Centrifugal type clutch and its assembly method

A technology of centrifugal clutches and clutch housings, applied in clutches, automatic clutches, mechanical equipment, etc., can solve the problems that abnormal noise cannot obtain outstanding effects, and the radial displacement of clutch housings cannot be fully suppressed, so as to prevent abnormal noise, Effects of suppressing abnormal noise and suppressing radial displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

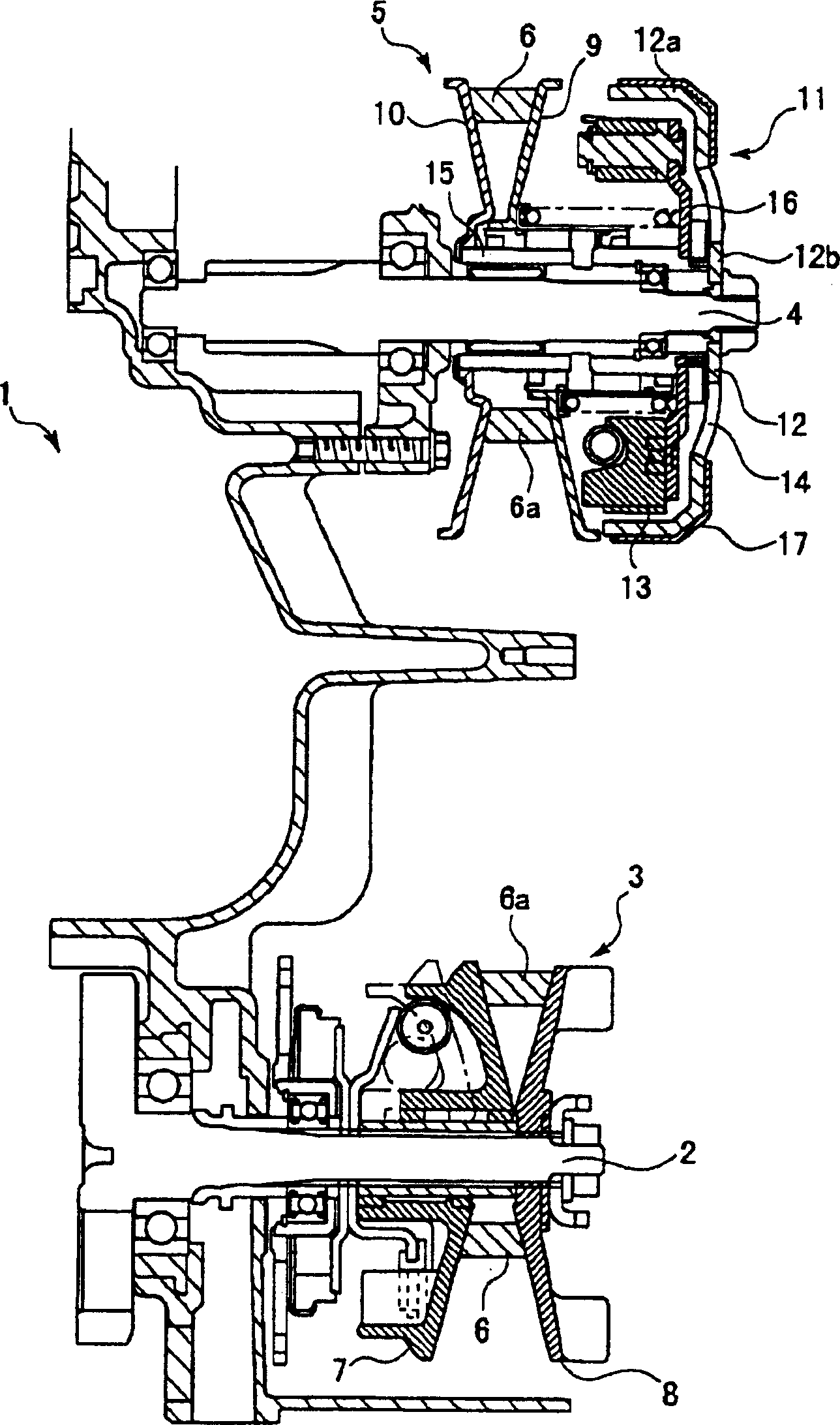

