Shell type heat exchanger configured from composite tubes of figured pattern card

A combined tube and heat exchanger technology, applied in the direction of heat exchanger types, heat exchanger shells, indirect heat exchangers, etc., can solve the problem of low natural frequency of heat exchange tubes, shortened life of heat exchangers, poor anti-vibration capabilities, etc. problem, to achieve the effect of reducing the flow dead zone and leakage dead zone, increasing the effective heat transfer area, and improving the effective heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

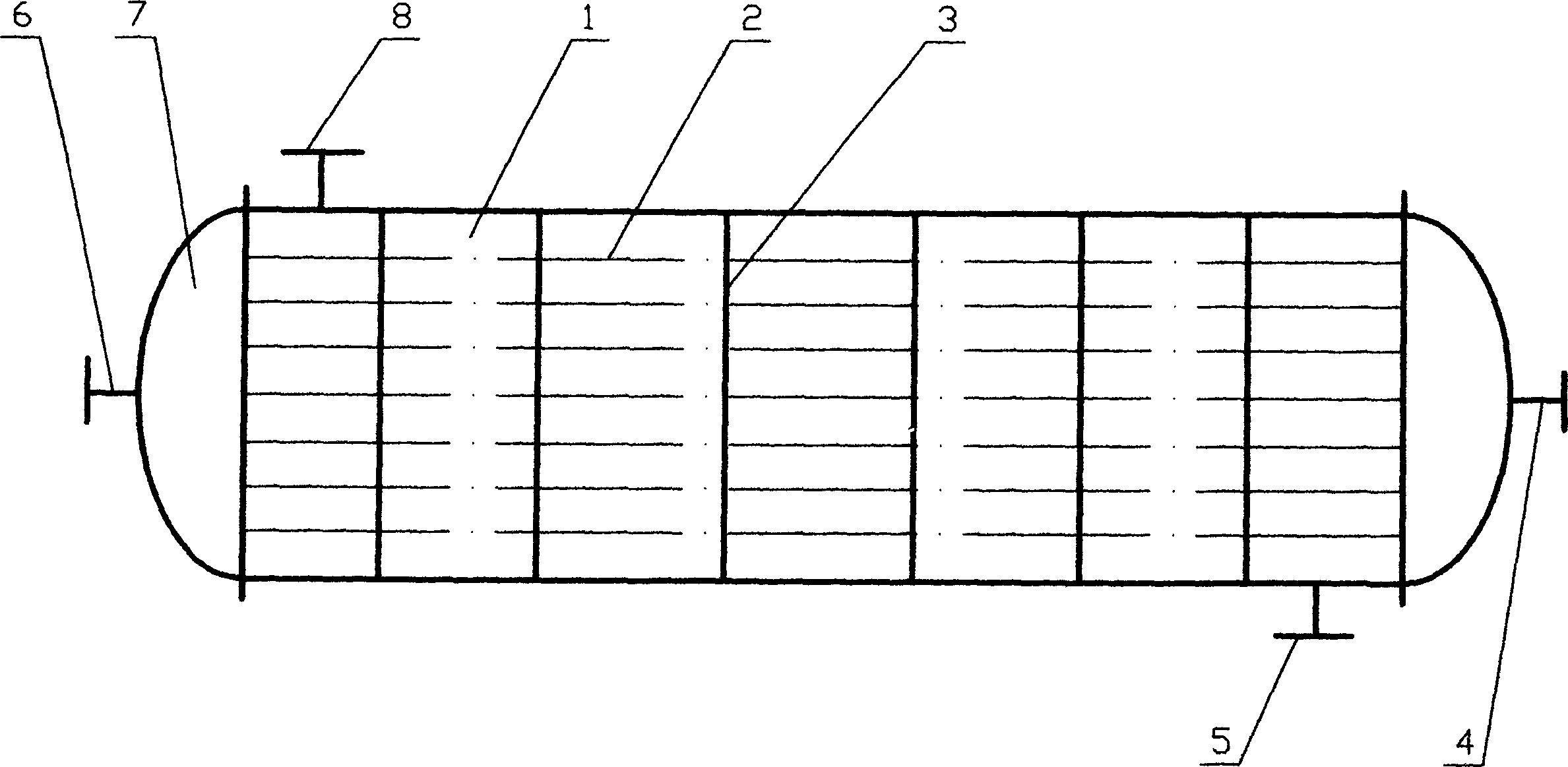

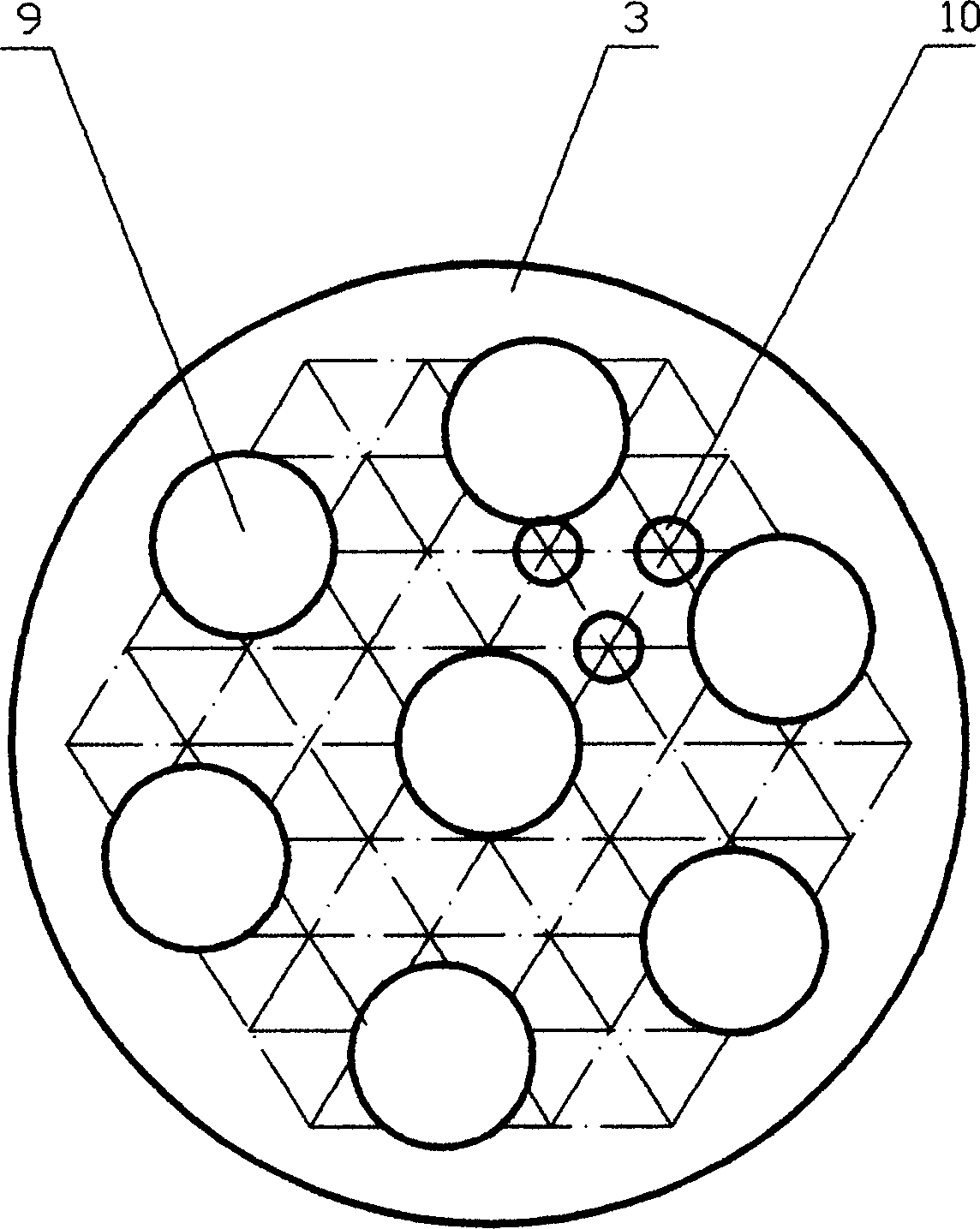

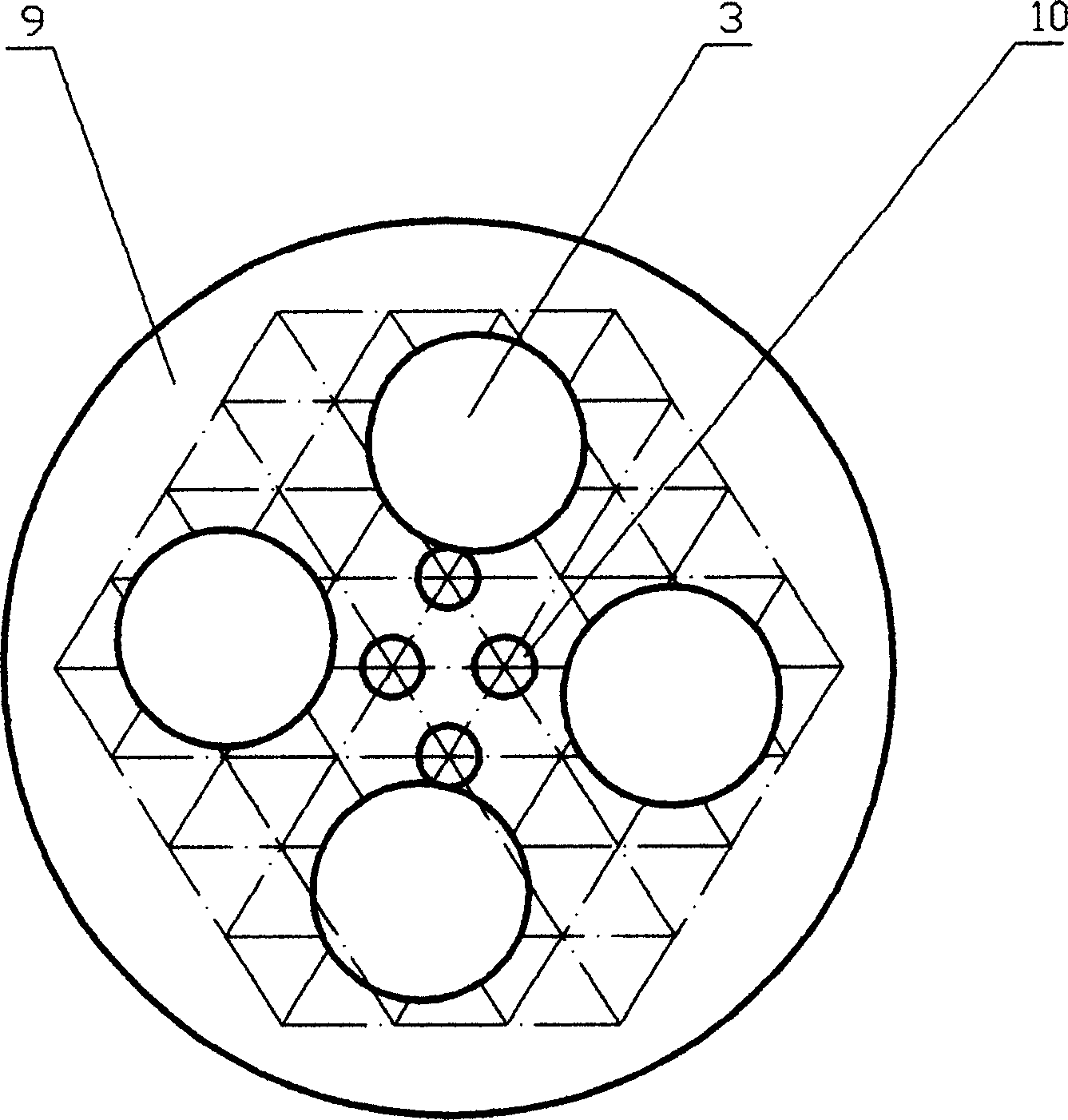

[0021] refer to figure 1 , figure 2 , image 3 , flower-plate combined shell-and-tube heat exchanger, including shell [1], cover [7], tube bundle [2] and tube-side inlet and outlet [6], [4] on the cover and shell on the shell Cheng import and export [5], [8], in the shell [1], there are flower plates [3] whose outer diameter corresponds to the inner diameter of the shell, and the flow direction of the flower plate [3] is perpendicular to the tube bundle [2]. The flower board [3] has several through holes [9], and the positions of the through holes [9] between adjacent flower boards [3] are staggered. The shell-side fluid flow is organized by staggering the positions of the through holes [9] of each flower plate [3], and the flow direction and velocity of the fluid are constantly changed to generate mixed flow and improve heat exchange efficiency.

[0022] The through hole [9] of flower plate is circular, see figure 2 , image 3 , and the projection of each through hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com