Method of adding mass to MEMS structures

A detection mass body and substrate technology, applied in the field of MEMS devices, can solve the problems of increased weight, unpopularity, and increased size of the detection mass body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

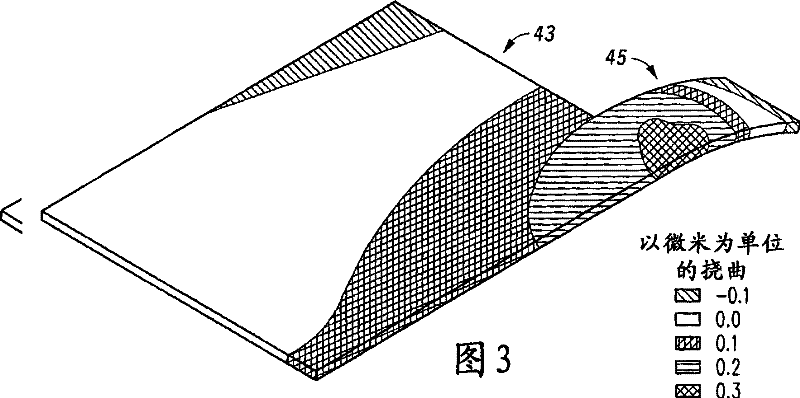

[0045] This example is used to illustrate the effect of CTE differential stress between the appendage of the proof mass and the base for a proof mass separated from the base by a narrow rod and the appendages are composed of different materials (i.e. aluminum and polysilicon). transfer.

[0046] Repeat the simulation test of comparative example 1, but adopt such as Image 6 Proof masses of the type indicated. The detection mass body 51 is composed of a polysilicon substrate 53 and a square appendage 55 connected thereto. The appendages consist of a layer of polysilicon 59 with a layer 57 of aluminum deposited to a thickness of 3 microns. The side length of the appendages is 100 μm. The appendages are separated from the base body by rods 61 having a width of 3 microns and a length of 2 microns, the main surfaces of the appendages being parallel to those of the base body.

[0047] exist Figure 5 The graph in the figure shows the calculated stresses during the temperature c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coefficient of thermal expansion | aaaaa | aaaaa |

| coefficient of thermal expansion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com