Method for making bent-tube and its special equipment

A production method and technology of special equipment, which are applied to the production of elbows and the field of special equipment, can solve the problems such as the inability to take out the inner core of the elbows, and achieve the effects of low power, low energy consumption, and guaranteeing the quality of the elbows.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

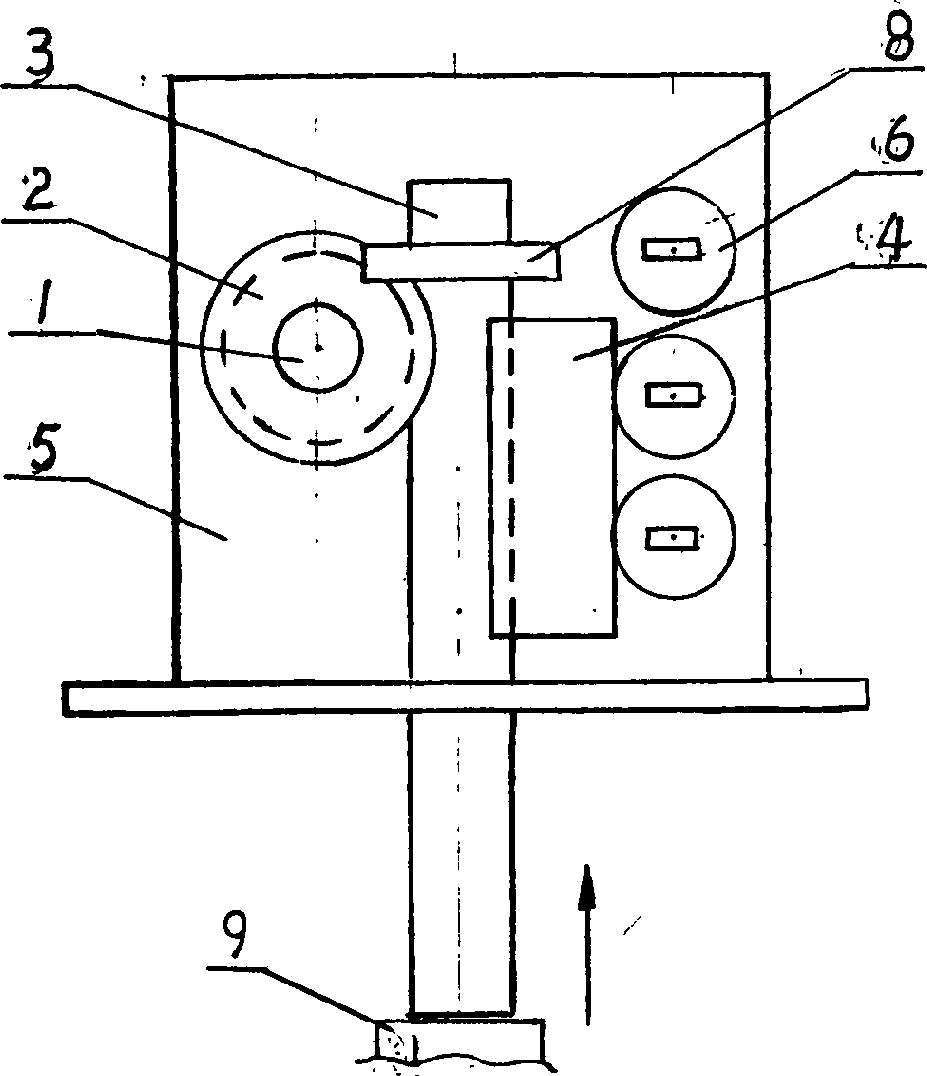

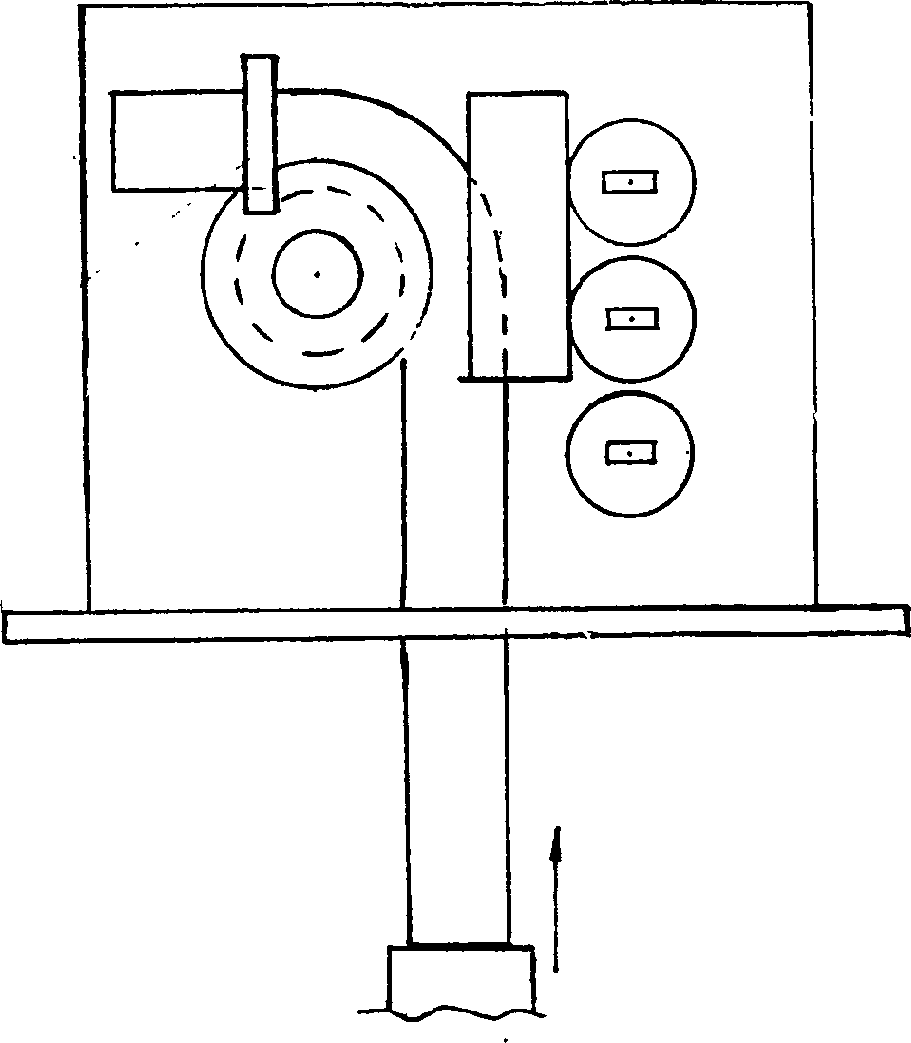

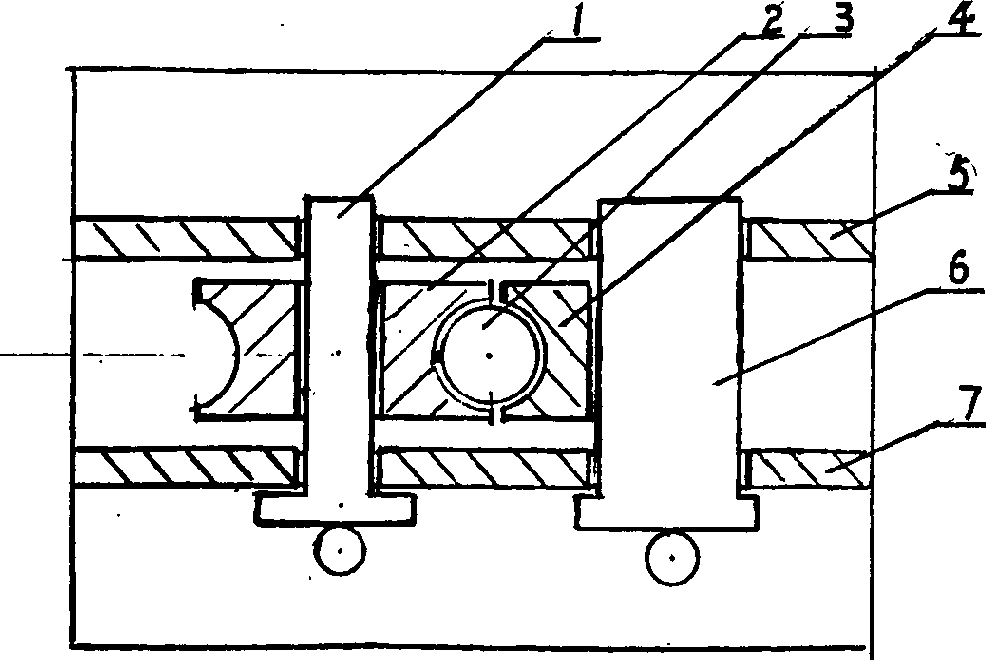

[0023] As shown in the drawings, the special equipment for bending pipes involved in the present invention includes a mold wheel 2 with a circular groove set on the frame through a rotating shaft 1, and a mold wheel 2 with a circular groove that can be clamped to a steel pipe corresponding to the position of the mold wheel 2. The template 4 of the groove, the jacket 8 that can fix the steel pipe 3 on the mold wheel 2 and the hydraulic pushing device 9 that are arranged on the frame. Template 4 of the present invention can adopt the mold wheel that has circular groove.

[0024] Taking the bent Φ219*35 high-pressure seamless steel pipe 3 for fertilizer production as an example, one end of the bent part of the steel pipe 3 is clamped on the mold wheel 2, and the exposed part of the steel pipe 3 is held tightly by the template 4 and jacketed on the exposed part of the mold wheel 2. 8. Fix firmly, and the steel pipe 3 is ready to be bent.

[0025] The other end of the bent steel p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com