Electromagnetic relay

An electromagnetic relay and current technology, applied in the direction of electromagnetic relay, relay, electromagnetic relay detailed information, etc., can solve the problem that the internal resistance of the contact circuit side cannot be reduced, and achieve the effect of ensuring contact stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

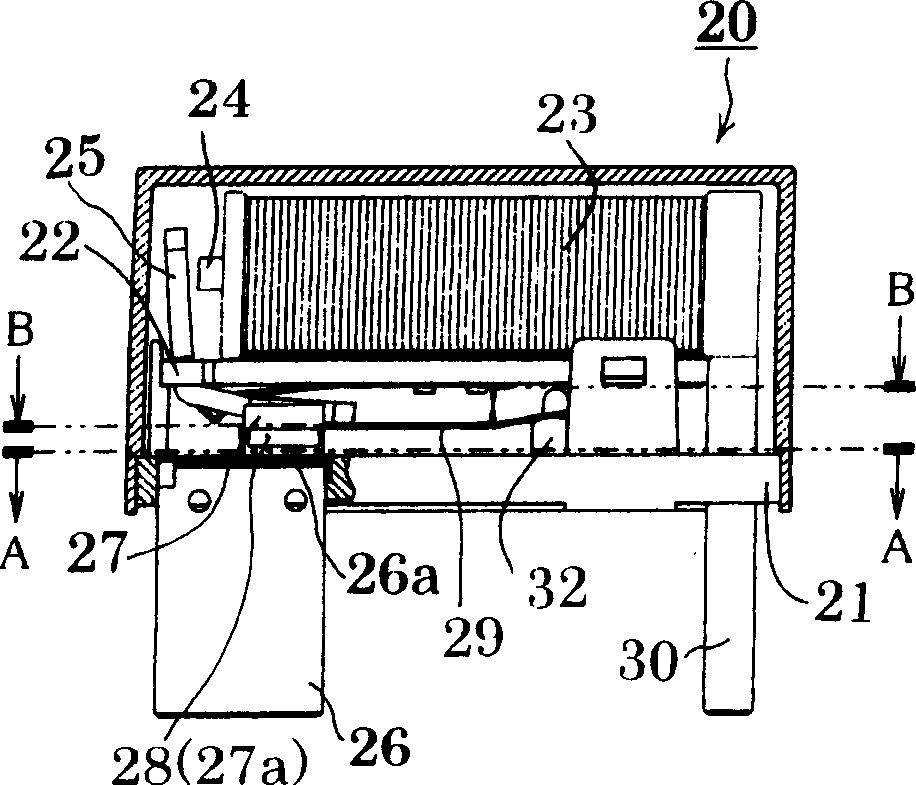

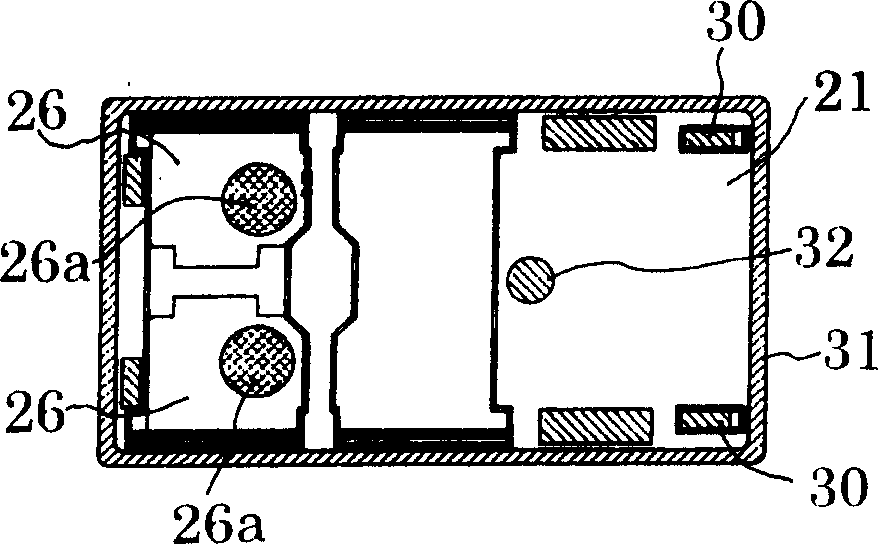

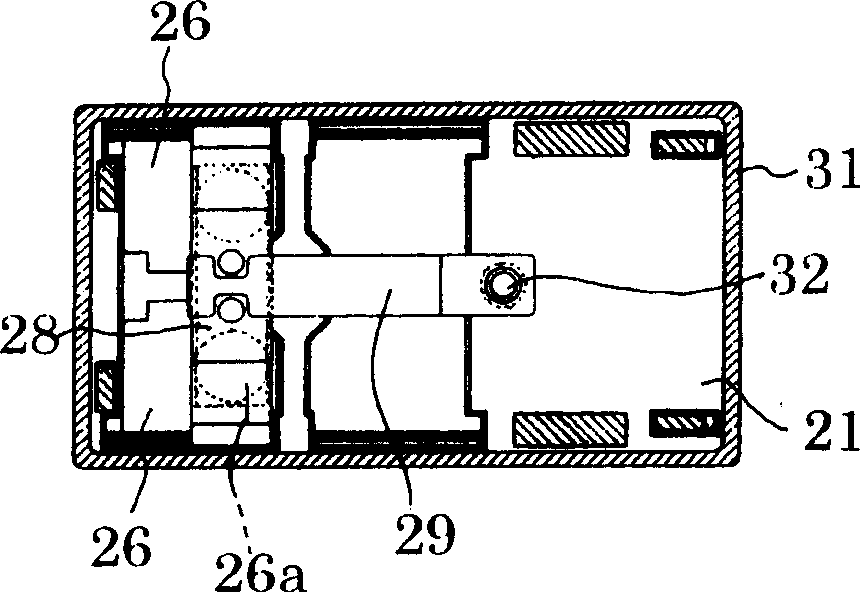

[0032] The present invention can make the internal resistance on the contact circuit side as small as possible and the purpose of conducting a large current can be achieved by providing an electromagnetic relay with an electromagnetic drive block formed by a coil, an iron core, a yoke and an armature, And each end of a pair of terminals fixed on the substrate is provided with a fixed contact, and a moving spring of a movable contact is provided at a position corresponding to each fixed contact. , the armature drives the moving spring and opens and closes the contact circuit, wherein the moving spring is held on the base body in a way of holding both ends, and is arranged side by side with the above-mentioned terminal piece, and a movable contact is provided on the moving spring.

[0033] Figure 1 (movable plate and movable contact described later) and Figure 4a with Figure 4b In (no movable plate), 20 denotes an electromagnetic relay of the present invention. This electrom...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap