Pasting and feeding apparatus for articles for freezing

A technology for feeding devices and frozen products, which is applied in the direction of household refrigeration devices, coolers, lighting and heating equipment, etc. It can solve the problems of frozen paste bonding, not being received, and not being good, so as to improve production capacity and prevent unsatisfactory Sequential sliding, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

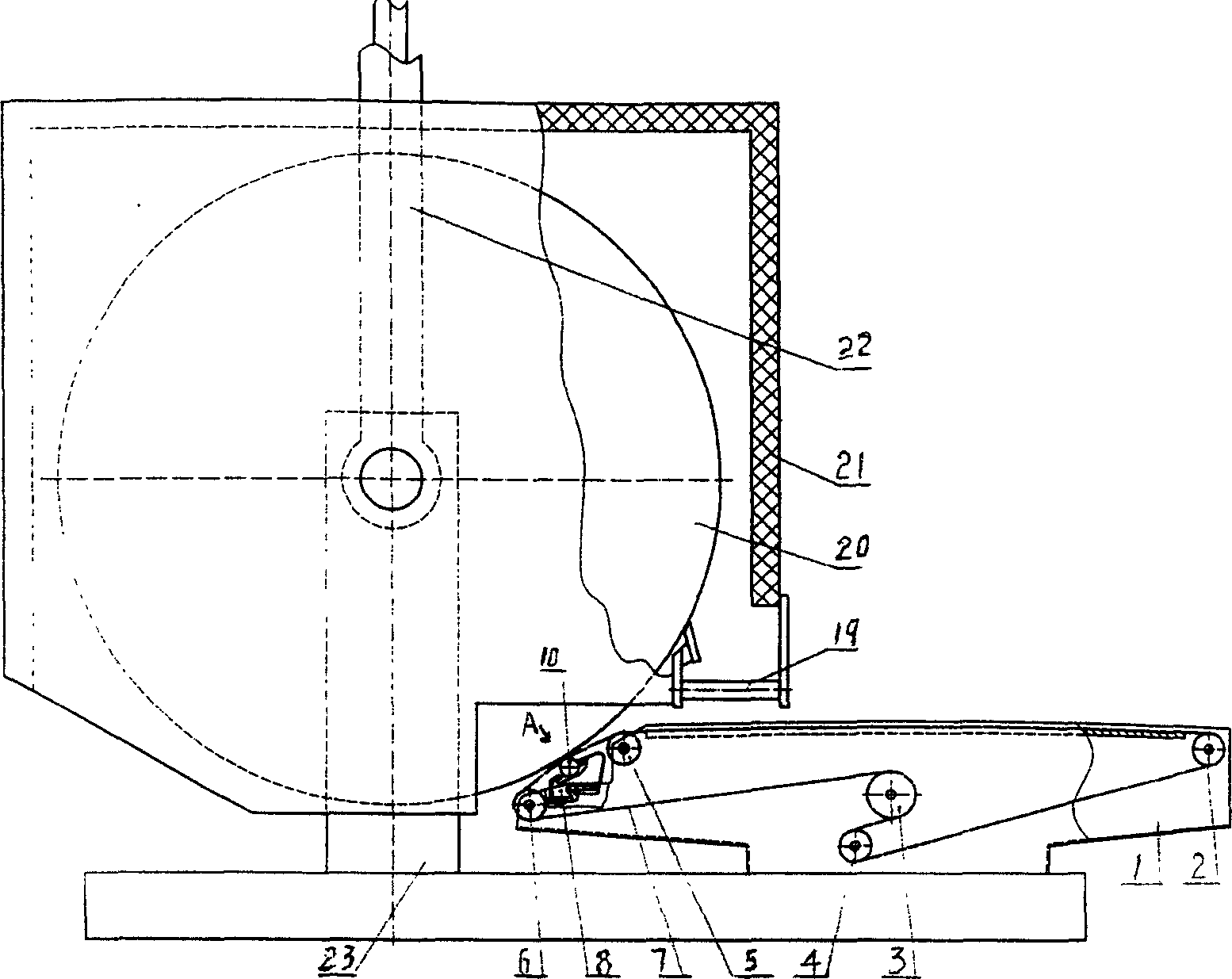

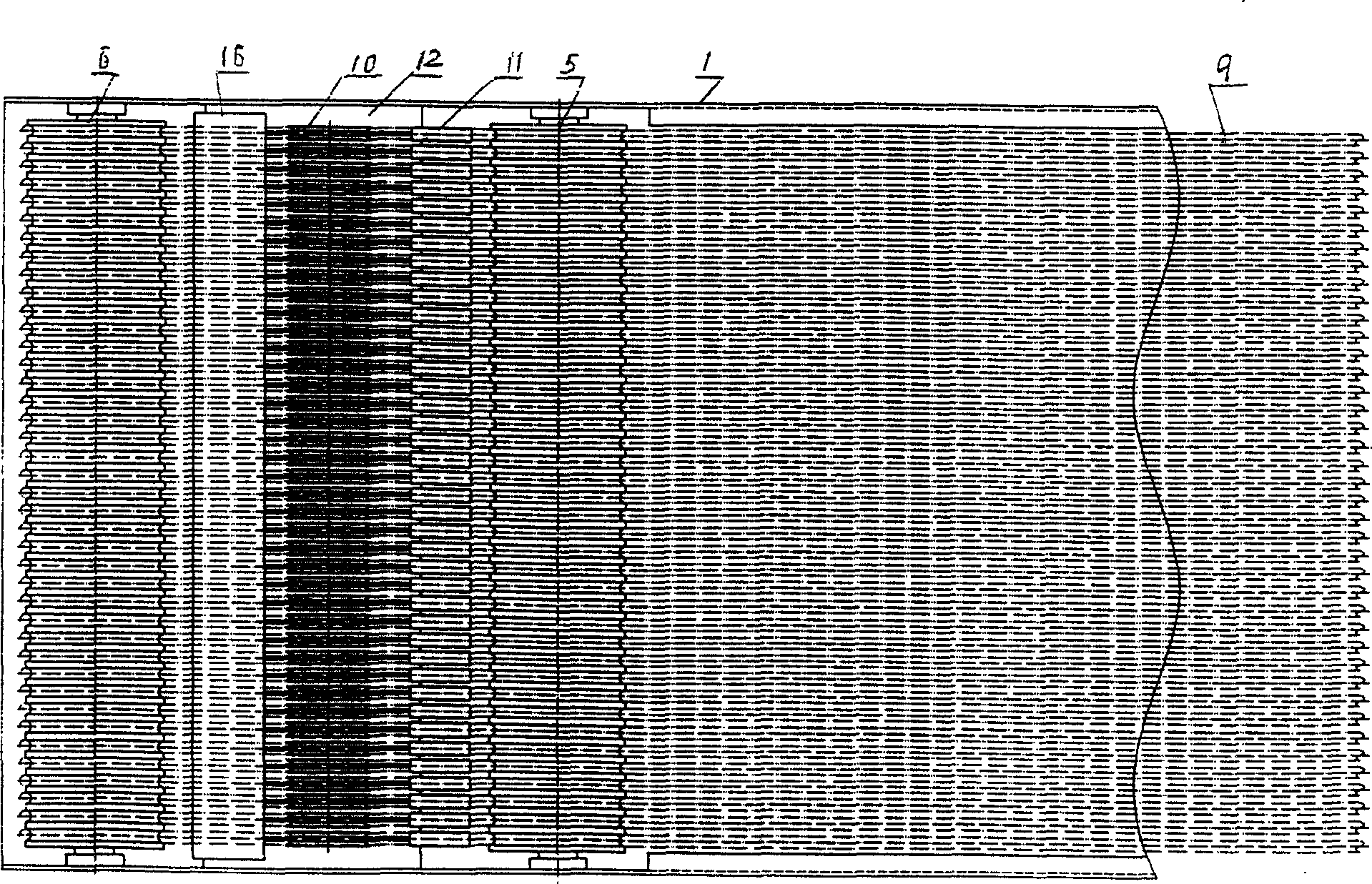

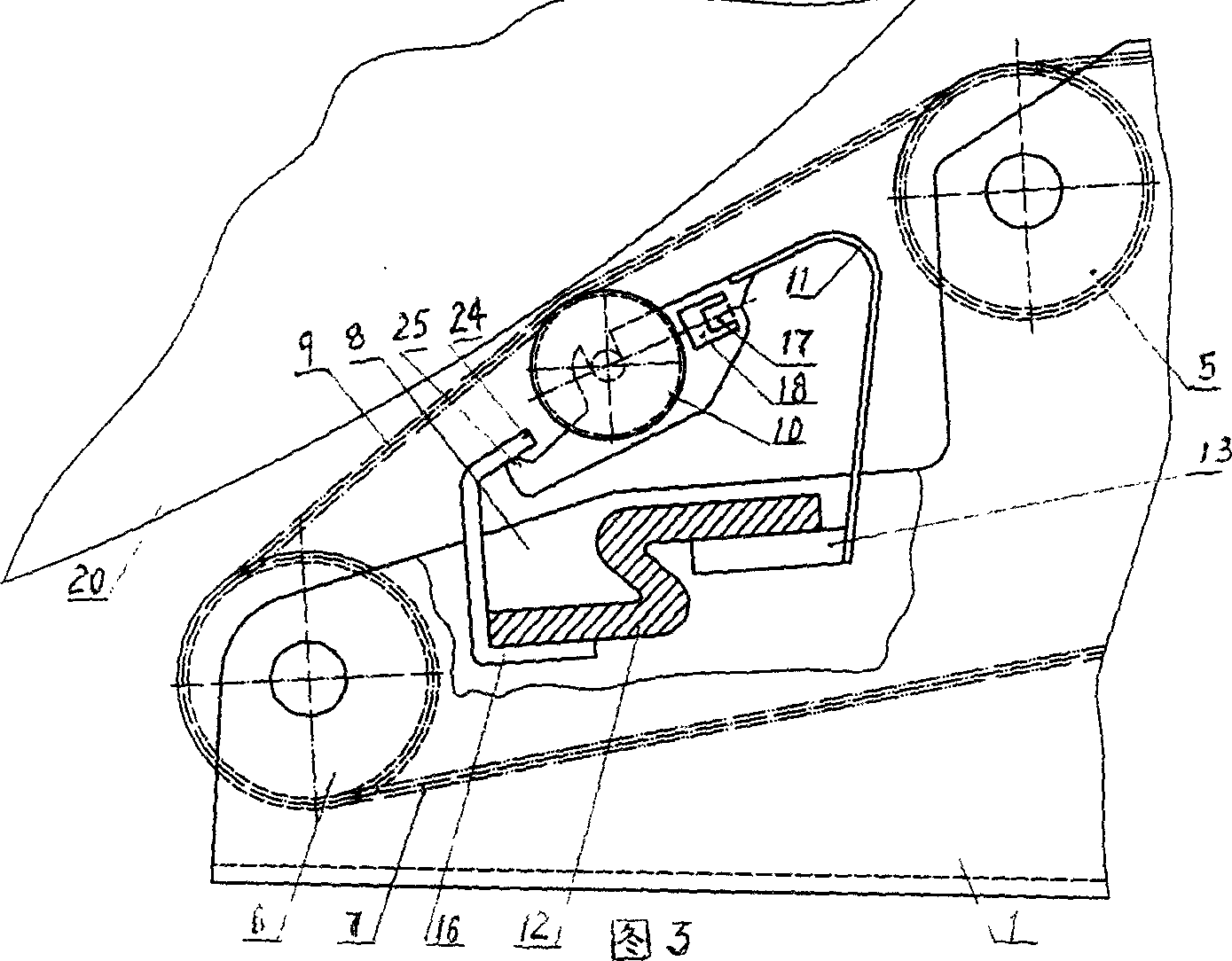

[0017] Paste feeding device for frozen products (see figure 1 ), there is a component frame 1, the driving shaft roller 3 and the tensioning shaft rollers 2, 4, 5, 6 mounted on the component frame, and the elastic conveyor belt 7 running around the driving shaft roller and the tensioning shaft