Reinforced plastic hand-bag and its producing method

A technology for strengthening plastics and carrying bags, applied in the field of plastic bags, can solve the problems of rupture, unreasonable design of the bottom seal of the bag, insufficient strength of the bottom seal, etc., and achieves the effect of enhanced bonding fastness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

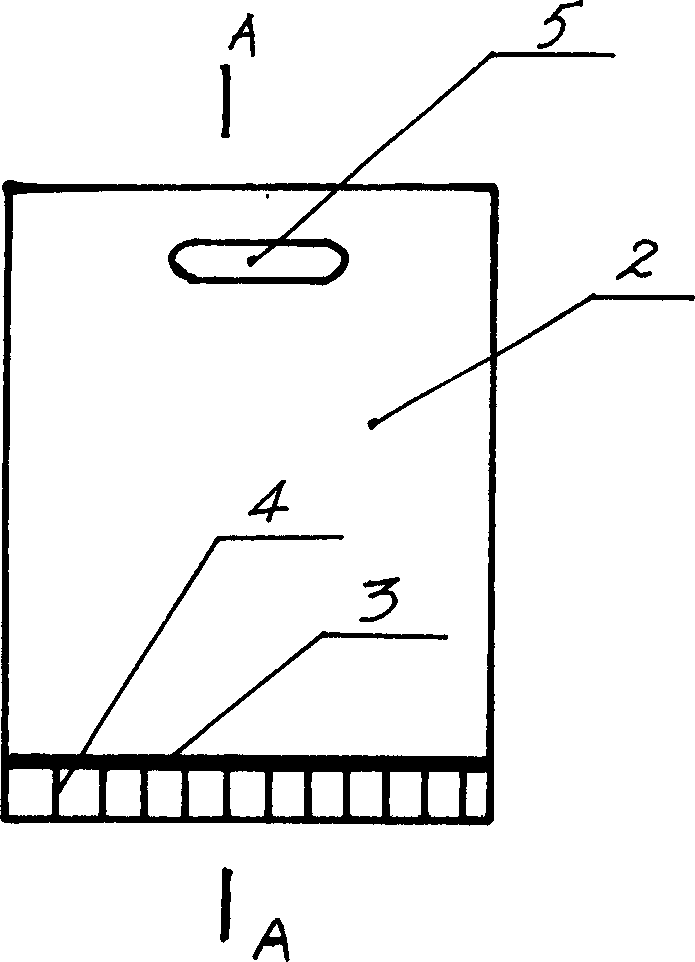

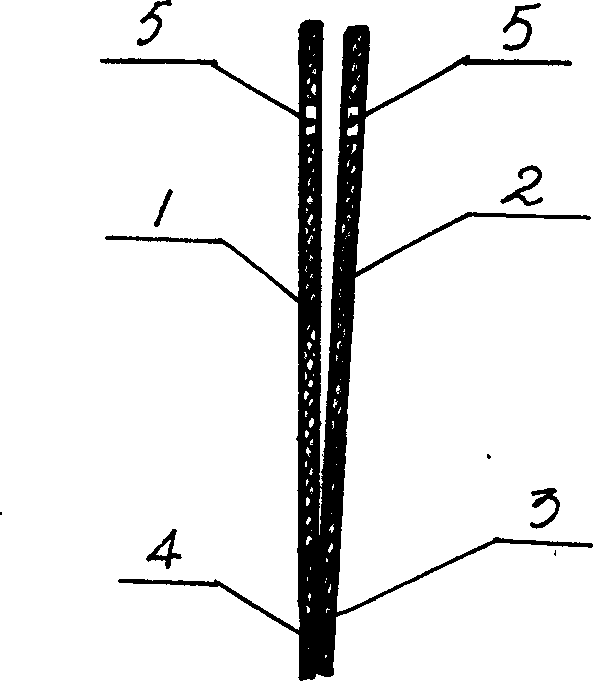

[0012] The reinforced plastic carrying bag of the present invention is composed of a left layer of plastic cloth 1, a middle layer of plastic cloth 2 and a linear bottom cover 3, and a handle for people to carry is provided on the left layer of plastic cloth 1 and the right layer of plastic cloth 2. Opening 5, the left layer of plastic cloth 1 and the right layer of plastic cloth 2 form a linear back cover 3 by thermal melting at the bottom, and several evenly distributed reinforcing rib seals 4 are arranged below the linear back cover 3 .

[0013] The manufacturing method of the reinforced plastic bag according to the present invention is as follows: cut the cylindrical plastic into semi-finished products according to a predetermined length, install a special sealing mold on the automatic sealing machine that matches the shape of the lower end of the reinforced plastic bag, and use an automatic The sealing machine is aligned with the cylindrical plastic to be melted and cut in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com