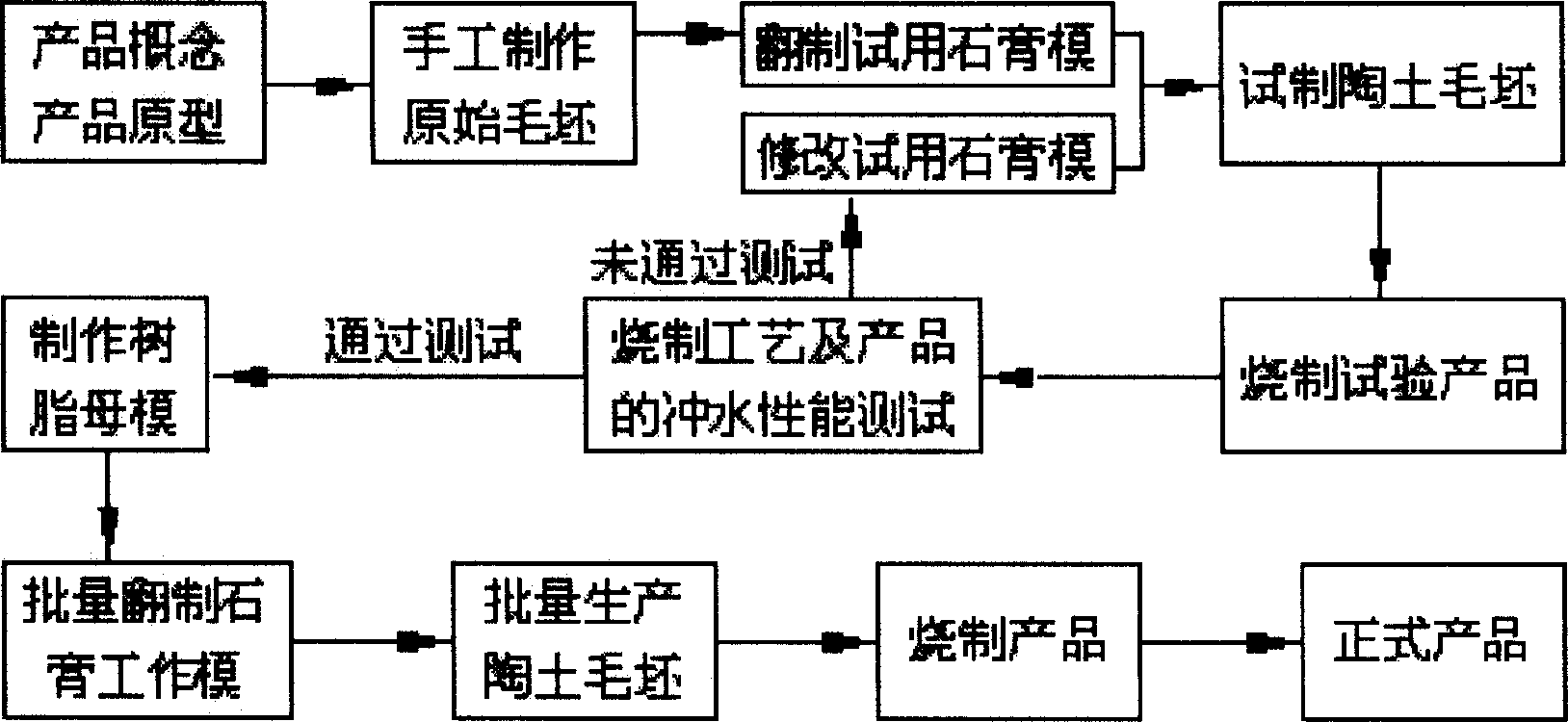

Fast moulding method of ceramic toilet based on CAD/CAE/CAM

A toilet and CAE technology, which is applied in the field of rapid molding of ceramic toilets, can solve the problems of low precision of original blanks, consume a lot of time and money, and achieve the goal of enhancing research and development capabilities, saving time and costs, and reducing development and production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