roller will form an elastic A row of elastic belts of the conveyor belt 7 is pressed against the sheave member 8 on the outer circumference of the low-temperature drum 20, the sheave member 8 is connected to the member frame 1, the drive shaft roller 3 is connected to the drive motor output shaft of the drive mechanism, and the elastic conveyor belt 7 consists of a row of elastic bands 9 with a circular section (see figure 2 ), each elastic band 9 facing the outer circumferential surface of the cryogenic drum has a sheave 10 supporting the elastic band 9, the back side of the elastic band 9 is placed in the groove of the sheave 10, and the sheave member 8 (see Fig. 3) elastic sheet 11,...

Embodiment 2

[0019] The difference with embodiment 1 is: the sheave member has swing piece 26, sheave 10 (seeing figure 7), and swing piece is movably connected with bearing pin support 30 one end with bearing pin 29, and swing piece can freely swing around pin shaft, Pin shaft support other end is connected with mounting plate 12 with seat plate 34, and the groove bottom 14 of sheave 10 (seeing Figure 5 ) is supported in the groove at the other end of the swing piece, and can rotate freely. One end of the swing piece 26 has elastic elements such as spring 28 to be connected with the mounting plate 12 or connected with the mounting plate by a connector 35. There is also a limit protrusion 27 corresponding to the position of the mounting plate on the oscillating piece, which is used to limit the oscillating piece to push the sheave 10 to press the elastic belt 9 to be close to the outer circumferential surface of the low-temperature drum 20 to prevent the elastic belt from freezing to the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com