Method for measuring non-calibrating neutron water content

A measurement method, calibration-free technology, applied in the use of radiation for material analysis, special data processing applications, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

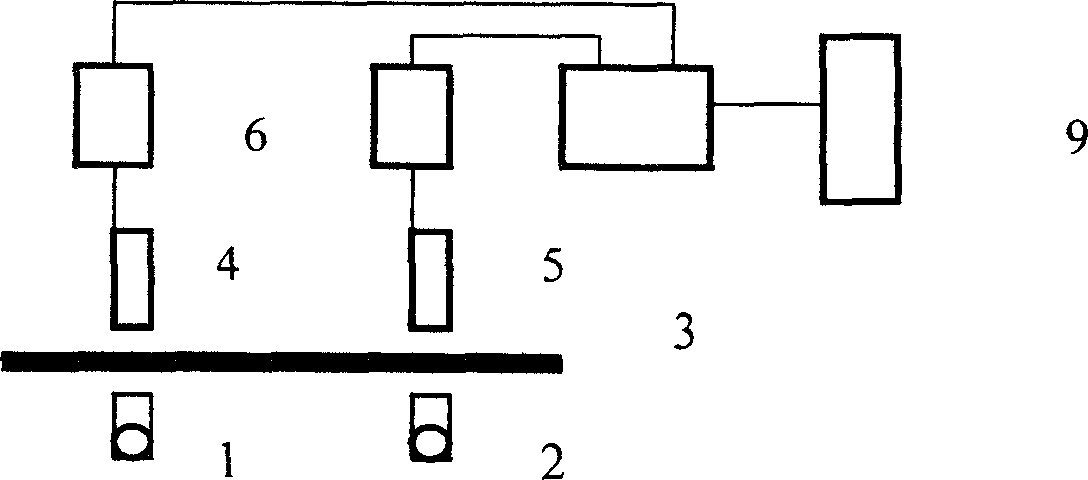

[0016] The method of the calibration-free neutron moisture meter of the present invention is: using fast neutrons and gamma rays to simultaneously detect the moisture and bulk density of materials on the conveyor belt. When the composition of the material changes, the moisture meter does not need to be re-calibrated. Fast neutron transmission is used to measure material moisture, and γ-ray transmission is used to measure bulk density. The purpose of measuring bulk density is to compensate the change of moisture measurement value caused by the change of material accumulation shape.

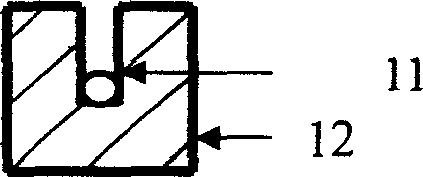

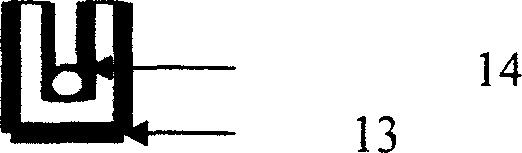

[0017] The invention adopts a fast neutron source (Am-Be or Pu-Be) and a fast neutron detector, and uses a ZnS(Ag)+GDB photomultiplier tube. The γ-ray test uses a γ-ray source (Cs-137) and a γ-ray detector NaI (Tl) or BGO+GDB photomultiplier tube. The profile of the neutron source of described fast neutron source (Am-Be or Pu-Be) is cylindrical, and diameter is 17.4mm, and height is 19.2mm, and ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Activity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com