Drier and method of controlling drying for the same

A dryer and drying technology, applied in dryers, household dryers, drying solid materials, etc., can solve problems such as increased manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Preferred embodiments of the present invention will now be described in detail with reference to the embodiments shown in the accompanying drawings.

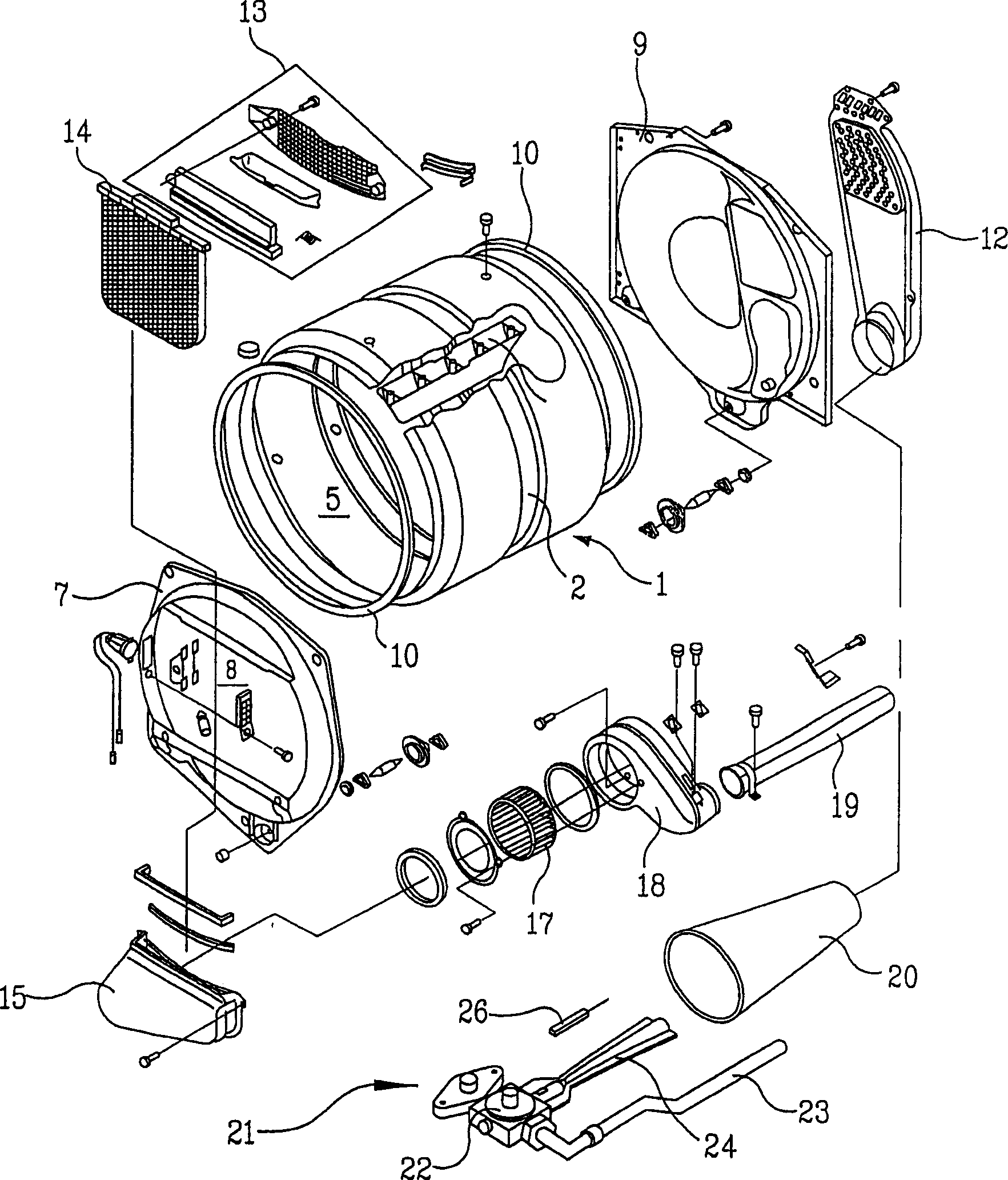

[0055] Figure 4 and 5 The structure of a dryer proposed according to the present invention is shown.

[0056] see Figure 4 and 5 , The dryer of the present invention has a housing 53 forming its outer cylinder. A front plate 41 is connected to the front end of the housing 53 to form the front of the dryer. The drum 44 is rotatably installed inside the housing 53 so that laundry can be loaded into the drum 44 and dried therein. The drum 44 is rotated by a drum drive belt 54 which is looped around the outer surface of the drum 44 .

[0057] A vent hole 43 is formed corresponding to the inner surface of the front plate 41 , which opens toward the inside of the drum 44 . The function of the exhaust hole 43 is to exhaust the air from the drum 44 . A lint filter 36 is provided at the entrance of the exhaust hole 43 to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com