Multiair cavity explosion proof safety tyre and its air inflation method

A safety tire and multi-cavity technology, which is used in the inflation of multi-cavity safety tires and the field of multi-cavity safety tires, can solve problems such as the hidden danger of overall bursting, improve safety and durability, optimize internal structure, and avoid overall burst effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

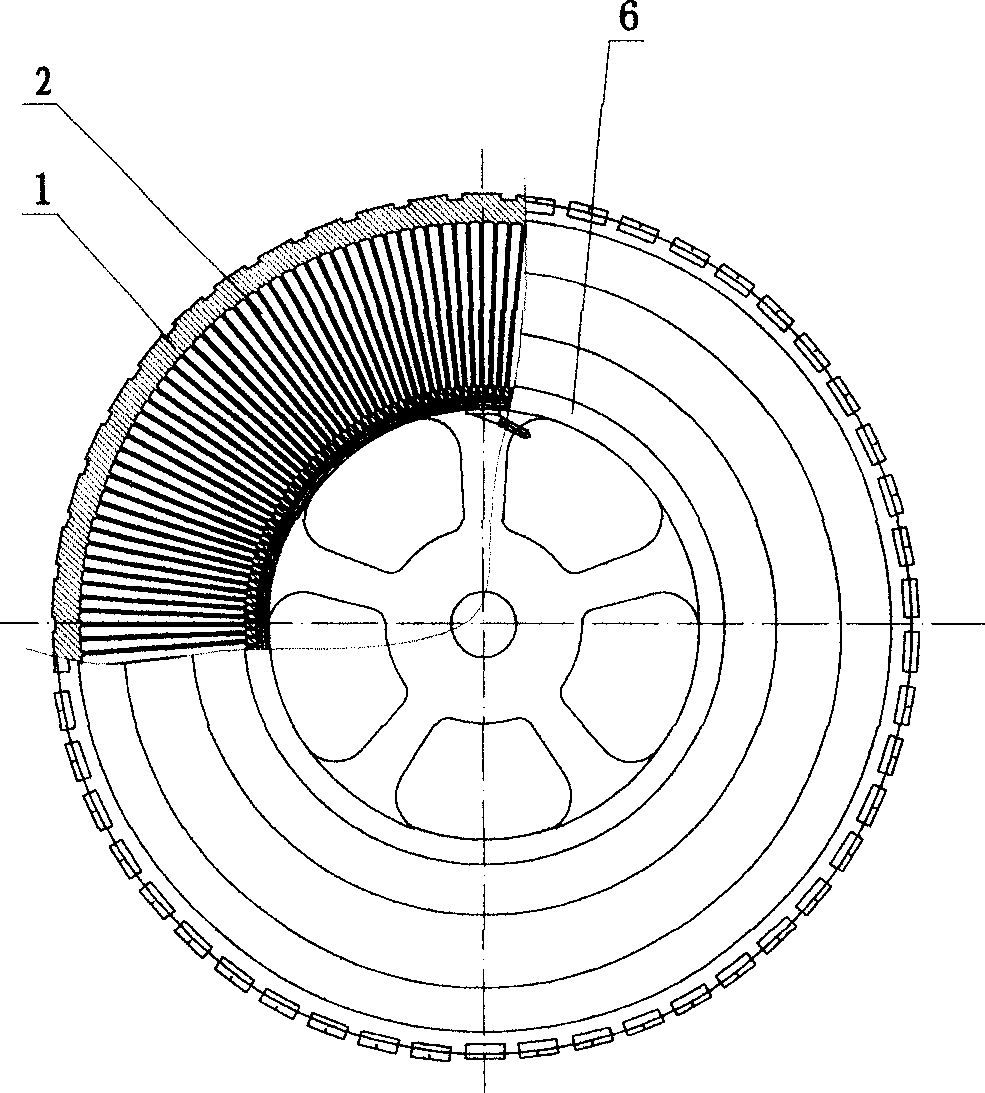

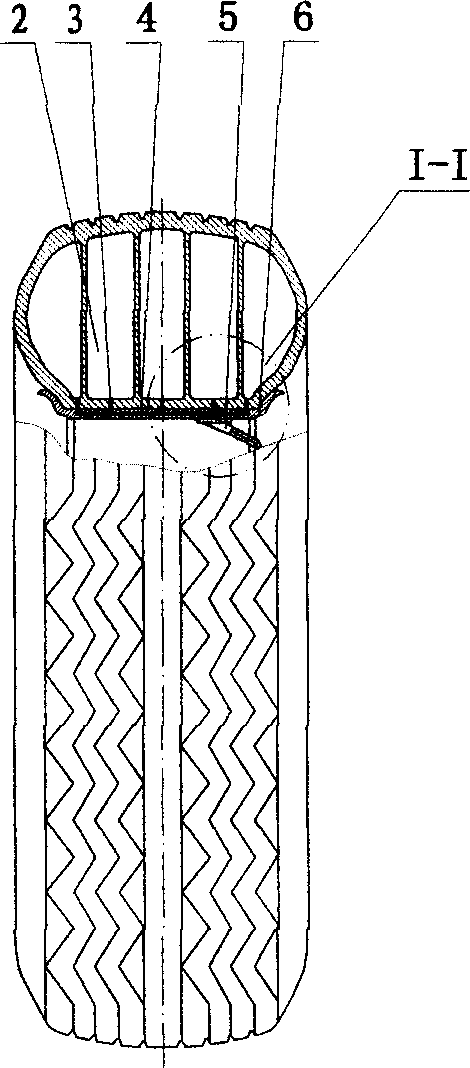

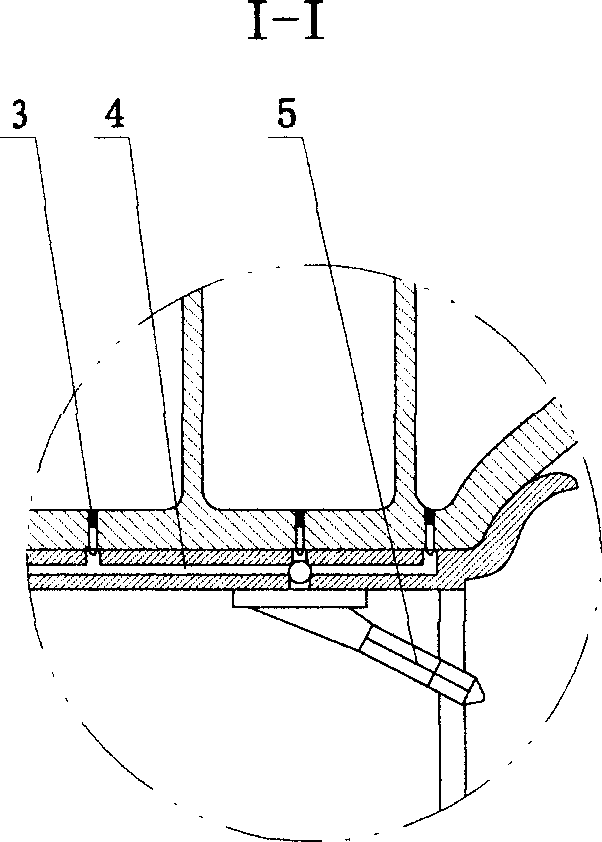

[0022] refer to figure 1 , figure 2 , image 3 The tire carcass (1) is composed of countless independent airtight air cavities (2), the air cavities (2) are evenly arranged in the circumferential and axial directions in the carcass, and the air cavities (2) are separated by rubber materials, Each air cavity (2) is provided with a needle check valve (3) at one end close to the rim (6), and each needle check valve (3) is connected with the air valve ( 5) Communicate. Each air cavity can be inflated at the same time through the air valve (5), air pipe (4) and needle check valve (3). Under the action of air pressure, each needle check valve opens simultaneously to ensure the pressure of each air cavity (2) Equal, when the air pressure reaches the set value and the inflation is completed, the needle check valve (3) is automatically closed, so that each air cavity (2) is completely sealed and becomes a force-bearing unit independent of each other.

[0023] Such as Figure 4-Fi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap