A kind of strength member for optical cable and its production device and method

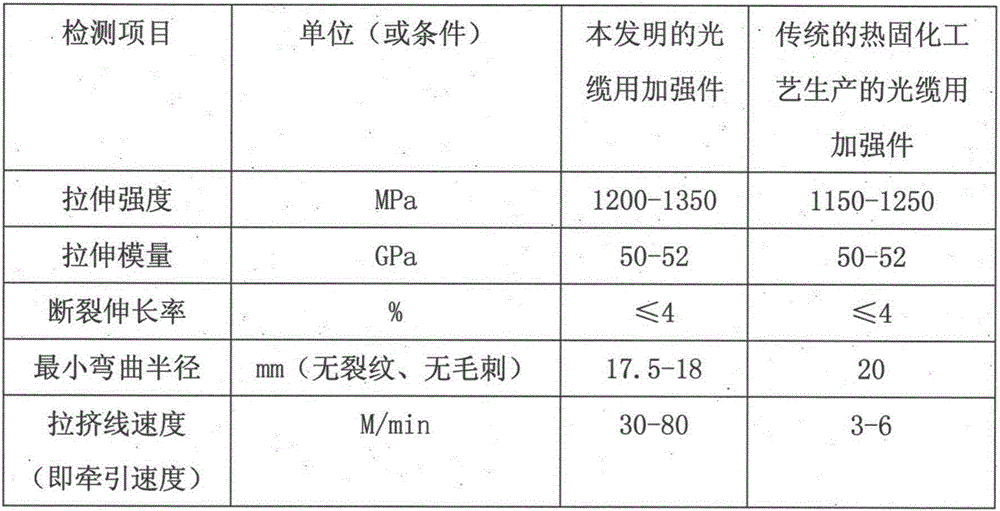

A production device and production method technology, applied in the field of optical cable materials, can solve the problems of irregular composite shape, insufficient internal structure, high mold manufacturing costs, etc., to achieve reduced light pollution, excellent tensile properties, and high utilization of ultraviolet light Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A strengthening member for an optical cable is made of 70 wt% of glass fiber roving and 30 wt% of light-cured acrylic epoxy resin as raw materials.

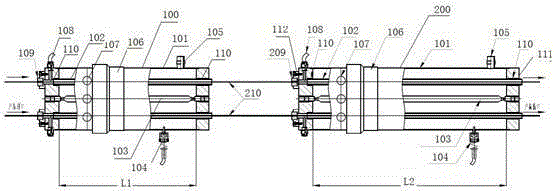

[0032] Such as figure 1 Shown is a production device for a strength member for an optical cable, and the production device for a strength member for an optical cable includes a pre-molding photo-curing furnace 100 and a secondary molding photo-curing furnace 200 .

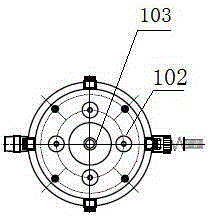

[0033] Described preform photocuring furnace 100 comprises furnace cylinder 101, and the two ends of furnace cylinder 101 are fixed with side plate 111, is provided with 200W ultraviolet lamp tube 103 and quartz glass tube 102 in furnace cylinder 101, the side of furnace cylinder 101 front end A mold cover 112 is fixed on the plate 111, and a preforming mold 109 is arranged on the mold cover 112. The front end of the quartz glass tube 102 is connected to the preforming mold 109, and the rear end of the quartz glass tube 102 extends from the side plate 111 at th...

Embodiment 2

[0038] A strength member for an optical cable, made of 75wt% glass fiber roving and 25wt% light-cured acrylic epoxy resin as raw materials. The power of the ultraviolet lamp 103 is 250W, and the power of the ultraviolet lamp 103 in the secondary molding light curing furnace 200 is 2000W. Its production method is:

[0039] The first step: place the light-curing acrylic epoxy resin in a constant temperature solution tank whose temperature is controlled at 100°C;

[0040] The second step: place the glass fiber roving in a constant temperature solution tank to soak the stagnant light-cured acrylic epoxy resin, use the frequency conversion speed regulation drawing machine to pull, first pass through the pre-forming light-curing furnace 100 for pre-curing, and then pass through the second step The molding photocuring furnace 200 performs secondary curing. The cavity temperature of the preforming photocuring furnace 100 is controlled at 150° C., the cavity temperature of the seconda...

Embodiment 3

[0042] A strength member for optical cables, made of 80wt% glass fiber roving and 20wt% light-cured acrylic epoxy resin as raw materials. The power of the ultraviolet lamp 103 is 300W, and the power of the ultraviolet lamp 103 in the secondary molding light curing furnace 200 is 3000W. Its production method is:

[0043] The first step: put the light-curing acrylic epoxy resin in a constant temperature solution tank whose temperature is controlled at 90°C;

[0044] The second step: place the glass fiber roving in a constant temperature solution tank to soak the stagnant light-cured acrylic epoxy resin, use the frequency conversion speed regulation drawing machine to pull, first pass through the pre-forming light-curing furnace 100 for pre-curing, and then pass through the second step The molding photocuring furnace 200 performs secondary curing, the cavity temperature of the preforming photocuring furnace 100 is controlled at 200°C, the cavity temperature of the secondary mold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com