Electromagnetic heating pressure cooking device

A cooking device and pressure technology, applied in pressure cookers, cooking utensils, household appliances, etc., can solve problems such as affecting the pressure control accuracy in the pot, large thermal inertia, and pressure overshoot.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

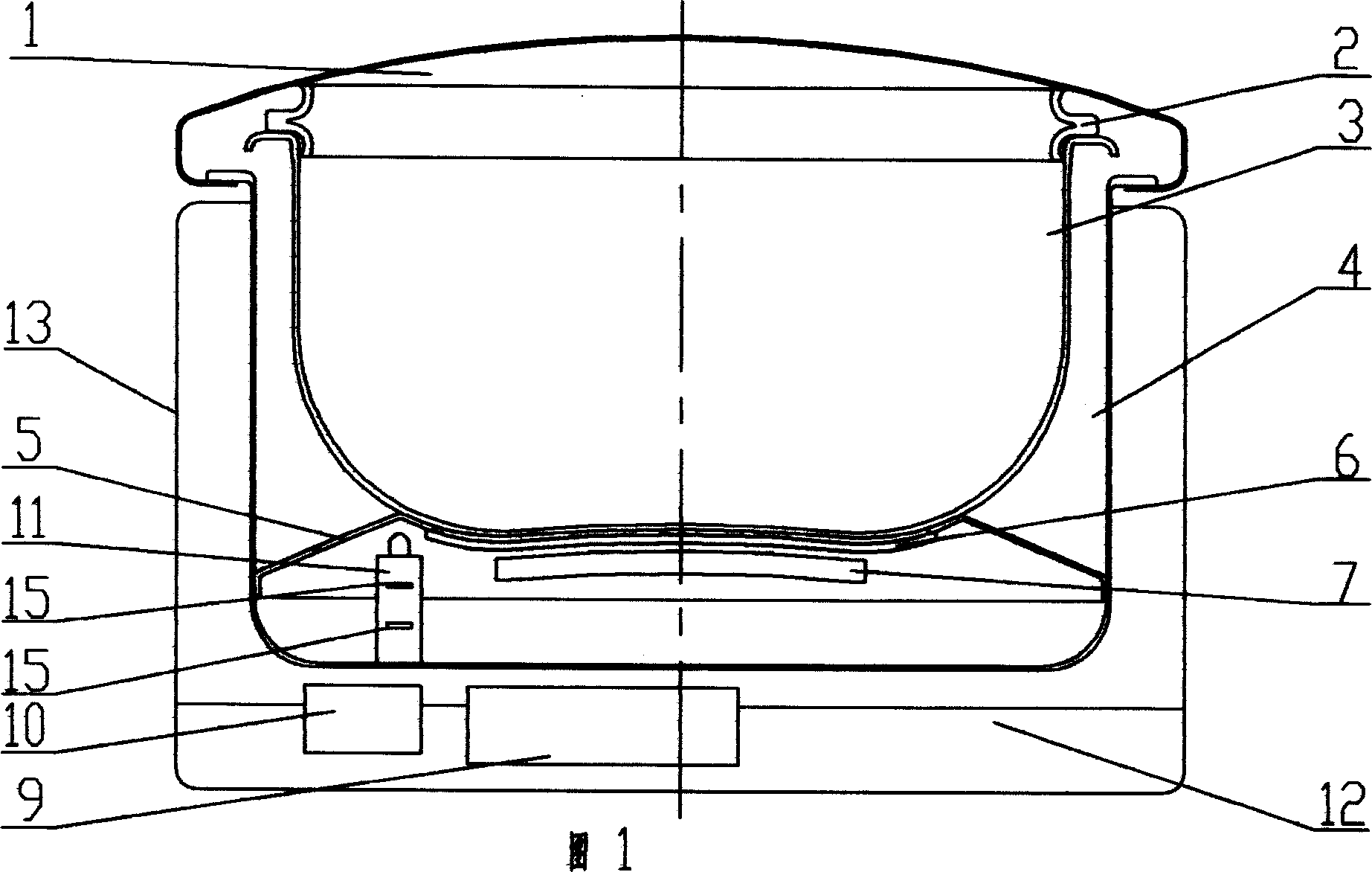

[0015]Embodiment 1 (see Fig. 1): Take 3 inner pots with a diameter of 20 cm as an example. The inner pot 3 is processed by an aluminum plate with a thickness of 2 mm, and a composite magnetically conductive stainless steel plate is welded on the bottom of the pot, so that the bottom of the inner pot 3 has magnetic conductivity. The inner pot 3 can also be made of a magnetically conductive stainless steel plate with good anti-corrosion performance, and the thickness of the stainless steel plate can be selected at about 0.7 mm. Outer pot 4 adopts the aluminized steel plate of 0.8mm, turns over the pot tooth on the pot mouth of outer pot 4, so that be screwed and connected with the pot cover tooth on the pot cover 1. Pot cover 1 adopts the stainless steel plate of about 1.0mm to make, and the overturning of pot cover teeth must match the pot teeth of outer pot 4, so that the cover teeth of pot cover 1 can be screwed and connected with the pot teeth of outer pot 4. Sealing ring 2...