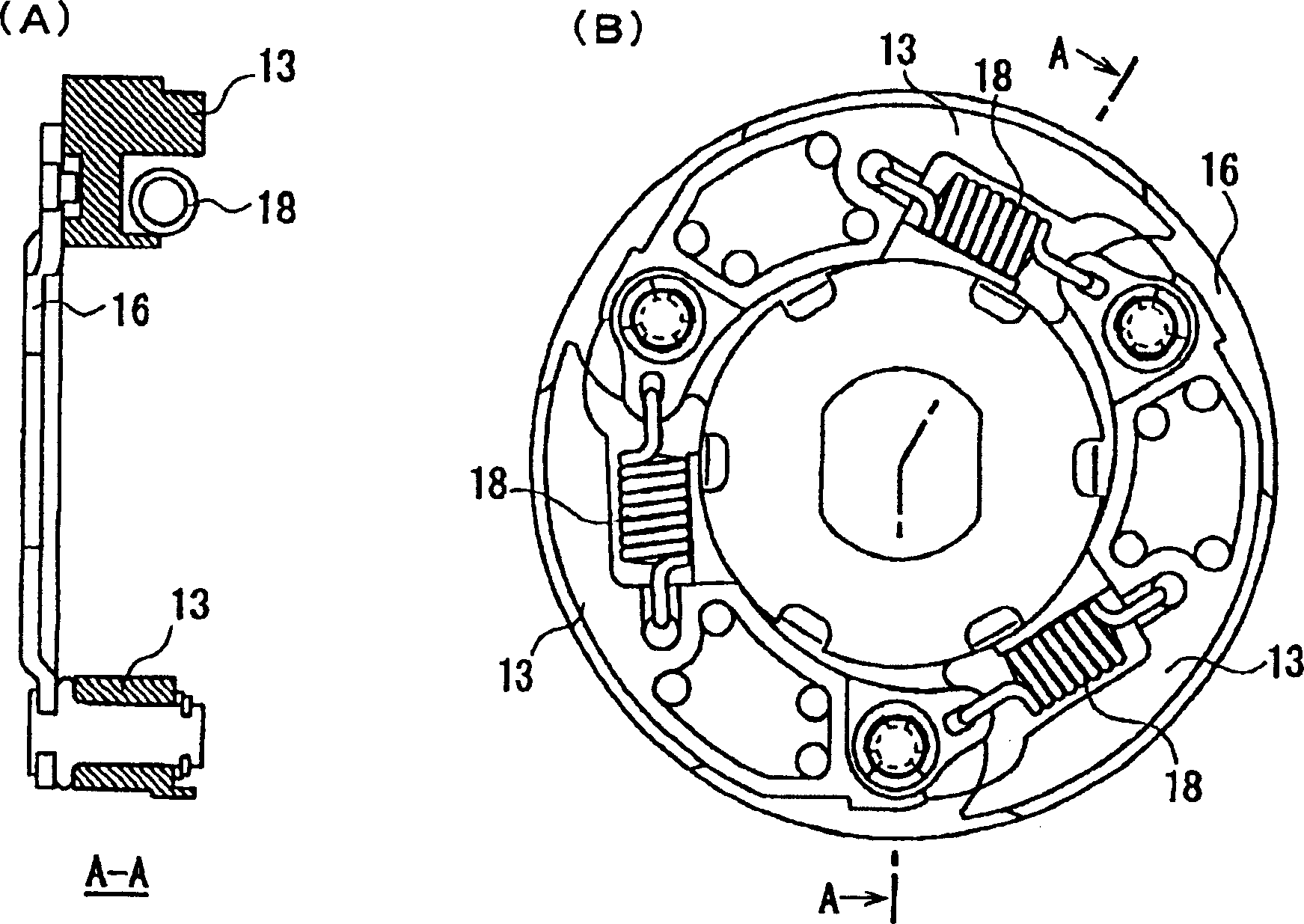

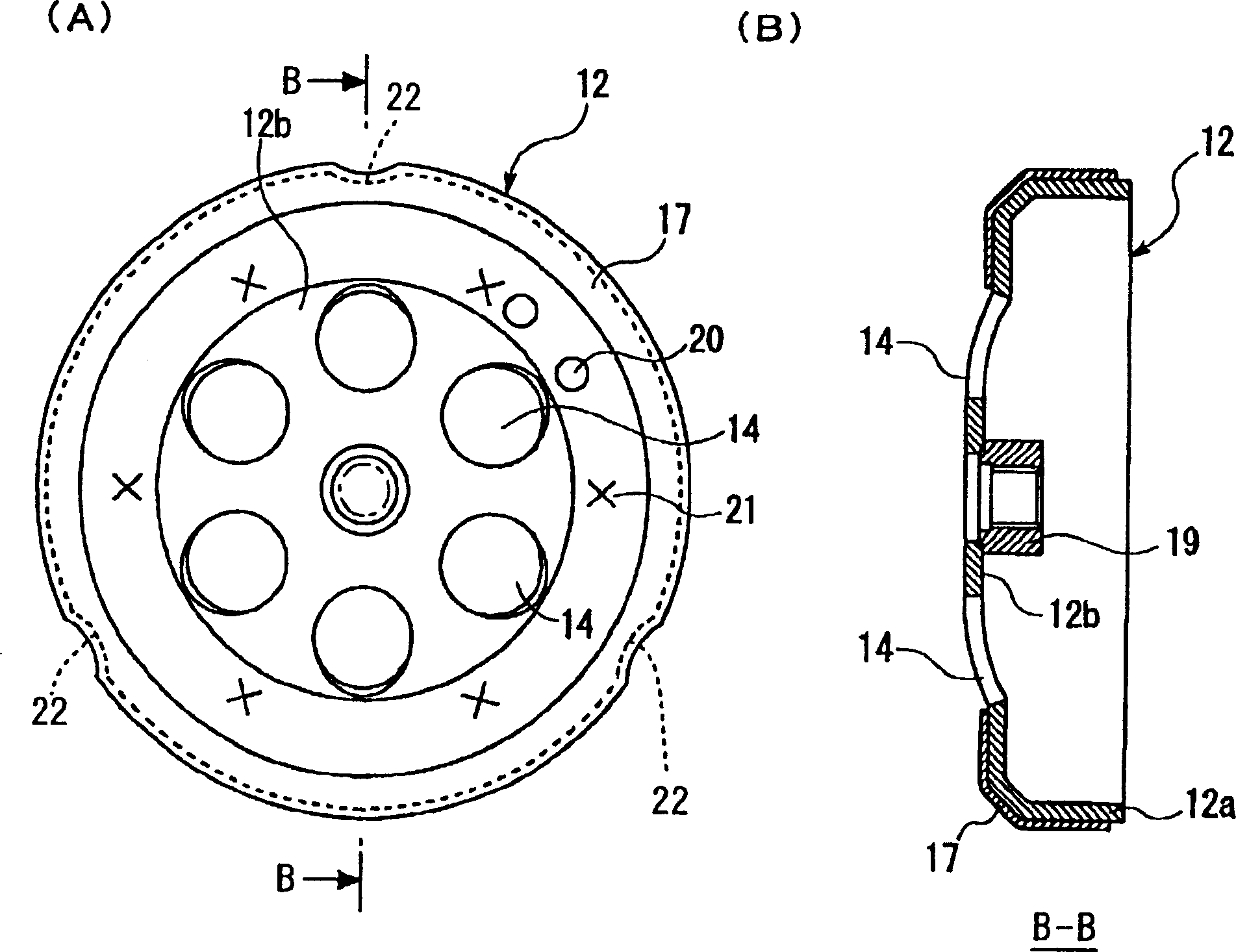

[0053] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings. However, this description is illustrative in all respects and not restrictive. It should be understood that various changes and modifications can be made without departing from the scope of the invention.

[0054] Figure 10 It is a side view of a motorcycle (a scooter in this embodiment) used as a typical example of a vehicle equipped with the centrifugal clutch of this embodiment.

[0055] Such as Figure 10 As shown, the motorcycle 100 of the present embodiment generally includes: a front fork 101 pivoted on the vehicle frame; a front wheel 102 connected to the lower end of the front fork 101; a steering handle 103 connected to the upper end of the front fork 101; The vehicle seat 104 on the top of the vehicle frame; the engine assembly 106 installed below the vehicle seat 104; the belt type continuously variable transmission 105 that is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com