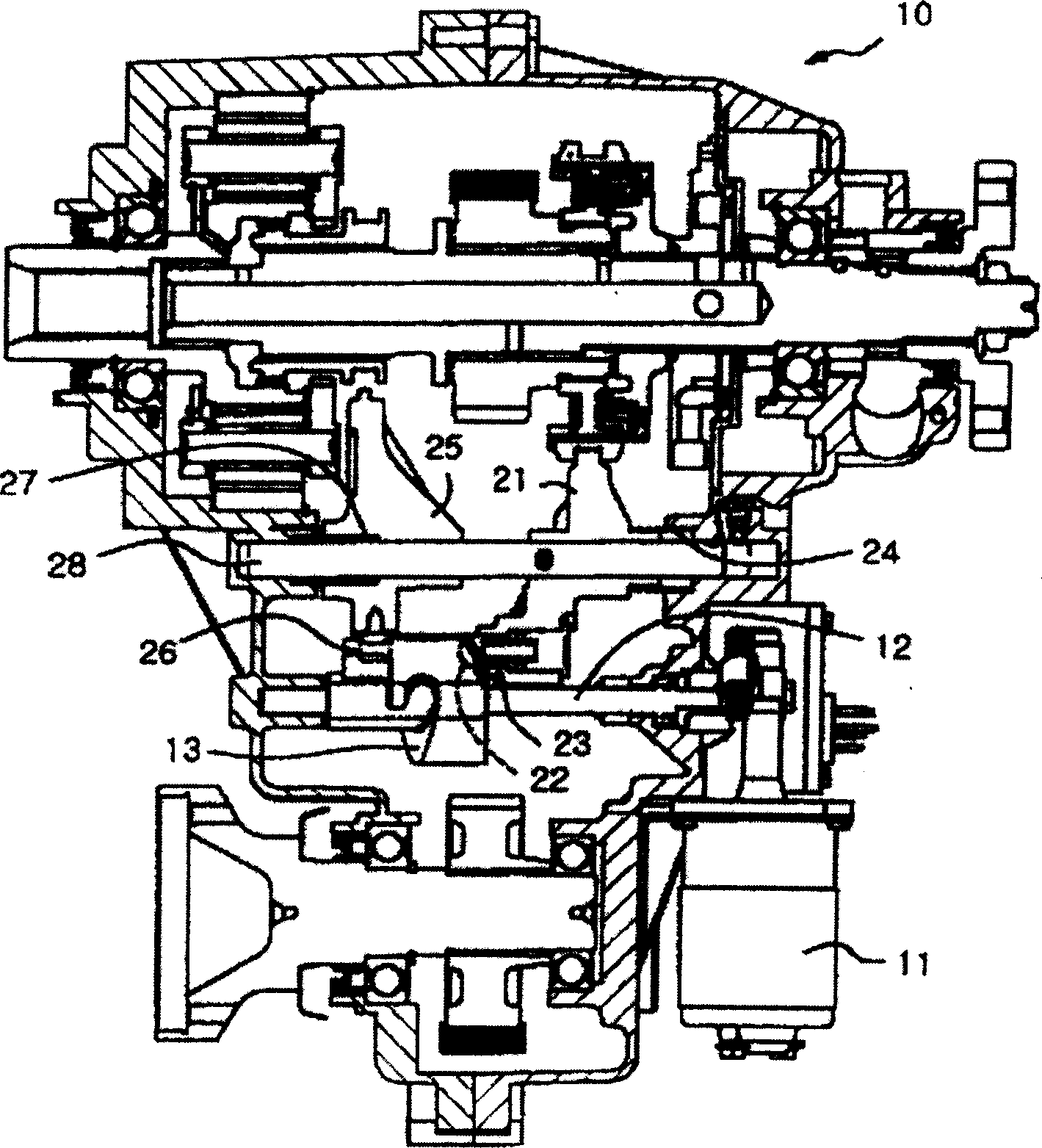

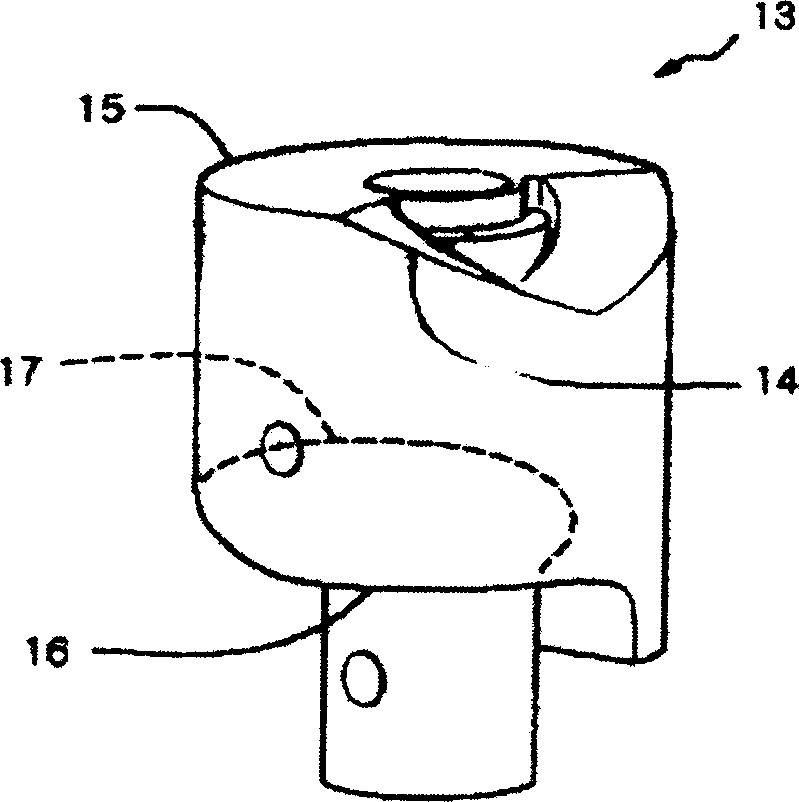

[0028] The preferred implementation device of the present invention will be described in more detail below, please refer to the accompanying drawings. The same or similar parts will be given the same reference number throughout all drawings and descriptions.

[0029] figure 2 It is a cross-sectional view of an electronically controlled gearbox assembly consistent with the preferred implementation device of the present invention; image 3 and Figure 4 Respectively, the perspective views of the cams of the electronically controlled gearbox assembly set forth in the present invention; Figure 5-7 It is a cross-sectional view of the operating state of the electronically controlled gearbox assembly explained in the present invention.

[0030] The electronic transmission device 10 of the four-wheel drive vehicle transmission assembly consistent with the preferred implementation device of the present invention is composed of a motor 11 and a camshaft 12 driven by the motor 11 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com