Single-camera real-time measurement system and method for measuring surface shape of trough-type solar paraboloid

A trough-type solar energy and real-time measurement technology, which is applied in the fields of optical measurement experiments, engineering materials, component deformation and three-dimensional reconstruction measurement, can solve the problems of measurement accuracy easily affected by the outdoor environment, complicated operation process, and difficult to be applied. , to achieve the effect of reducing cumbersome steps, simple and easy operation, and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

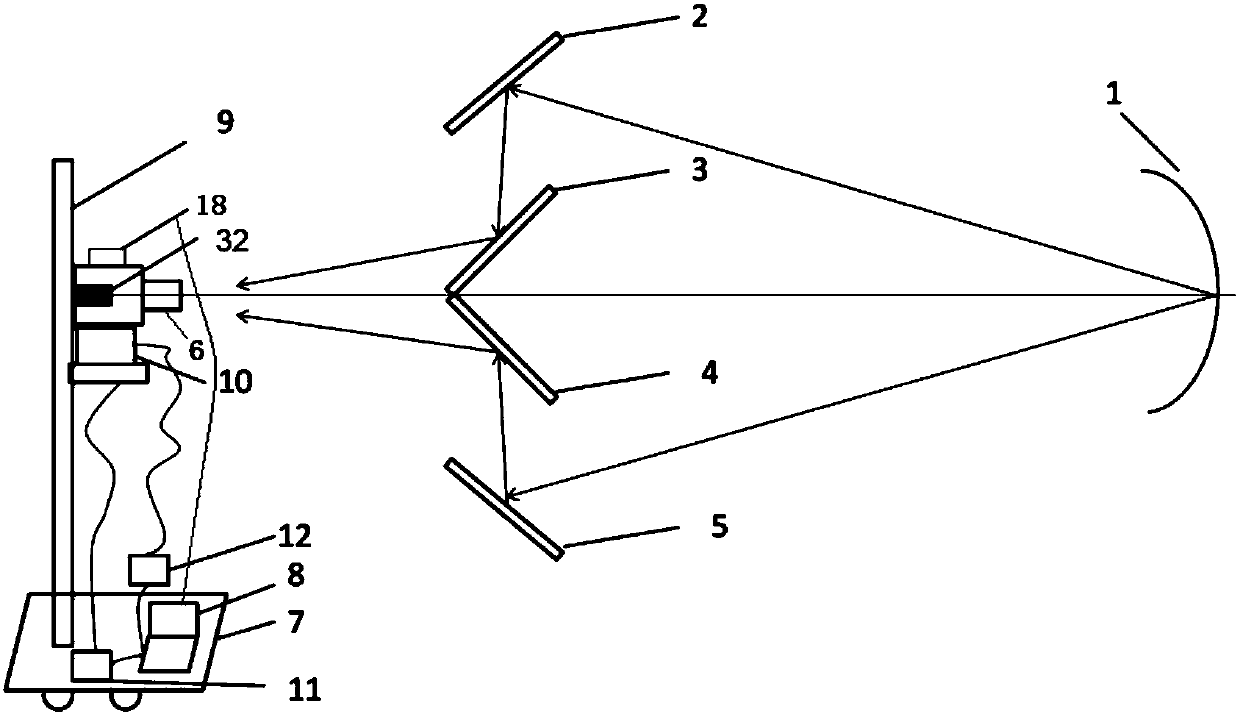

[0036] The following is attached Figure 1-4 The present invention is described in further detail.

