Hydrotreating catalyst and preparation method thereof

A hydrotreating and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, organic compound/hydride/coordination complex catalysts, etc., can solve the problem of uneven distribution of phosphorus atoms, phosphorus atoms affecting catalyst desulfurization , denitrification activity, excessive concentration of phosphorus atom distribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

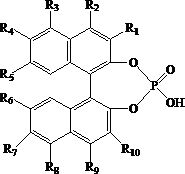

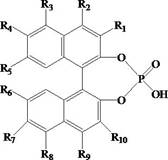

[0032]This example introduces the use of binaphthol phosphate as a phosphorus modification aid to prepare a phosphorus-modified hydrogenation catalyst.

[0033] Weigh 400.0 g of dry rubber powder, add 6.0 g of citric acid and 7.0 g of turnip powder, mix well, then add 340.0 g of nitric acid with a mass fraction of 2.0%. After rolling for 20.0 min, extrude the strips with a clover orifice plate with a diameter of 1.7 mm. Dry at 120°C for 4.0h and then bake at 500°C for 4.0h. The calcined carrier is denoted as S-1.

[0034] Weigh 17.3 g of binaphthol phosphate, dissolve it in 80.0 g of ethanol, weigh 100.0 g of S-1 carrier, add an equal volume of the above phosphorus-containing solution to impregnate, leave at room temperature for 12.0 h, and dry at 80°C for 18.0 h to obtain The desired phosphorus-modified carrier is denoted as S-2.

[0035] S-2 was impregnated with an equal volume of impregnation solution containing Mo and Ni, dried at 120°C for 4.0 h, and calcined at 450°C ...

Embodiment 2

[0038] This example introduces the preparation of a phosphorus-modified hydrogenation catalyst by using binaphthol phosphate and its Friedel-Crafts alkylation reactant as a phosphorus-modified auxiliary agent. The preparation of alumina carrier S-1 is the same as that in Example 1.

[0039] Weigh 17.3 g of binaphthol phosphate, dissolve in 100.0 g of n-butanol, add 25.0 g of anhydrous aluminum chloride, control the reaction temperature at 20.0 ° C, and the reaction time is 8.0 h. After the reaction, pour the reaction solution into a beaker of concentrated hydrochloric acid containing ice water, separate the water layer, and dry the organic layer to obtain the organic phosphorus source. Dissolve the above organic phosphorus source in 80.0 g of toluene, and weigh the S-1 carrier 100.0 g was added to the above-mentioned phosphorous-containing solution to impregnate in an equal volume. After standing at room temperature for 12.0 h, it was dried at 90°C for 24.0 h to obtain the des...

Embodiment 3

[0043] This example introduces the preparation of a phosphorus-modified hydrogenation catalyst by using binaphthol phosphate and its Friedel-Crafts alkylation reactant as a phosphorus-modified auxiliary agent. The preparation of alumina carrier S-1 is the same as that in Example 1.

[0044] Weigh 17.3 g of binaphthol phosphate, dissolve in 100.0 g of isobutanol, add 30.0 g of anhydrous aluminum chloride, control the reaction temperature to 20.0 ° C, and the reaction time to 8.0 h. After the reaction, pour the reaction solution into a concentrated hydrochloric acid beaker containing ice water, separate the water layer, and dry the organic layer to obtain an organic phosphorus source. Dissolve the above organic phosphorus source in 80.0 g of xylene, and weigh S-1 Add 100.0 g of the carrier, add the above-mentioned phosphorus-containing solution to impregnate in equal volume, leave it at room temperature for 12.0 h, and then dry it at 90°C for 24.0 h to obtain the desired phospho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com