Method and apparatus for producing reduced metal

A metal manufacturing and equipment technology, applied in the field of reduced metal manufacturing, can solve problems such as difficulties in regenerative combustion furnaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

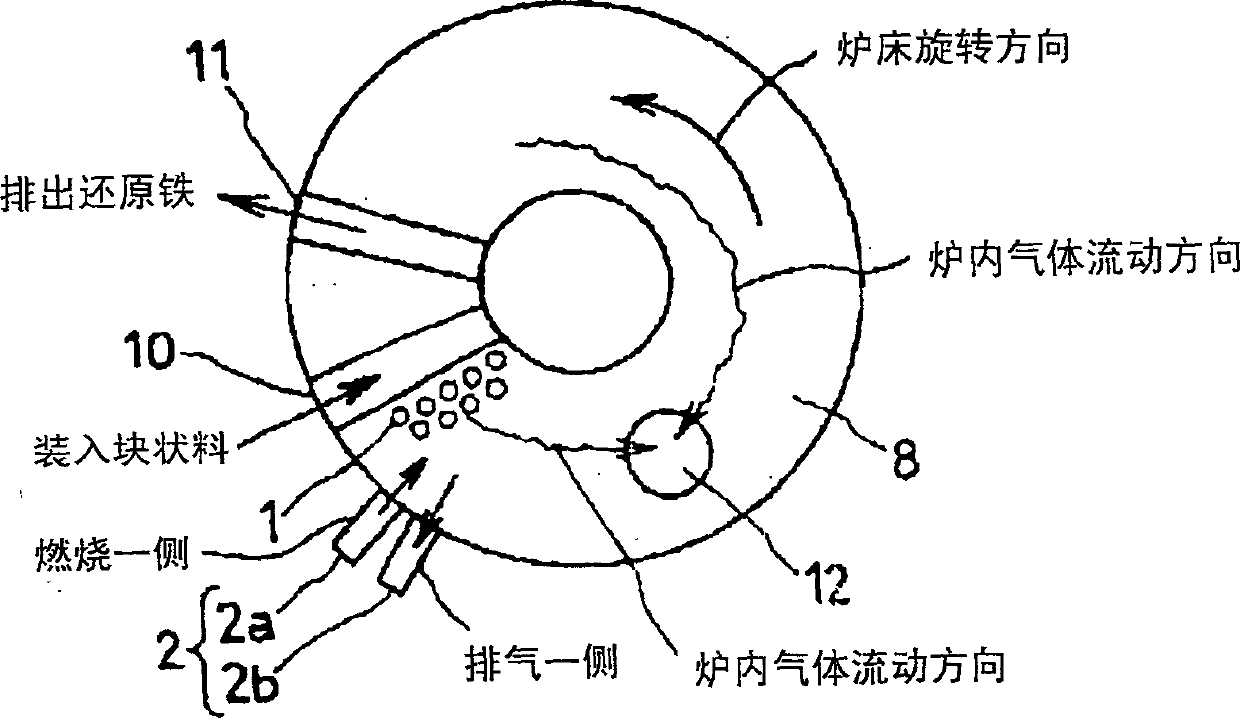

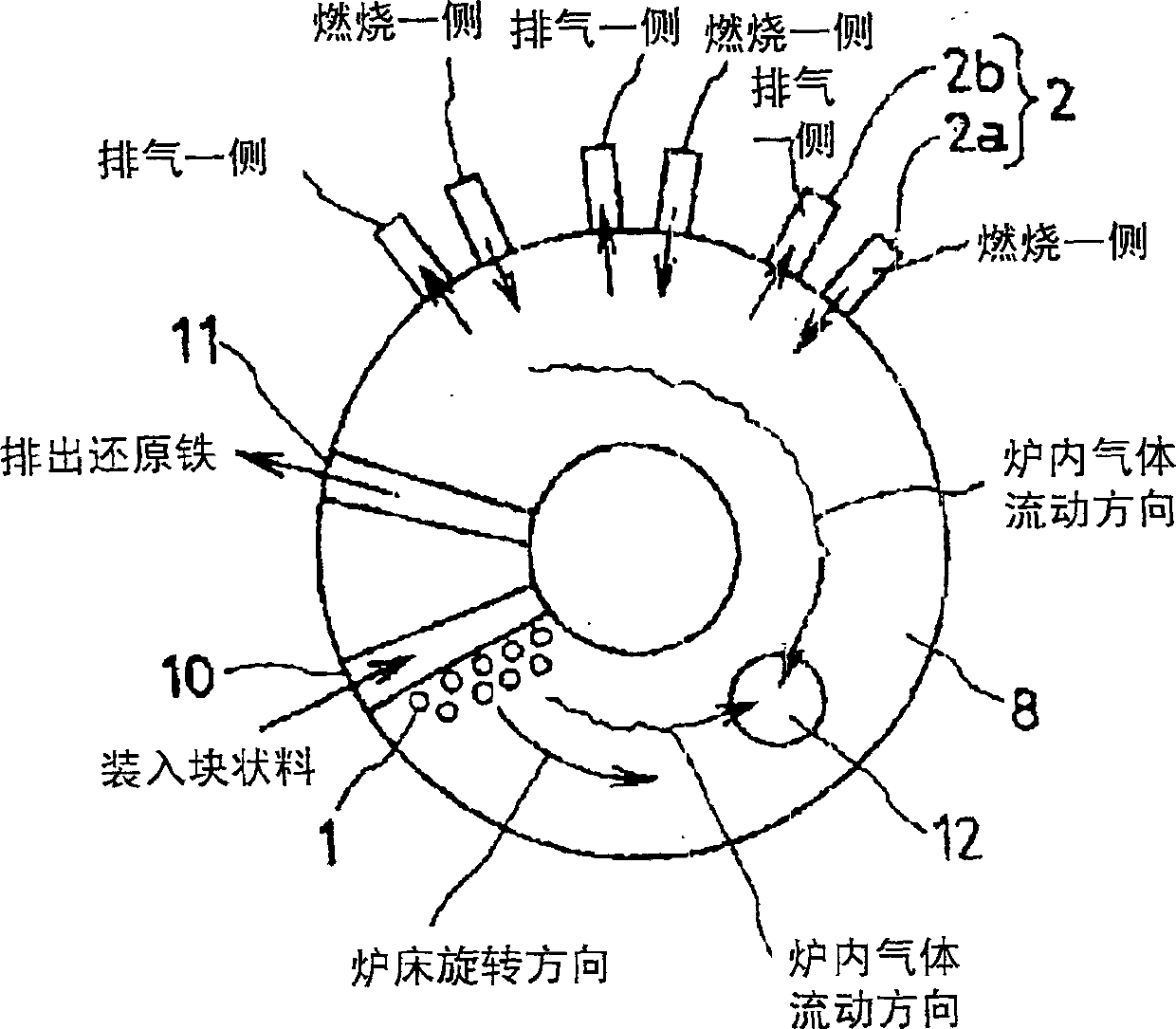

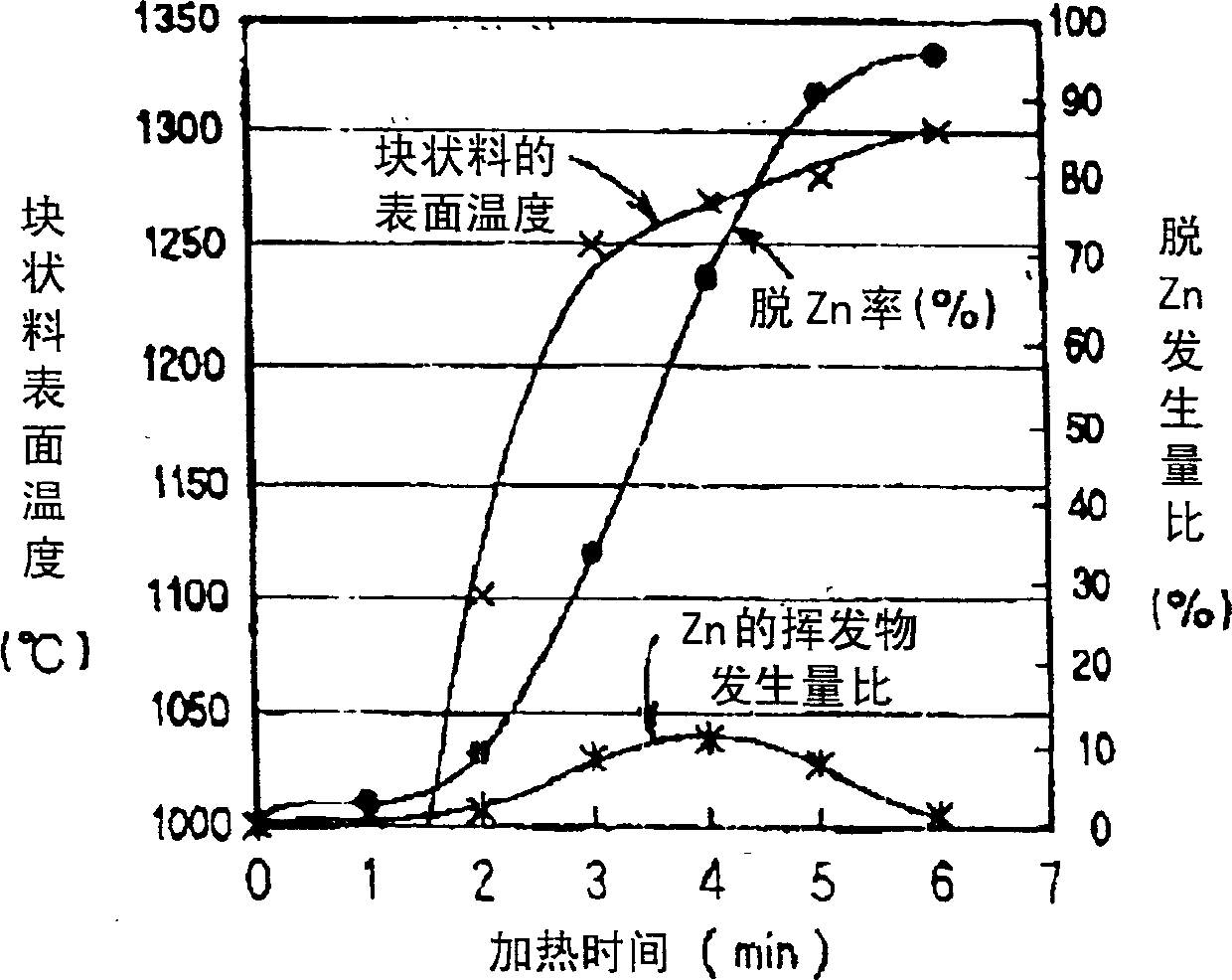

[0030] Hereinafter, referring to FIGS. 1 to 11 , an embodiment of the present invention will be described by taking reduced iron manufacturing equipment as an example.

[0031] The reduced iron manufacturing facility of the present invention uses the regenerative combustion furnace shown in Fig. 7A and Fig. 7B. The regenerative combustion furnace 2 has two intake and exhaust sections (2a, 2b). First, in the state shown in FIG. 7A , the air intake and exhaust portion 2a on one side is used as the combustion side where fuel and combustion air pass through the fuel pipeline 3 through the fuel switching valve 5a and then pass through the regenerator 7a for combustion. The other side of the suction and exhaust part 2b sucks heated air or high-temperature gas such as combustion gas on the combustion side of the suction and exhaust part 2a, passes through the regenerator 7b, and passes through the exhaust switching valve 6b from the exhaust pipe 4b to the Exhaust gas externally. At...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com