Floor-supporting structure of building

A technology for supporting structures and buildings, used in building structures, building components, buildings, etc., can solve the problems of occupants' shaking, vibration deformation, seasickness, etc., and achieve the effect of improving habitability and preventing the increase of up and down vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be described below based on the embodiments of the present invention shown in the drawings.

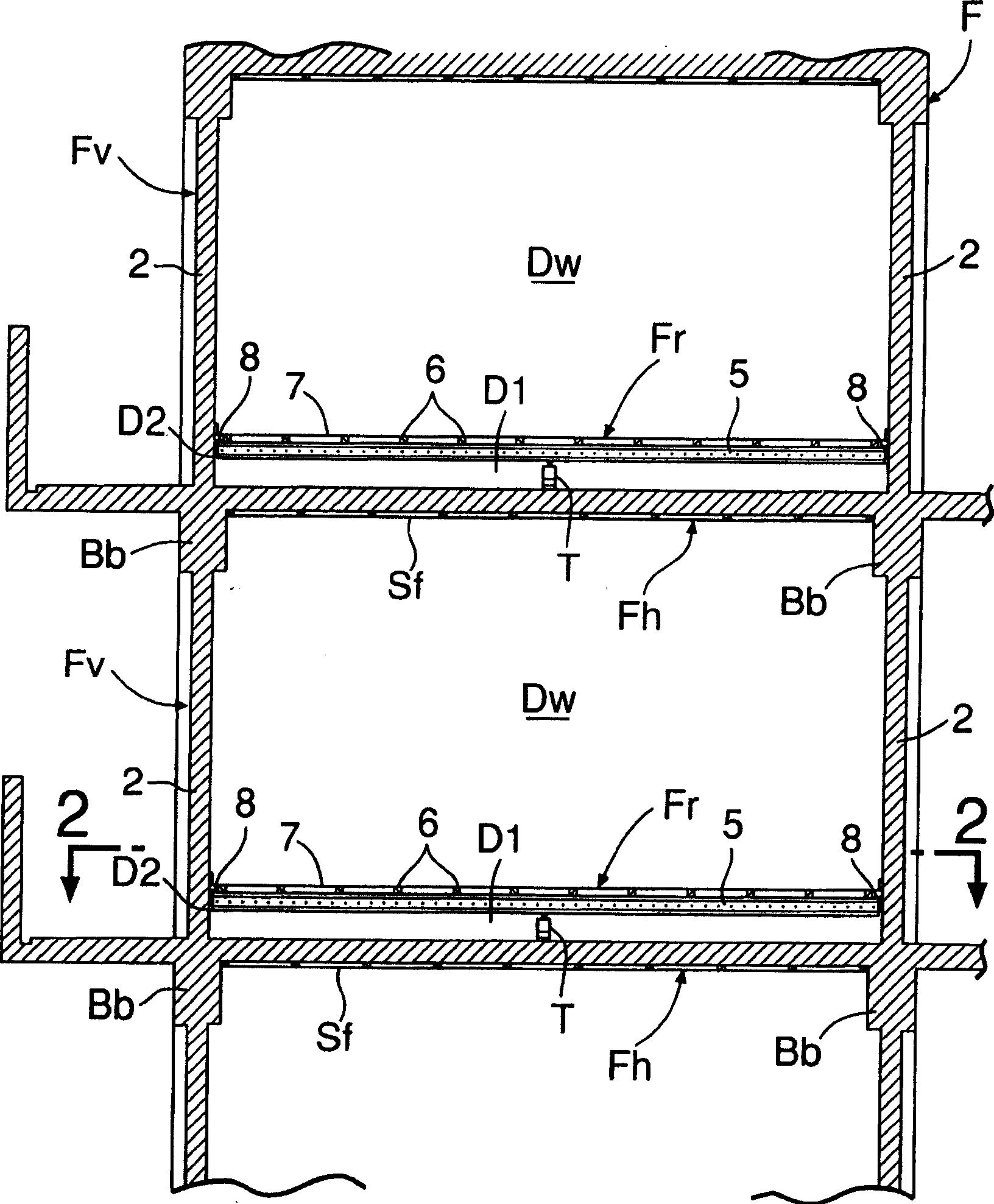

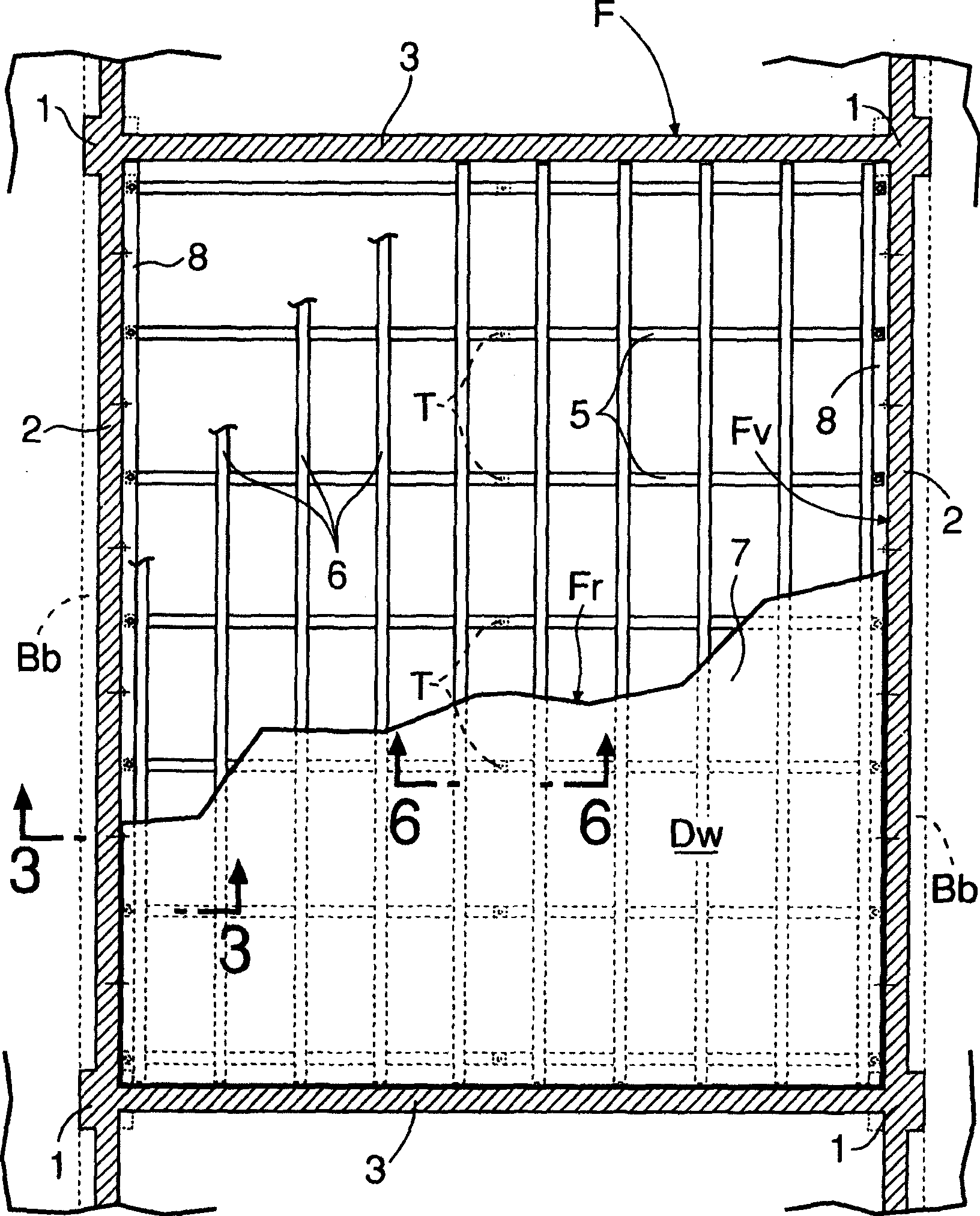

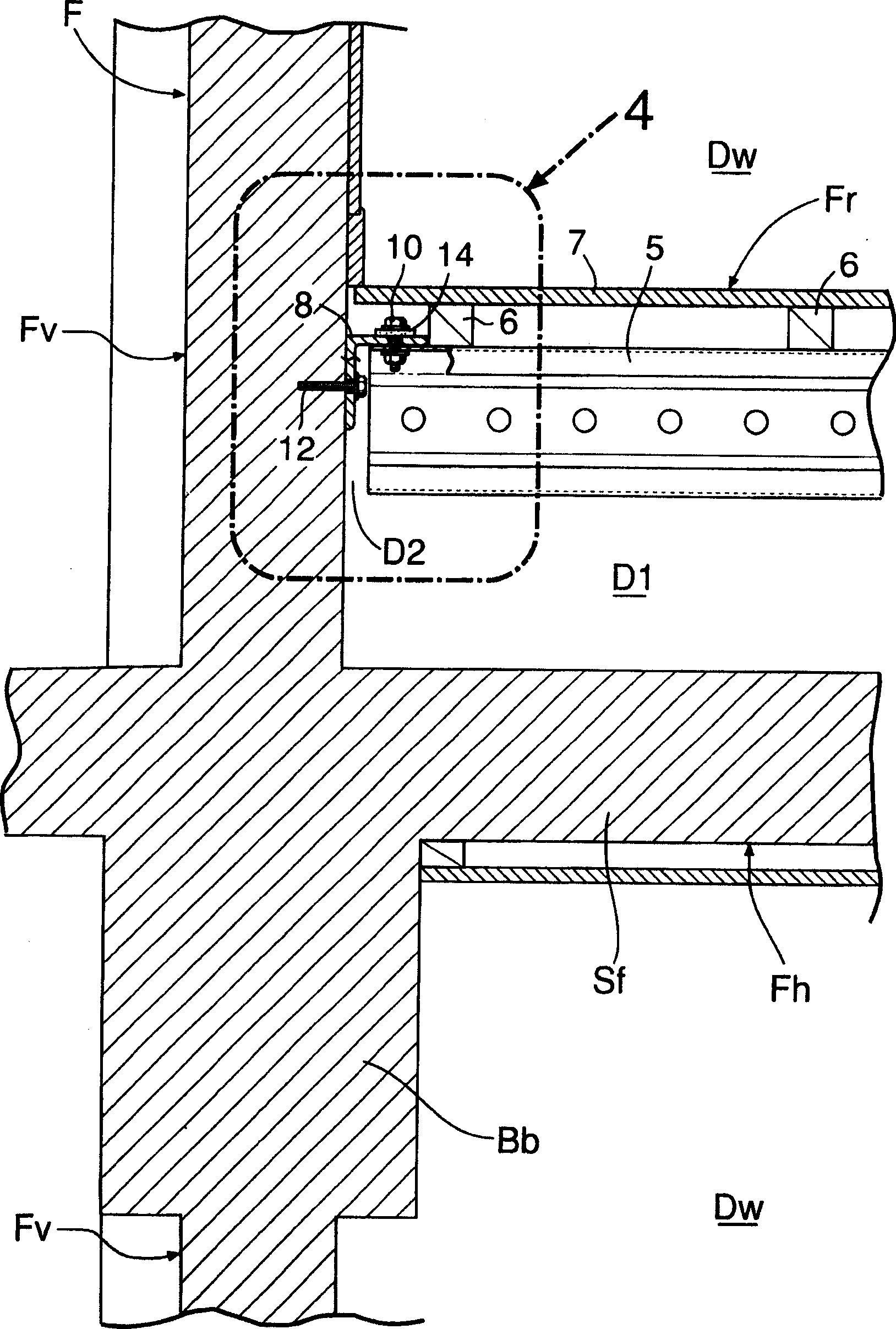

[0023] First, refer to Figure 1 to Figure 9 A first embodiment of the present invention will be described.

[0024]The concrete frame F of the main beam structure constituting the skeleton of the collective housing has a horizontal frame portion Fh and a vertical frame portion Fv; the horizontal frame portion Fh extends horizontally and divides the building into multiple floors; Extending in the vertical direction, the upper and lower horizontal frame parts Fh are connected to each other.

[0025] The above-mentioned horizontal frame portion Fh has a floor Sf that divides the living space Dw up and down (according to the characteristics of the present invention, it can be made as thin as possible compared with the conventional floor). The girder Bb is configured as a so-called "main beam structure". Moreover, the said vertical frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com