Linear motor

A linear motor and polarity technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit static parts, electrical components, etc., to achieve the effect of avoiding magnetic leakage and excess heat release, and preventing direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be described below with reference to the drawings. In the following figures, the same parts are marked with the same symbols. The figures are appropriately scaled down for ease of understanding.

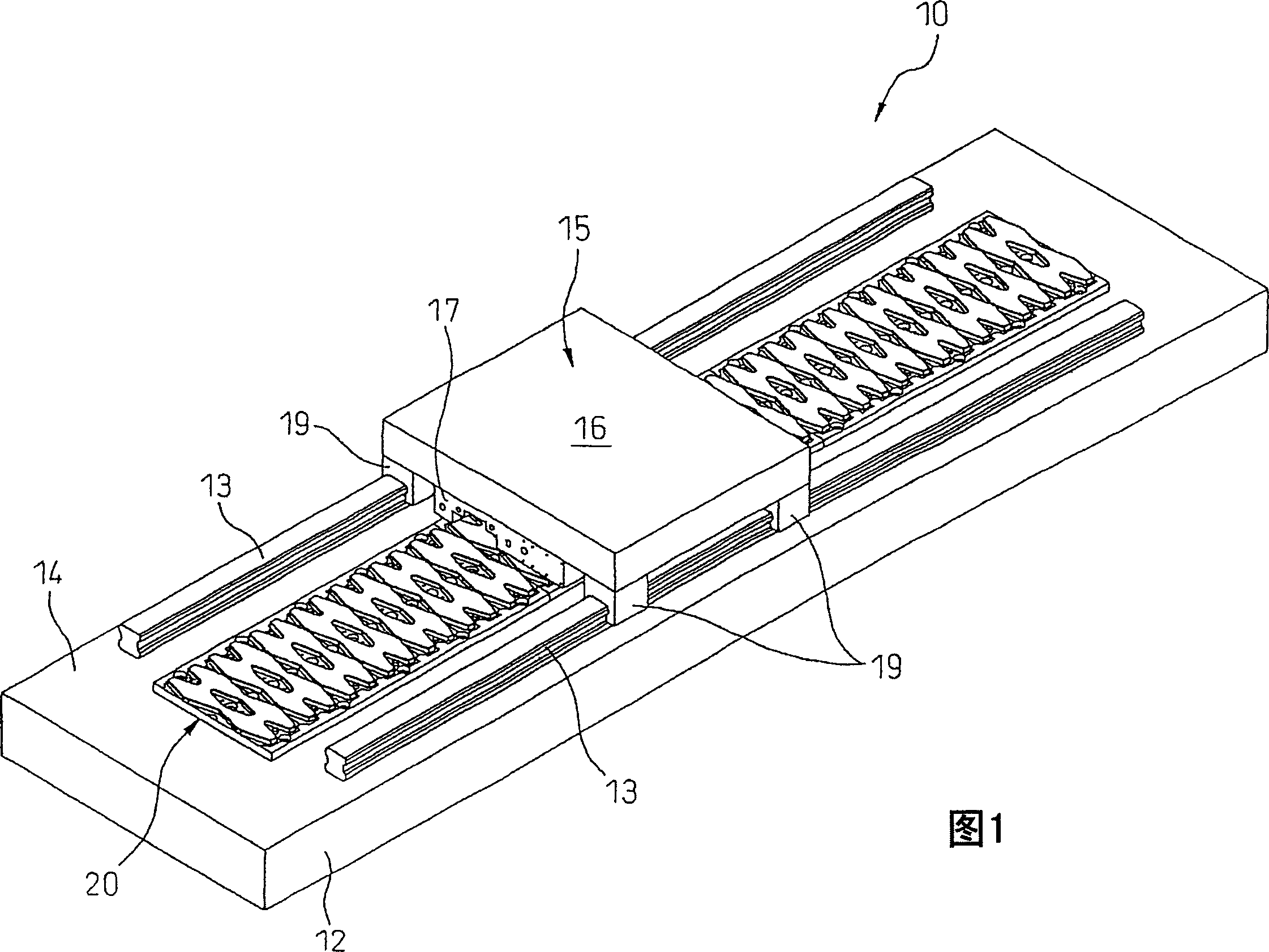

[0032] FIG. 1 is a perspective view of a linear motor according to the present invention. As shown in FIG. 1 , a linear motor 10 used in machine tools and the like is a linear synchronous motor in which an armature 15 is a movable member and a field yoke 20 is a stator. A field yoke 20 serving as a stator is provided on the surface 14 of the base 12 . Further, guide rails 13 extending parallel to the field yoke 20 are disposed on both sides of the base 12 .

[0033] The armature 15 includes a substantially rectangular parallelepiped armature core 16 made of laminates of a plurality of magnetic thin plate materials such as silicon steel sheets, and a plurality of narrow slots recessed substantially parallel to each other on one surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com