Method for preparing carbon rod of containing catalyst and sintering unit

A technology for sintering equipment and catalysts, which is applied to the preparation of carbon rods containing catalysts and the field of sintering equipment, can solve the problems of easy consumption of metal particles and uneven distribution of carbon rods, and achieve the effect of not easy consumption and good products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

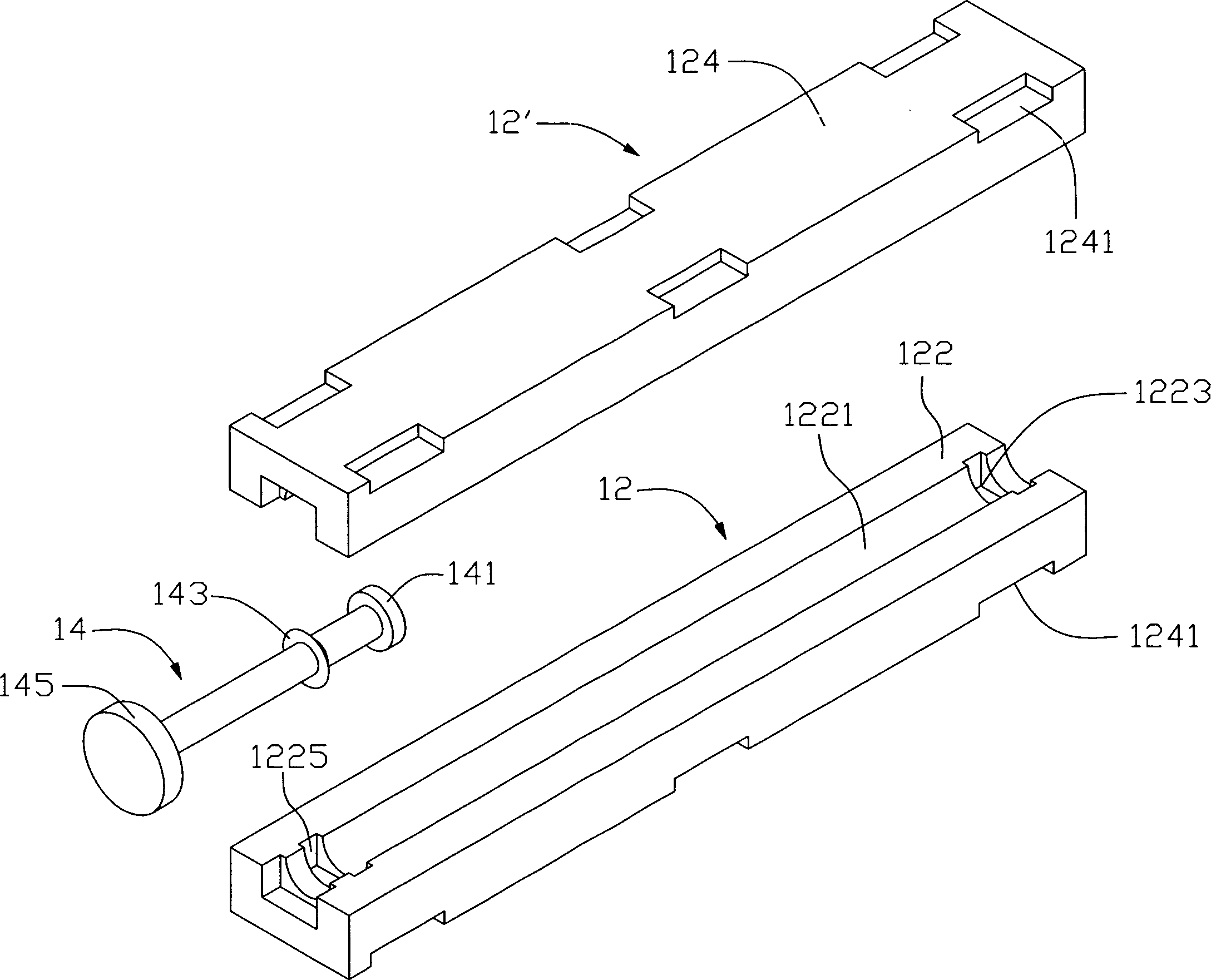

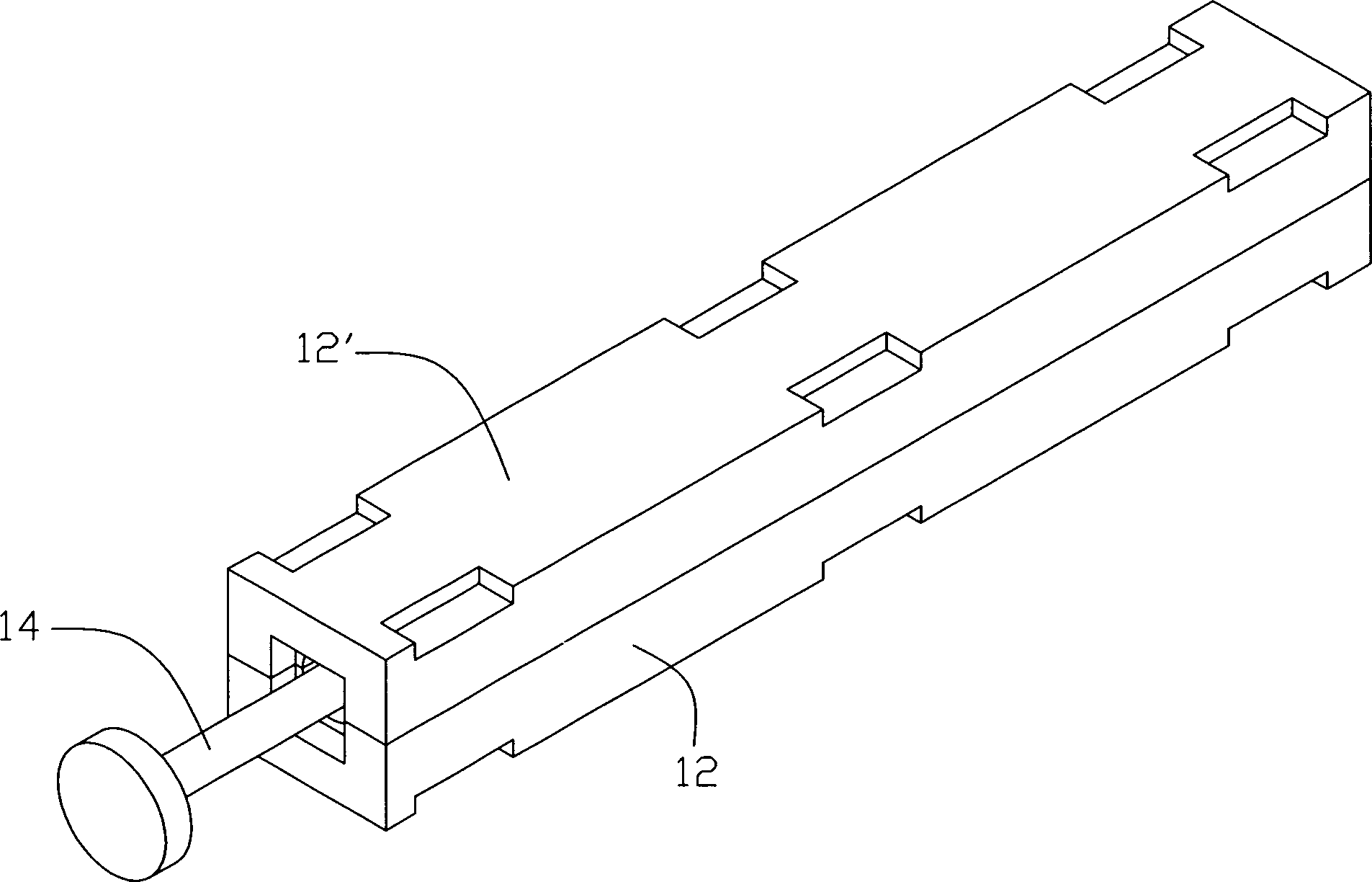

[0023] The method for preparing the carbon rod uniformly dispersed with catalyst particles in the present invention mainly adopts powder sintering technology. Powder sintering technology is to extrude catalyst metal powder and carbon powder into a mold with a specific shape, extrude the loose mixed powder into a powder, and then send the pressed powder into a high-temperature furnace for heating and sintering to make the powder The bodies are bonded together to form carbon rod products.

[0024] The present invention provides a kind of sintering equipment of carbon rod containing catalyst, which comprises: two half molds and a pressing device; the two half molds can cooperate to form a mold cavity, one end of which is closed and the other end is open; the pressing device can Extend into the mold cavity and cooperate with the two half molds.

[0025] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

[0026]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com