Liquid crystal panel and liquid crystal display apparatus

A technology of liquid crystal panel and liquid crystal layer, which can be used in television, optics, instruments, etc., can solve the problems of not obtaining retardation film, film breakage, and small photoelastic coefficient, and achieve excellent display uniformity, prevent unevenness, and good display. The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

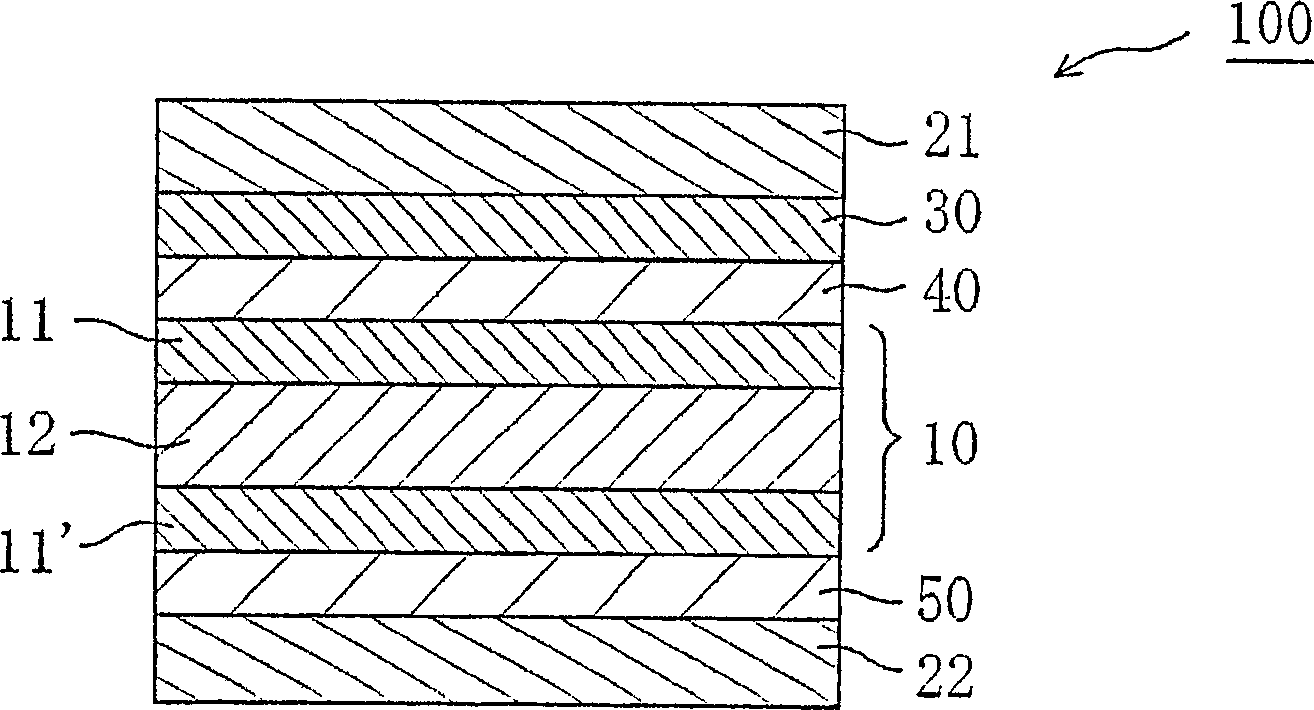

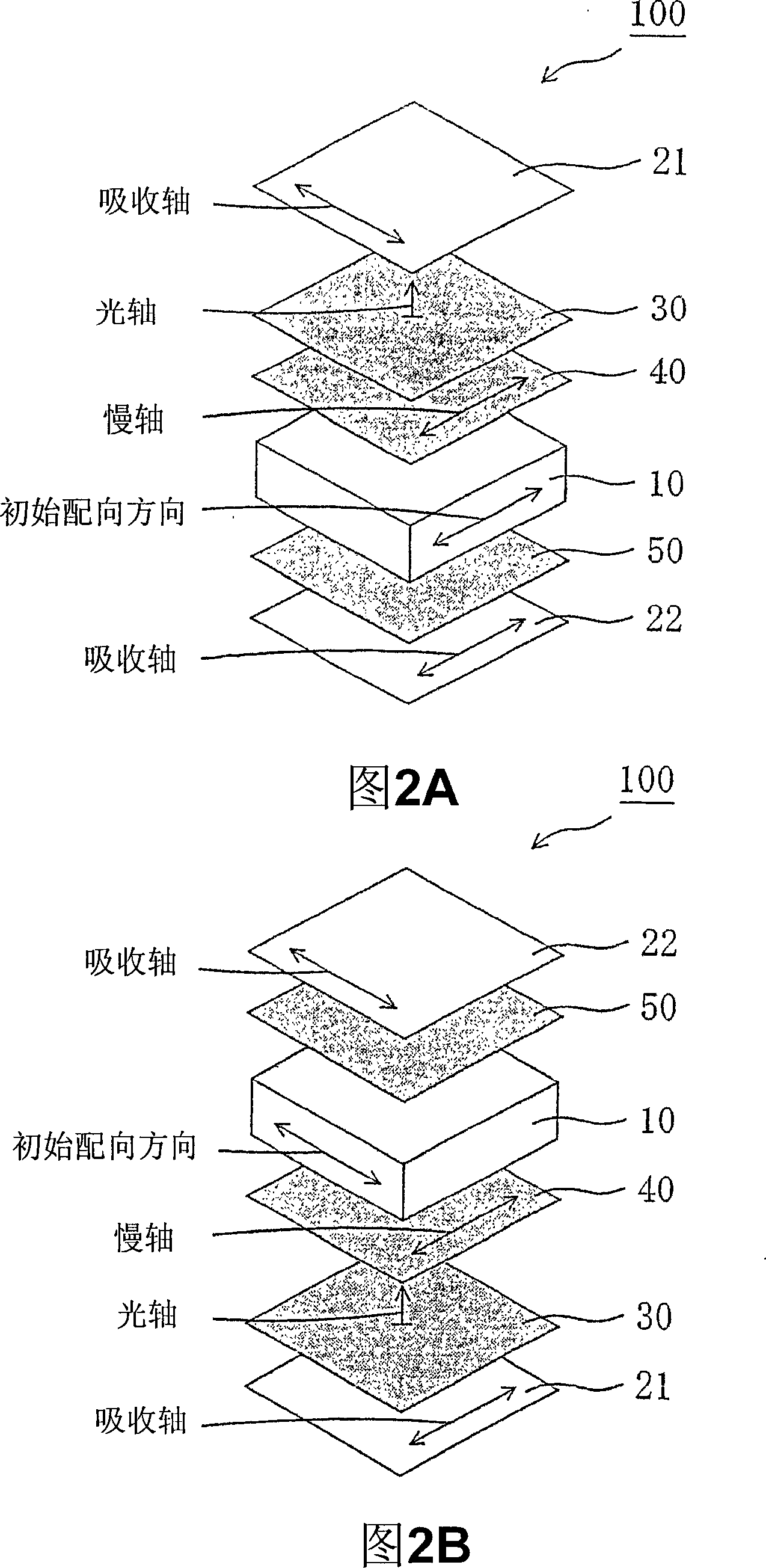

[0371] The retardation film 2-A obtained in Reference Example 4 was laminated as a second optical member on the viewing side of the liquid crystal cell obtained in Reference Example 12 through an acrylic pressure-sensitive adhesive layer (20 μm in thickness), so that The short sides of the liquid crystal cell and the slow axis of the retardation film 2-A are parallel to each other. Then, the retardation film 1-A obtained in Reference Example 2 was laminated as the first optical element on the surface of the retardation film 2-A through an acrylic pressure-sensitive adhesive layer (20 μm in thickness), so that the retardation film The slow axis of 2-A and the slow axis of retardation film 1-A are perpendicular to each other. Next, the polarizer P1 obtained in Reference Example 1 was passed through an adhesive layer "GOHSEFIMER Z200" (trade name, thickness 1 µm, Nippon Synthetic Chemical Industry Co. ., Ltd.) to be laminated on the surface of the retardation film 1-A so that th...

Embodiment 2

