Sewing machine rotary shaft supporting device

A technology for supporting devices and rotating shafts, which is applied in the direction of sewing machine control devices, sewing machine components, sewing equipment, etc., can solve the problems of high cost of bearings and the need for special tools, and achieve the effects of cost suppression, easy bearings, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

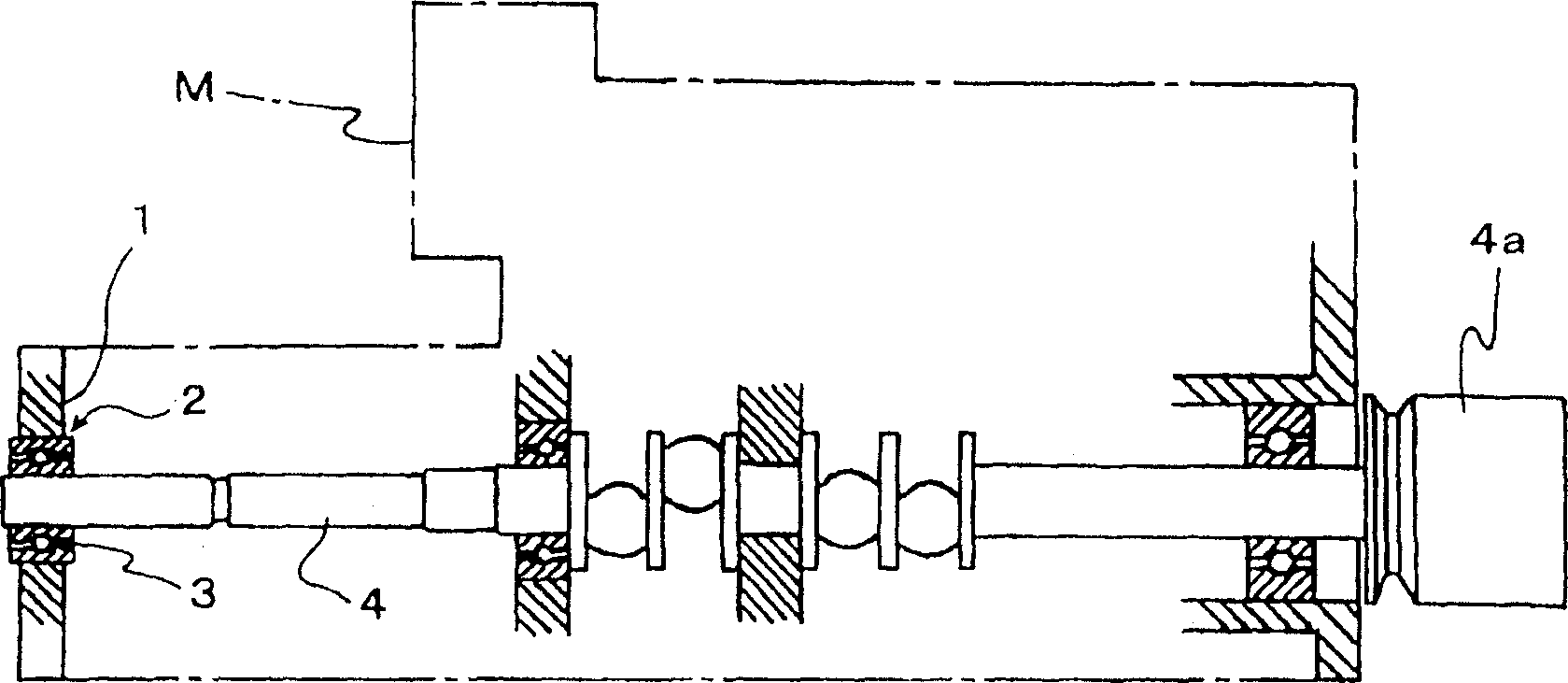

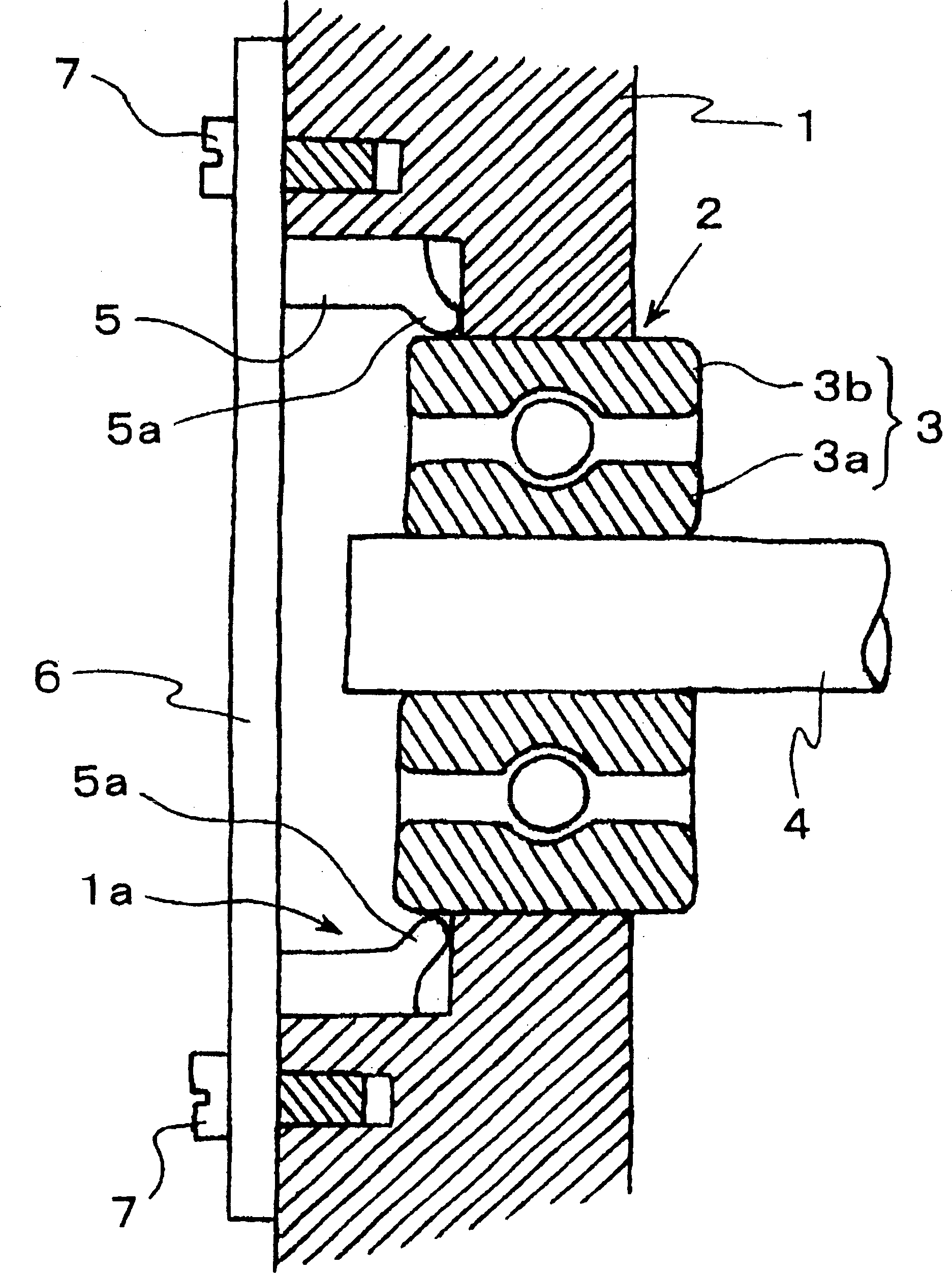

[0011] Hereinafter, specific embodiments of the present invention will be described with reference to the drawings. A frame 1 of the sewing machine M has a frame hole 2 on which a bearing 3 is provided. The inner ring 3a of the bearing 3 supports the rotary shaft 4, which rotates in one direction when the sewing machine is driven. The rotary shaft 4 has a hand wheel 4a at the right end, and the operator can operate the sewing machine through the hand wheel 4a. The outer ring 3 b of the bearing 3 is rotatably supported on the frame hole 2 of the frame 1 , and both ends thereof protrude from the frame hole 2 . The rack hole 2 is formed in the recessed portion 1a of the frame 1, and the jig 5 is provided in the recessed portion 1a.

[0012] The jig 5 is integrally formed with a mounting cover 6 covering the recessed portion 1 a of the frame 1 . The installation cover 6 is installed on the frame 1 by screws 7,7. At this time, the clamp 5 is pressed into the recess 1 a of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com