Seedless wampee fruit juice beverage and preparation method and application thereof

A technology of dried yellow-skinned fruit and fruit juice, which is applied in the fields of application, function of food ingredients, food science, etc., and can solve the problems of easily changing flavor and chemical composition of fruit juice drinks, raw green flavor and heavy bitter taste of fruit juice drinks, and semi-finished products prone to rancidity To achieve the effect of improving production capacity and equipment utilization rate, ensuring active ingredients and product quality, and increasing juice yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

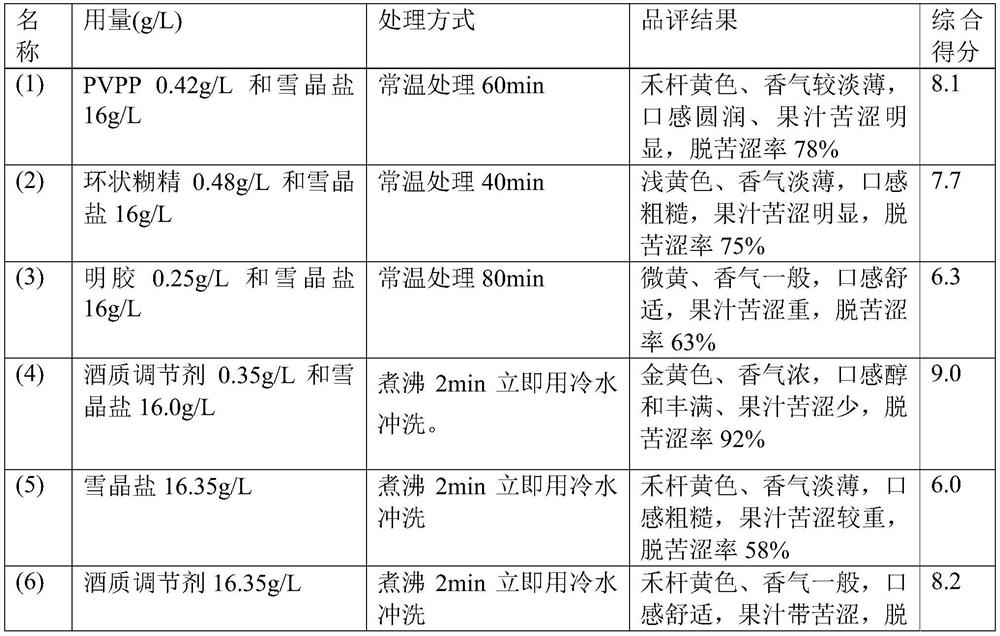

Method used

Image

Examples

Embodiment 1

[0053] (1) Raw material selection, sorting and cleaning: choose medium-ripe, less bitter, fruit juice with more than 60%, total sugar content of 145-158g / L, total acid content of 12.5-14.3g / L, with good flavor, aroma and High quality seedless yellow leather with stable color. Remove over-ripe, over-ripe and diseased fruits, and fully rinse the raw materials with pure water.

[0054] (2) Debitter treatment of the original fruit: after putting the seedless yellow skin into a pinhole machine to break the skin, use 14g / L snow crystal salt water (Guangdong Salt Industry Group Company) and 249mg / L wine quality regulator (Gaomi City) Donghai Trading Co., Ltd., TM-10005) Stir well, rinse with cold water immediately after boiling.

[0055] (3) beating and juicing: smash into pulp with a fruit and vegetable beater to obtain yellow peel pulp; then add 41mg / L (final concentration) pulp enzyme SAD-016 (Cangzhou Xiasheng Enzyme Biotechnology Co., Ltd.) Enzymolysis at ℃ for 9.4 hours, afte...

Embodiment 2

[0061] (1) Raw material selection, sorting and cleaning: choose medium-ripe, less bitter and astringent, juice with more than 60% content, total sugar content of 145-158g / L, total acid content of 12.5-14.3g / L, with good flavor, aroma and color. Stable high-quality seedless yellow skin. Remove raw, overripe and diseased fruit, and use pure water to fully rinse the raw materials.

[0062] (2) Debitter treatment of the original fruit: after putting the seedless yellow skin into a pinhole machine to break the skin, use 16g / L snow crystal salt water (Guangdong Salt Industry Group Company) and 350mg / L wine quality regulator (Gaomi City) Donghai Trading Co., Ltd.) and stir well, rinse with cold water immediately after boiling.

[0063] (3) beating and juicing: smash into pulp with a fruit and vegetable beater to obtain yellow-skin pulp; then add 48mg / L (final concentration) pulp enzyme SAD-016 (Cangzhou Xiasheng Enzyme Biotechnology Co., Ltd.) Enzymolysis at ℃ for 10.8 hours, after...

Embodiment 3

[0069] (1) Raw material selection, sorting and cleaning: choose medium-ripe, less bitter and astringent, juice with more than 60% content, total sugar content of 145-158g / L, total acid content of 12.5-14.3g / L, with good flavor, aroma and color. Stable high-quality seedless yellow skin. Remove raw, overripe and diseased fruit, and use pure water to fully rinse the raw materials.

[0070] (2) Debitter treatment of the original fruit: after putting the seedless yellow skin into a pinhole machine to break the skin, use 18g / L snow crystal salt water (Guangdong Salt Industry Group Company) and 451mg / L wine quality regulator (Gaomi City) Donghai Trading Co., Ltd.) and stir well, rinse with cold water immediately after boiling.

[0071] (3) beating and juicing: smash into pulp with a fruit and vegetable beater to obtain yellow-skin pulp; then add 55mg / L (final concentration) pulp enzyme SAD-016 (Cangzhou Xiasheng Enzyme Biotechnology Co., Ltd.) Enzymolysis at ℃ for 12.2 hours, after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com