Light guide panel and surface emitting device

A light guide plate and reflective surface technology, applied in optics, nonlinear optics, diffuser elements, etc., can solve the problems of difficult manufacturing of light guide plates and small control range of the angle of outgoing light, etc., and achieve the effect of cost saving and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

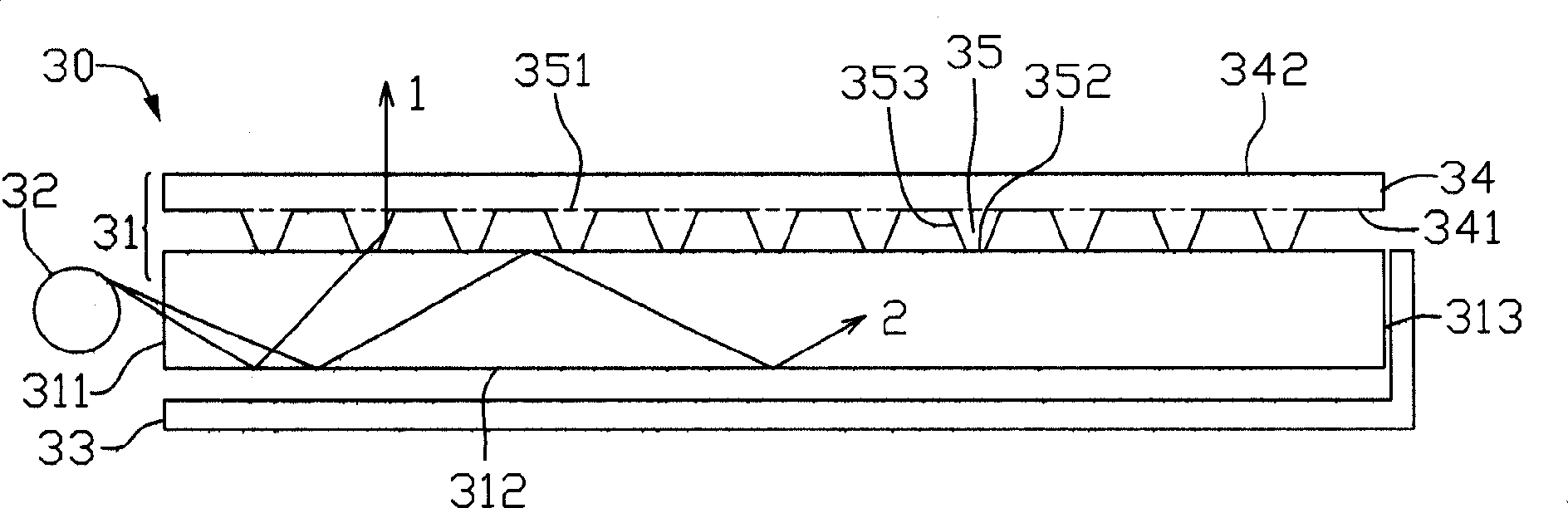

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

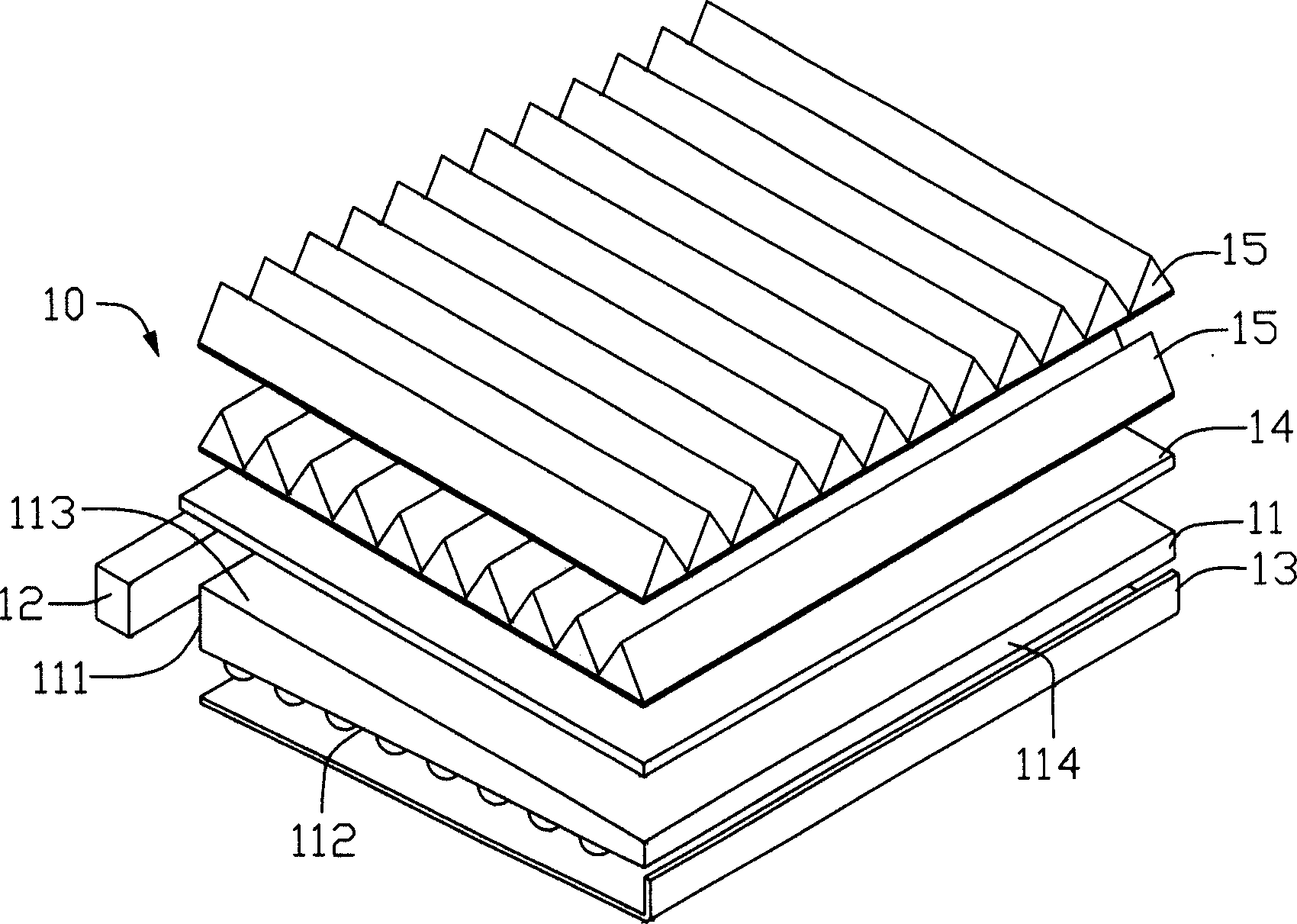

[0031] see image 3 , is a schematic structural view of the surface light-emitting device provided by the present invention. The surface emitting device 30 includes a light guide plate 31 , at least one light source 32 close to the side of the light guide plate 31 , and a reflection sheet 33 close to the bottom of the light guide plate 31 . Wherein, the light guide plate 31 has an upper and lower structure, and the lower structure has at least one light incident surface 311 close to the light source 32 , a bottom reflective surface 312 , and an end surface 313 opposite to the light incident surface 312 . The upper structure includes a substrate 34 . The substrate 34 at least has a substrate bottom surface 341 facing the lower layer of the light guide plate and a light emitting surface 342 opposite to the substrate bottom surface 341 . Protrusions 35 are arr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com