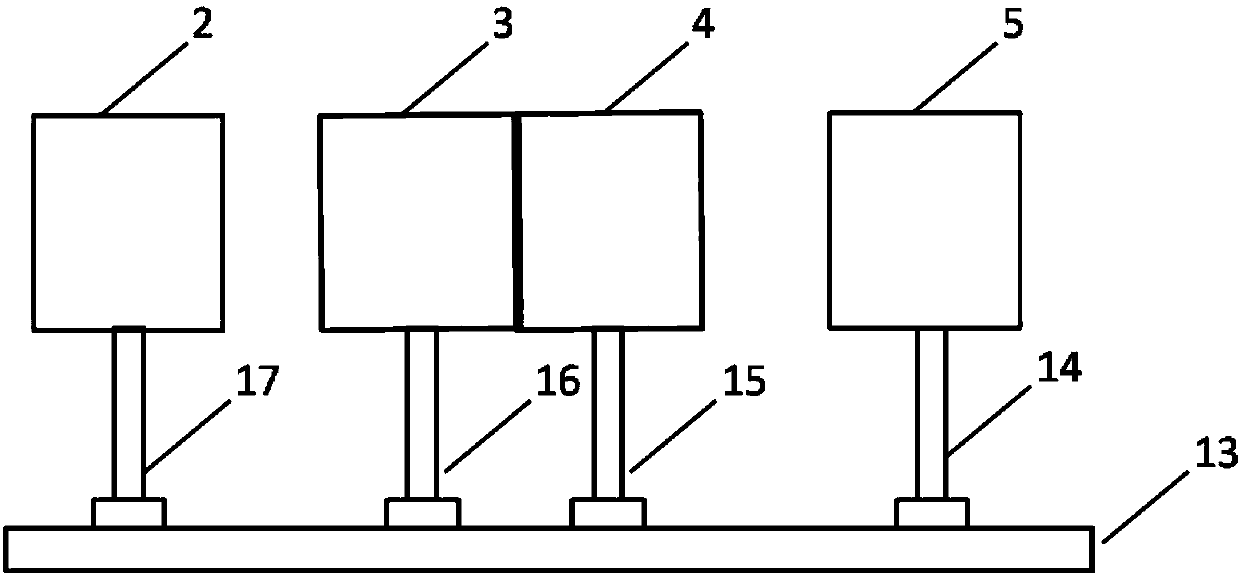

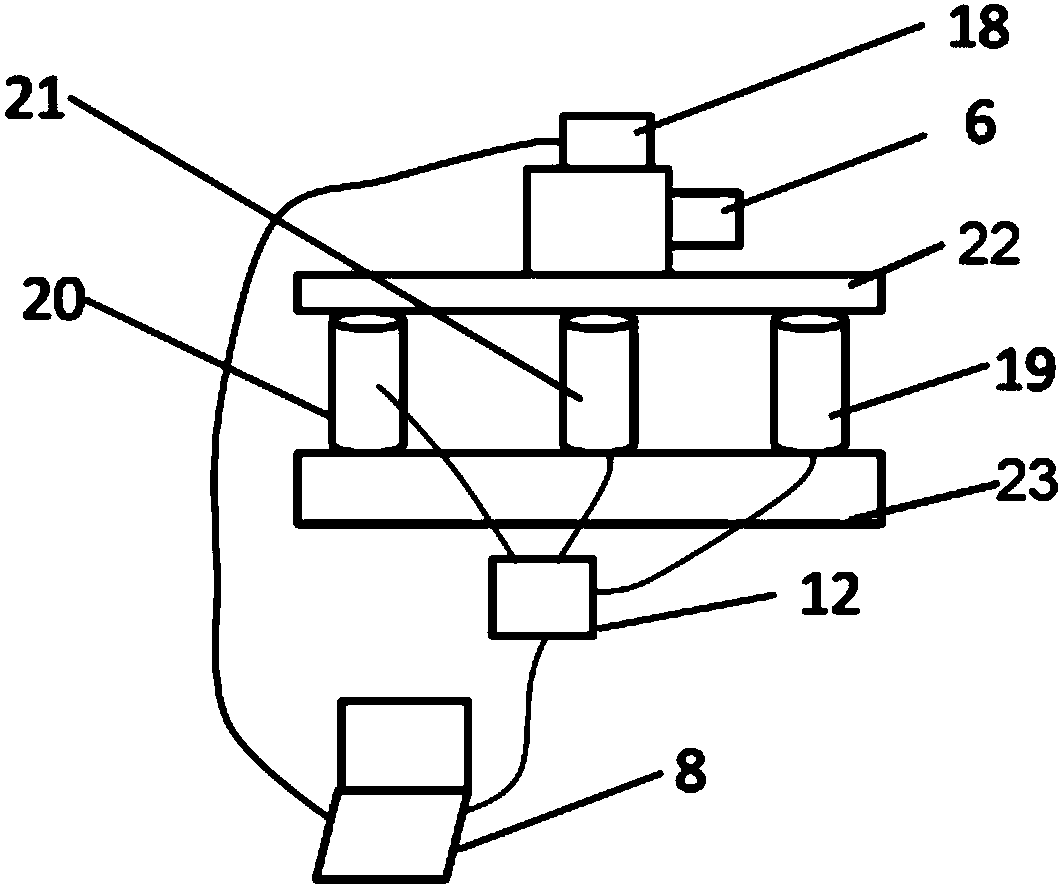

[0037]The single-camera real-time measurement system of the trough solar parabolic surface provided by the present invention includes: four reflection systems, horizontal guide rails 13, lifting and rotating translation devices, CCD cameras 6, movable platforms 7, computers 8, first controllers 11, Second controller 12, lifting device 9, angle meter 18, camera level adjustment device 10 and laser range finder 32;

[0038] The four-reflection system is installed on the horizontal guide rail 13 through the lifting rotation translation device, the camera level adjustment device 10 is installed on the lifting device 9, the lifting device 9, the first controller 11, the second controller 12 and the computer 8 are respectively installed on the movable platform 7, the angle meter 18 is placed on the CCD camera 6, the CCD camera 6 is placed on the camera level adjustment device 10, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com