Wire feeder for plastic hose steel wire winding machine

A steel wire winding machine and plastic hose technology, which is applied in the direction of thin material processing, transportation and packaging, and delivery of filamentous materials, etc., can solve the problem of reducing the overall bearing pressure of plastic hoses, reducing the strength of the wire skeleton, and the position cannot be adjusted and other problems, to achieve the effect of enhanced strength, smooth surface, and improved overall bearing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

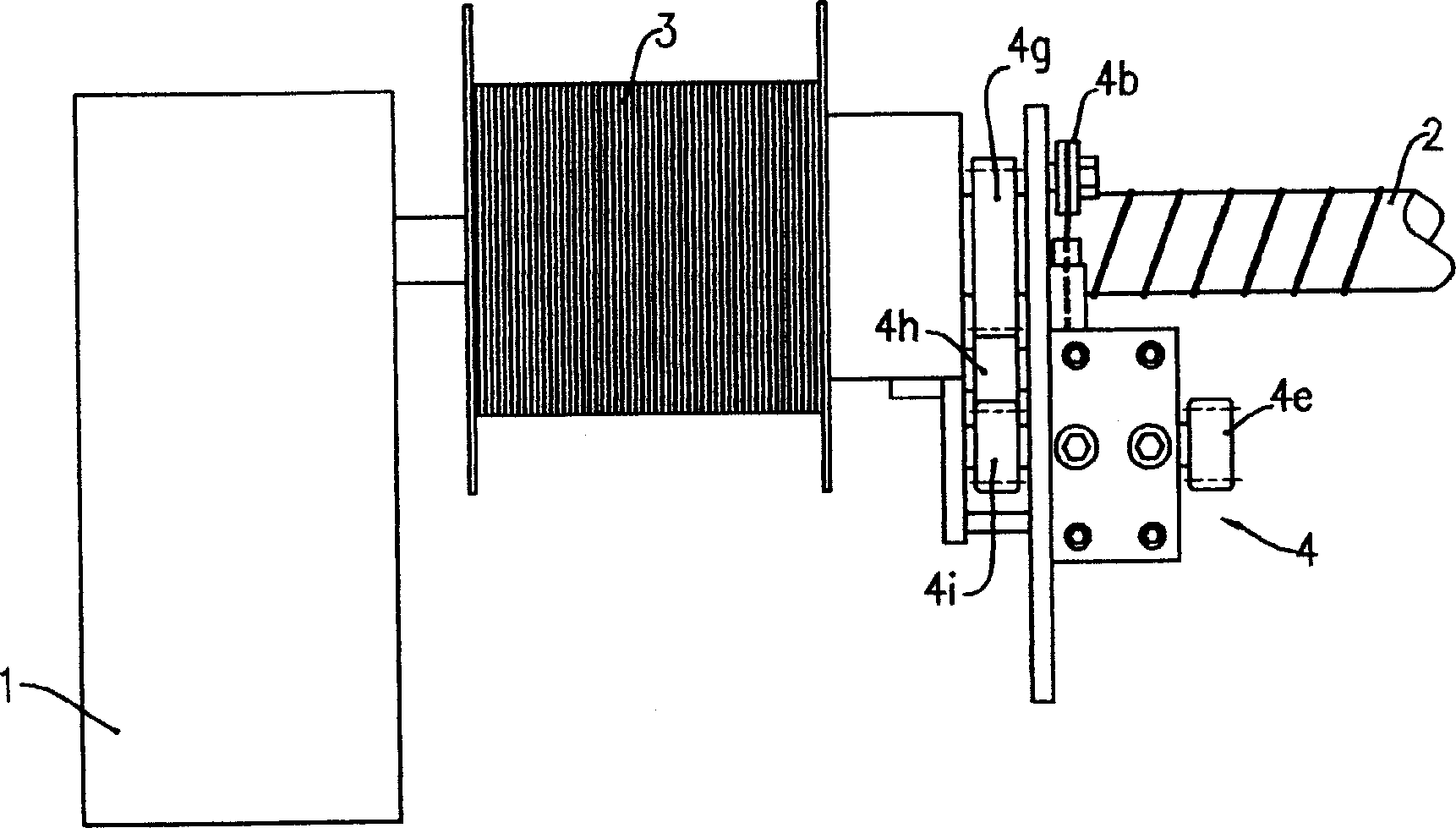

[0017] figure 1 A plastic hose wire winding machine is shown, the winding machine main shaft 2 is driven by the power device 1, the steel wire roller 3 wrapped with steel wire is installed on the winding machine main shaft 2, and the frame of the wire feeding device 4 is installed on the winding machine main shaft 2.

