Trapped vortex combustor

A burner, vortex type technology, applied in the direction of combustion chamber, combustion equipment, combustion method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

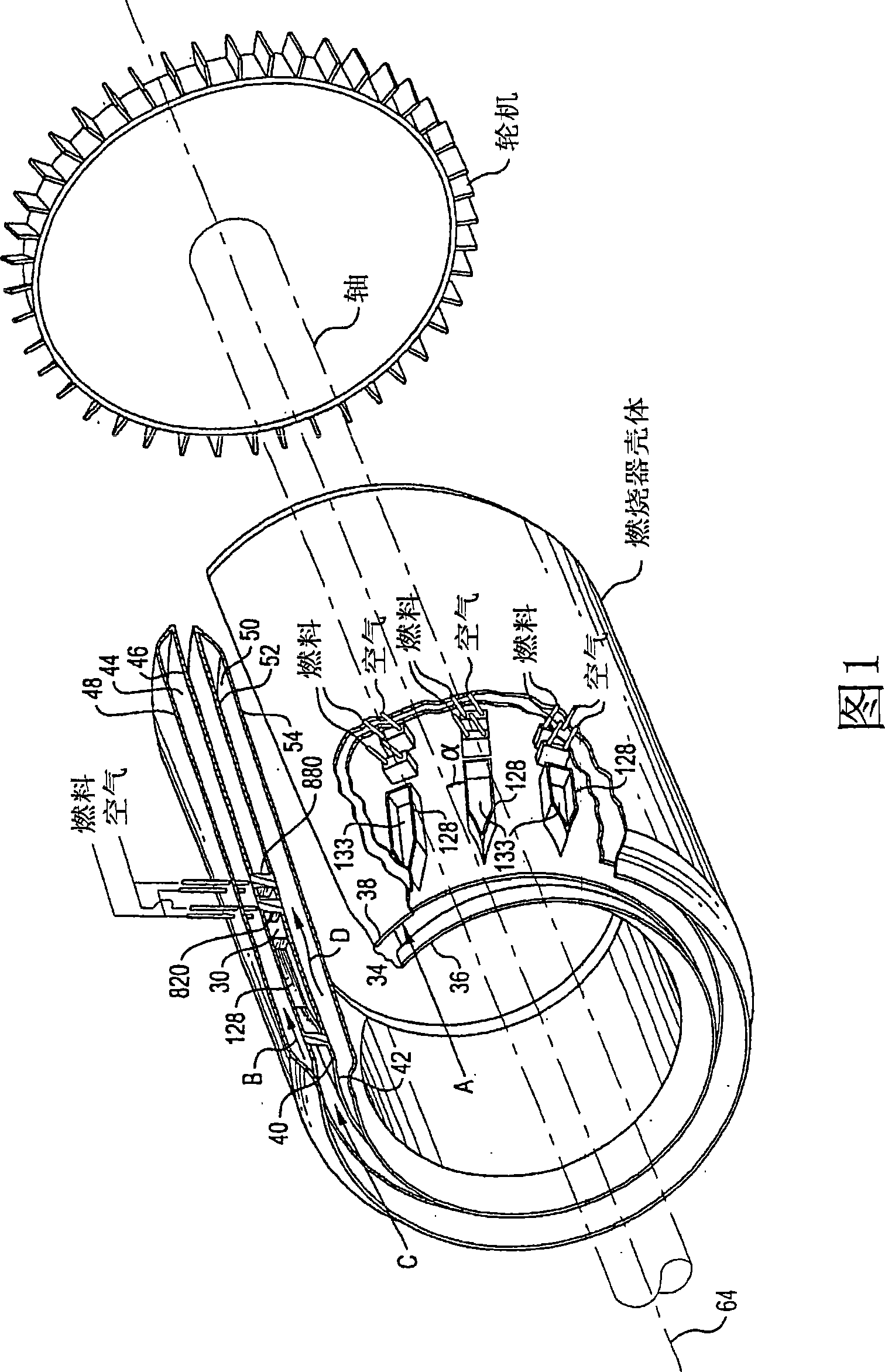

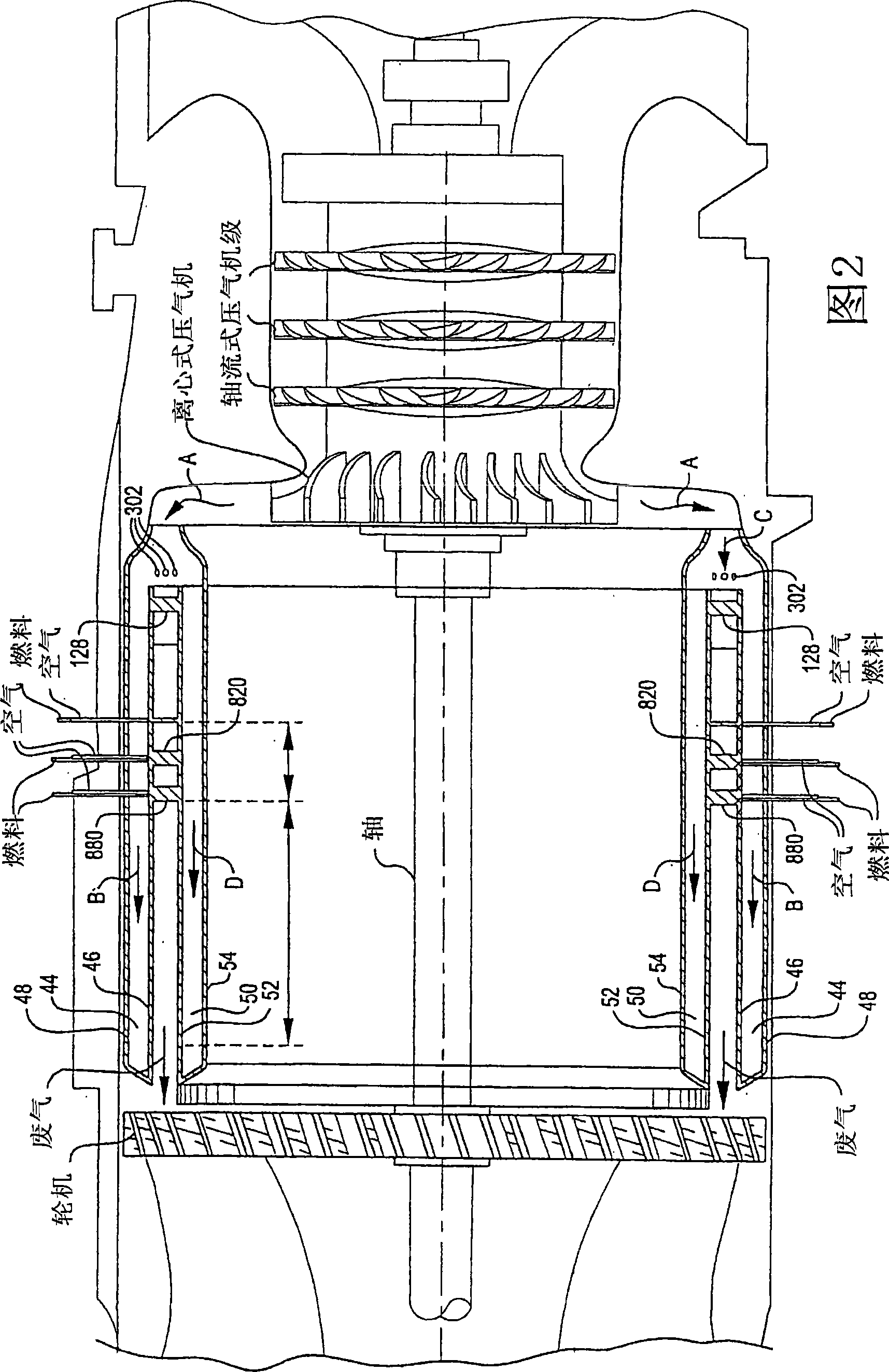

[0049] figure 1 A detailed view of an exemplary embodiment of a shut-off vortex combustor 30 for a gas turbine is provided. An inlet fluid, typically compressed air A, indicated by the reference letter A, is delivered through an inlet 34 defined between an inner inlet wall 36 and an outer inlet wall 38 . Downstream of the inlet 34, the inlet fluid A is divided into three streams, an external cooling air supply flow B, a combustion air supply flow C and an internal cooling air supply flow D. The leading edges 40 and 42 thus separate the incoming air. An external cooling air supply flow is contained within an outer plenum 44 defined between a combustor outer wall 46 and an outer plenum wall 48 . An internal cooling air supply flow D is contained between the inner plenum 50 defined between the inner combustor wall 52 and the inner plenum wall 54 . As shown, each of the walls 48, 46, 52 and 54 are placed in a solid portion by a tubular cylindrical portion of the desired diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com