Fluorescent lamp tube and plane lamp

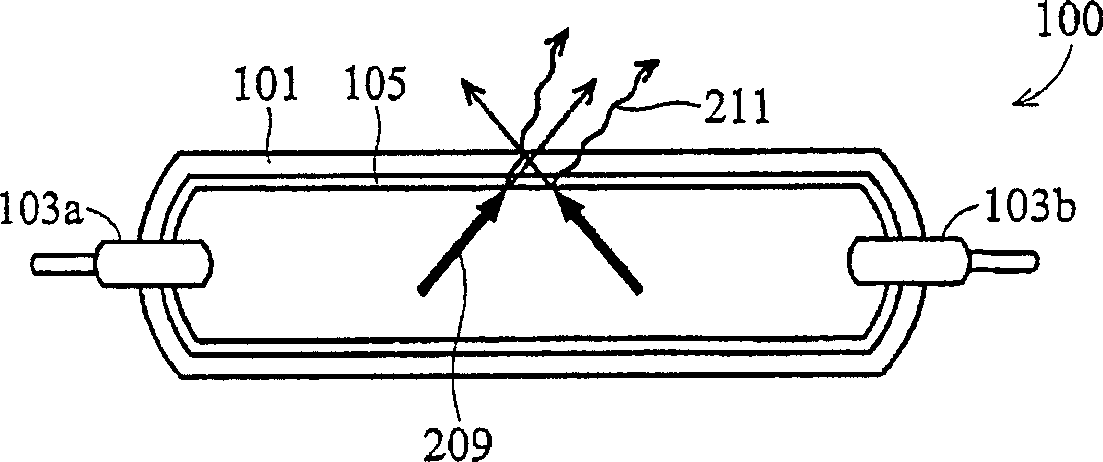

A technology for fluorescent tubes and flat lamps, which is applied to discharge lamps, gas discharge lamps, parts of gas discharge lamps, etc., can solve the problems of inability to effectively utilize ultraviolet light, and the inability of the fluorescent layer 105 to completely absorb ultraviolet light and visible light.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

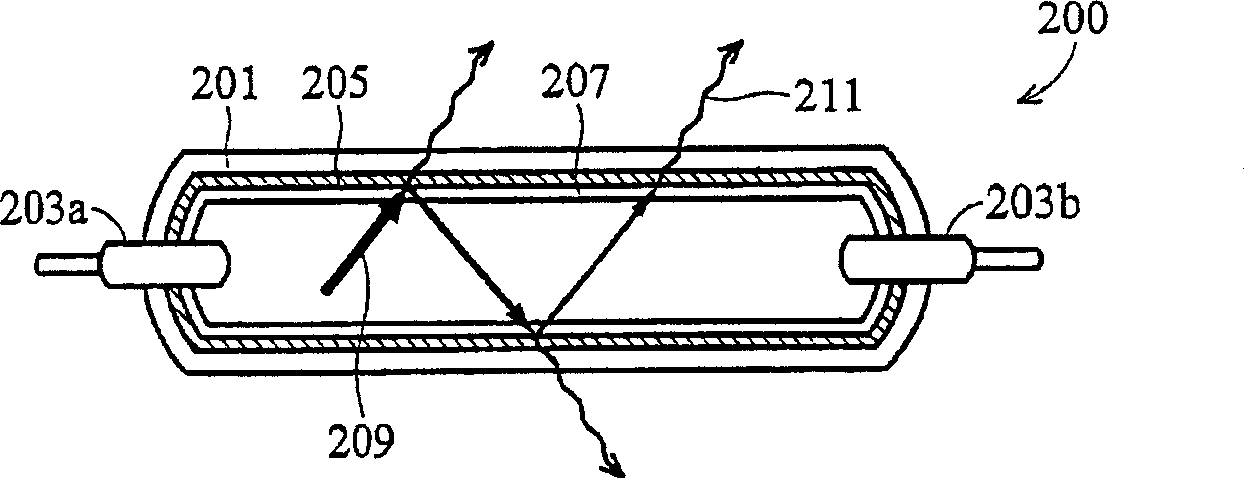

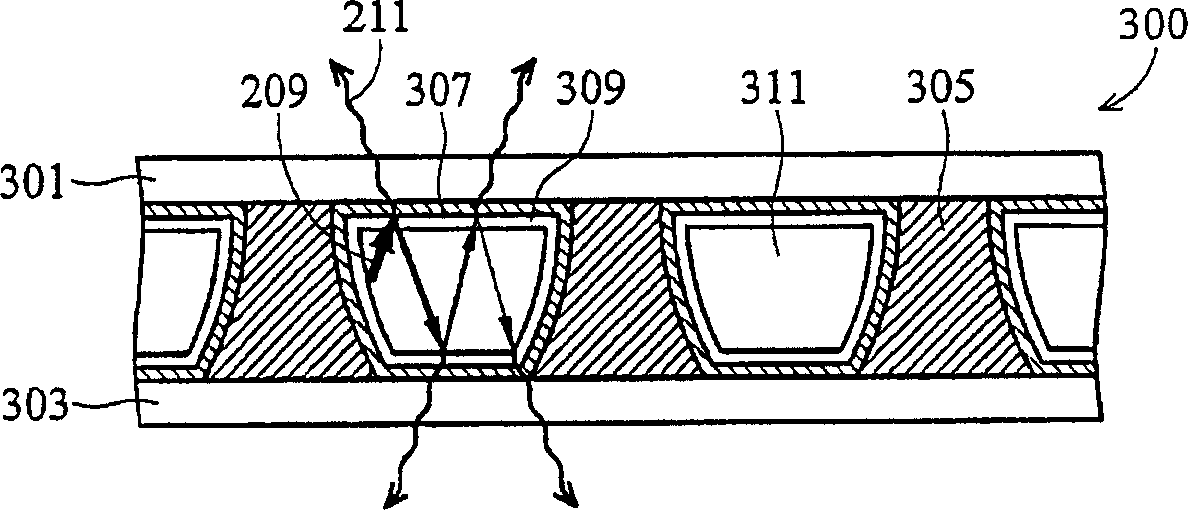

[0013] figure 2 A fluorescent lamp 200 with a dielectric omni-directional reflective layer in a preferred embodiment of the present invention is shown, including a transparent lamp 201, such as a glass lamp, with a pair of electrodes 203a and 203b at both ends of the lamp. In this figure, a cold cathode fluorescent lamp (CCFL) is taken as an example, and the electrodes are located inside the lamp. However, the electrodes can also be placed outside the lamp, eg in the design of an external electrode fluorescent lamp (EEFL). The inner wall of the fluorescent tube has a dielectric omni-directional reflective layer 205 and a fluorescent layer 207, wherein the dielectric omni-directional reflective layer 205 is placed between the transparent lamp tube 201 and the fluorescent layer 207, which is a light in the range of visible light. Periodically stack reflective layers for transparency. The principle of reflection is to use the energy gap phenomenon generated by the periodic str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com