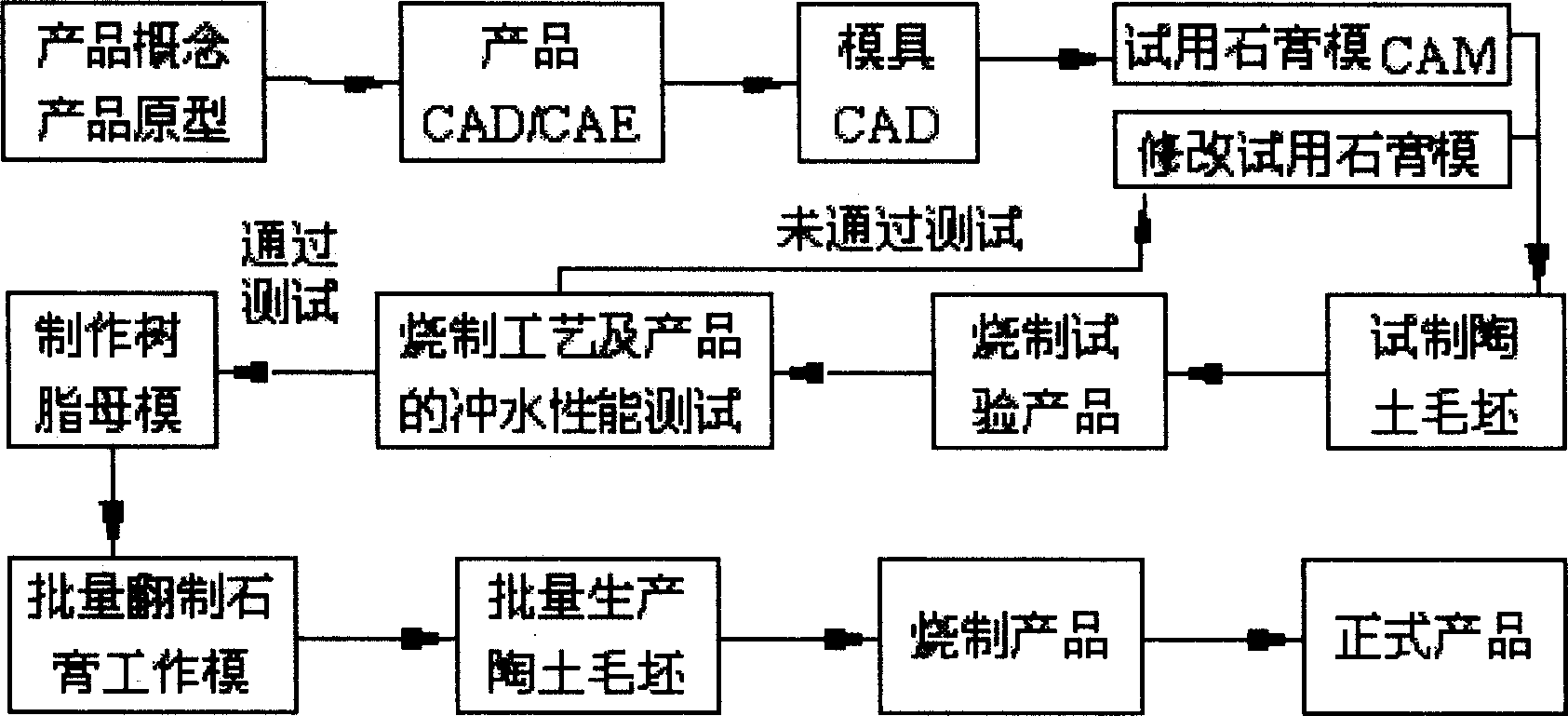

[0019] The molding flow chart of the present invention is as figure 2 Shown, the present invention is based on the CAD / CAE / CAM ceramic sanitary product rapid modeling method and comprises the following steps:

[0020] 1) Computer-aided design and aided engineering (CAD / CAE) of products;

[0021] 2) Computer-aided design (CAD) of plaster molds for test products;

[0022] 3) Computer-aided manufacturing (CAM) of plaster molds for test products;

[0023] 4) Pouring the clay blank of the test product;

[0024] 5) firing test products;

[0025] 6) The flushing performance test of the test product and the modification of the plaster mold;

[0026] 7) Make a resin master mold from a plaster mold;

[0027] 8) Make gypsum working molds in batches.

[0028] The product CAD in the above step 1) can quickly establish a three-dimensional data model of the product according to the product concept or prototype, and can pre-evaluate the appearance and structure of the sanitary ware pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com