Glass bulb for cathode ray tube

A cathode ray and tube technology, applied in the direction of cathode ray/electron beam tube shell/container, cathode ray tube/electron beam tube, discharge tube, etc., can solve the problem of increasing the overall depth of the main body, and avoid concentration and suppression Increase in mass, effect of suppressing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

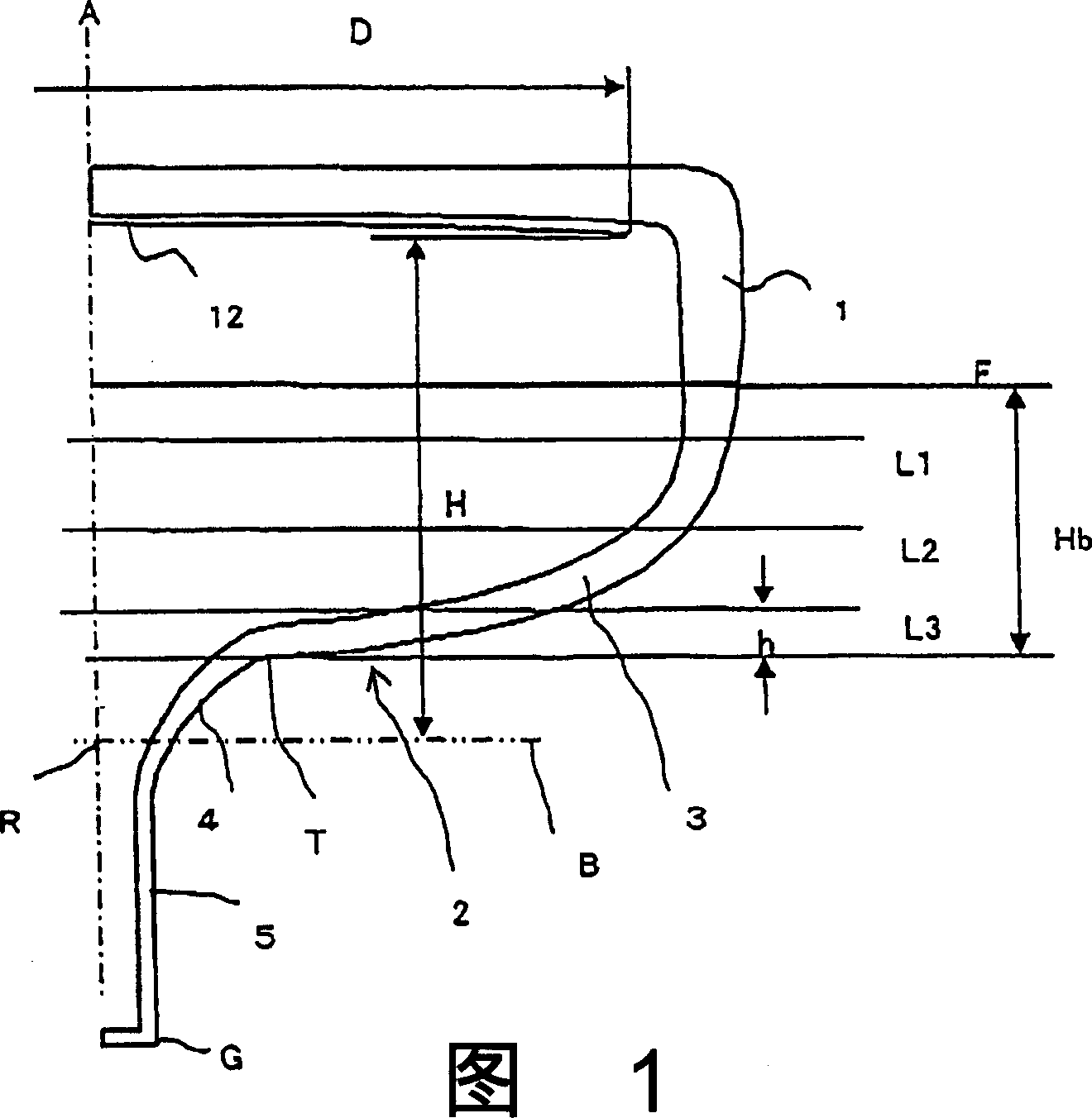

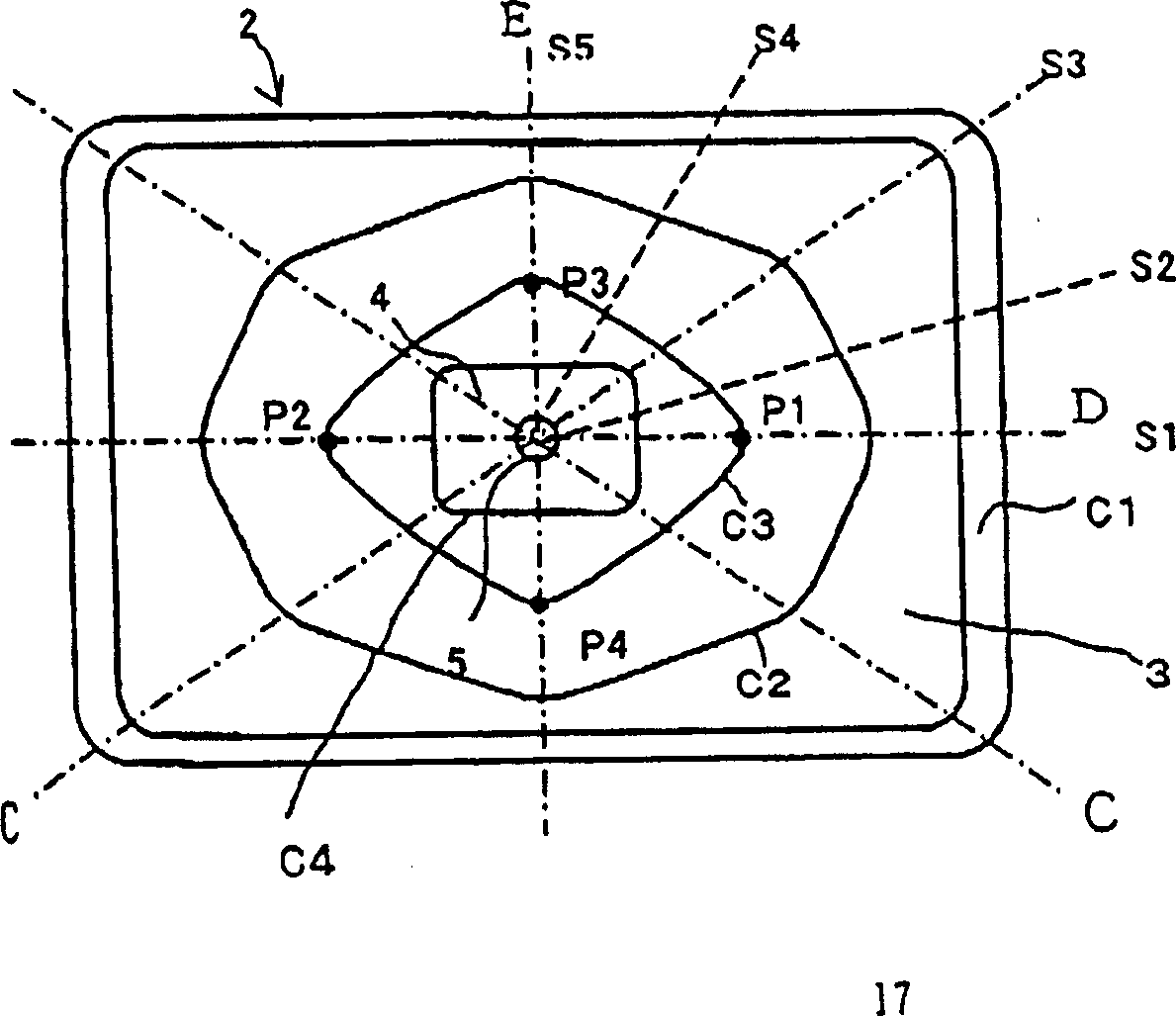

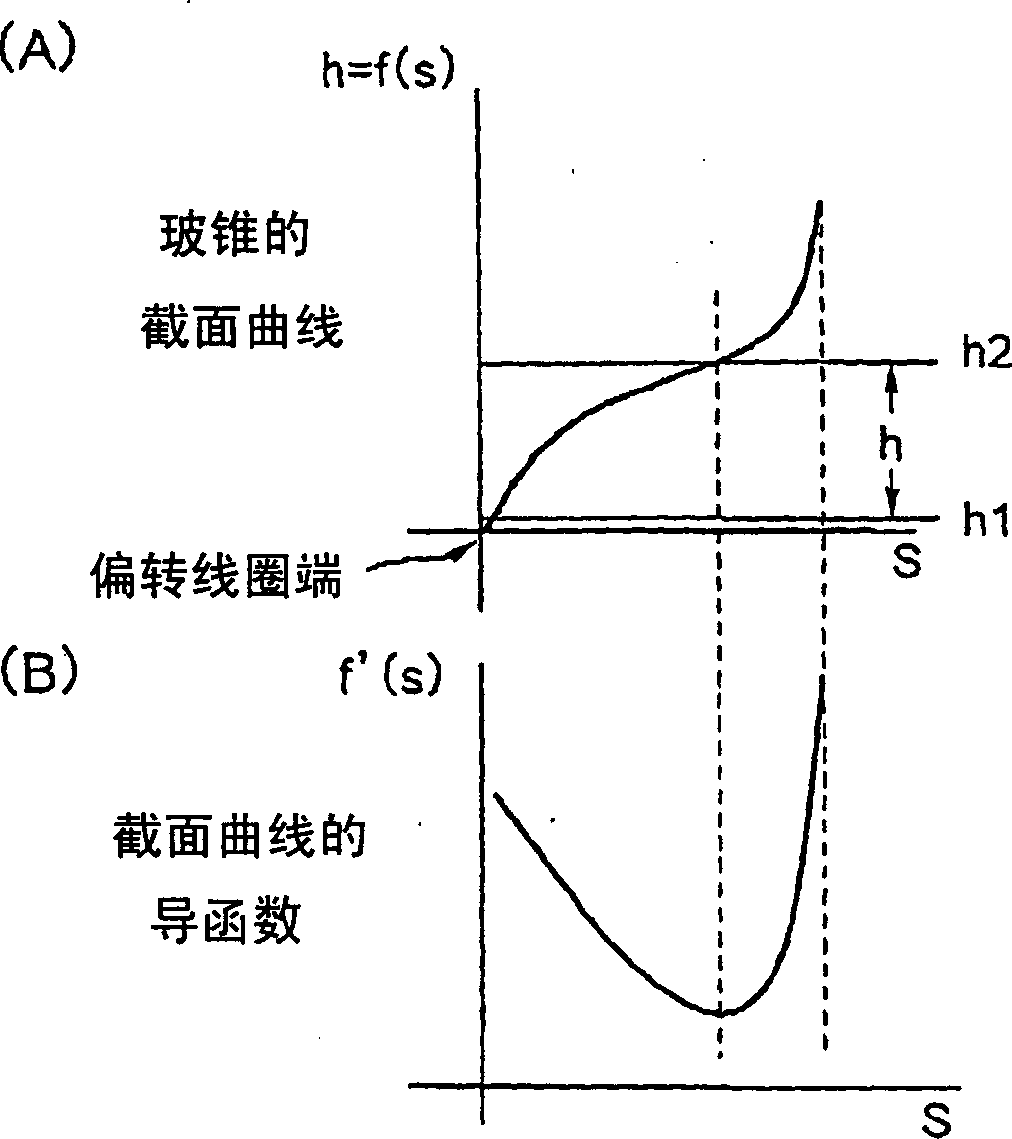

[0076] 0.1H of the main body with a maximum effective screen diameter of 676mm b b The cross-sectional external shape of the region (hereinafter referred to as the position of the present invention) is figure 2 In the rhomboid-like embodiment shown, the stress of each part is within the standard, and the quality can be designed to be the lightest.

Embodiment 2

[0078] By changing the shape of the approximately rhombic section in Embodiment 1, the stress of the deflection yoke portion can be designed to be lower.

Embodiment 3

[0080] The maximum diameter of the effective screen is 760mm, and the cross-sectional external shape of the part of the present invention is figure 2 In the example shown in the approximate rhombic shape, the stress of the deflection yoke portion of Comparative Example 4 which does not have the structure of the present invention can be lowered by 1.4 MPa, which satisfies the standard of stress. The mass can be designed to be approximately the same as Comparative Example 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com