High frequency binding profiling technology of piano tuning plate rib wood and its special device

A high-frequency gluing, special device technology, applied in wood processing appliances, wood veneer bonding, wood compression and other directions, can solve the problems of uneven heating of the glue surface, lack of specifications, long time, etc., to achieve high-quality gluing stereotypes , The effect of improving the firmness and improving the curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

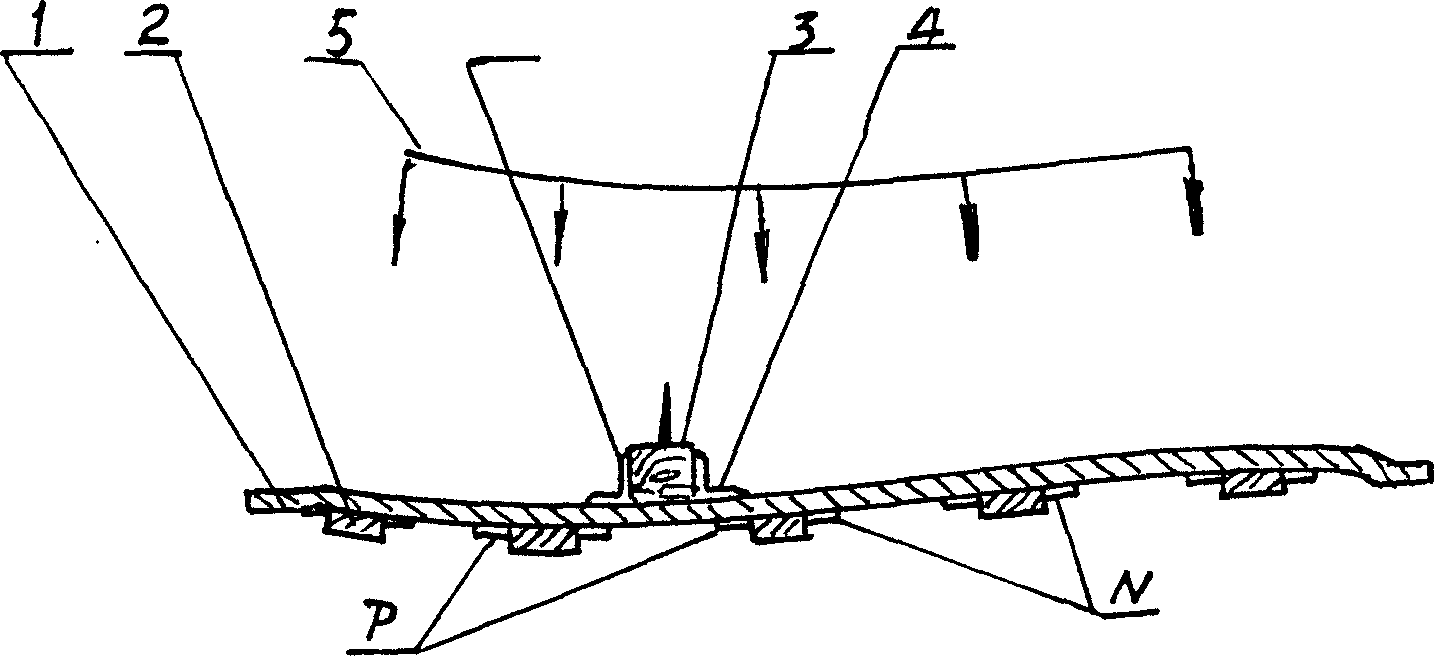

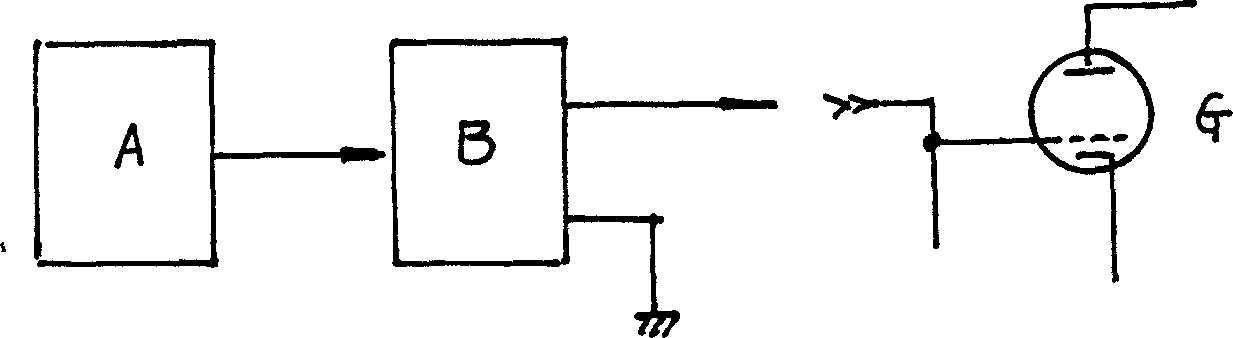

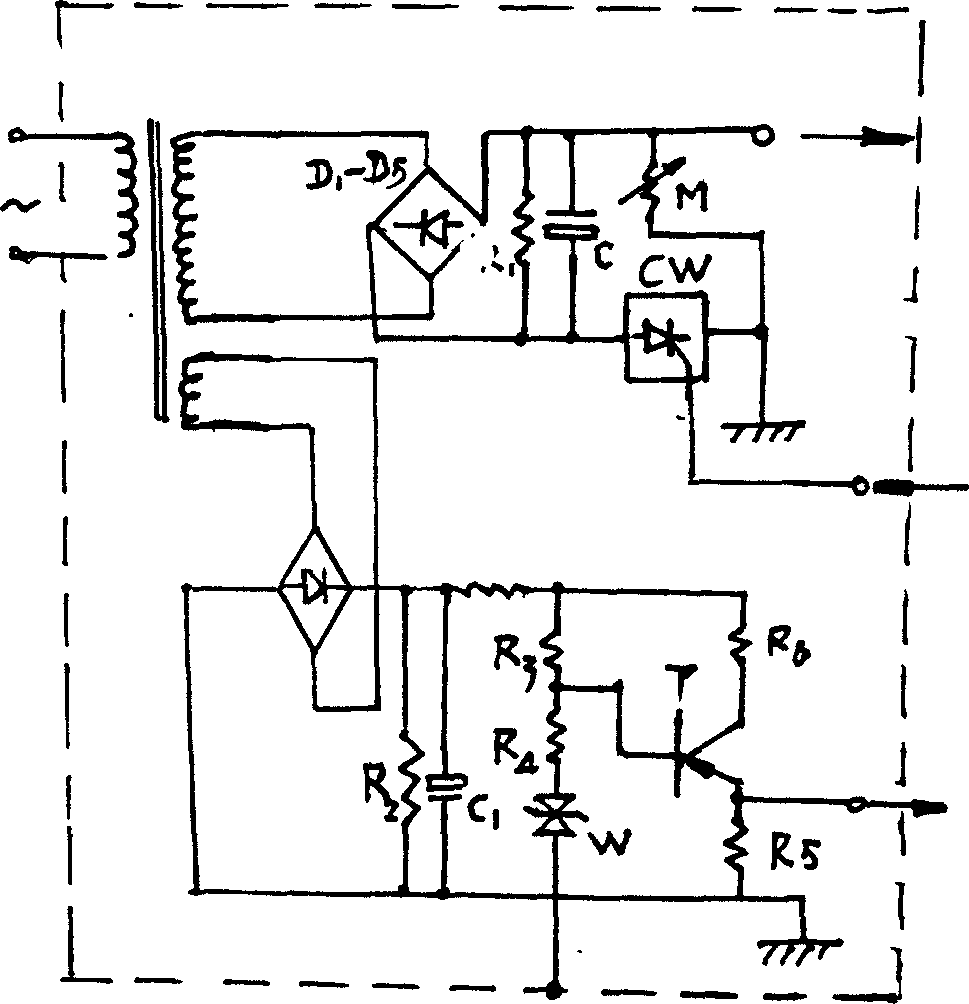

[0013] The key to the improvement of the traditional process is the introduction of a specially improved high-frequency press designed to adapt to the new processing technology. The improved process includes the assembling and molding of the flat soundboard and the pre-set nails, the processing and shaping of the ribbed strips, the preparation of the curved soundboard, the gluing between the ribbed strips and the flat soundboard, and adding Pressing the mold and heating, gluing, curing and shaping each process at the same time. The key improvement is that the following process characteristics are formed after the high-frequency press is used in the process:

[0014] ①The evenly distributed independent hydraulic cylinder 5 pressurizes and attaches the mold above the lower profiler.

[0015] ②Using high-frequency electric field induction heating method to realize the heating and curing of the glue medium.

[0016] In order to ensure the uniform force of each rib 2 and the soundboard...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com