Process for making high quantitative watermark anti-forge paper

A production method and technology of anti-counterfeit paper, which is applied in papermaking, paper machine, paper machine wet end, etc., can solve the problems of complicated process, low anti-counterfeiting performance, and difficult light-transmitting observation, etc., and achieve good light-transmitting observation and anti-counterfeiting performance high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

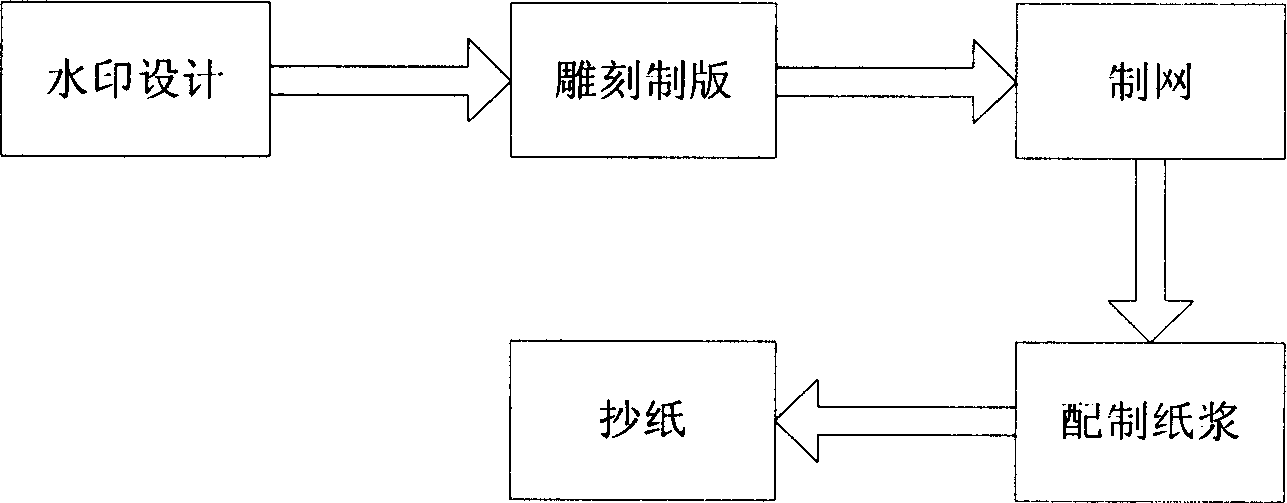

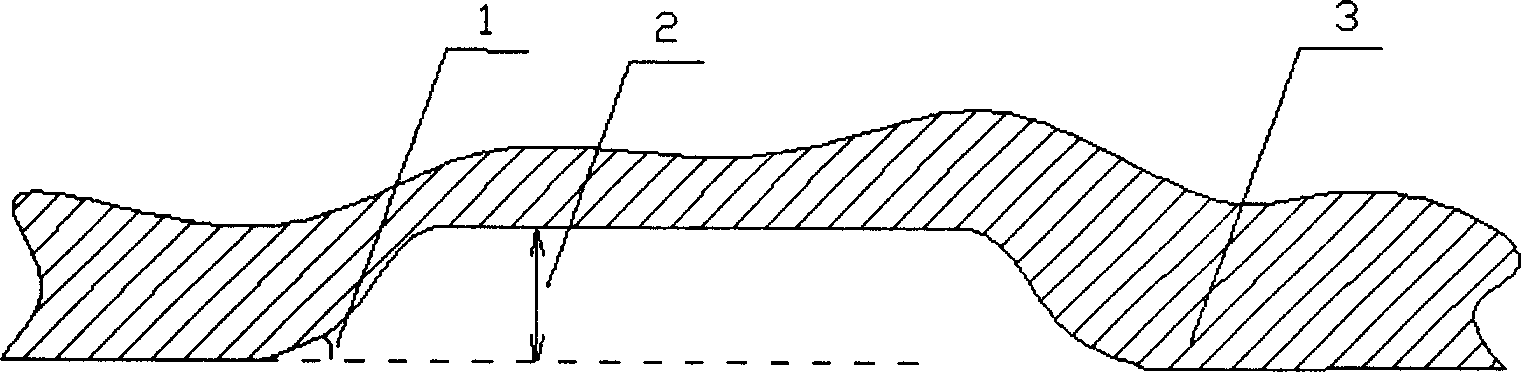

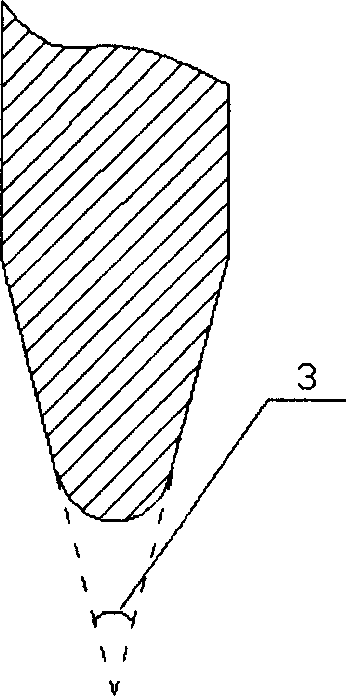

[0014] Embodiment 1: as figure 1 As shown, the production steps of the present invention are according to the processes of watermark design, engraving plate making, net making, pulp preparation, papermaking, etc., wherein, when designing the watermark, the height of the watermark plate is designed to be 1.0mm, and the slope is 5°, and then the watermark is designed by The computer converts the designed watermark scheme into a machine language that the engraving machine can recognize to control the cutting of the engraving machine. image 3 As shown in the spherical knife, the cone angle of the spherical knife is 20°, and the spherical knife is carved according to the height and slope scheme of the watermark design, such as figure 2 As shown in the watermark template, the height of the watermark template is 1.0mm, and the slope is 5°. Use this template to press the watermark area on the copper grid, then prepare the pulp, and put the pulp into the pulp tank for papermaking. Du...

Embodiment 2

[0015] Embodiment 2: operate according to the steps of embodiment 1, wherein, the height-1.0mm of design watermark template during watermark design, slope is 15 °, use as image 3 A spherical knife with a cone angle of 30° as shown engraves figure 2 As shown in the watermark template, the height of the watermark template is -1.0mm, and the slope is 15°. Use this template to press the watermark area on the copper wire, then prepare the pulp, and put the pulp into the pulp tank for papermaking. During the papermaking process When drying, control the running speed of the production line at 35 m / min, so as to facilitate the dehydration and drying of high-weight watermark paper, and the watermark anti-counterfeiting paper produced is 150g / m 2 .

Embodiment 3

[0016] Embodiment 3: operate according to the steps of embodiment 1, wherein, the height-2.5mm of design watermark stencil when printing design, slope is 20 °, use such as image 3 A spherical knife with a taper angle of 45° as shown engraves figure 2 As shown in the watermark template, the height of the watermark template is -2.5mm, and the slope is 20°. Use this template to press the watermark area on the copper wire, then prepare the pulp, and put the pulp into the pulp tank for papermaking. During the papermaking process When drying, control the running speed of the production line at 28 m / min, so as to facilitate the dehydration and drying of high-weight watermark paper, and the watermark anti-counterfeiting paper produced is 220g / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Cone angle | aaaaa | aaaaa |

| Cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com