Yarn guide

A technology of yarn guide and yarn guide hole, which is applied in the direction of yarn, textiles, papermaking, and thin material processing, etc., and can solve the problems of multi-color strands, quality defects, decreased attention, strands that cannot be used, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

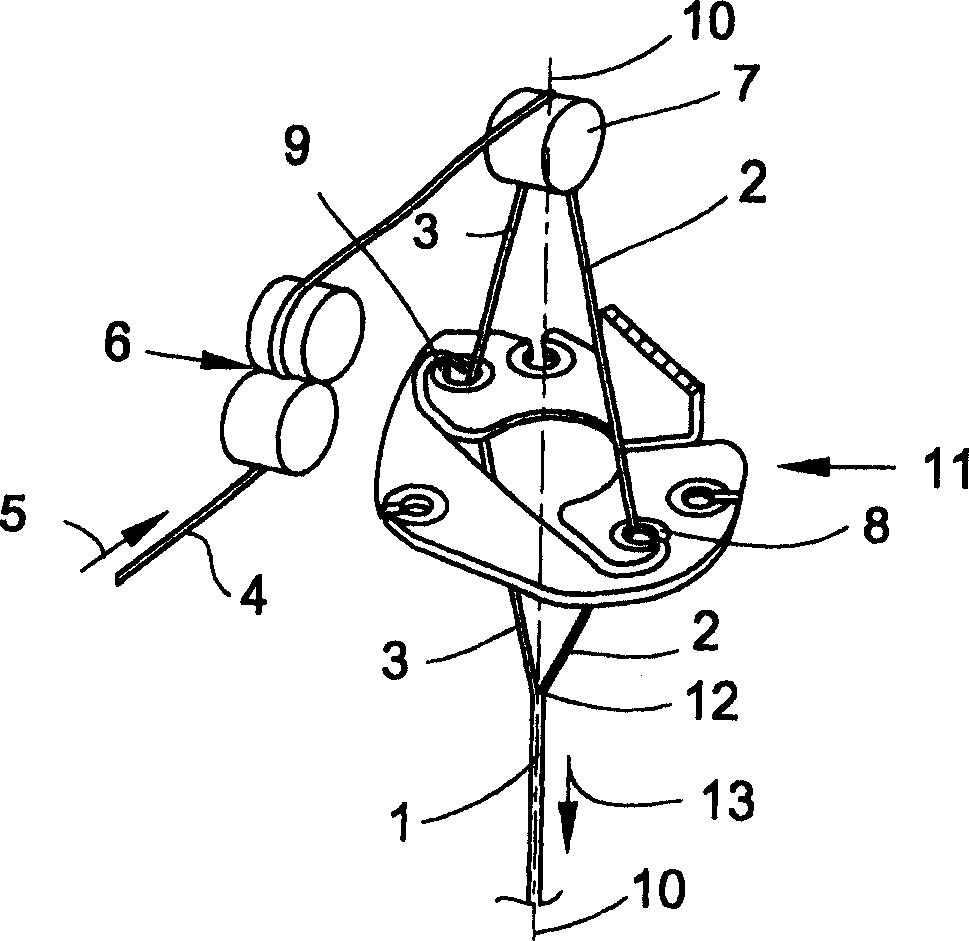

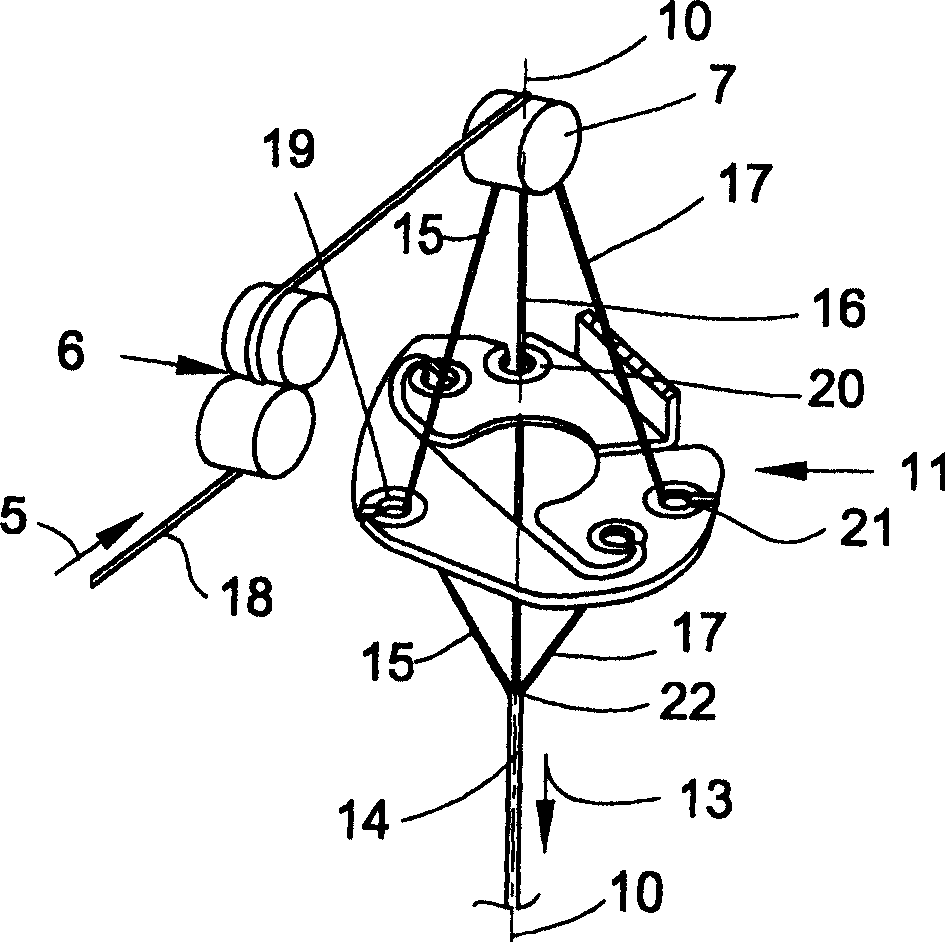

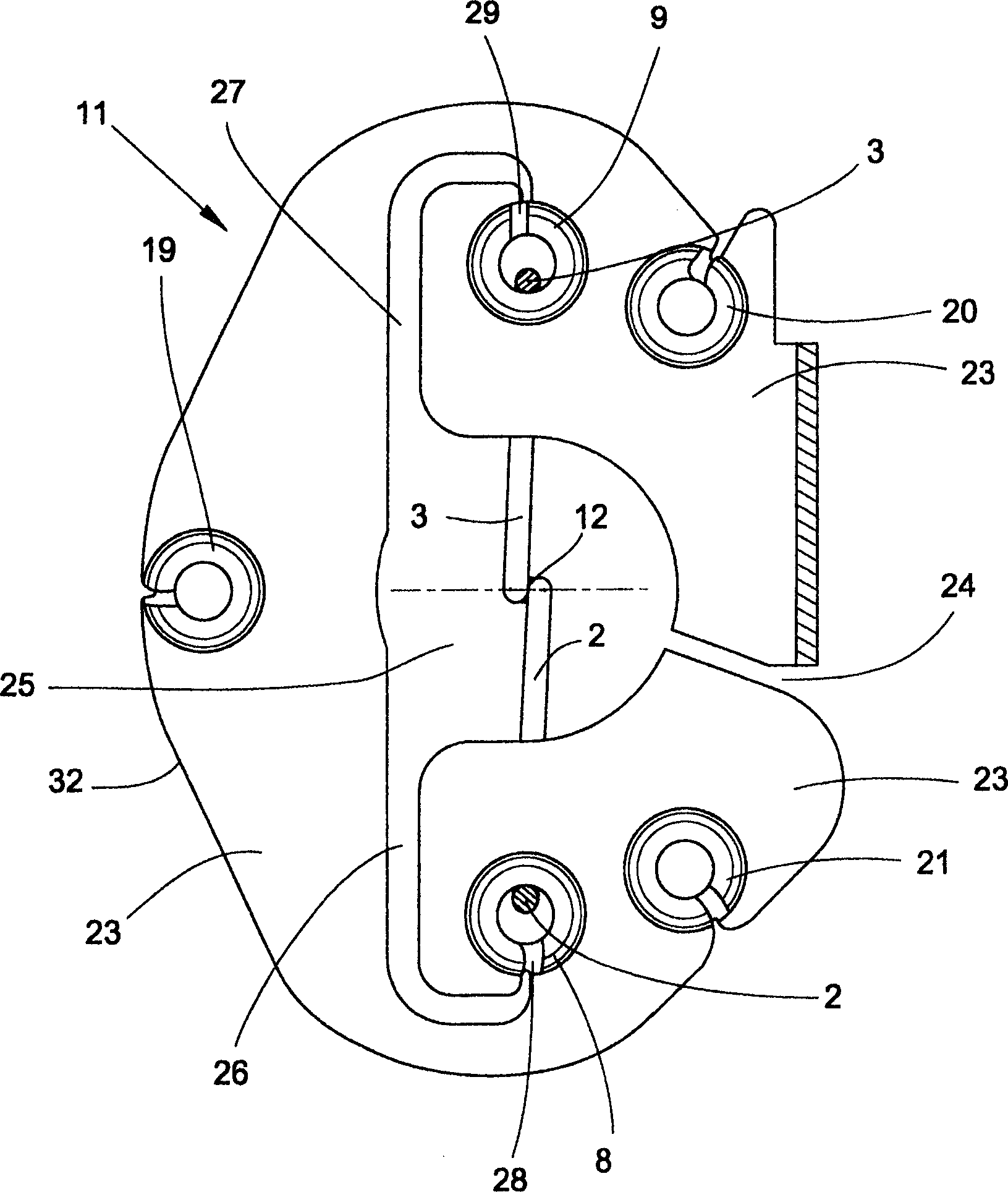

[0023] figure 1 Middle means that a multi-color strand (Mouliné-Gam) 1 is made by the twisting of two twisted single yarns 2, 3, and these single yarns are fed in the direction of arrow 5 as a combined thread 4 . The combined line 4 undergoes a downward direction change through a roller pair 6 and by means of a guide roller 7. After the guide roller 7, the combined thread 4 is divided into its two single yarns 2, 3 which are still running side by side at this time. The single yarn 2 is guided through the guide hole 8 and the single yarn 3 passes through the guide. Hole 9 guides. The point where the single yarns 2, 3 are separated from each other is exactly located at a lower part, figure 1 On the extension of the spindle hollow shaft 10 of the spindle not shown in the figure, the multicolor strands 1 are wound on the spindle. The yarn guide holes 8, 9 are arranged on the yarn guide 11 at equal distances opposite to each other and thus axisymmetrically with respect to the hollow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com