Shaping machine of vertical cement tube

A tube forming machine and cement technology, which is applied to ceramic forming machines, manufacturing tools, molds, etc., can solve the problems of low production efficiency and affect production costs, and achieve the effect of simple structure and ensuring working life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

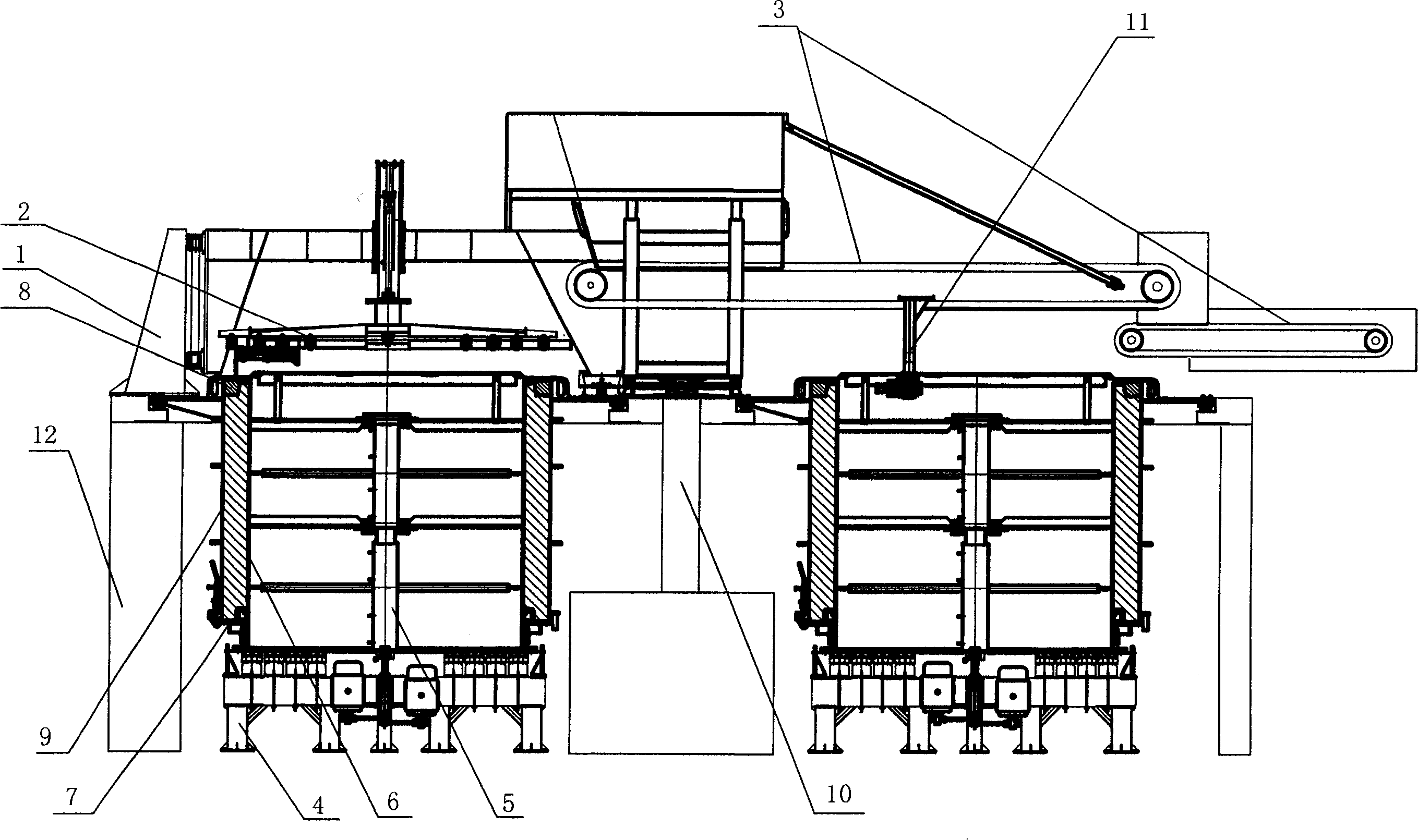

[0021] Depend on figure 1 It can be seen that the cement pipe forming machine includes a frame 12 and two sets of bases 4, on each set of bases 4, a concentric inner mold 6, an outer mold 9 and a vibrating mandrel 5 are arranged respectively, between the outer mold 9 and the inner mold 6 A socket forming die 7 is arranged at the annular bottom formed between the two, and a socket forming die 8 is arranged at the annular upper part formed between the outer die 9 and the inner die 6 . Set up a group of door frames 1 outside each group of machine bases 4, and set a set of die frames 2 on each group of door frames 1, and a feeding device composed of a conveyor belt 3 and a walking mechanism 11 is fixed on the frame 12. , the feeding device can rotate around the support column 10 under the action of the traveling mechanism 11 .

