Color filter and electro-optical device

An electro-optical device and color filter technology, which is applied in optics, optical filters, nonlinear optics, etc., can solve problems such as uneven distribution of liquid crystal layers, uneven surfaces of colored layers and barrier layers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

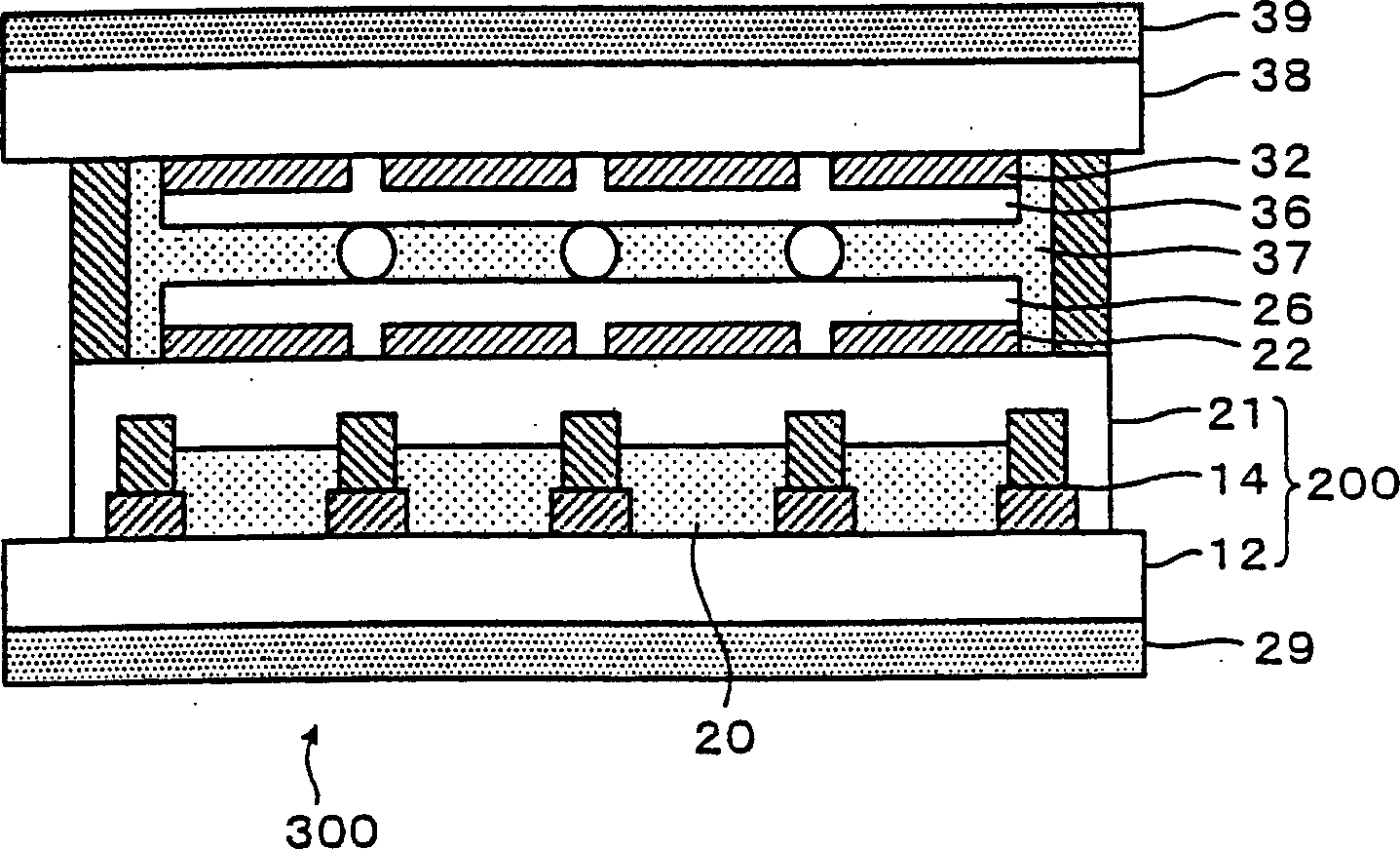

[0033] Embodiments of the present invention will be described below with reference to the drawings.

[0034] (1. The structure of the color filter layer)

[0035] (1-1 First Embodiment)