Embodiment 2

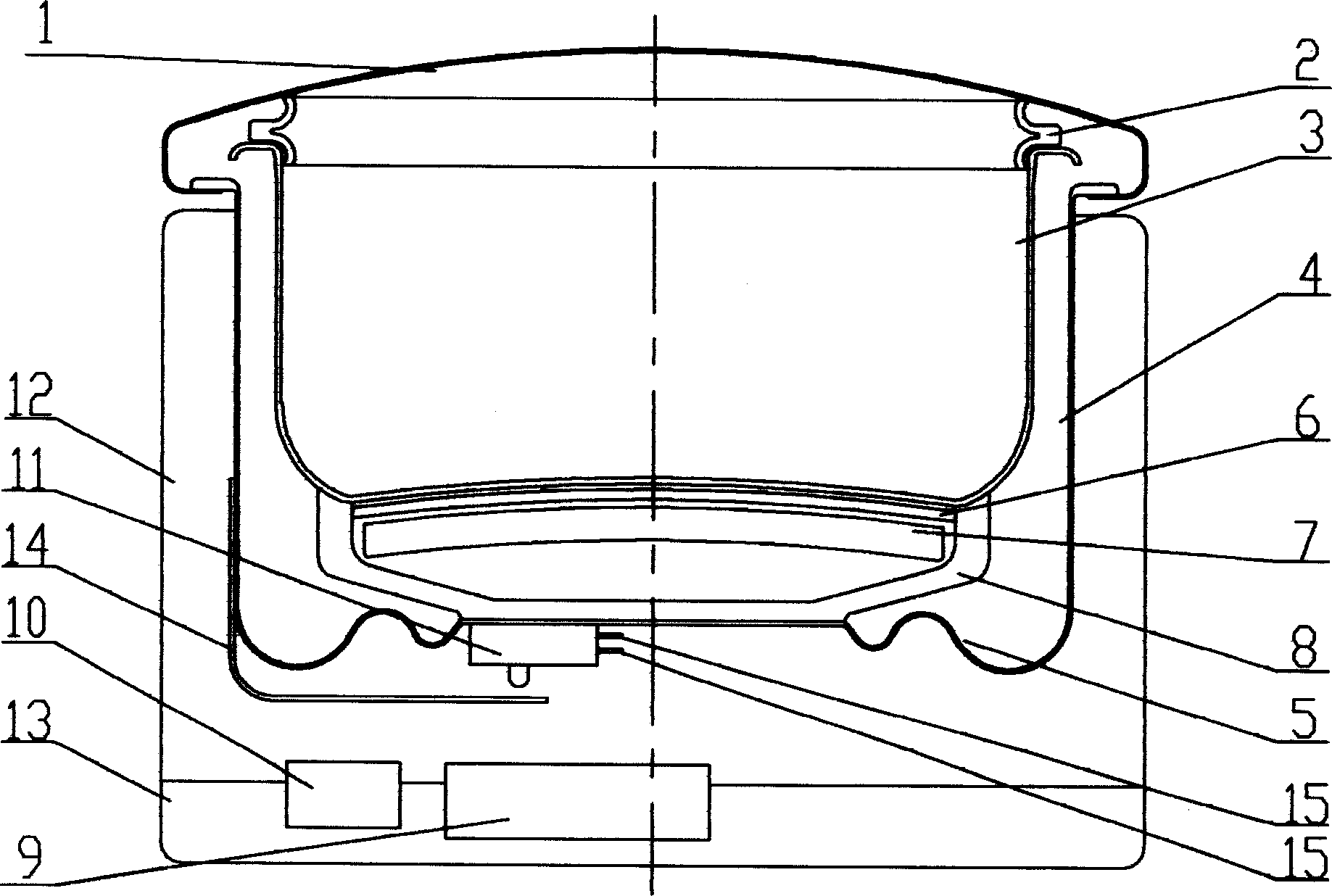

[0017] Embodiment 2 (see figure 2 ): the diameter of 3 inner pots is the same as Example 1. The outer pot 4 adopts 0.8mm aluminum-plated steel plate, and the bottom of the pot is stamped into a corrugated shape to form elastic arms 5 . It should be noted that the corrugated elastic arm 5 is the product of the combination of the diaphragm technology in the aviation high technology and the outer pot processing technology in the rice cooker industry. It has the characteristics of good product integration performance, high moldability and stable performance. The force transmission part 8 is made of a non-magnetic material, and can be made into various shapes. Considering that the direction and size of the force cannot be changed during the process of transmitting the pressure in the pot, the cross-sectional shape of the force transmission part 8 is as follows: The bow shape is better, and the real thing can be made into a bowl-shaped cast aluminum structure or zinc-aluminum allo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com