Manufacture of metal reinforced plastic spiral ripple pipe

A spiral corrugated pipe, metal reinforced technology, applied in the direction of thin material handling, tubular goods, transportation and packaging, etc., can solve problems such as difficult control, and achieve the effect of overcoming torsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

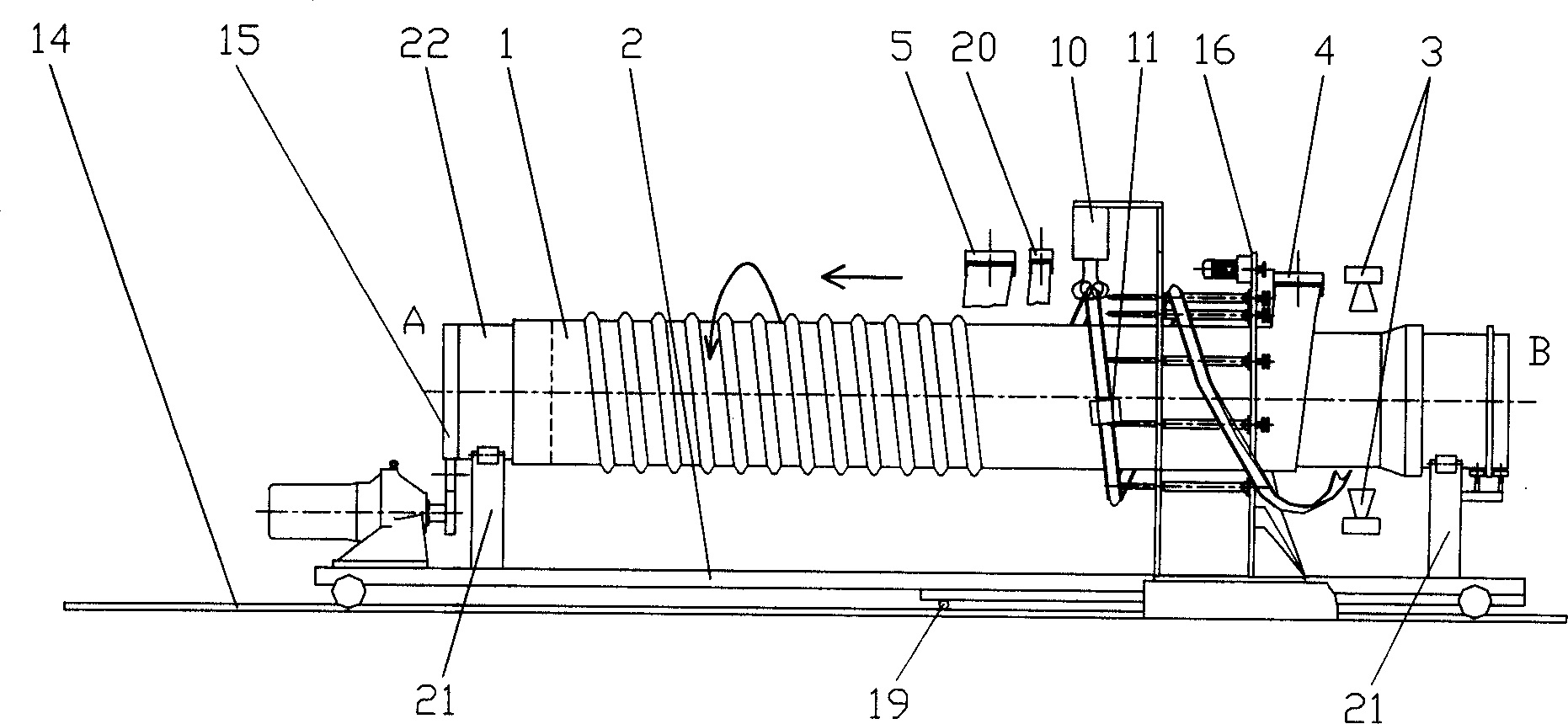

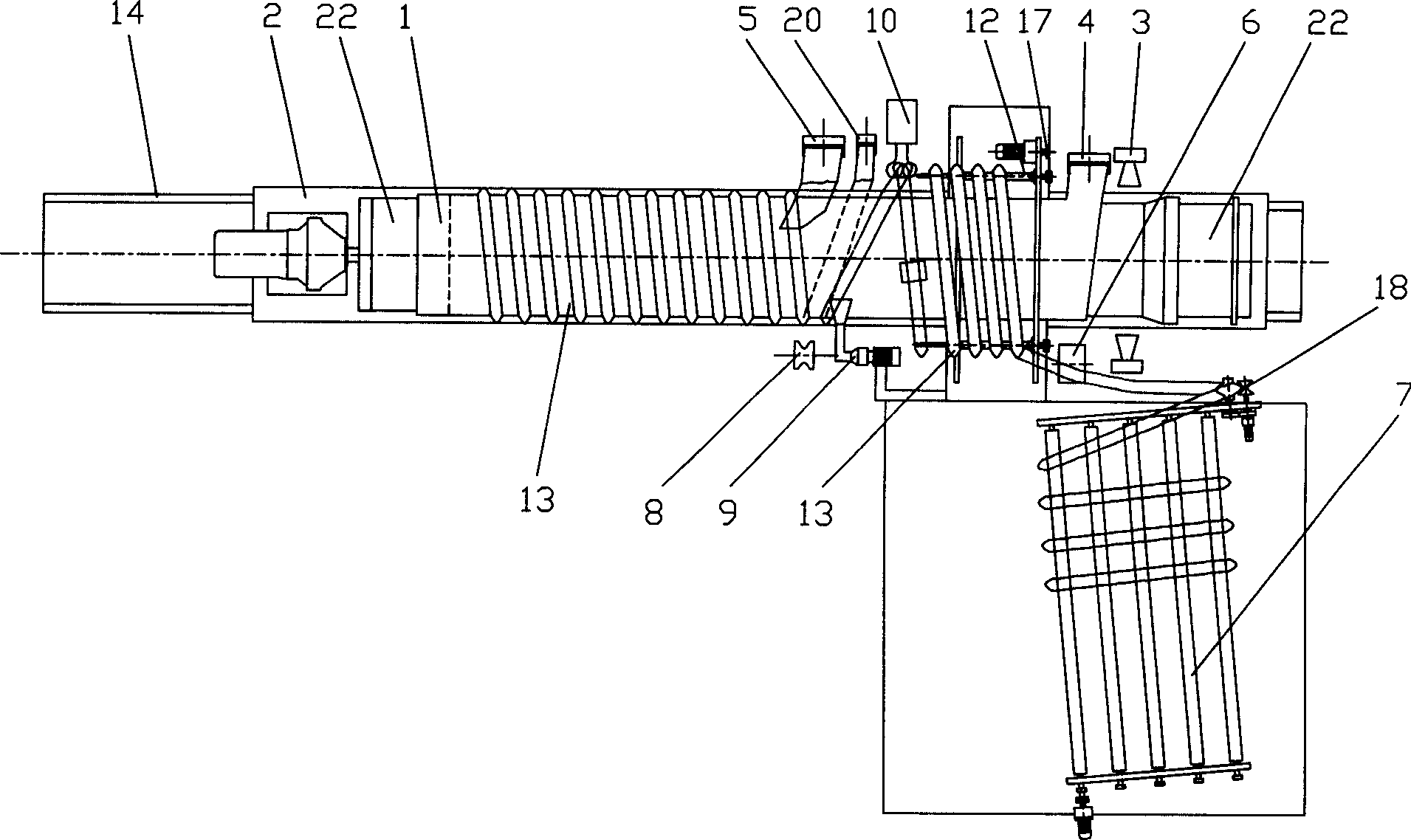

[0022] figure 1 with figure 2 What is shown is a structural state of the metal-reinforced plastic spiral corrugated pipe manufacturing device of the present invention. Wherein, there is a guide rail 14 arranged in a straight line, on which a mobile vehicle frame 2 that can reciprocate along the guide rail 14 is arranged. The vehicle frame 2 can reciprocate along the guide rail 14 through the gear-rack transmission mechanism 19 provided between the guide rail and the corresponding driving motor and other mechanisms. On the mobile frame 2, a mandrel 1 that can be replaced and can be rotated under the driving structure 15 including the motor and the transmission gear-ring gear is provided through the rolling support frame 21 at both ends of the moving direction. The mandrel 1 can adopt the common multi-lobe folded and reduced-diameter structure, and is supported on the rolling support frame 21 through a section of small-diameter mandrel 22 at both ends of the mandrel.

[0023...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com