[0378] A liquid crystal panel B and a liquid crystal display device B were produced in the same manner as in Example 1, except that the optical film 3-C obtained in Reference Example 11 was used as a third optical element. As soon as the backlight is turned on, the LCD panel exhibits good display uniformity across the entire surface. Then, the backlight was turned on for 10 minutes, thereby measuring the contrast in the oblique direction and the color shift in the oblique direction. Tables 5 and 6 show the resulting properties. With the backlight turned on continuously for 2 hours, the display screen of the liquid crystal display device was photographed in a dark room with a two-dimensional color distribution measuring apparatus "CA-1500" (manufactured by Konica Minolta Holdings, Inc.). Such as Figure 7 As shown, slight display unevenness due to heat of the backlight was observed.

Embodiment 3

[0380] Produce liquid crystal panel C and liquid crystal display device C according to the same method as embodiment 1, except that the retardation film 1-B obtained in reference embodiment 3 is used as the first optical element, and the retardation film 2 obtained in reference embodiment 6 -C was used as the second optical element and the optical film 3-C obtained in Reference Example 11 was used as the third optical element. When the backlight is turned on, the liquid crystal panel exhibits good display uniformity across the entire surface. Then, the backlight was turned on for 10 minutes, thereby measuring the contrast in the oblique direction and the color shift in the oblique direction. Tables 5 and 6 show the resulting properties. With the backlight kept on for 2 hours, the display screen of the liquid crystal display device was photographed in a dark room with a two-dimensional color distribution measuring apparatus "CA-1500", manufactured by Konica Minolta Holdings, I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com