Robot for disassembling work

A technology for demolition robots and demolition heads, which is used in manipulators, building maintenance, manufacturing tools, etc., can solve the problems of high labor intensity, restricted use scope, and large safety hazards, and achieves a wide range of use, reasonable structure, and heavy lifting. effects of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

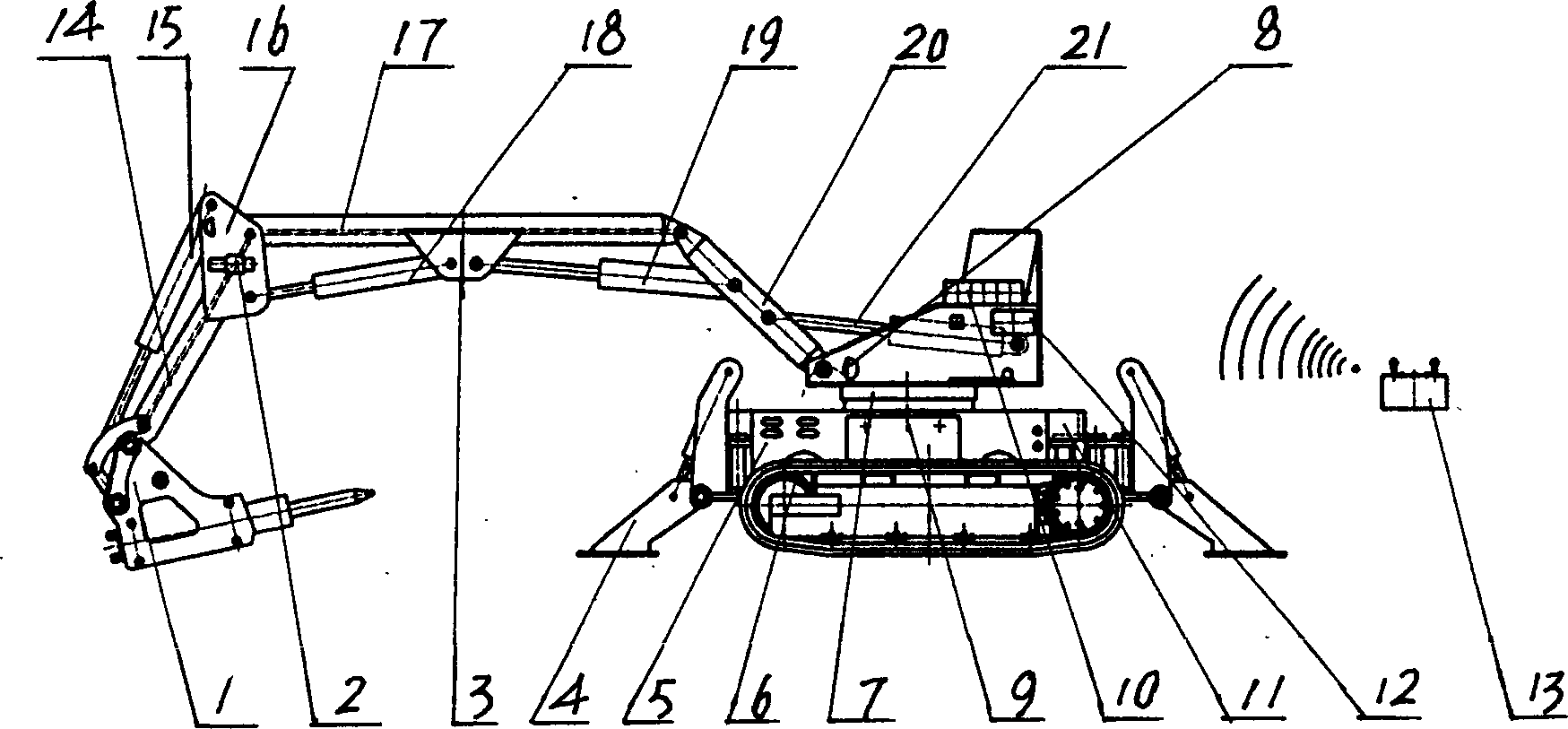

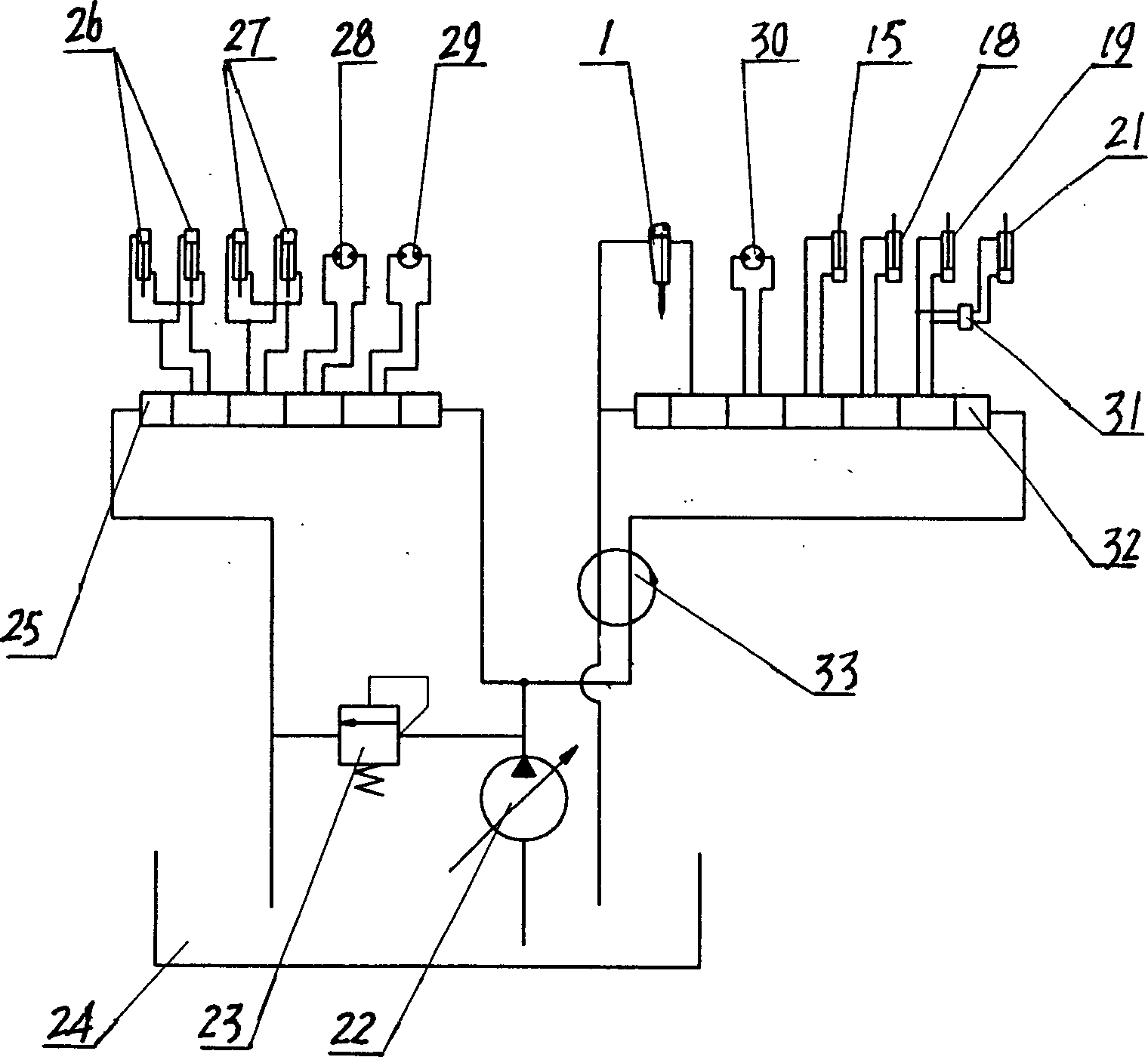

[0012] From figure 1 , figure 2, it can be seen that a demolition robot is based on an electric-driven hydraulic excavator chassis, and consists of a frame 9, a hydraulic crawler device 6, a hydraulic slewing device 7, a hydraulic working mechanism, a hydraulic demolition head 1, and a power unit 11 , electrical device 12, hydraulic device 10, forced cooler 5, wherein frame 9 is a box structure, hydraulic crawler running device 6 is composed of crawler beam, track shoe, driving wheel, guide wheel, load-bearing wheel, supporting wheel, crawler belt Tensioner, left and right traveling hydraulic motors 28, 29 are composed of a connecting device on the crawler beam and connected with the frame 9; the hydraulic rotary device 7 is composed of a rotary support, a rotary platform, a rotary bracket, and an electro-hydraulic center rotary joint 33 Composed of rotary hydraulic motor 30, the fixed ring of the slewing support is connected with the frame 9 through bolts, and its rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com