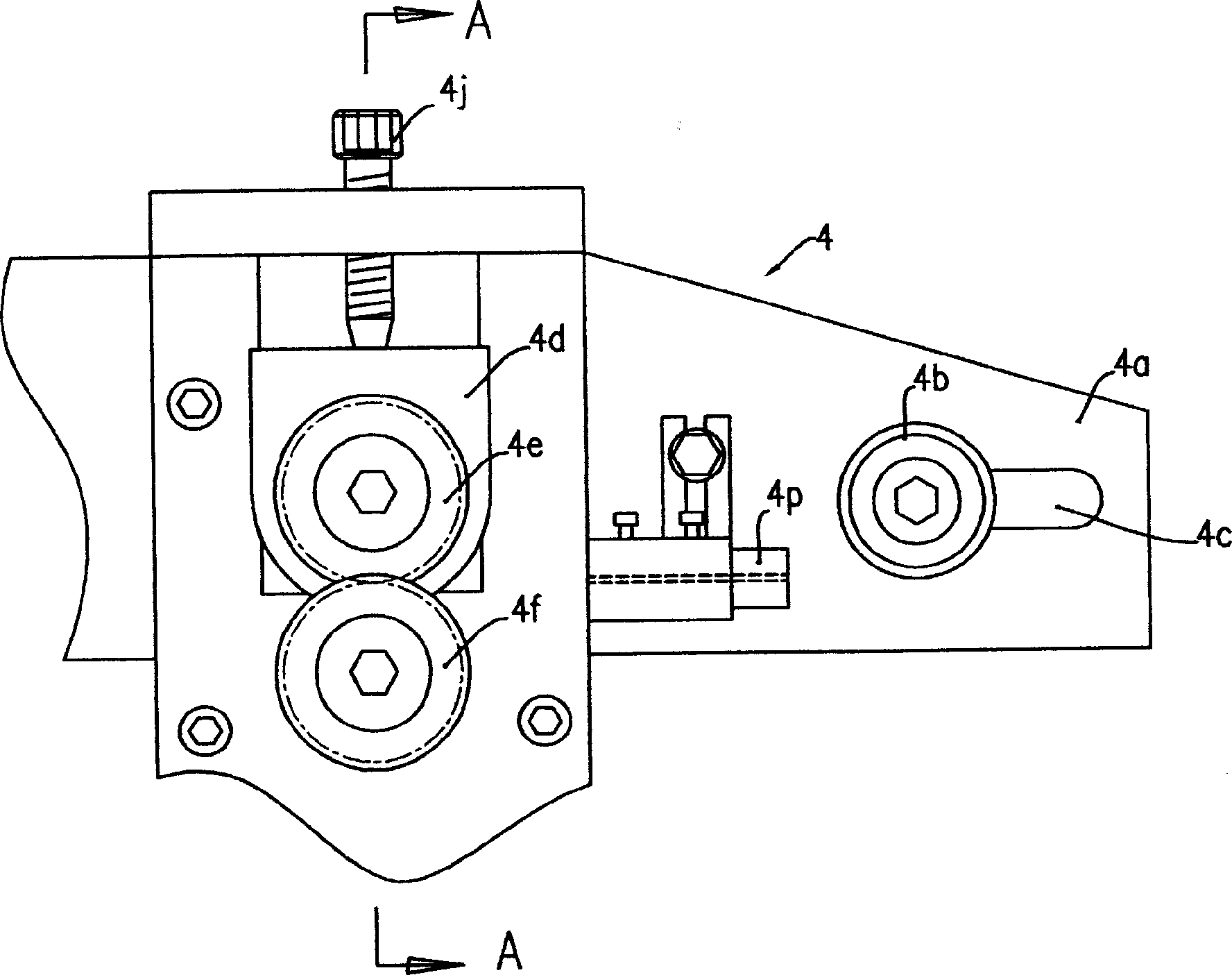

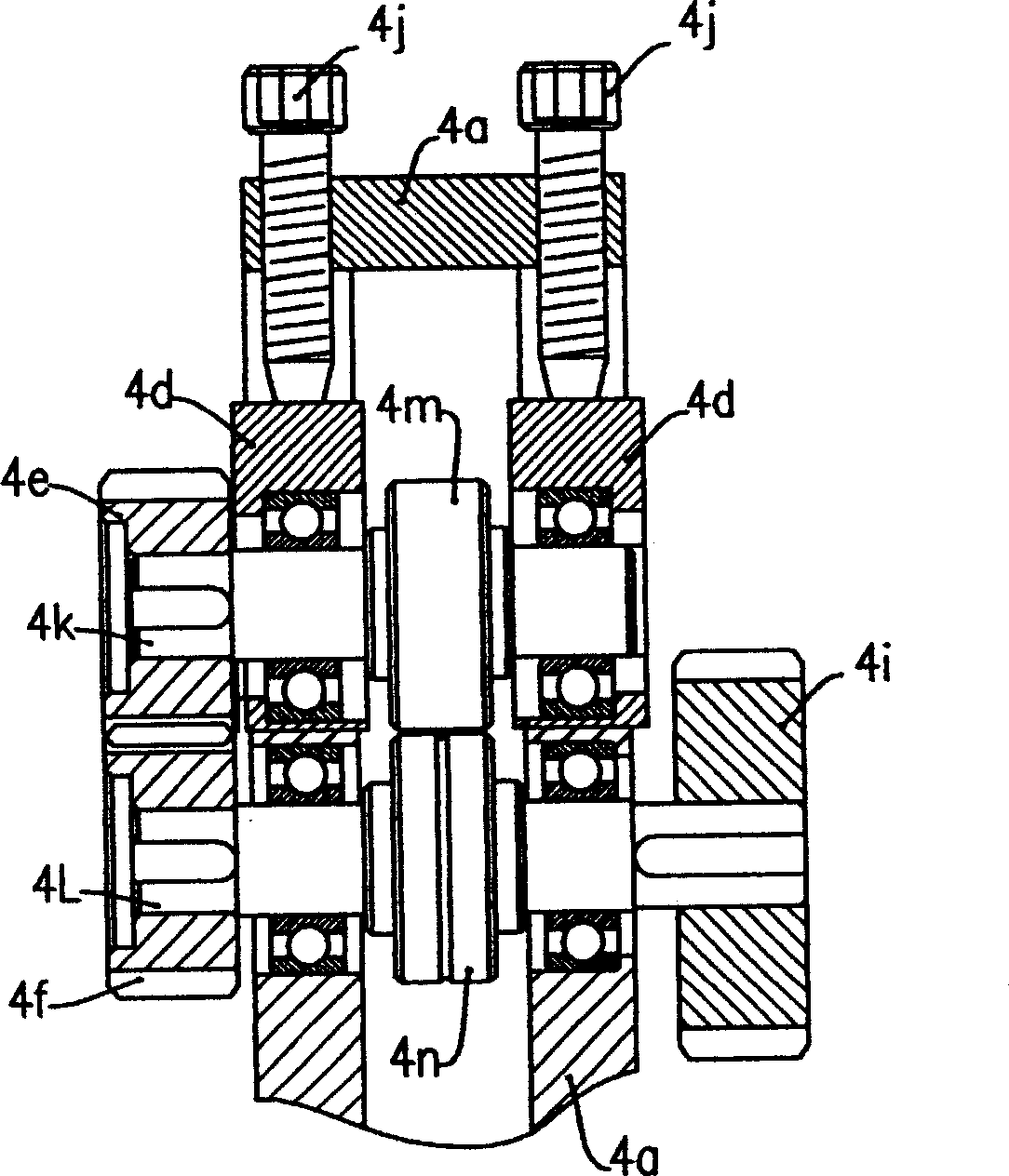

[0018] Such as figure 2 and image 3 Commonly shown, the wire feeding device 4 includes first and second wire pressing wheel shafts 4L and 4k mounted on the frame, and two wire pressing wheels respectively fixed to the first and second wire pressing wheel shafts 4L and 4k 4n and 4m, the pressing wheels 4n and 4m may also be integrated with the first and second pressing wheel shafts 4L and 4k respectively. A main gear drive is provided between the first wire pressing wheel shaft 4L and the winding machine main shaft 2, and a wire pressing wheel 4m and 4n are arranged between the first and second wire pressing wheel shafts 4L and 4k to face each other. Rotatin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap