Heat exchanger and heat exchange process

一种热交换器、耐热的技术,应用在热交换设备、间接换热器、换热器类型等方向,能够解决过热湿蒸汽应力腐蚀等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

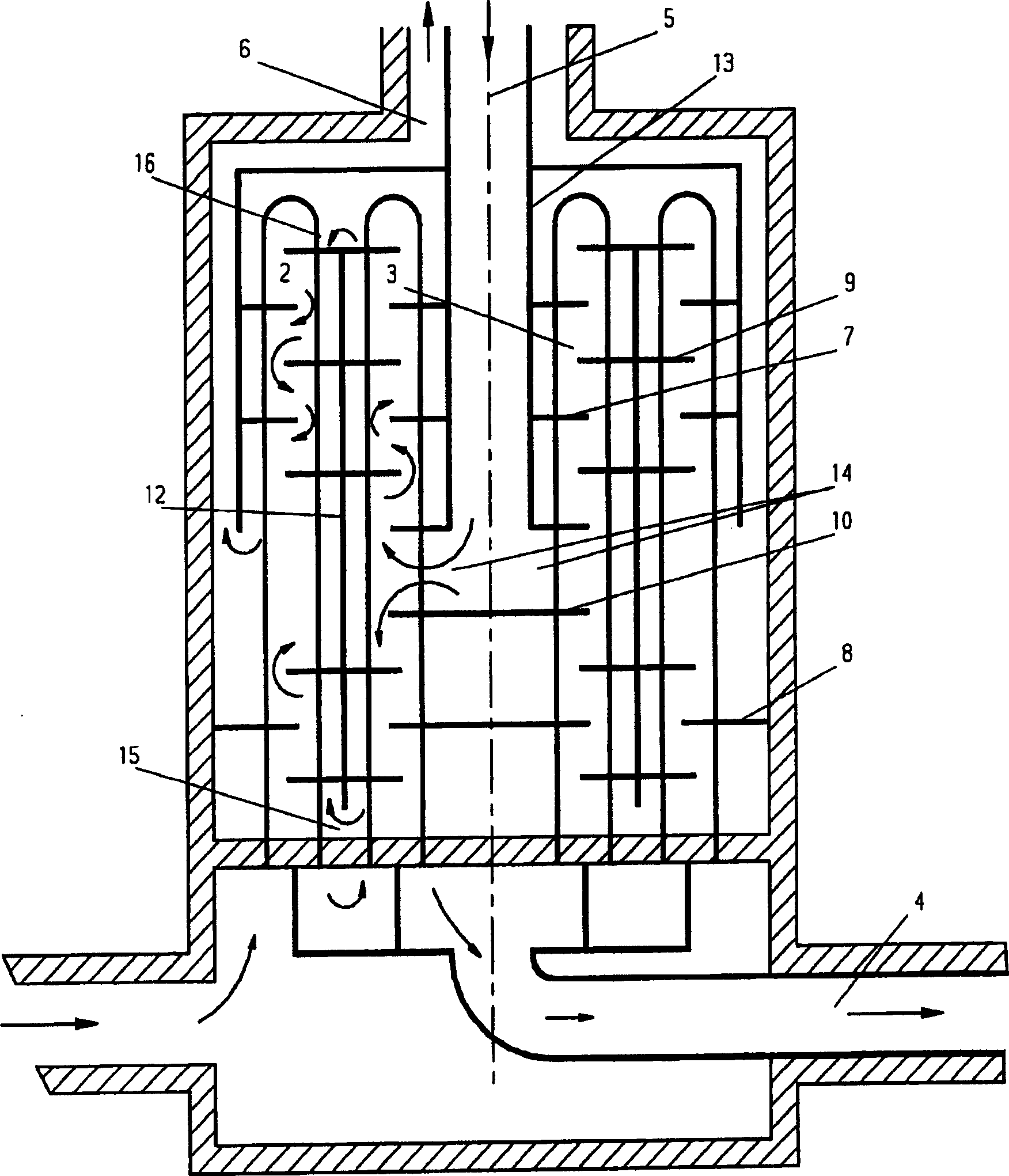

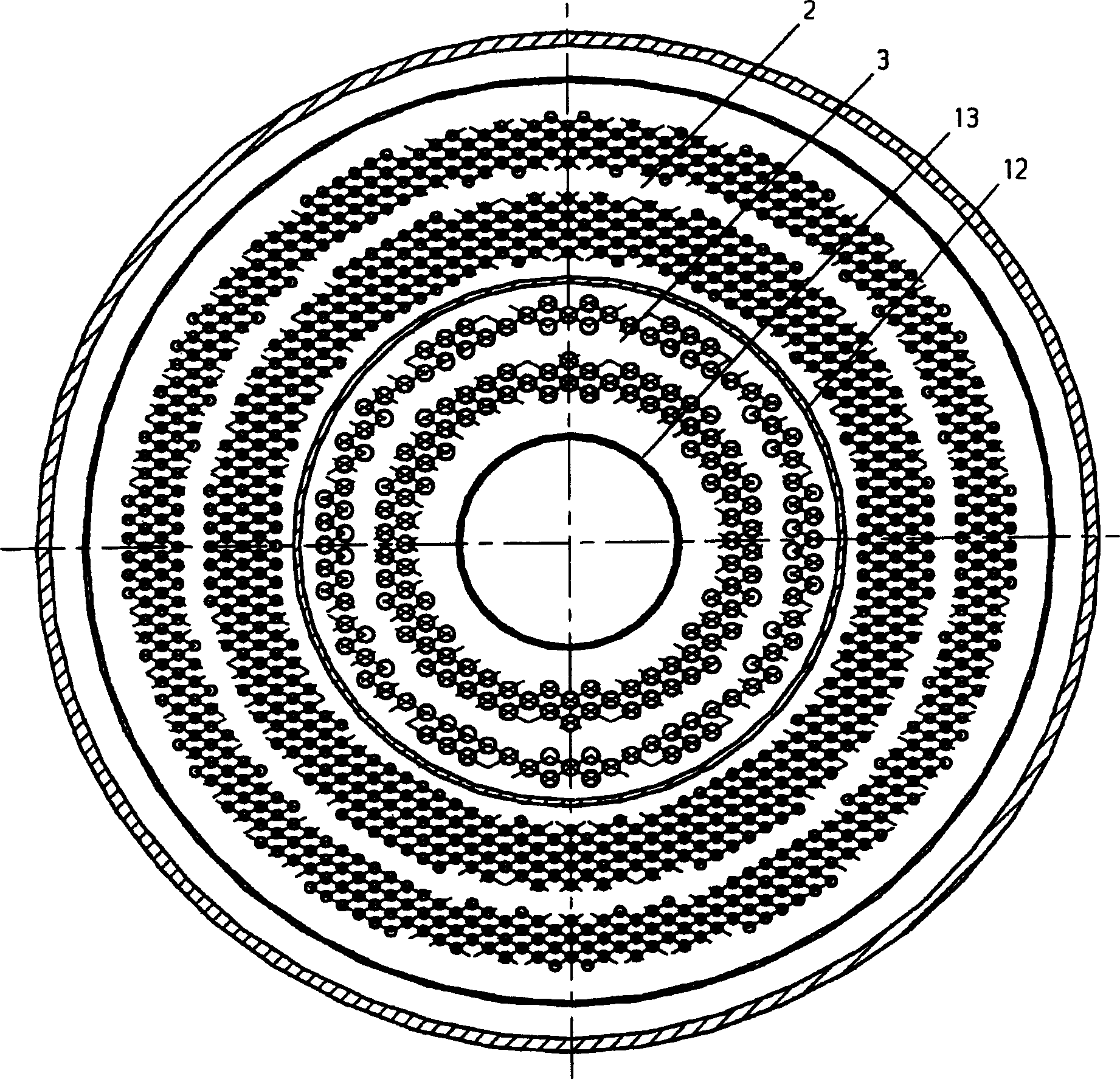

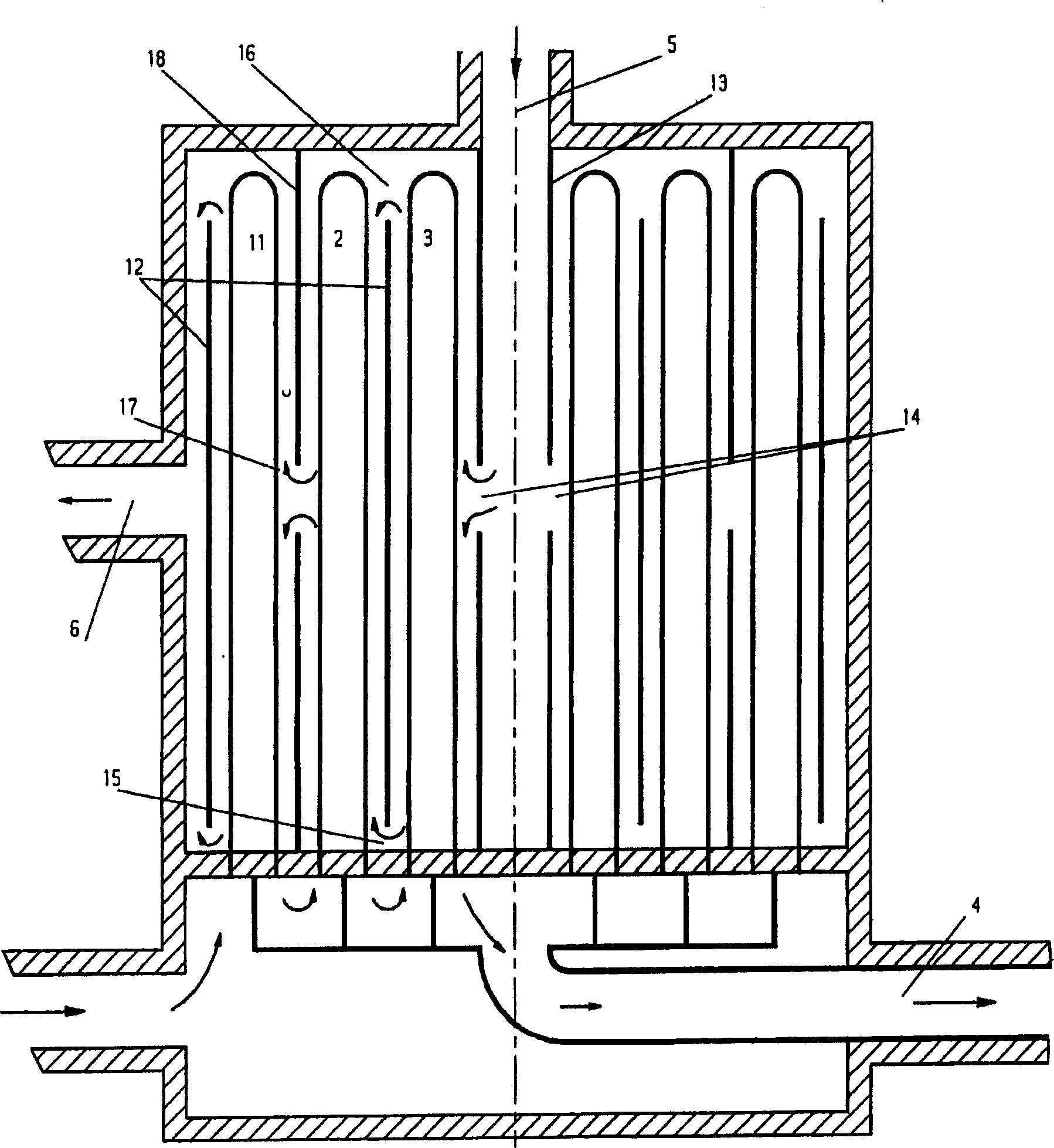

[0015] The present invention relates to a heat exchanger which is used as a superheater and which is designed to avoid the occurrence of Metal dusting and stress corrosion. The heat exchanger is adapted to exchange heat between the first and second fluids. Examples of said fluids are steam (first fluid) and synthesis gas (second fluid). In the heat exchanger, the hot synthesis gas from the steam reforming reactor is cooled by steam.

[0016] The heat exchanger is a U-tube type with thick tube sheets. A plurality of U-shaped tubes for conveying the first fluid are arranged in parallel and spaced apart from the intermediate inlet and the peripheral outlet of the second fluid. Heat transfer on the shell side is enhanced by means of discs and ring baffles. A plurality of tubes are arranged in tube bundles, each tube bundle corresponding to a specific heating zone.

[0017] The first fluid, for example steam, flows in the tubes, the second fluid, for example synthesis gas, flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com