Process and plant for the production of sealed packages of homemade-style ice cream

A technology of sealing packaging and ice cream, which is applied in the direction of packaging ice cream, packaging, packaging food, etc., and can solve the problems of space production time mixture contamination, ice cream contamination danger, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

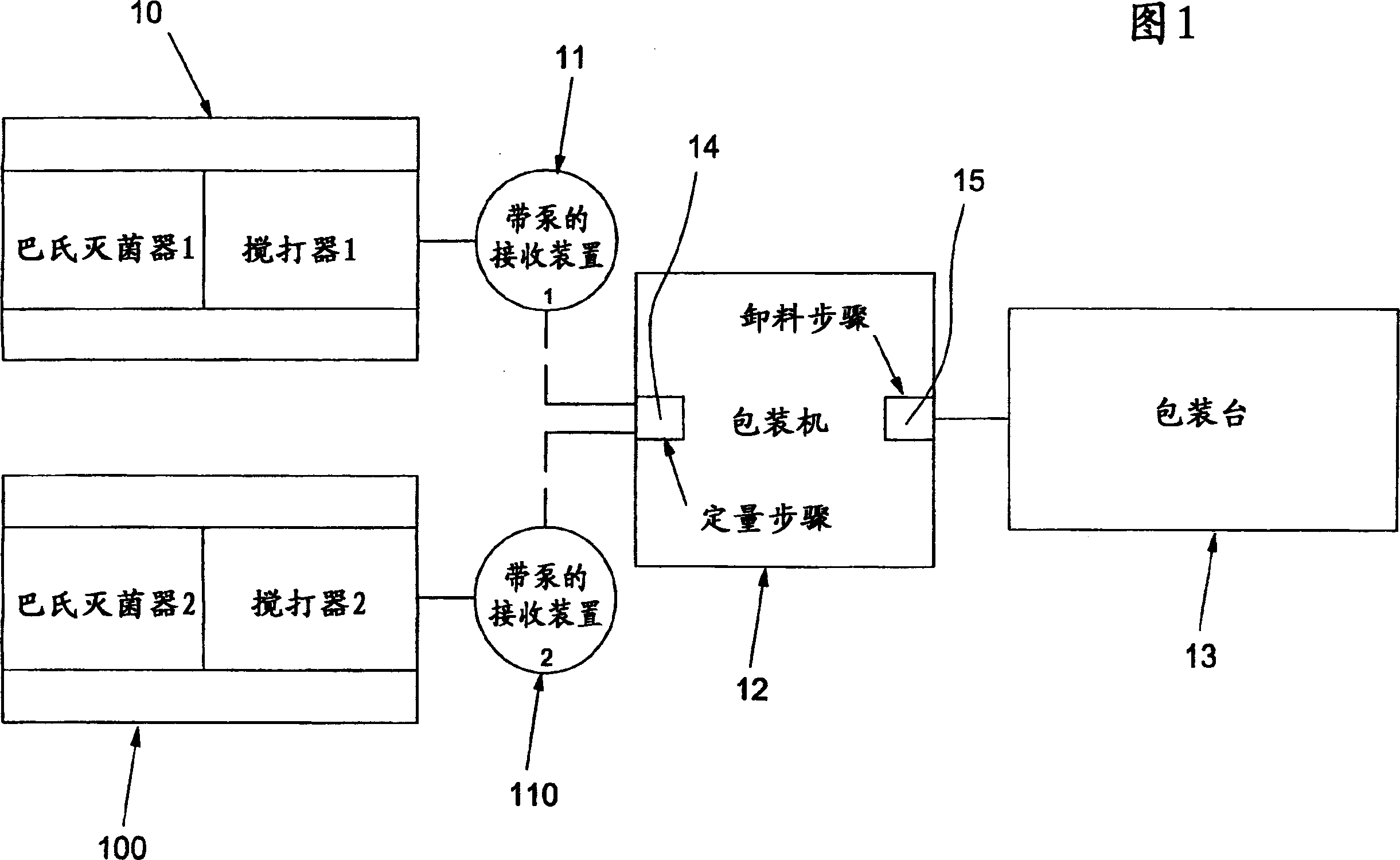

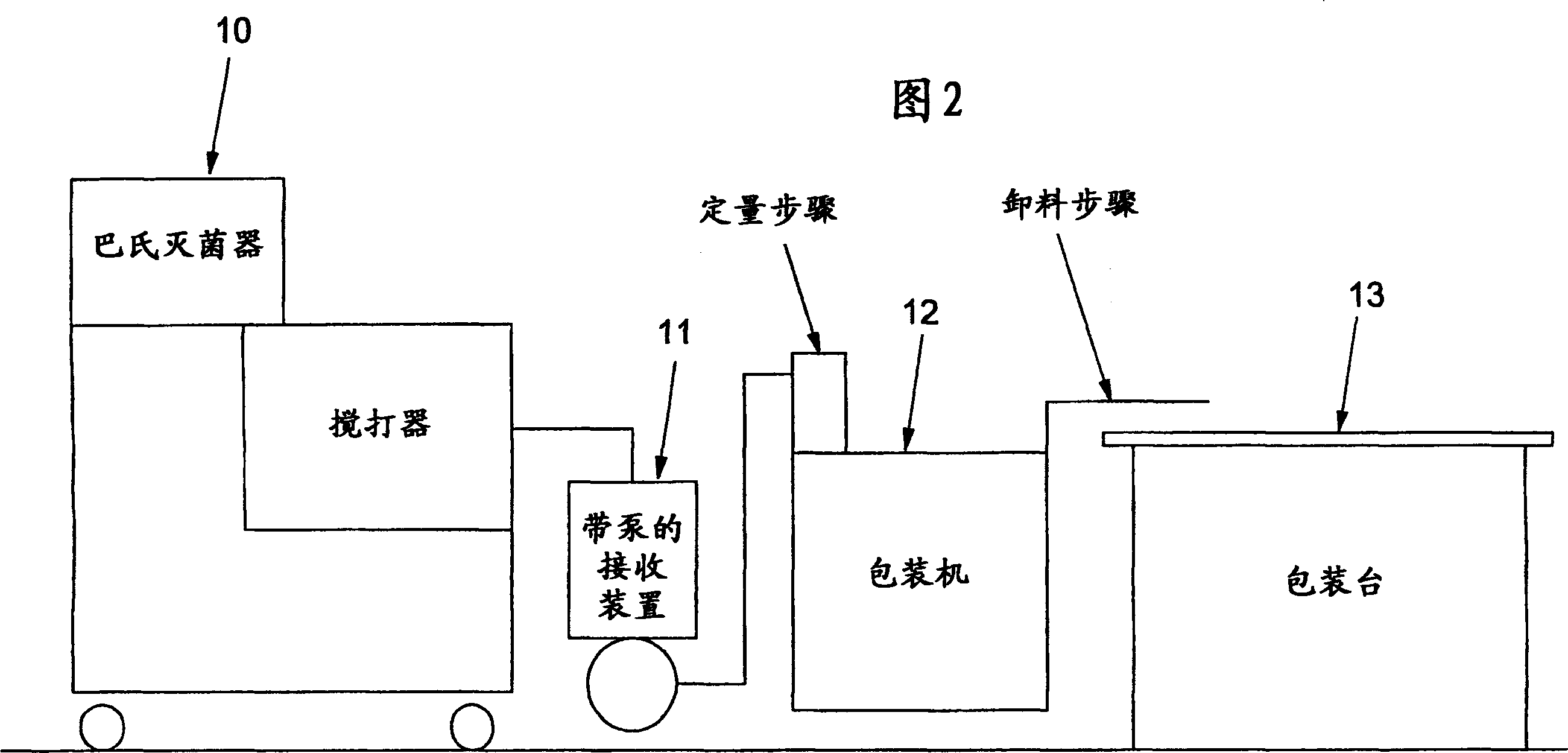

[0035] Shown in the figure is only a non-limiting example, in this figure, the device comprises two Trittico machines (or equivalent machines) 10, 100, which are fed alternately or simultaneously to obtain two flavors, and Quantitative packaging machine 12 with pumps 11,110. Downstream of the packaging machine 12 a packaging station 13 is visible.

[0036] As stated, the "Trittico" machine 10, 100 may be of the type described and exemplified in the previously cited patents, while the portion packaging machine 12 may be a well known commercially available Sigmateck machine named "ROTARY 1500".

[0037] Briefly, the machines 10, 100 each comprise a pasteurizer and a beater, operatively interconnected, wherein the mixture is emptied directly into the corresponding pump 11, 110 via a receiving device (hopper), whereby The whipped ice cream is pumped to the packaging machine 12. The packaging machine 12 provides a given amount of ice cream (such as 50 grams to 1 kilogram) through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com