Method for moving large-scale heavy member to launch and float on water, and member mounting method

A large-volume, component-based technology, applied in the field of transportation and installation of large-volume and heavy components, to reduce costs, wide application range, and reduce construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing but does not form any restriction to the present invention:

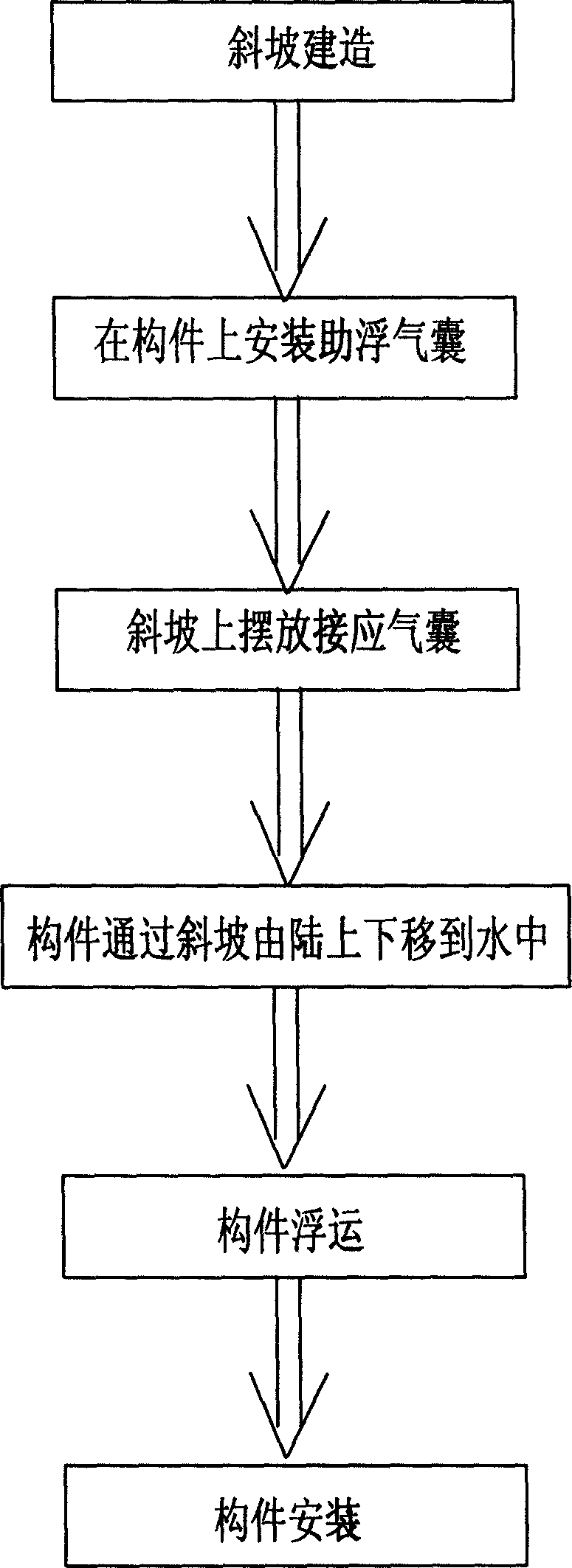

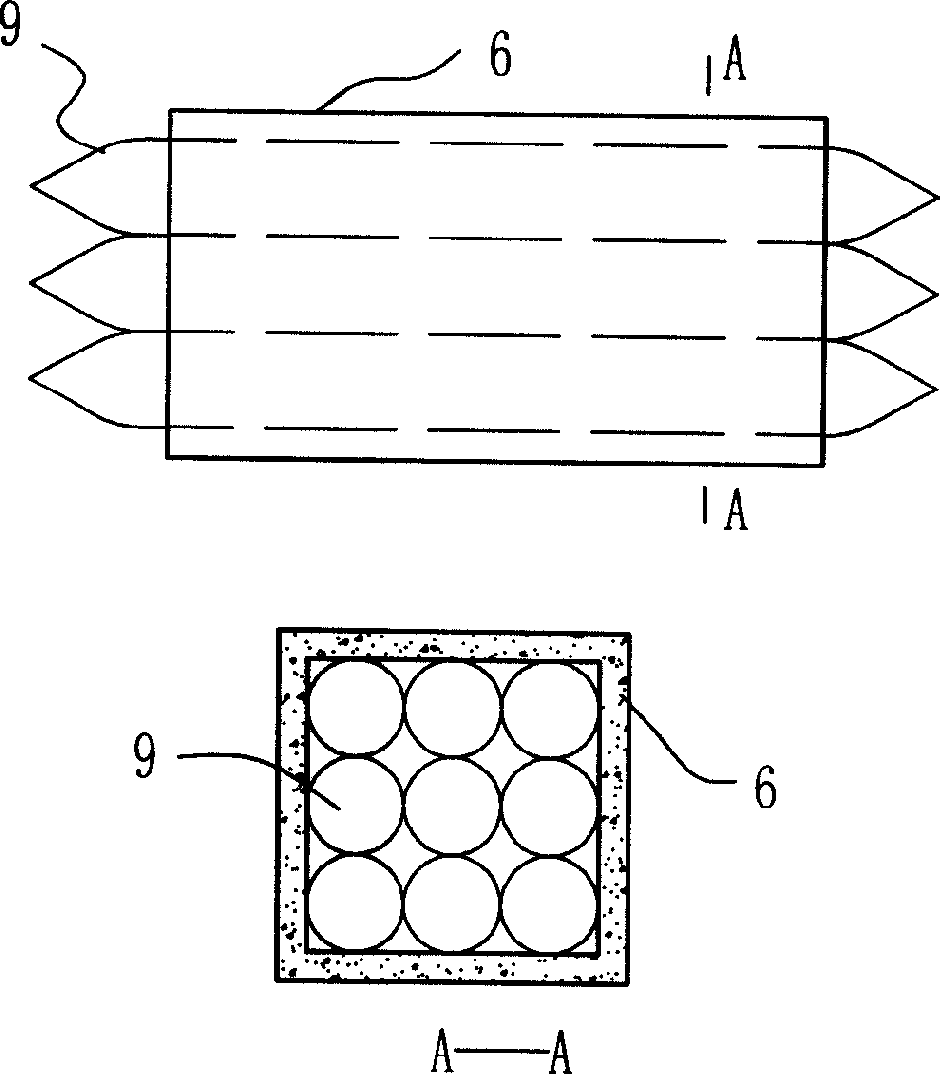

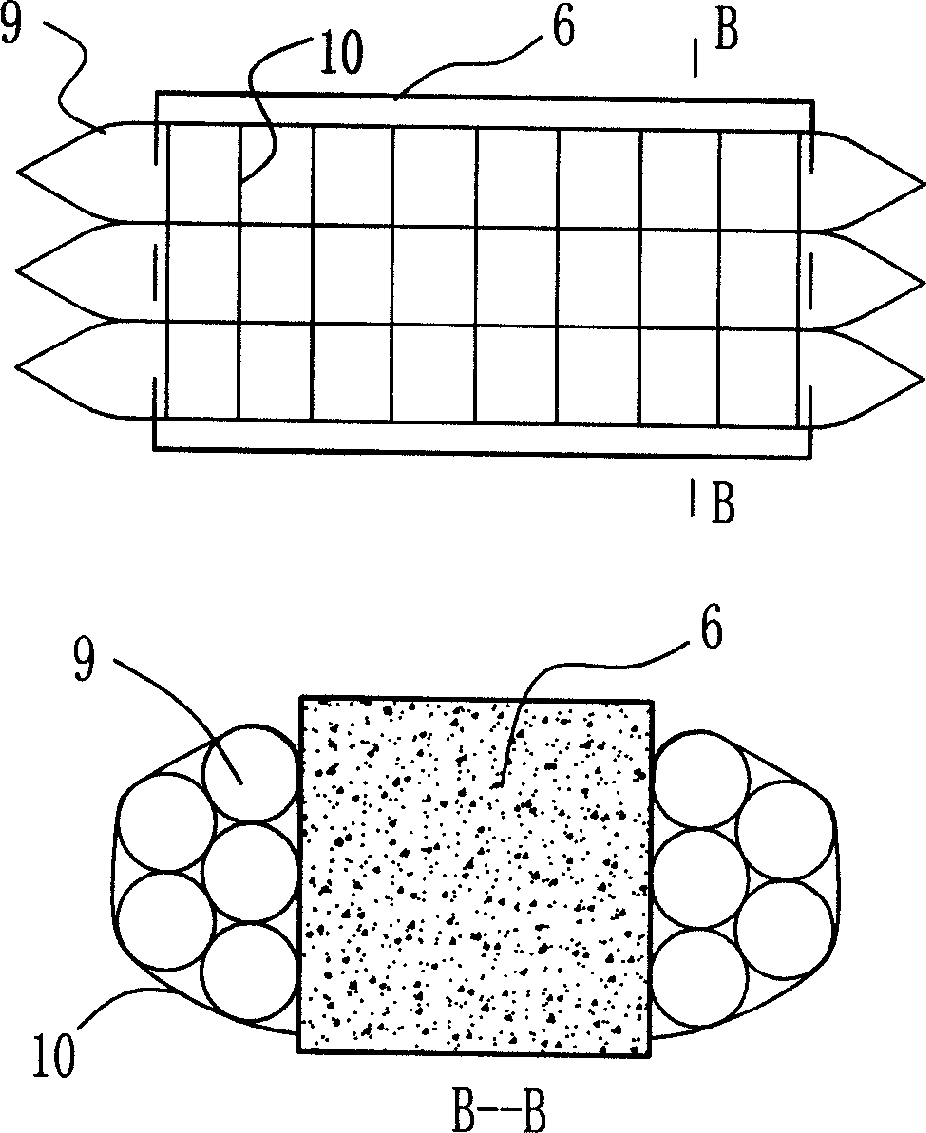

[0032] like Figure 1 to Figure 10 As shown, the present invention discloses a method of using an airbag to transport a large-volume heavy component into the water through a slope, and then float and install the component on the water, including the following steps:

[0033] (1) Slope construction, such as Figure 4 As shown, the slope is composed of an onshore section and an underwater section. The onshore section 1 of the slope adopts the method of laying and filling block stones on the compacted foundation, and pouring concrete on the block stones; Stone, leveling, and finally the flow method of laying a layer of steel plate or concrete pad on the leveled block stone surface to build the transport slope, and pre-embed the pull ring 3 for fixing the underwater air bag on the steel plate or reinforced concrete pad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com