Door structure of container, its making method and the container therewith

A container and door leaf technology, applied in the field of containers, can solve the problems of low cargo loading efficiency, insufficient opening height of the operating area door, and large container door occupation, and achieve the effect of improving loading and unloading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

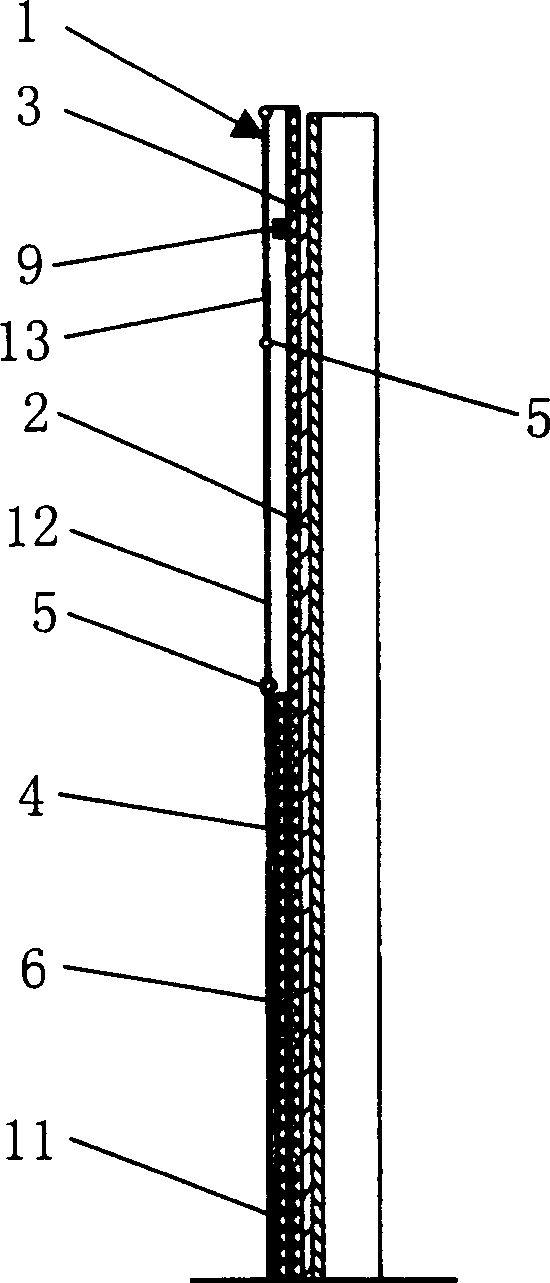

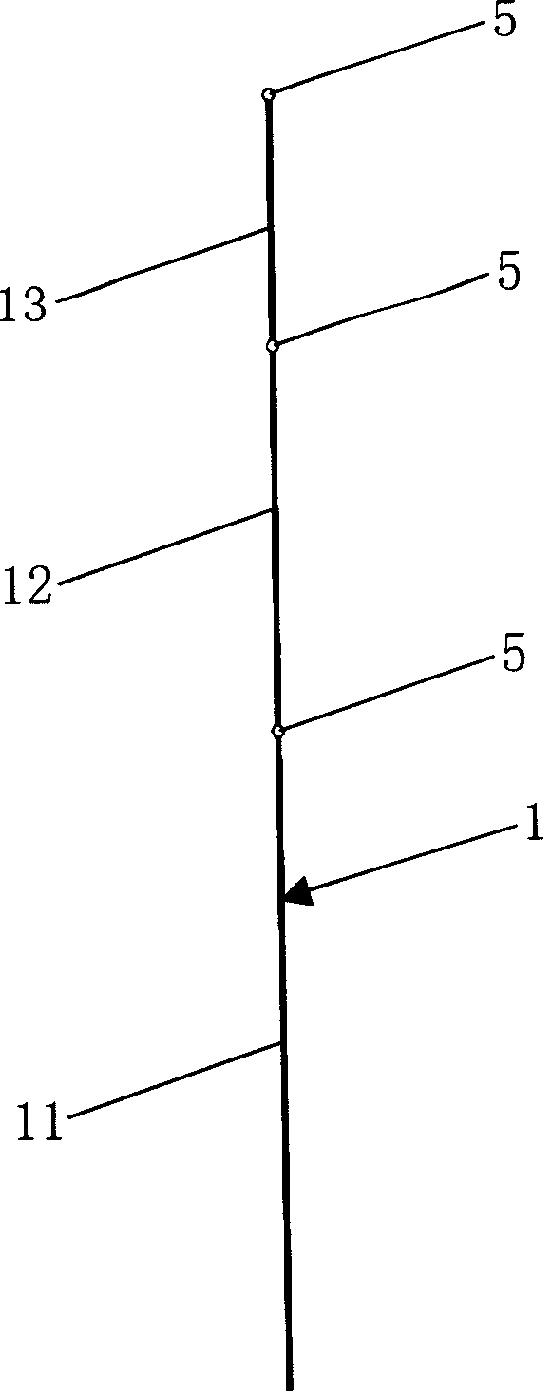

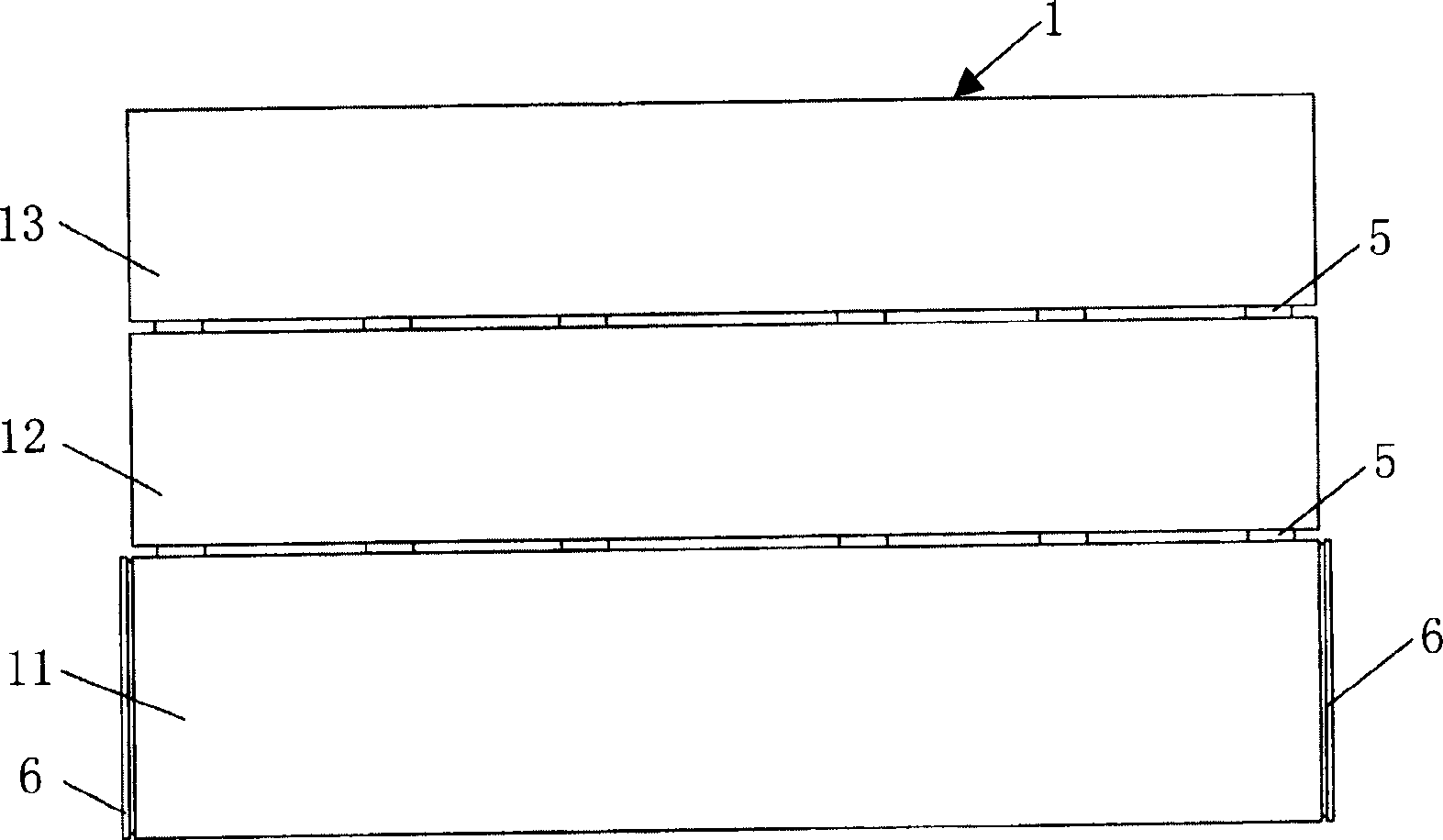

[0069] Such as figure 1 As shown, the door structure of the present invention includes: a door leaf 1, a secondary sliding block 2, a supporting column 3, a guide rail 4, a hinge 5, a primary sliding block 6 and a guide block 9, wherein the door leaf 1 is integral in the width direction, and the vertical direction The upper part is divided into three pieces hinged with each other by hinges 5, namely the bottom door leaf 11, the middle door leaf 12 and the top door leaf 13. The top door leaf 13 is hinged to the guide rail 4 and the hinge point is at the top of the guide rail 4. The hinged bottom door leaf 11, middle door leaf 12 and top door leaf 13 can be folded. figure 2 and image 3 The structure of the door leaf 1 is clearly shown. The guide rail 4 is arranged between the primary sliding block 6 and the secondary sliding block 2. Such as Figure 4 As shown, the guide rail 4 made of metal or non-metal has two C-shaped guide grooves 41 on both sides. Each guide groove 41 slides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com