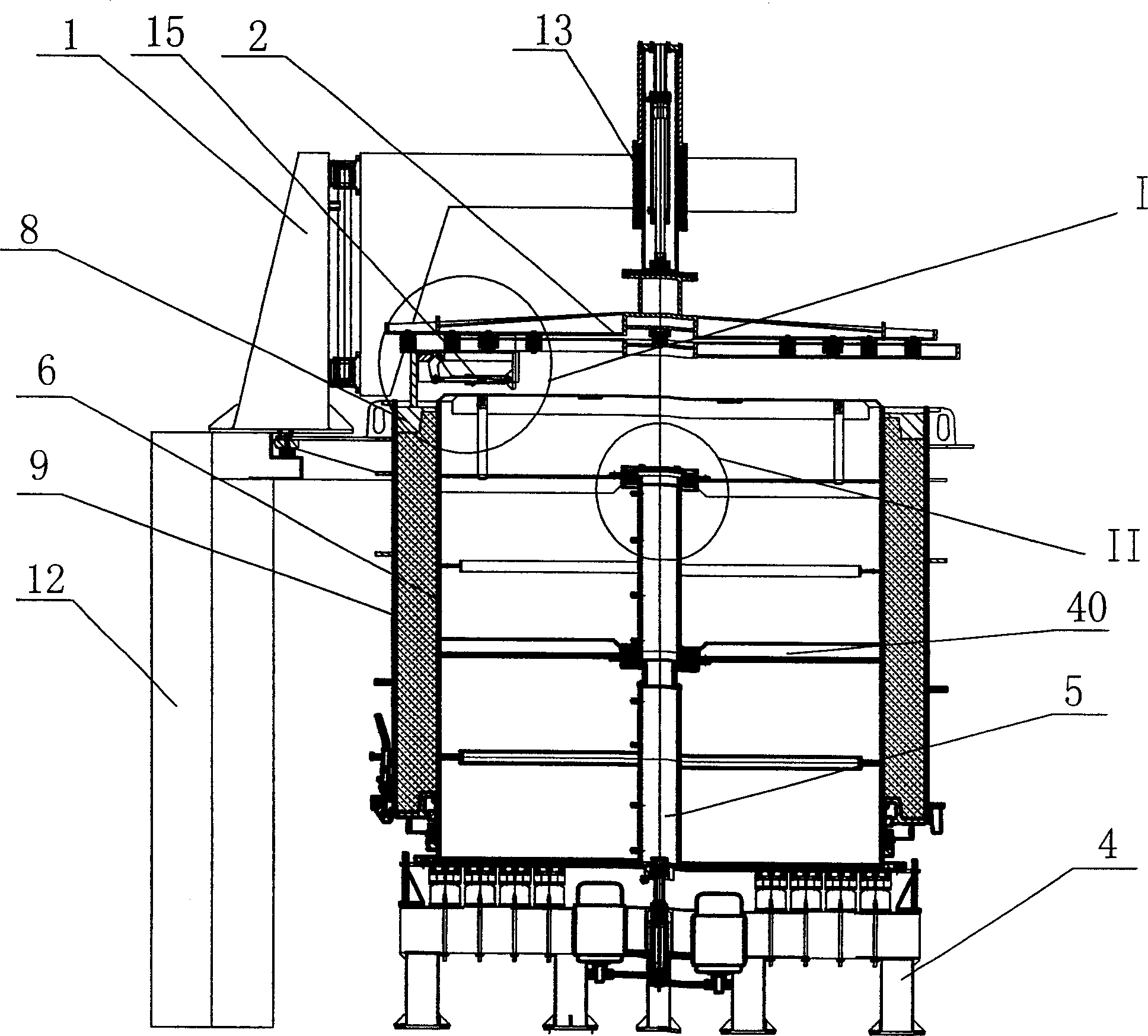

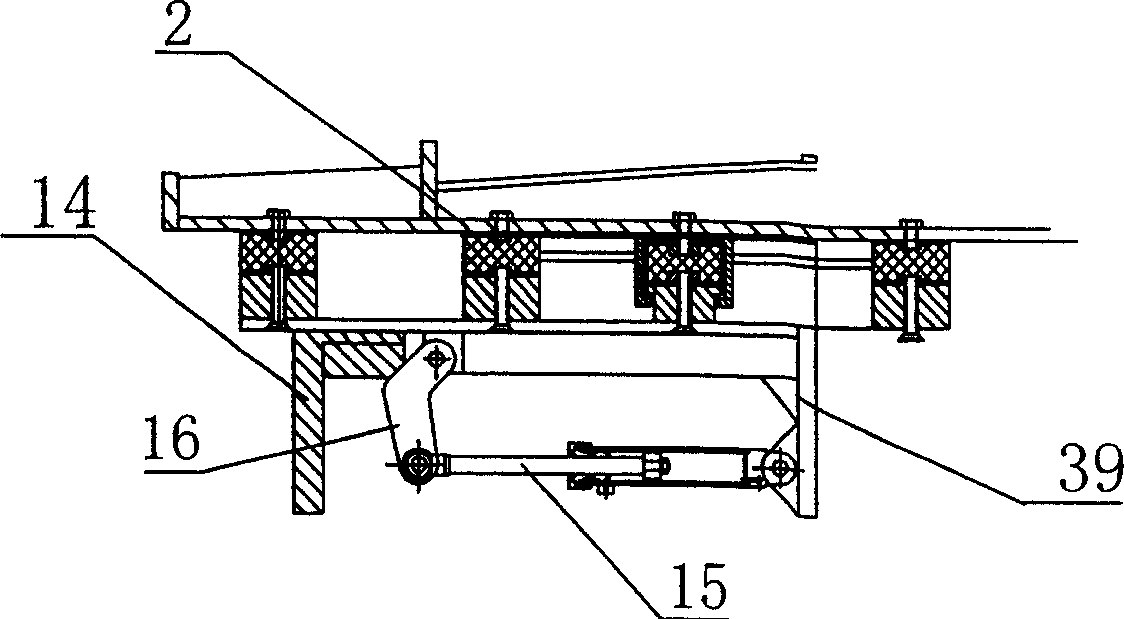

[0022] Such as figure 2 , 3 As shown, the door frame 1 is connected with a vertically telescopic oil cylinder 13, and the lower end of the oil cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com