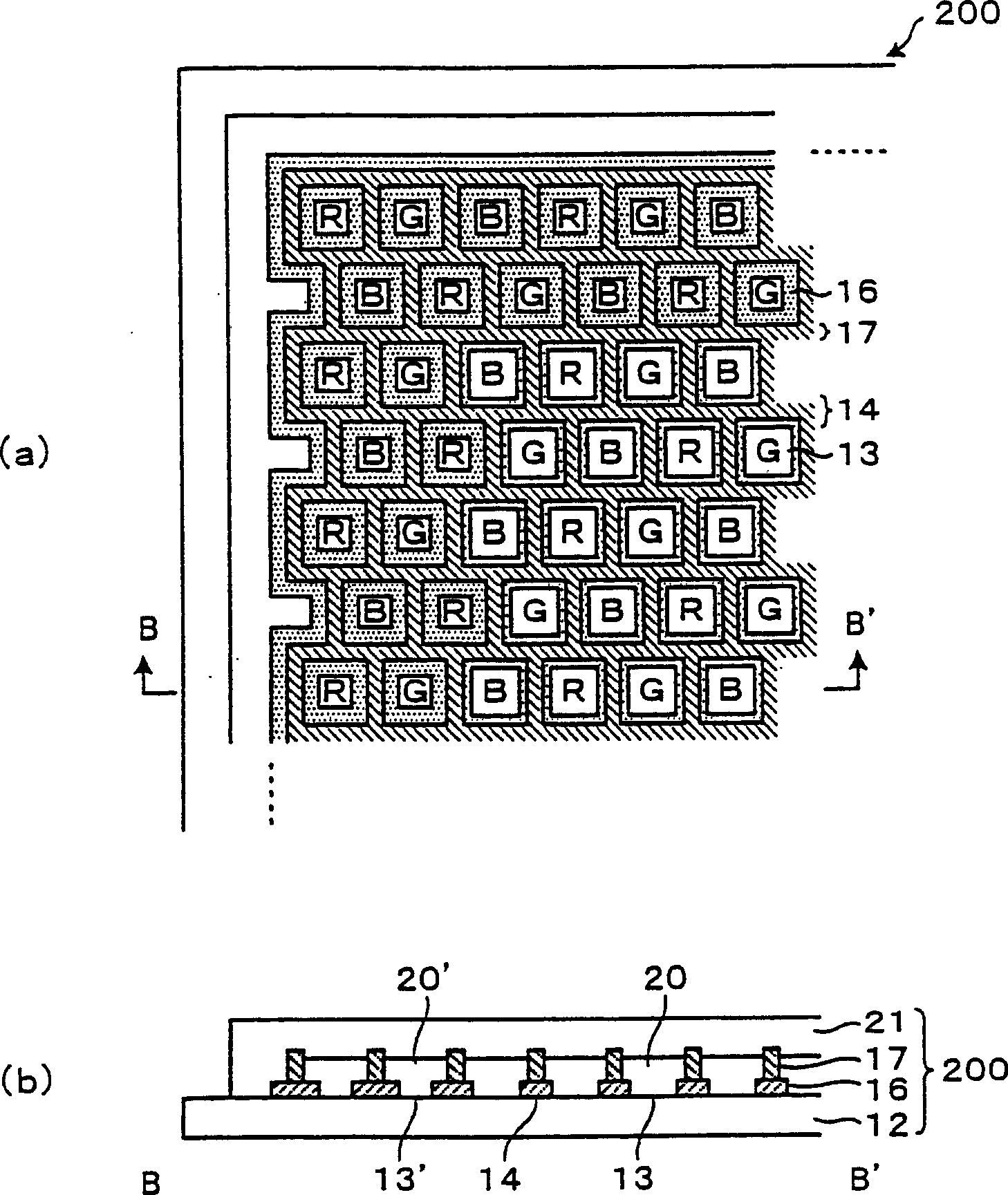

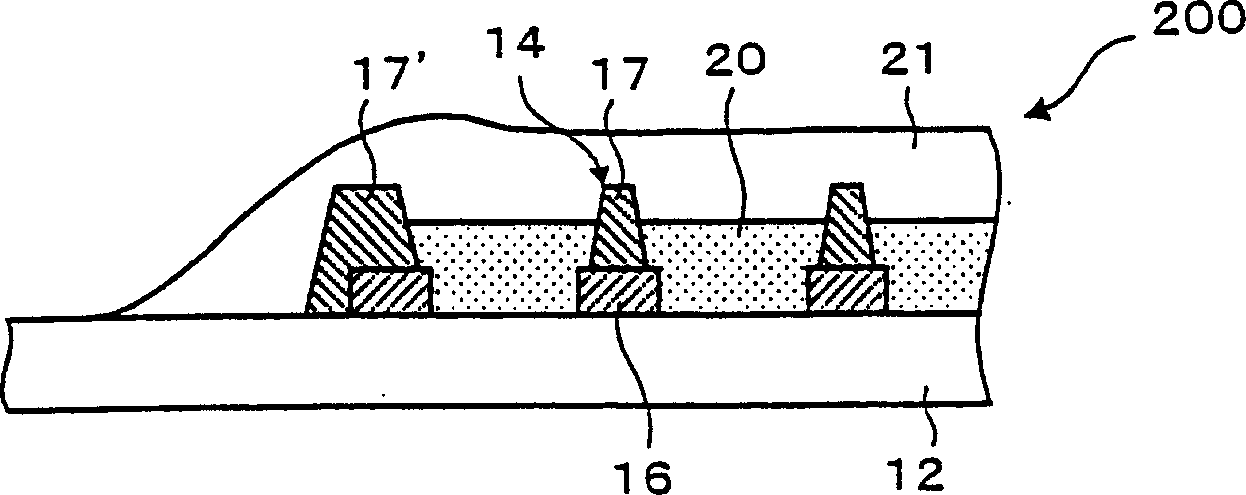

[0036] figure 1 It is a partially enlarged view of the color filter film layer in the first embodiment of the present invention. figure 1 (a) is a top view, figure 1 (b) is along figure 1 (a) Cross-sectional view along line B-B'.

[0037] Such as figure 1 As shown in (a), the color filter layer 200 is provided with pixels 13 arranged in a square array on the substrate 12 , and the boundaries between pixels are divided by partition walls 14 . One of red (R), green (G), and blue (B) inks is introduced into each pixel 13 . In this example, the arrangement of red, green, and blue is a mosaic arrangement, but other arrangements such as a stripe arrangement and a triangle arrangement may also be used.

[0038] Such as figure 1 As shown in (b), the color filter layer 200 is provided with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com